Aluminum bronze and preparation method thereof

An aluminum bronze, weight percentage technology, applied in the field of alloys, can solve the problems of high manufacturing cost, low friction coefficient polishing performance, low yield strength performance, etc., and achieve low production cost, low sliding friction coefficient and high wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

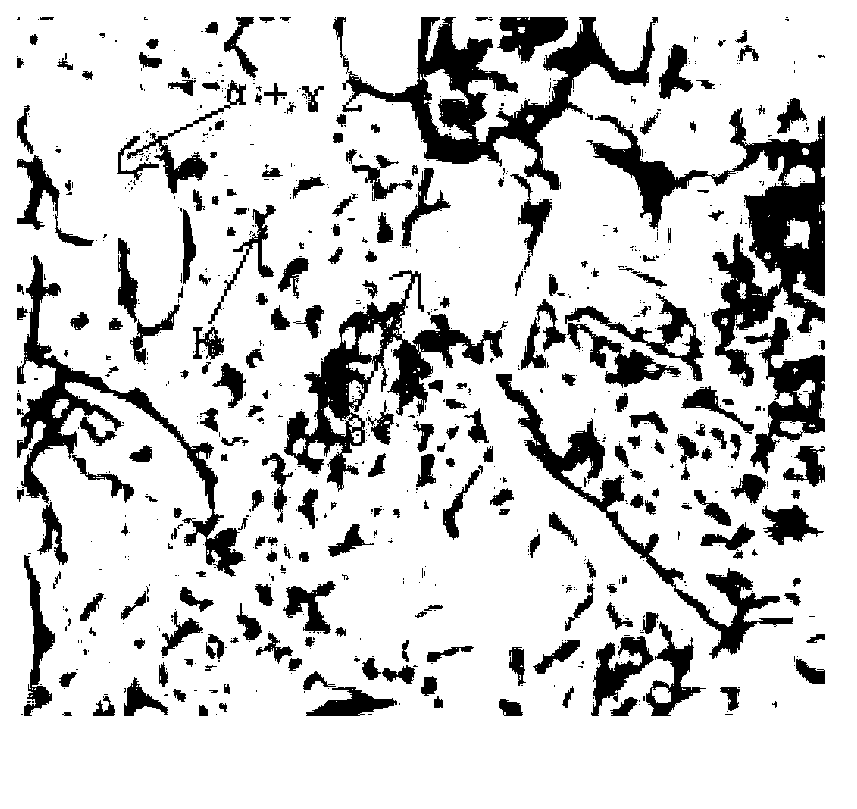

Image

Examples

Embodiment Construction

[0048] The present invention is described in further detail below in conjunction with specific embodiment:

[0049] The raw materials in Examples 1 to 41 of the present invention (the specific alloy composition and properties are shown in Table 1) use conventional copper, aluminum, iron, manganese, zinc, cobalt and other elements as raw materials, and are melted by induction furnace under industrial scale conditions , the melting temperature is 1150 ℃ ~ 1400 ℃, and then semi-continuous casting (or continuous casting) into aluminum bronze round (flat) ingots, the casting temperature is 1200 ℃ ~ 1300 ℃, if hot extrusion is required, the extrusion temperature 700°C~850°C. If forging is required, the forging temperature is 700°C~850°C, and then machining is performed to prepare products of different specifications and states.

[0050] The comparative examples of the present invention are aluminum bronzes of C63000 and US1961012510419610719.

[0051] The specific chemical composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com