Steel-aluminum bronze bimetal material compounding method

A technology of aluminum bronze and bimetal, which is applied in the field of metal composite material preparation, to avoid adverse effects and improve the interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

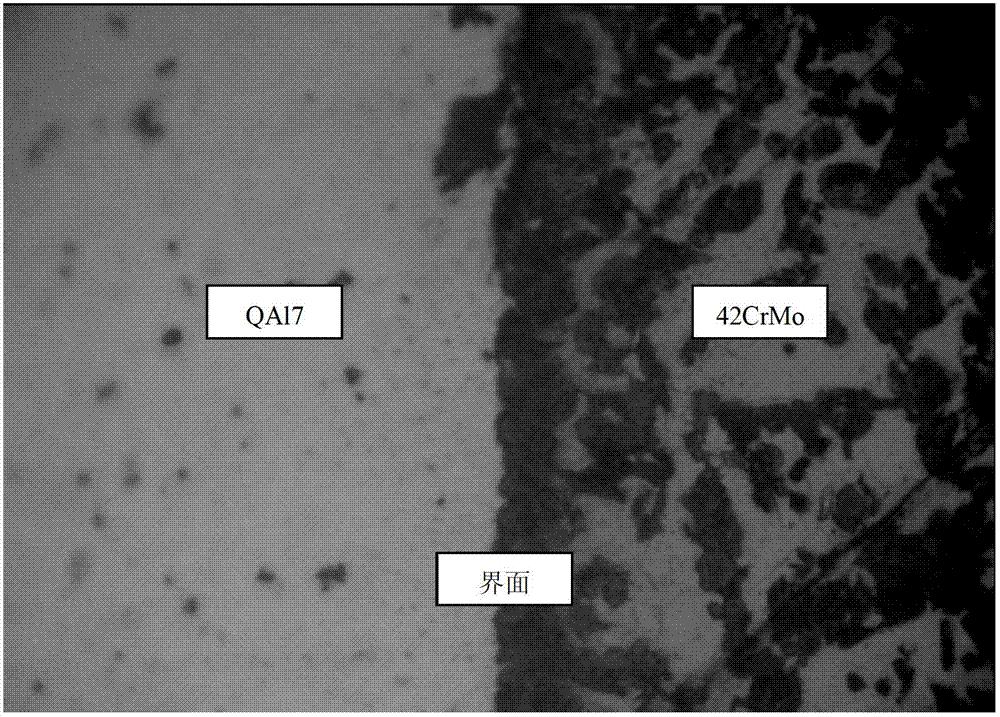

[0031] Example 1 Composite of 42CrMo steel and QAl7 aluminum bronze

[0032] (1) First, heat the 42CrMo steel plate at about 850°C and keep it warm for about 1 hour, then transfer it to a furnace at about 680°C and keep it warm for 10 hours, and then slowly cool to room temperature with the furnace, and the elongation of the steel plate is about 40%. Heat the QAl7 aluminum bronze to 650°C and keep it warm for 1h, and then cool it slowly to room temperature with the furnace. At this time, the elongation of the copper plate is about 45%.

[0033] (2) The 42CrMo steel after surface cleaning and activation is hot-dip aluminized in 710 ℃ aluminum liquid. The immersion plating time and extraction speed are controlled so that the thickness of the pure aluminum layer is about 20 μm.

[0034] (3) After surface cleaning and roughening again, the aluminum-plated 42CrMo steel and QAl7 aluminum bronze are laminated, and the steel and aluminum bronze are cold-rolled and composited with 50%...

Embodiment 2

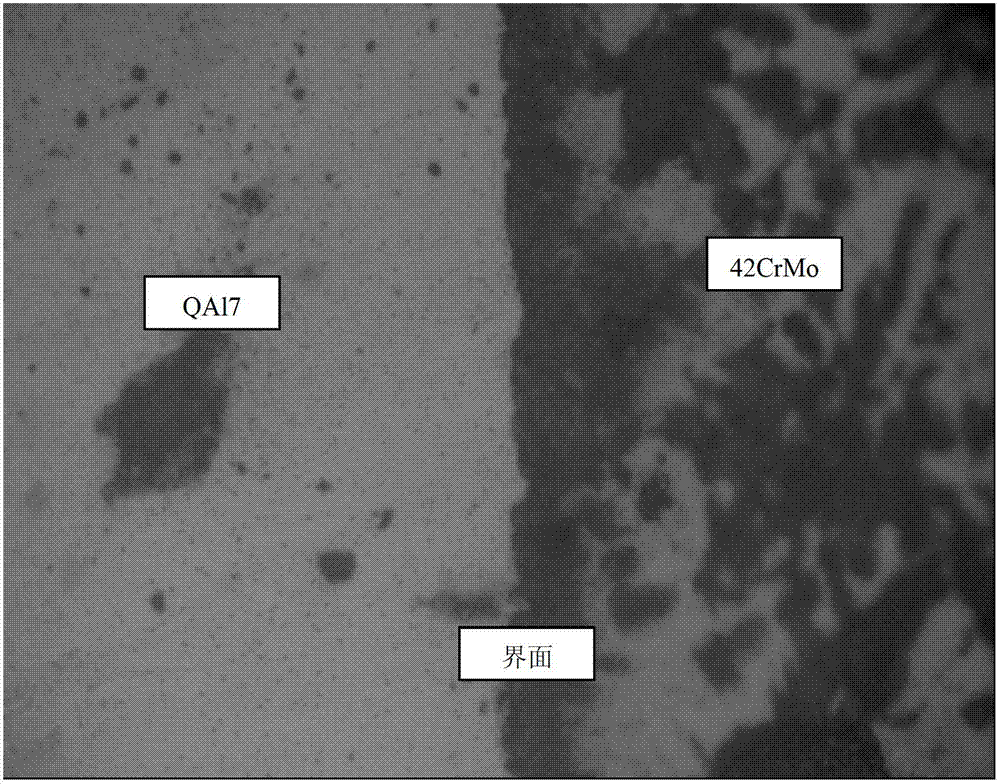

[0039] Example 2 Composite of 42CrMo steel and QAl7 aluminum bronze

[0040] (1) First, heat the 42CrMo steel plate at about 850°C and keep it warm for about 1h, then transfer it to a furnace at about 680°C and keep it warm for 10h, and then slowly cool to room temperature with the furnace, at which time the elongation of the steel plate is about 40%. Heat the QAl7 aluminum bronze to 650°C and keep it warm for 1h, and then cool it slowly to room temperature with the furnace. At this time, the elongation of the copper plate is about 45%.

[0041] (2) The 42CrMo steel after surface cleaning and activation is hot-dipped in aluminum liquid at 680°C. The immersion plating time and extraction speed are controlled so that the thickness of the pure aluminum layer is about 60 μm.

[0042] (3) After surface cleaning and roughening again, the aluminum-plated 42CrMo steel and QAl7 aluminum bronze are laminated, and the steel and aluminum bronze are cold-rolled and composited with 80% sin...

Embodiment 3

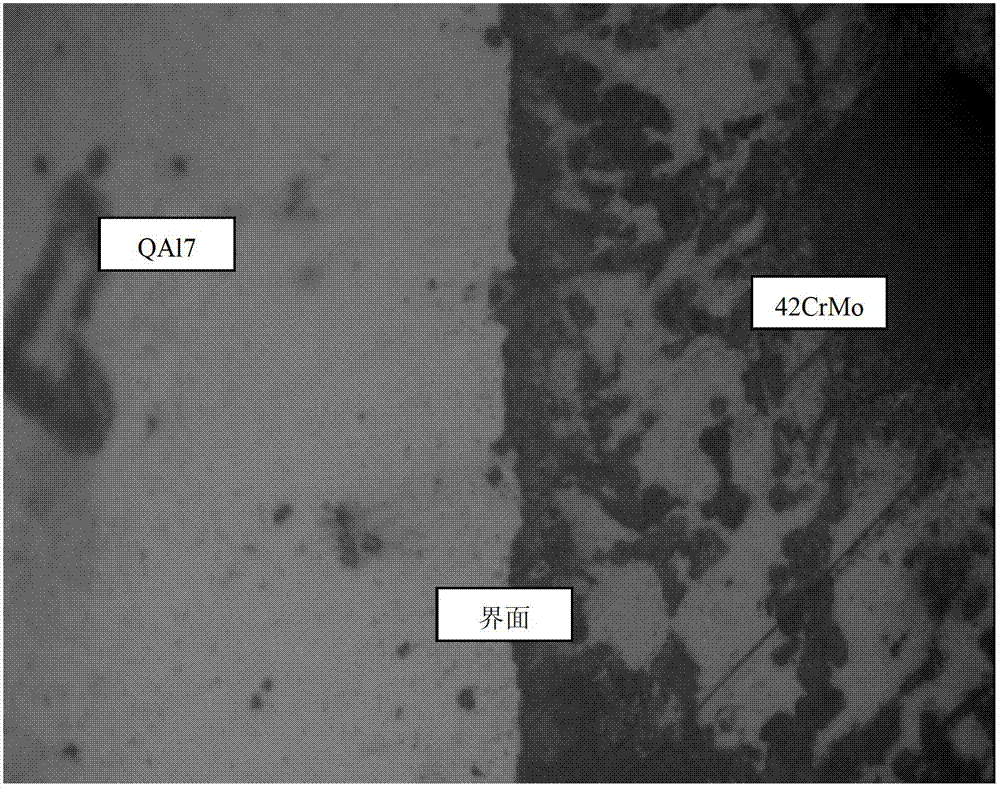

[0047] Example 3 Composite of 42CrMo steel and QAl7 aluminum bronze

[0048] (1) First, heat the 42CrMo steel plate at about 850°C and keep it warm for about 1h, then transfer it to a furnace at about 680°C and keep it warm for 10h, and then slowly cool to room temperature with the furnace, at which time the elongation of the steel plate is about 40%. Heat the QAl7 aluminum bronze to 650°C and keep it warm for 1h, and then cool it slowly to room temperature with the furnace. At this time, the elongation of the copper plate is about 45%.

[0049] (2) The 42CrMo steel after surface cleaning and activation is hot dipped in aluminum liquid at 690 ℃. The immersion plating time and extraction speed are controlled so that the thickness of the pure aluminum layer is about 40 μm.

[0050](3) After surface cleaning and roughening again, the aluminum-plated 42CrMo steel and QAl7 aluminum bronze are laminated, and the steel and aluminum bronze are cold-rolled and composited with 60% sing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com