Grain refining method of aluminium bronze

A technology of grain refinement and aluminum bronze, which is applied in the field of metal materials, can solve the problems of grain growth, increase in material cost, and reduce the order degree of copper alloys, etc., to achieve enhanced strength and wear resistance, and uniform grain structure Small, stable and reliable results

Inactive Publication Date: 2008-11-19

YANSHAN UNIV

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, there are the following methods for refining grains: (1) Adding alloy elements: this method is easy to be popularized and applied in industry, but it will increase the cost of materials, and there are strict requirements on the heat treatment system, especially the temperature. During the subsequent heat treatment, the grains will grow

In addition, because the addition of alloying elements will introduce impurity elements, due to various reasons during the solidification process, it will lead to uneven segregation of chemical components and structures, and even the formation of non-metallic inclusions.

(2) Rapid solidification method: The advantage of this method is that the finished product can be obtained directly after the alloy is melted without going through an intermediate process, and the refinement effect is good, but it reduces the order degree of the copper alloy, and the phase transition temperature is unstable during aging. There are also limitations in size and shape, and only thin ribbons and filaments can be obtained

(3) Powder metallurgy method: the copper-based memory alloy prepared by this method has anti-cycle attenuation and good ductility, but its process parameters are difficult to control

(5) Electric pulse inoculation treatment: it has an effective thinning effect, and the equipment and process of this technology are simple and easy to operate, but the thinning effect for products with larger cross-sections is not obvious enough, and it only stays in the experimental stage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

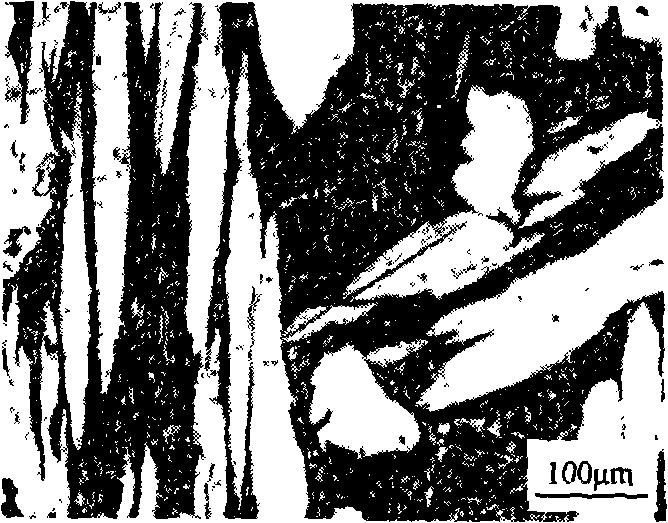

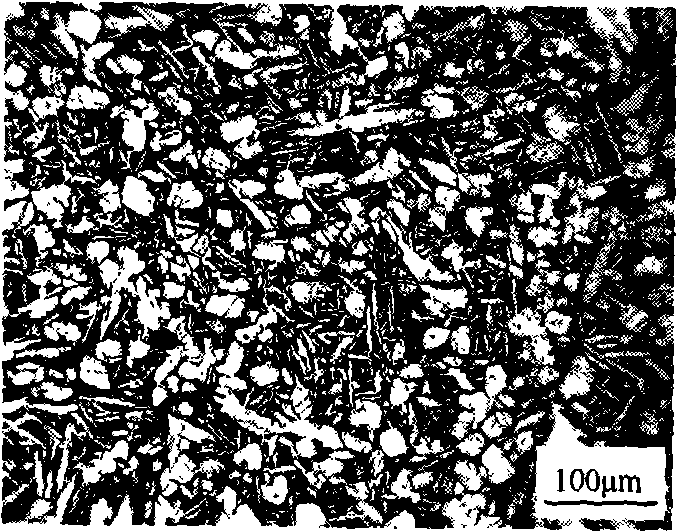

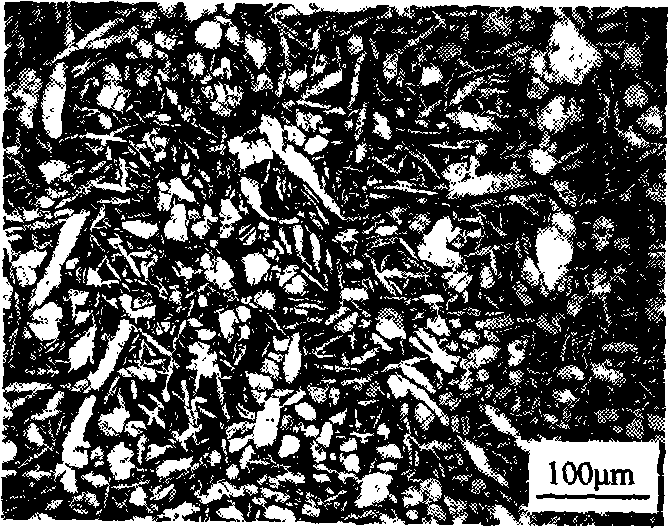

The invention discloses a method for thinning aluminium bronze crystal grains. The invention is characterized in that: the method comprises two parts of high pressure treatment and heat treatment, wherein, in the high pressure treatment, aluminium bronze is treated in a solid-state phase change region; the high pressure treatment comprises the following process parameters that: the pressure is between 1 and 6 GPa; the treatment temperature is between 700 and 900 DEG C and the heat preservation time is between 5 and 20 minutes; and the aluminium bronze is naturally cooled to the room temperature through power cutoff and pressure maintenance; in the heat treatment: the treatment temperature is between 600 and 750 DEG C; the heat preservation time is between 0.5 and 2 minutes; and the cooling speed is between 5 and 30 DEG C / min; and the aluminium bronze is cooled to the room temperature. The Al content in the aluminium bronze is between 10 and 15 weight percent. In the method, the aluminium bronze can acquire thinner and evener crystal grains by a combination of high pressure treatment and heat treatment, thereby achieving the perfect effect of crystal grain thinning.

Description

A kind of method for grain refinement of aluminum bronze alloy technical field The invention belongs to the field of metal materials, and relates to a process method for refining an aluminum bronze alloy structure. Background technique Aluminum bronze alloy has excellent mechanical properties, wear resistance, corrosion resistance and oxidation resistance, and has been widely used in the fields of machinery, instrumentation, automobiles, ships and oceans. With the rapid development of modern industry, various fields have put forward higher requirements for aluminum bronze materials. Grain refinement can simultaneously improve the alloy's performance in many aspects. At present, the methods for refining grains are as follows: (1) Adding alloying elements: This method is easy to popularize and apply in industry, but it will increase the cost of materials, and there are strict requirements for the heat treatment system, especially the temperature, otherwise it will be Durin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22F1/08

Inventor 张瑞军刘建华

Owner YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com