Metallographic erosion method of nickel-aluminum bronze crystal boundary

A nickel-aluminum bronze, metallographic corrosion technology, applied in the field of metallographic corrosion of nickel-aluminum bronze grain boundaries, can solve the problem of no suitable corrosion method for nickel-aluminum bronze grain boundaries, and achieve the effect of clear and complete grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

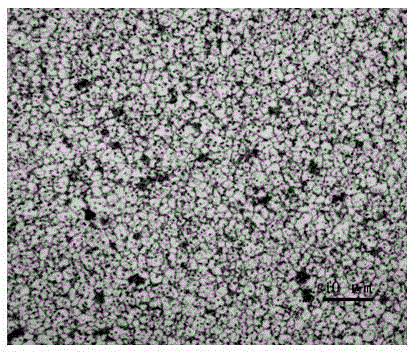

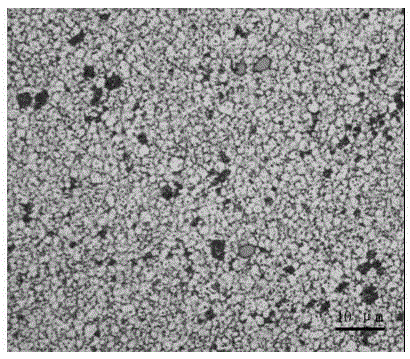

Image

Examples

Embodiment Construction

[0018] The invention relates to a metallographic corrosion method of nickel-aluminum bronze grain boundaries. The metallographic corrosion method comprises three steps: polishing treatment of nickel-aluminum bronze samples, preparation of etchant, and corrosion of nickel-aluminum bronze samples. In the metallographic corrosion method Water sandpaper, velvet cloth, diamond polishing liquid, hydrochloric acid, nitric acid, plastic tweezers, absorbent cotton, absolute ethanol and hair dryer are used, and nickel-aluminum bronze samples are made according to metallographic corrosion standards.

[0019] The three specific steps of polishing treatment, etchant preparation and nickel-aluminum-bronze sample corrosion are subject to the technical scheme, and will not be described in detail.

[0020] According to the technical scheme, the action mechanism of the present invention is briefly described as follows:

[0021] Commonly used etchant for copper alloys contains ferric ions, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com