Corrosive agent and etching method for displaying grain boundary of deposited metal of 690 nickel base alloy

A technology for depositing metal and nickel-based alloys, applied in the field of physical and chemical inspection, can solve problems such as unclearness and incomplete display of grain boundaries, and achieve the effect of good corrosion degree, clear and complete grain boundaries, and strong reproducibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

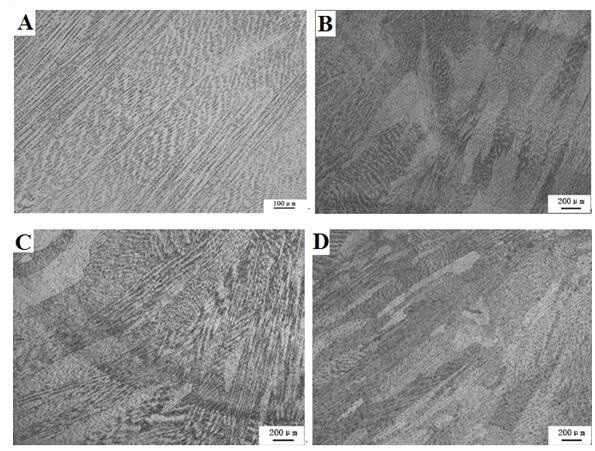

Image

Examples

Embodiment 1

[0022] 1) Sample preparation:

[0023] Sampling at the welding deposited metal of 690 nickel-based alloy, the sampling direction is perpendicular to the welding direction, taking the cross-section of the deposited metal of 690 nickel-based alloy as the analysis surface, and using 200#, 400#, 600#, 800#, 1000 for the section in sequence #Metallographic sandpaper is ground and polished step by step, and the grinding direction needs to be rotated 90° every time the sandpaper is replaced until the surface is bright without scratches to obtain the sample.

[0024] 2) Reagent preparation:

[0025] Add 8g of ferric chloride to 100mL of deionized water, then add 40mL of concentrated hydrochloric acid with a mass fraction of 36-38%, and finally add 3g of EDTA and mix evenly to prepare a corrosive agent; add 3mL of concentrated nitric acid with a mass fraction of 65-68% into 97mL of absolute ethanol to prepare a nitrate ethanol solution with a mass fraction of 3%.

[0026] 3) Etching ...

Embodiment 2

[0029] 1) Sample preparation:

[0030] Sampling at the welding deposited metal of 690 nickel-based alloy, the sampling direction is perpendicular to the welding direction, taking the cross-section of the deposited metal of 690 nickel-based alloy as the analysis surface, and using 200#, 400#, 600#, 800#, 1000 for the section in sequence #Metallographic sandpaper is ground and polished step by step, and the grinding direction needs to be rotated 90° every time the sandpaper is replaced until the surface is bright without scratches to obtain the sample.

[0031] 2) Reagent preparation:

[0032] Add 10g of ferric chloride to 100mL of deionized water, then add 48mL of concentrated hydrochloric acid with a mass fraction of 36-38%, and finally add 1.2g of EDTA and mix evenly to prepare a corrosive agent; add 4mL of concentrated nitric acid with a mass fraction of 65-68% Add it into 96mL of absolute ethanol to prepare a nitric acid ethanol solution with a mass fraction of 4%.

[003...

Embodiment 3

[0036] 1) Sample preparation:

[0037] Sampling at the welding deposited metal of 690 nickel-based alloy, the sampling direction is perpendicular to the welding direction, taking the cross-section of the deposited metal of 690 nickel-based alloy as the analysis surface, and using 200#, 400#, 600#, 800#, 1000 for the section in sequence #Metallographic sandpaper is ground and polished step by step, and the grinding direction needs to be rotated 90° every time the sandpaper is replaced until the surface is bright without scratches to obtain the sample.

[0038] 2) Reagent preparation:

[0039] Add 8g of ferric chloride to 120mL of deionized water, then add 60mL of concentrated hydrochloric acid with a mass fraction of 36-38%, and finally add 2.5g of EDTA and mix evenly to prepare a corrosive agent; add 3mL of concentrated nitric acid with a mass fraction of 65-68% Add it into 97mL of absolute ethanol to prepare a 3% nitric acid ethanol solution.

[0040] 3) Etching treatment: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com