Patents

Literature

181results about "Testing metal structures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

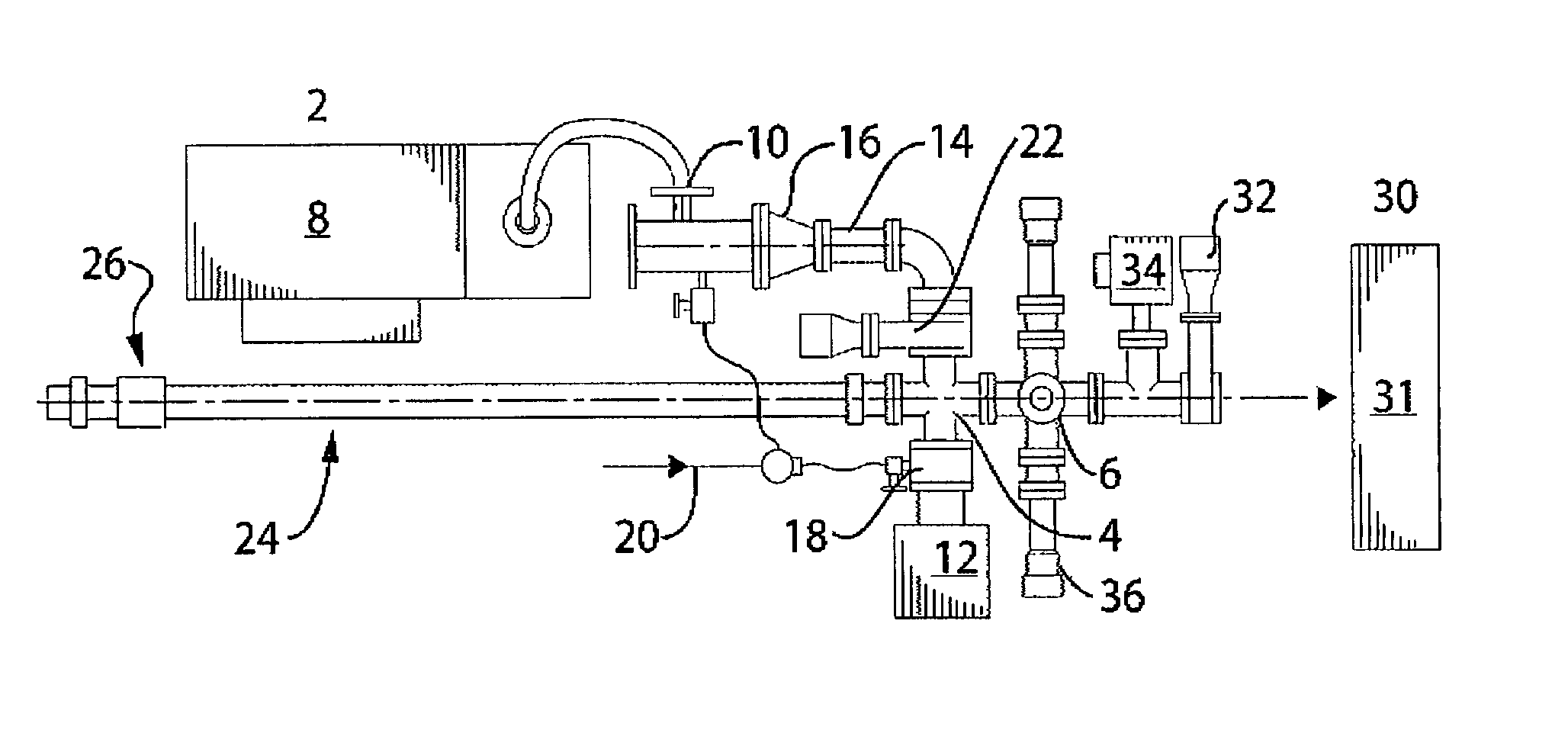

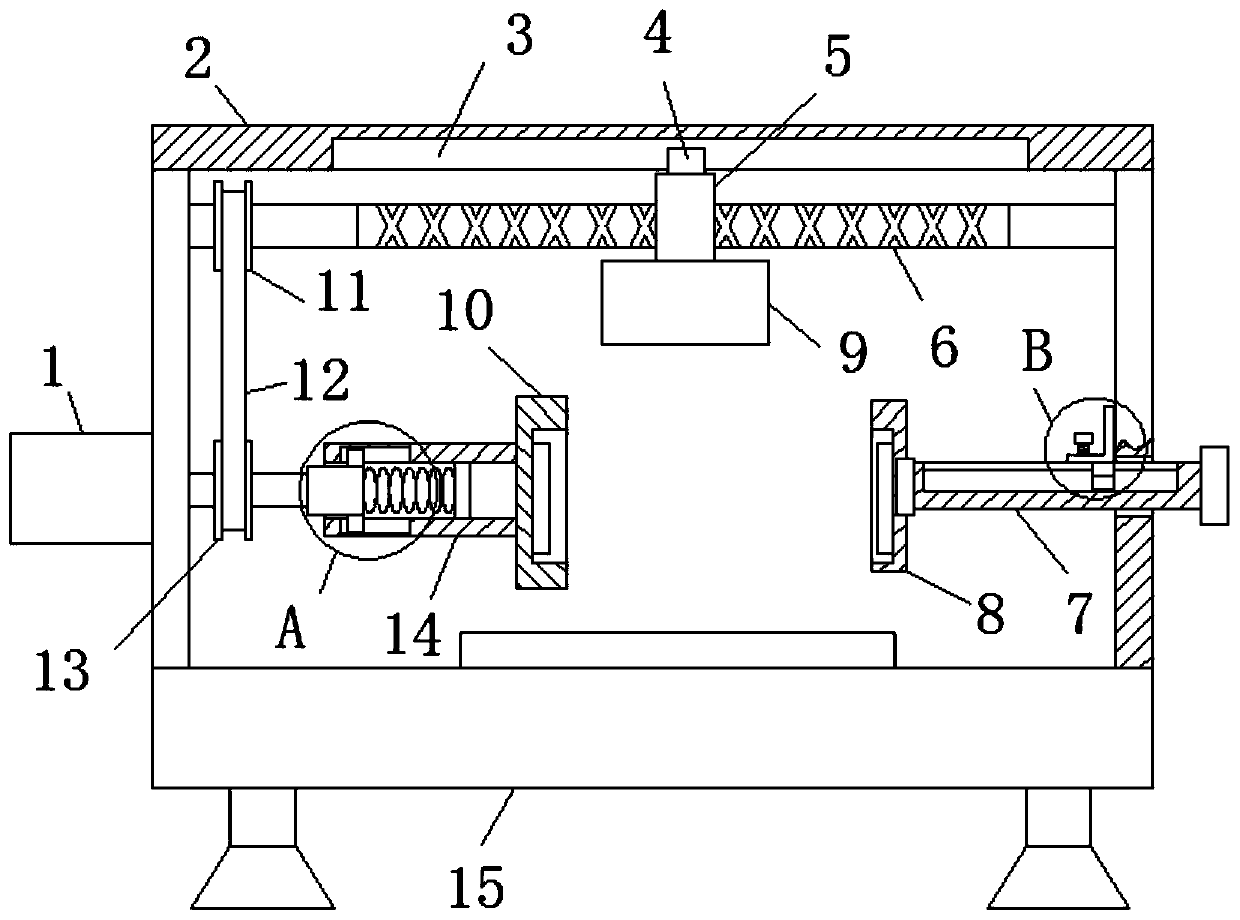

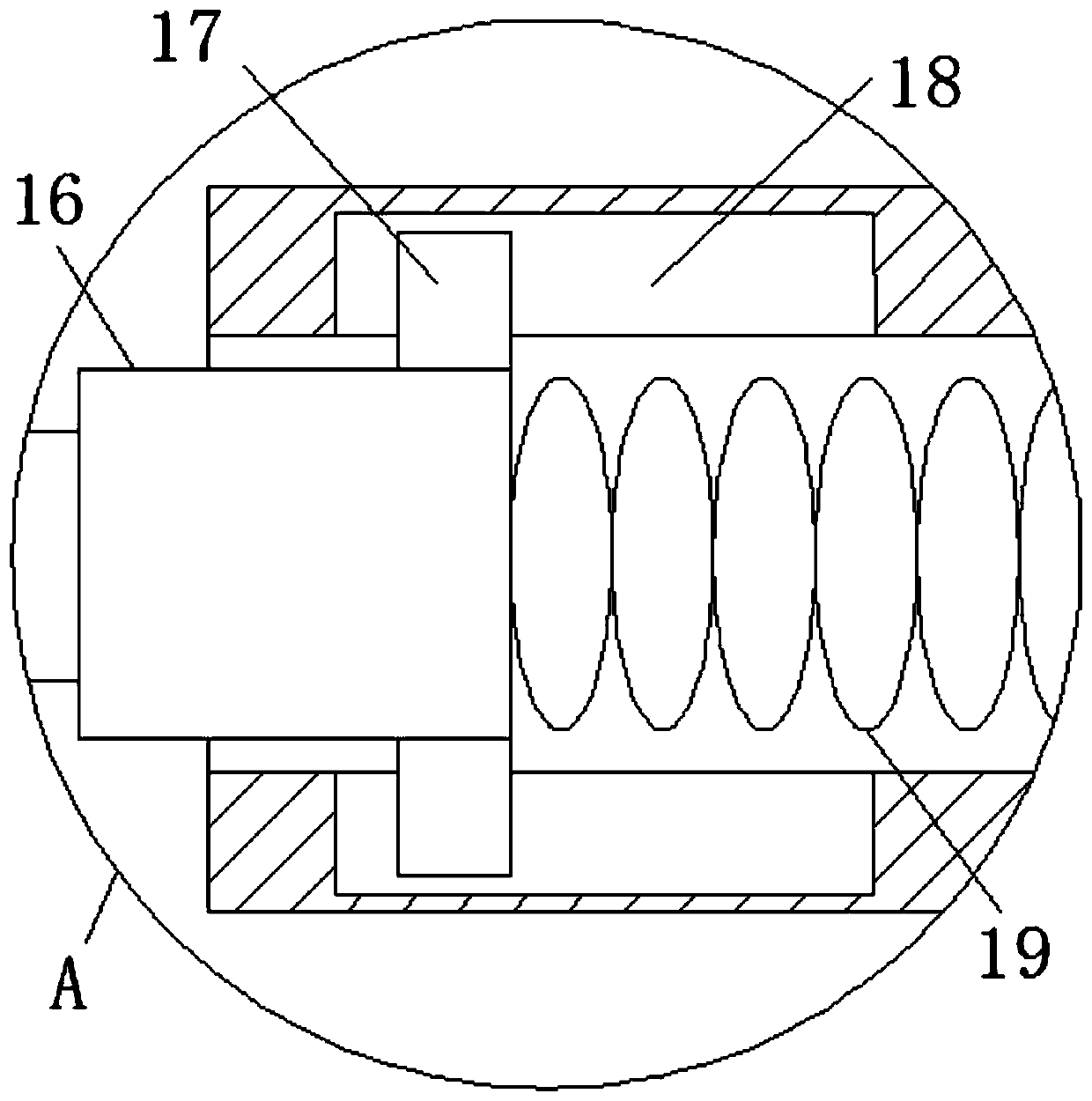

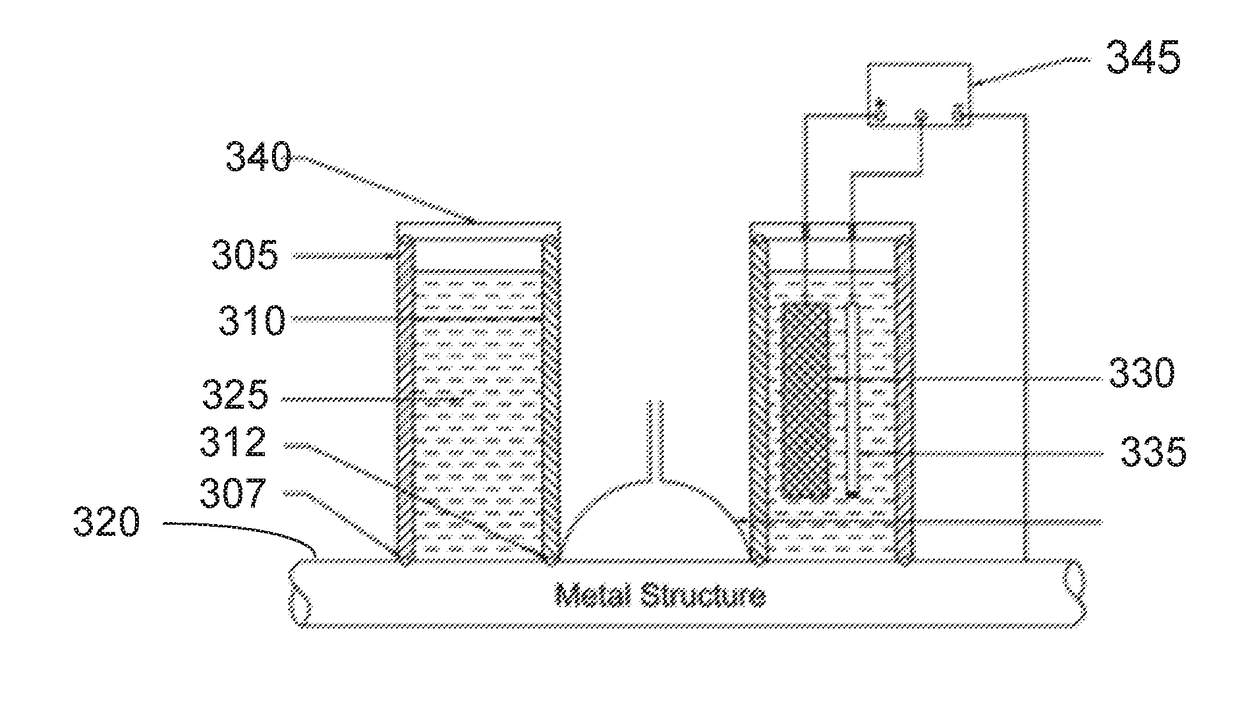

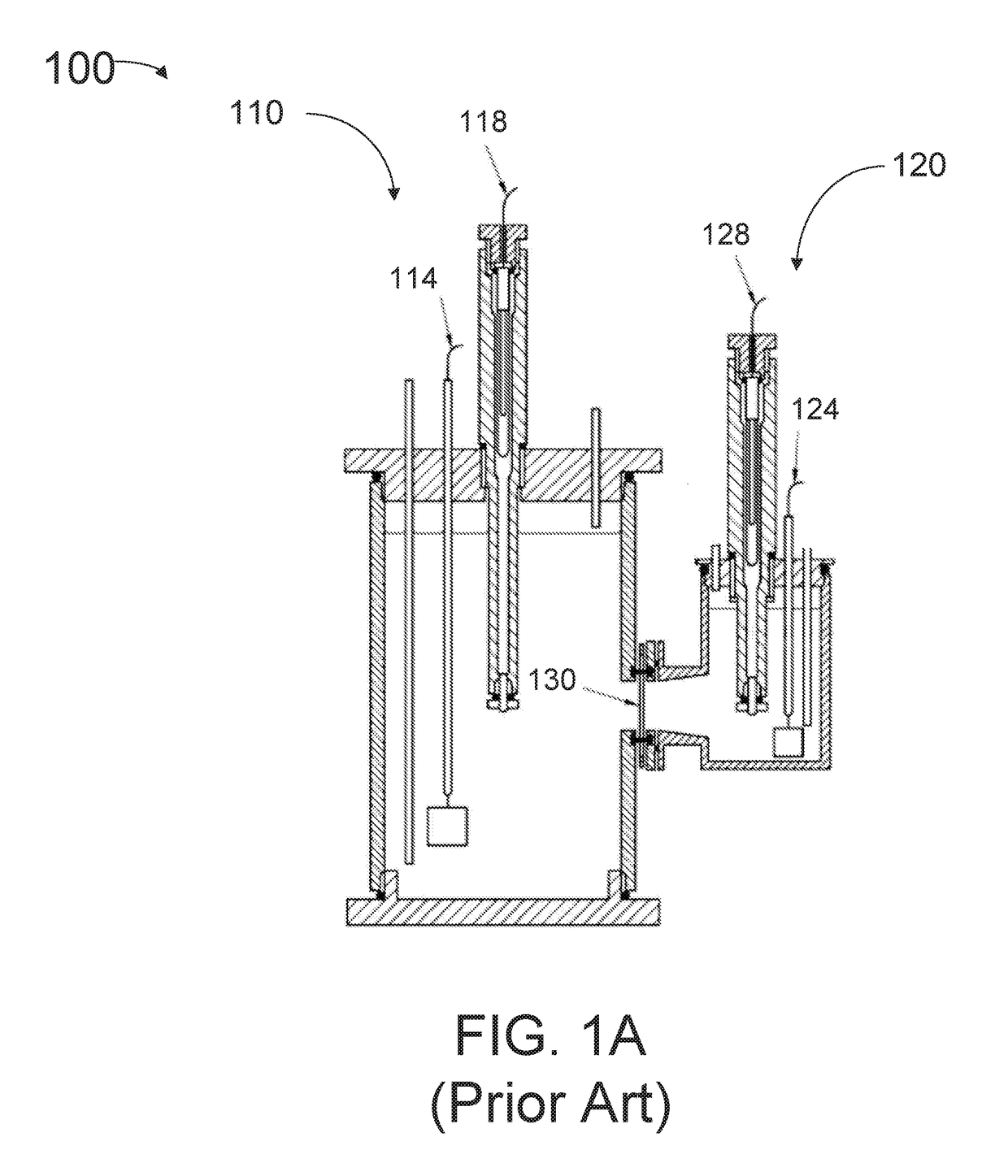

Method and apparatus for universal metallurgical simulation and analysis

InactiveUS20050151306A1High degree of accuracyHigh precisionPreparing sample for investigationBlast furnace detailsResonant inverterControl system

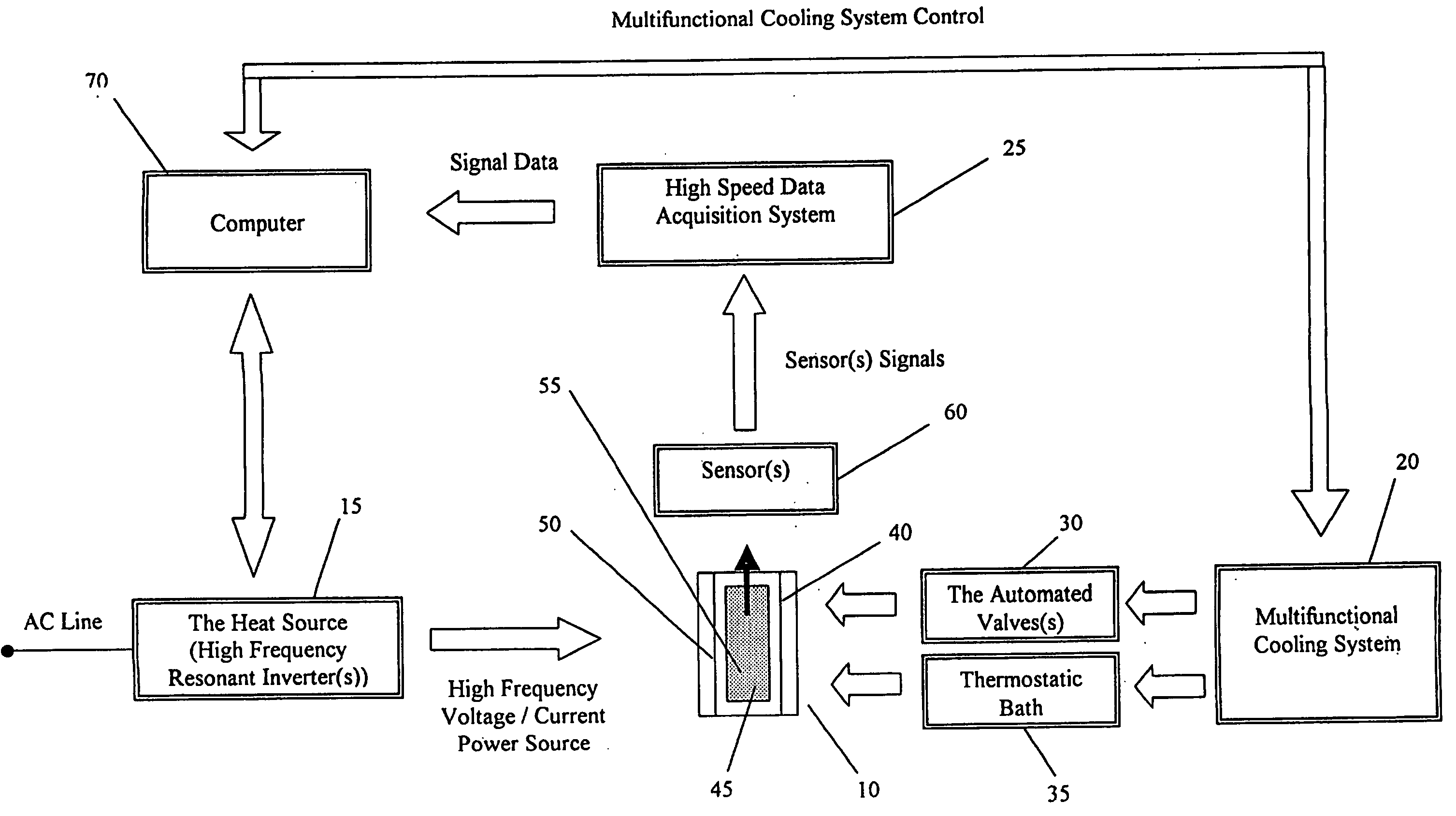

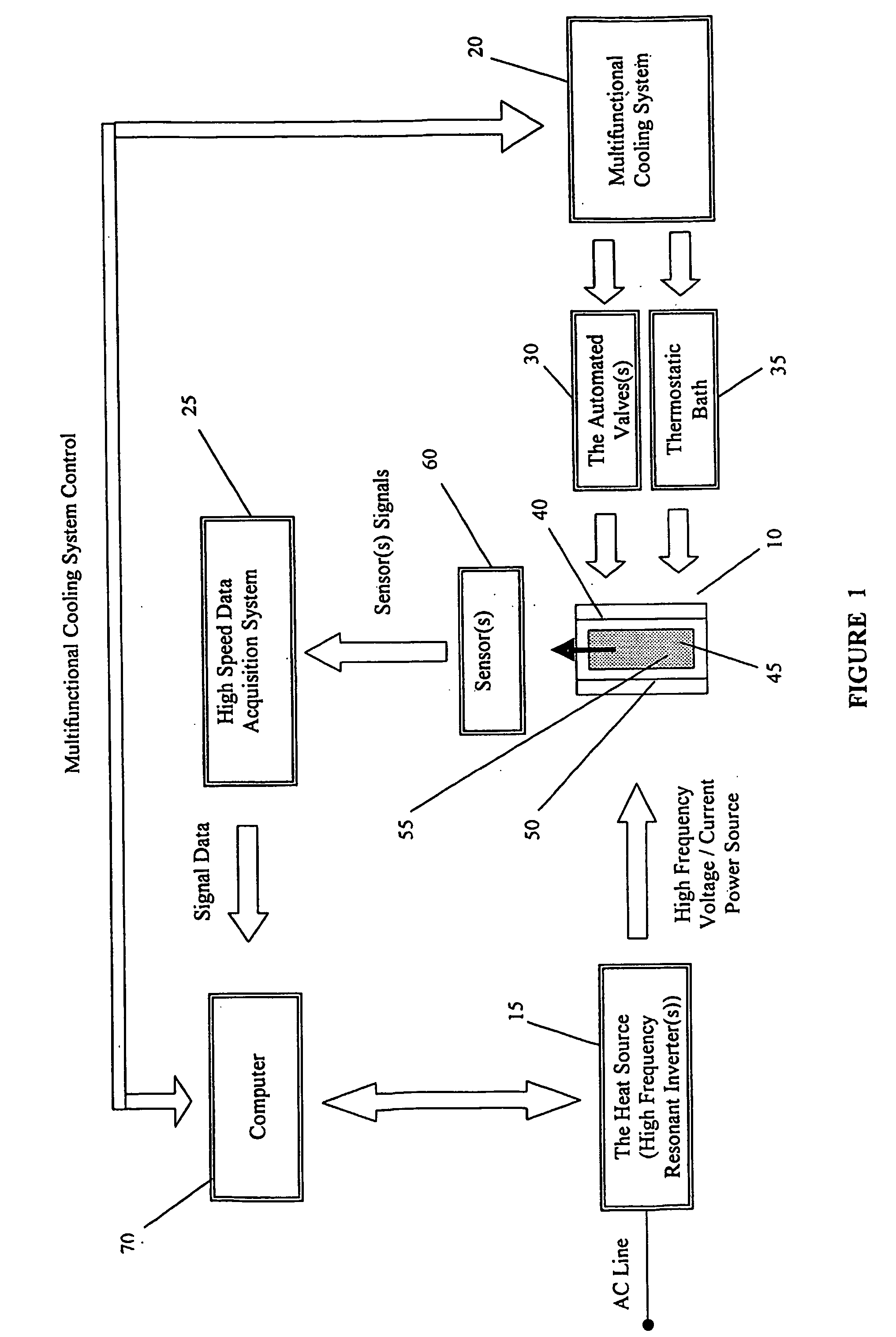

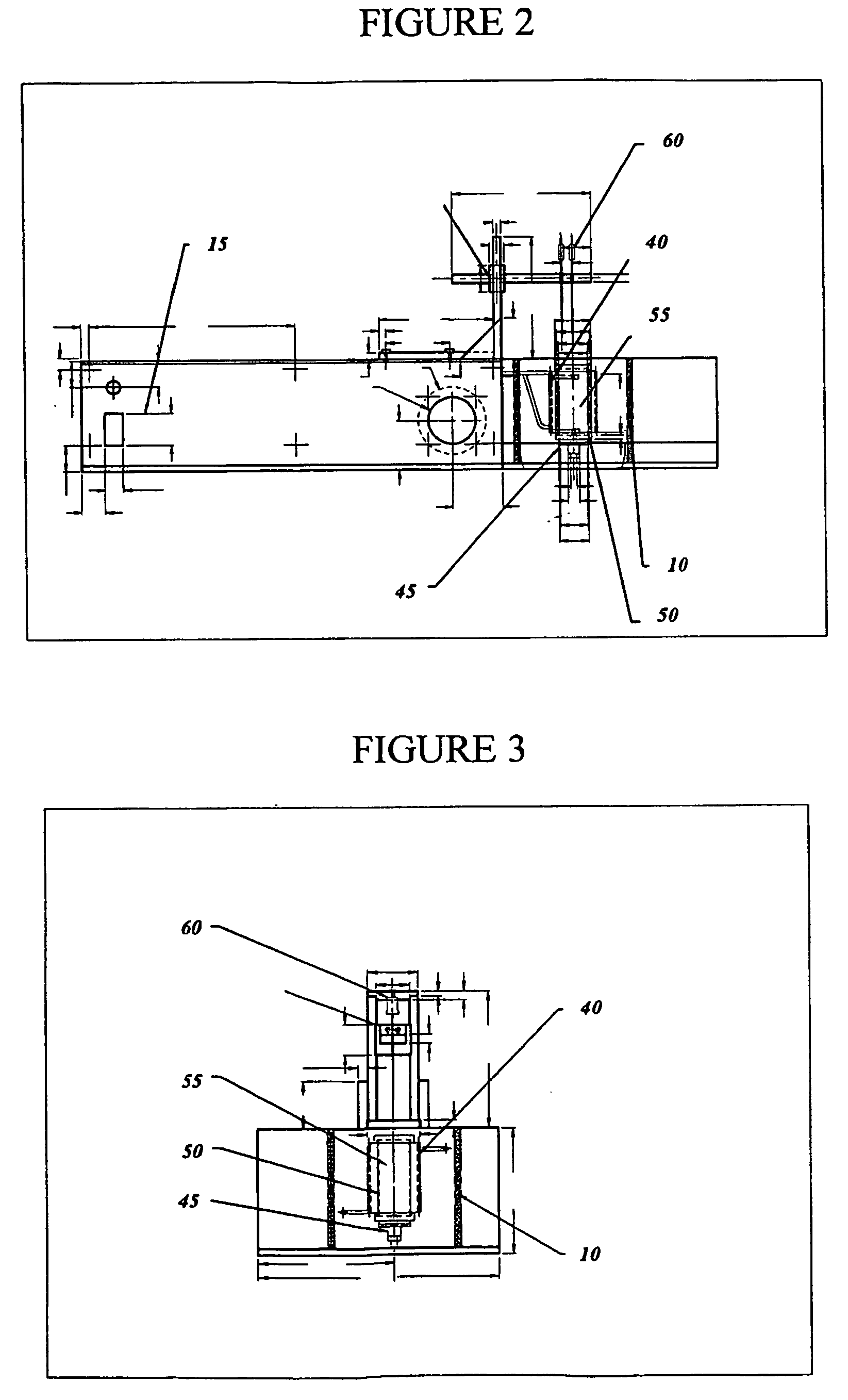

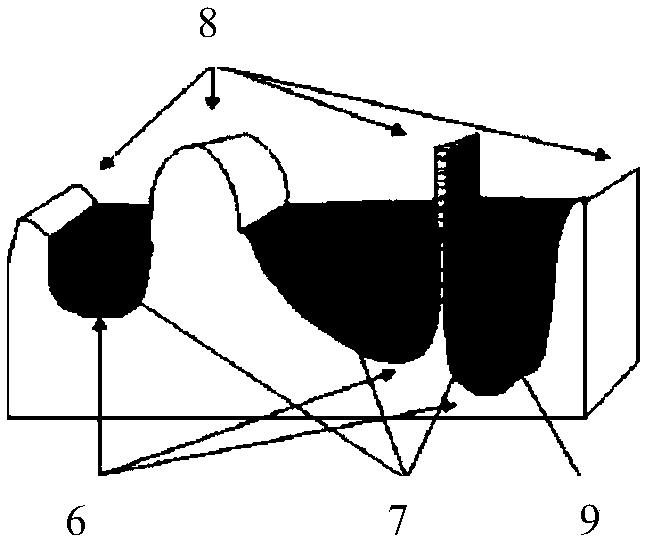

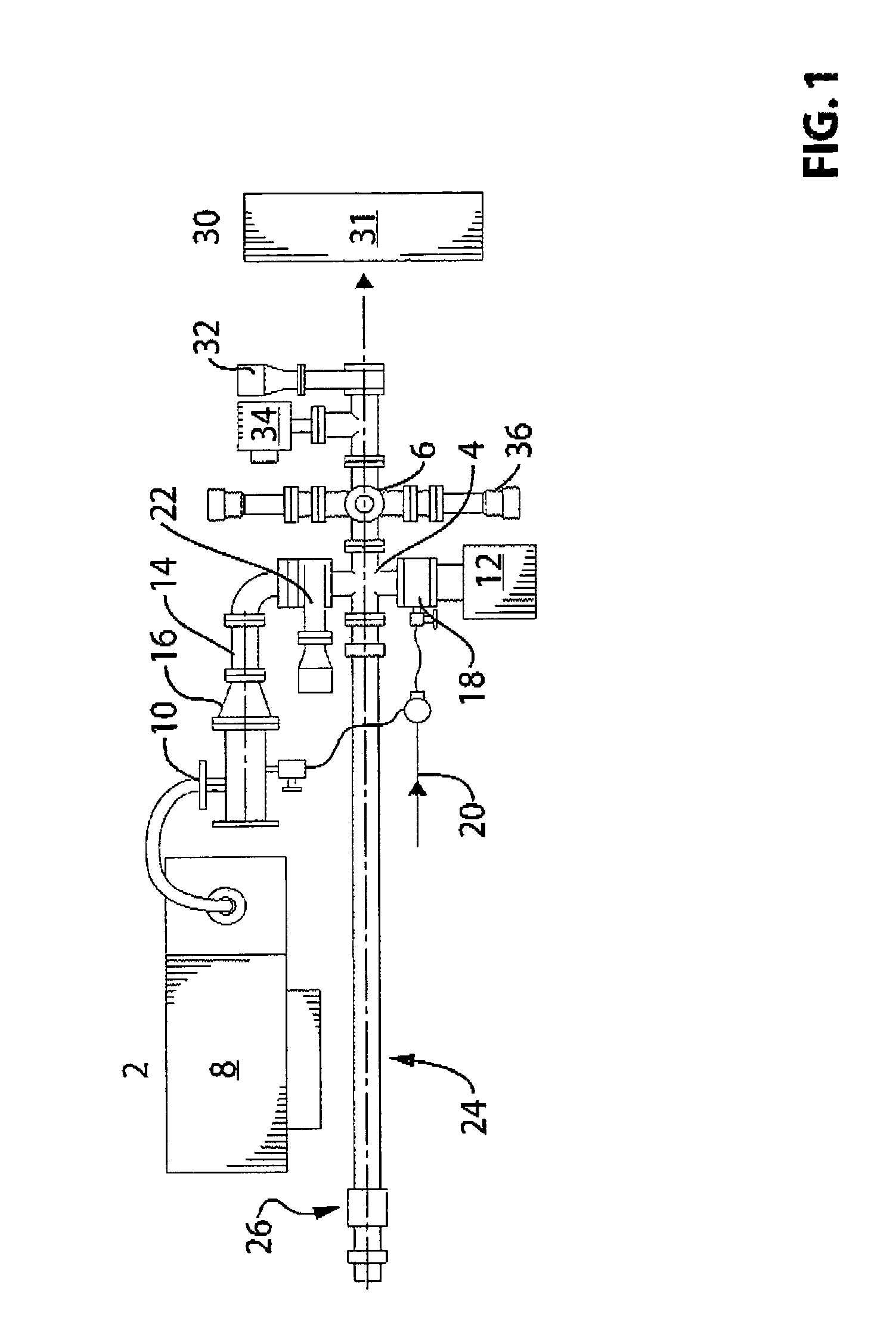

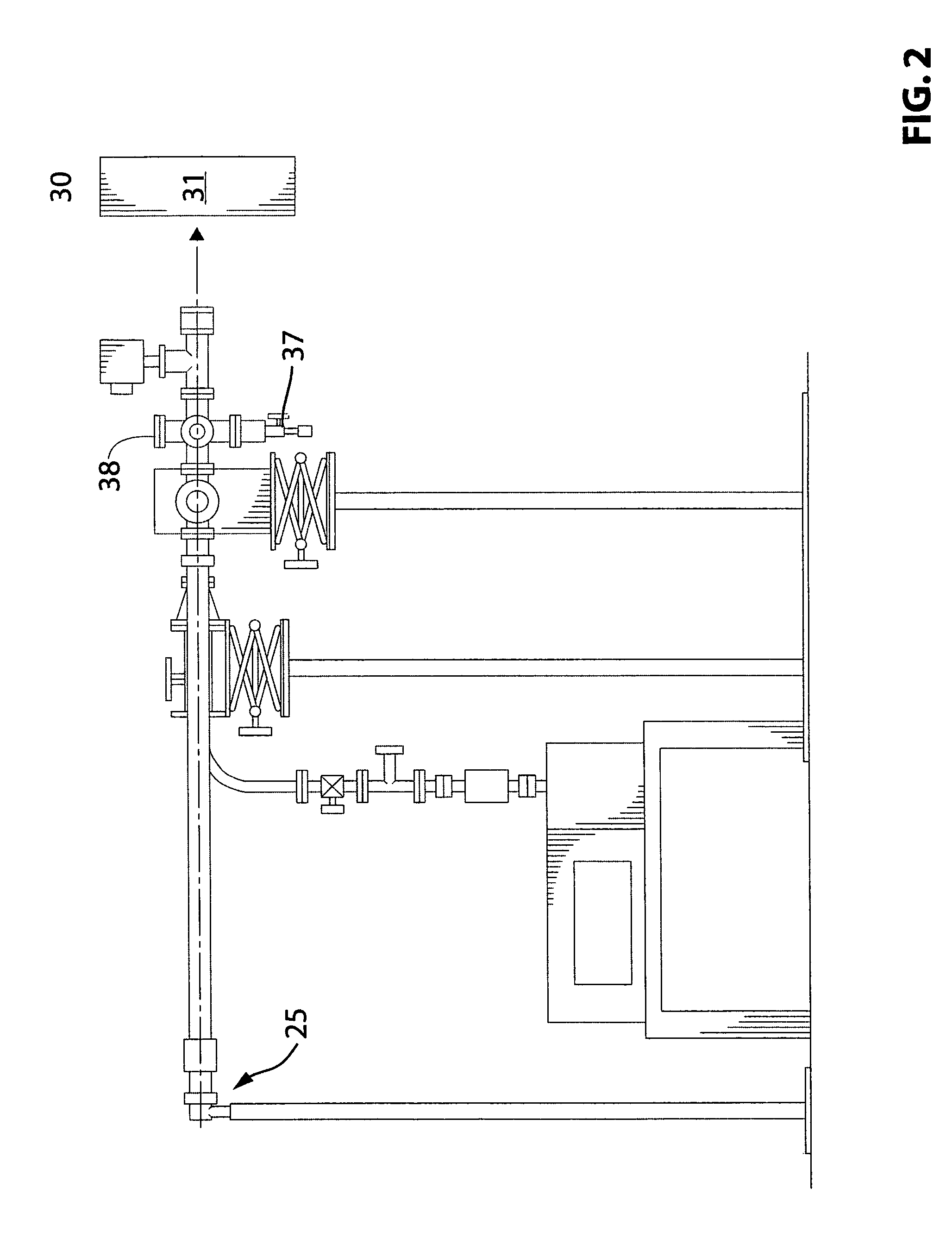

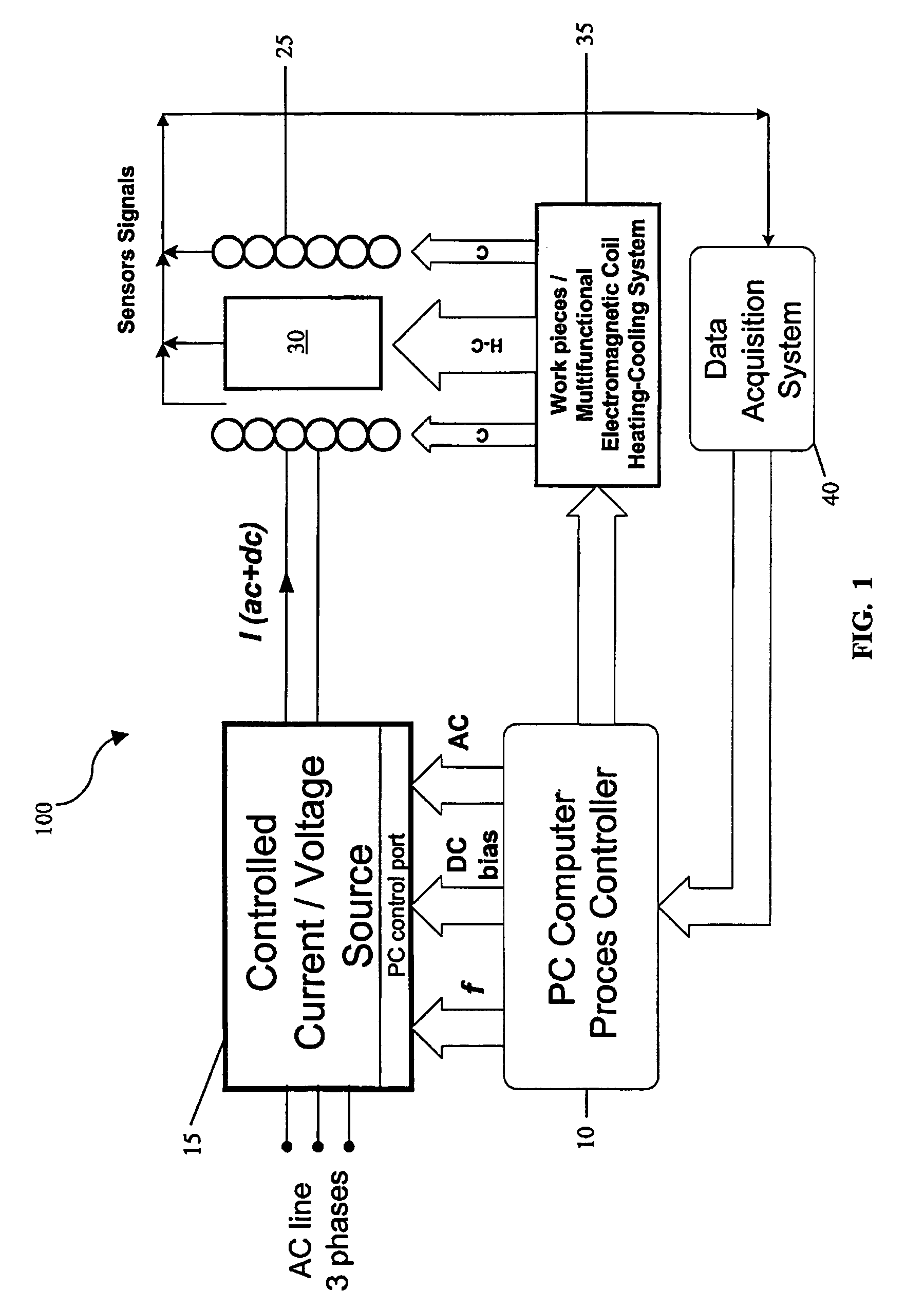

A method and apparatus (5) for simulating and analyzing industrial thermal processes, including industrial heat-treatment, processes, melting, solidification, quenching and the like, used in the manufacture of metals, alloys and metal matrix composite components. The apparatus (5) includes an optional environmental chamber (10) used for situations where testing room conditions are too hot or too cold and would thus interfere with operation of the apparatus (5) without such chamber (10). The apparatus (5) includes a multifunctional excitation coil (40) that serves the function of the omitted environmental chamber (10). The apparatus (5) also includes one or more high frequency resonant inverters (15) and a cooling means (20). The apparatus (5) integrates melting and thermal processing capabilities with a thermal analyzer and a control system. The apparatus (5) allows for the rapid design and optimization of industrial thermal processes used in the manufacture of metallurgical engineering material with superior structural and metallurgical chactacterics, suitable for advanced component service performance.

Owner:SOKOLOWSKI JERZY H +3

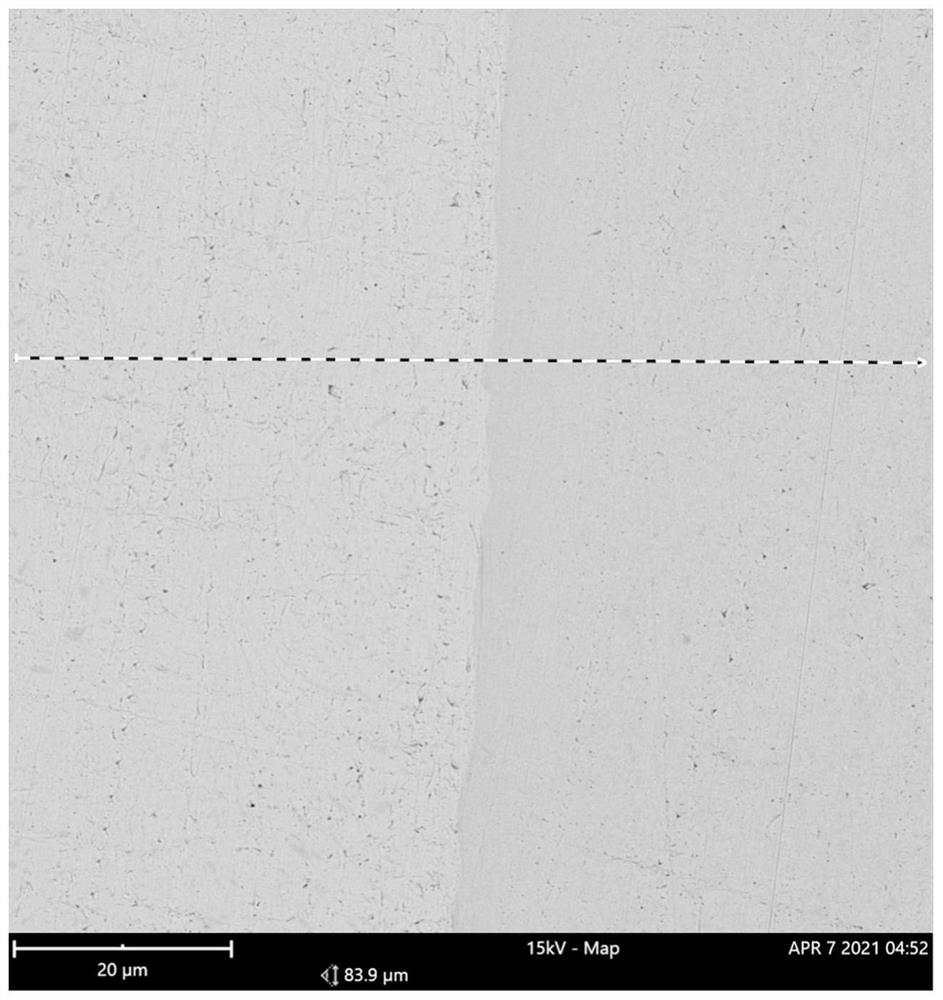

Full-view-field quantitative statistical distribution representation method of precipitated phase particles in metal material

ActiveCN108226159ARealize analysisEliminate statistical incompletenessImage enhancementImage analysisMathematical modelMetallic materials

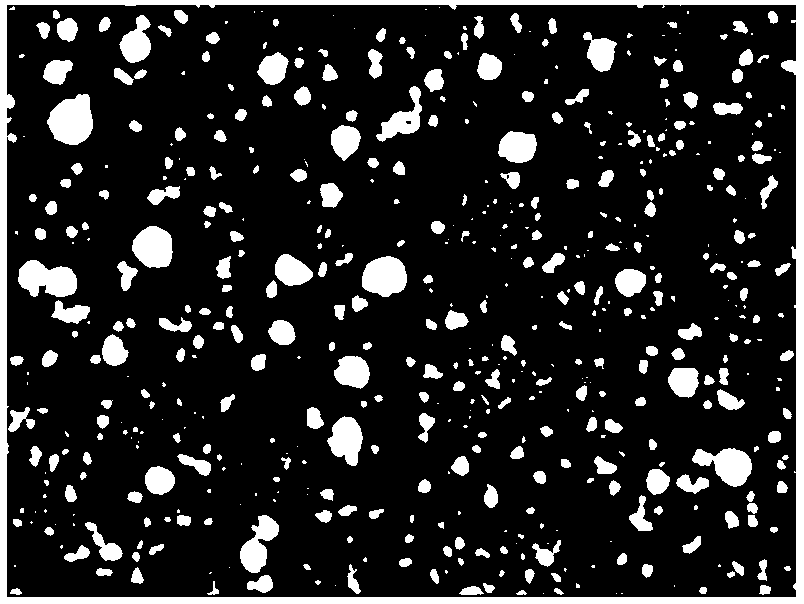

The invention belongs to the technical field of the quantitative statistical distribution analysis of characteristic chromatograms of microstructures and precipitated phases in metal materials, and relates to a full-view-field quantitative statistical distribution representation method of precipitated phase particles in a metal material. The method comprises the following steps of electrolytic corrosion of a metallic material sample, automatic collection of a characteristic chromatogram of a metallurgical structure, automatic splicing and fusion of the characteristic chromatograms of full-view-field metallurgical structures, automatic identification and segmentation of the precipitated phase particles and quantitative distribution representation of the large-range full-view-field precipitated phase particles. According to the full-view-field quantitative statistical distribution representation method, through establishing a mathematic model, the automatic splicing and fusion of the characteristic chromatograms of the full-view-field large-area metallurgical structures in a characteristic region and the automatic segmentation and identification of the precipitated phase particles are realized; the quantitative statistical distribution representation information of the full-view-field morphology, quantity, size, distribution and the like of plentiful precipitated phases in a larger range is quickly obtained, and the method has the features of being accurate and high-efficiency and large in quantitative distribution representation information quantity, and has much more statistical representativeness compared with conventional single-view-field quantitative image analysis.

Owner:CENT IRON & STEEL RES INST

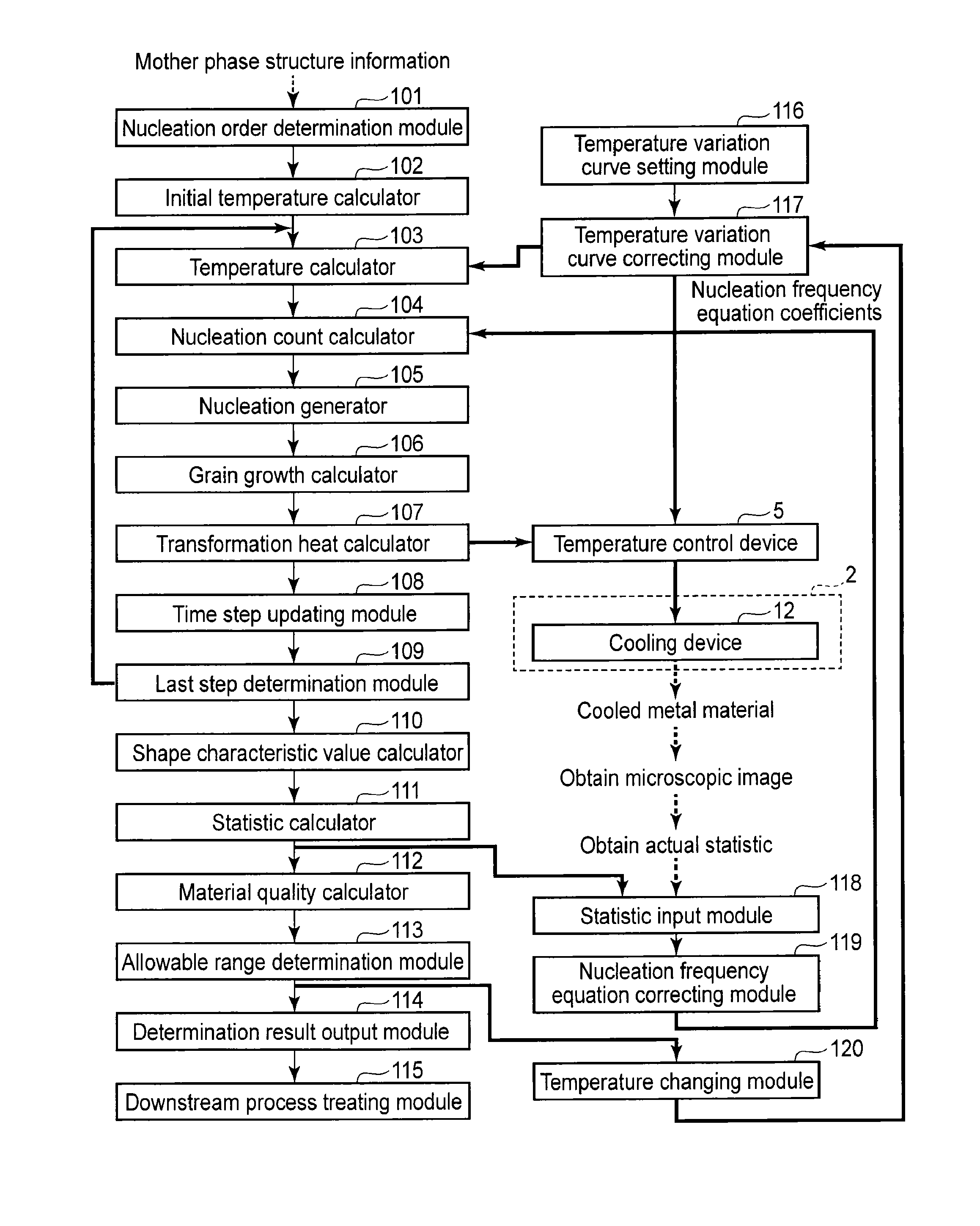

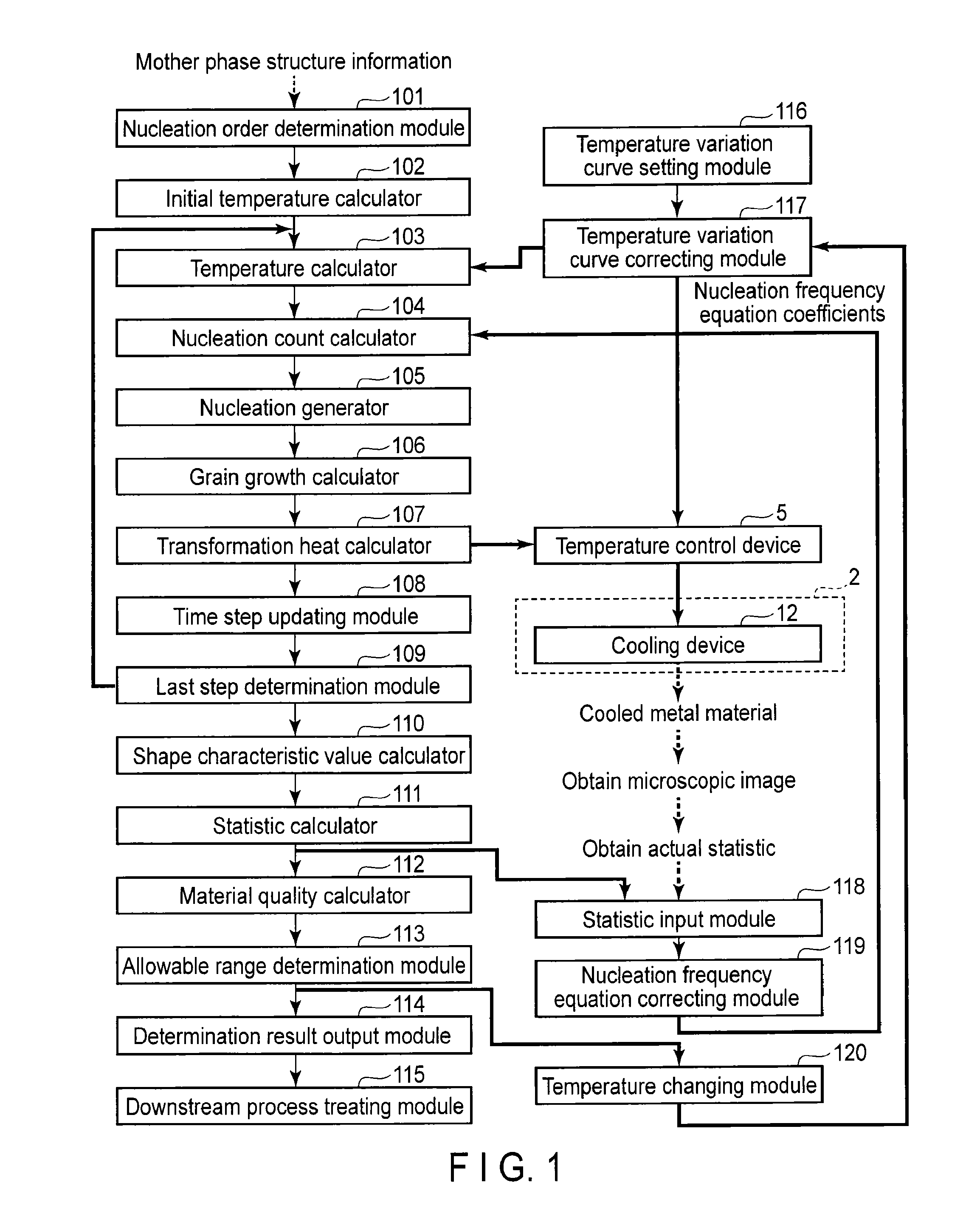

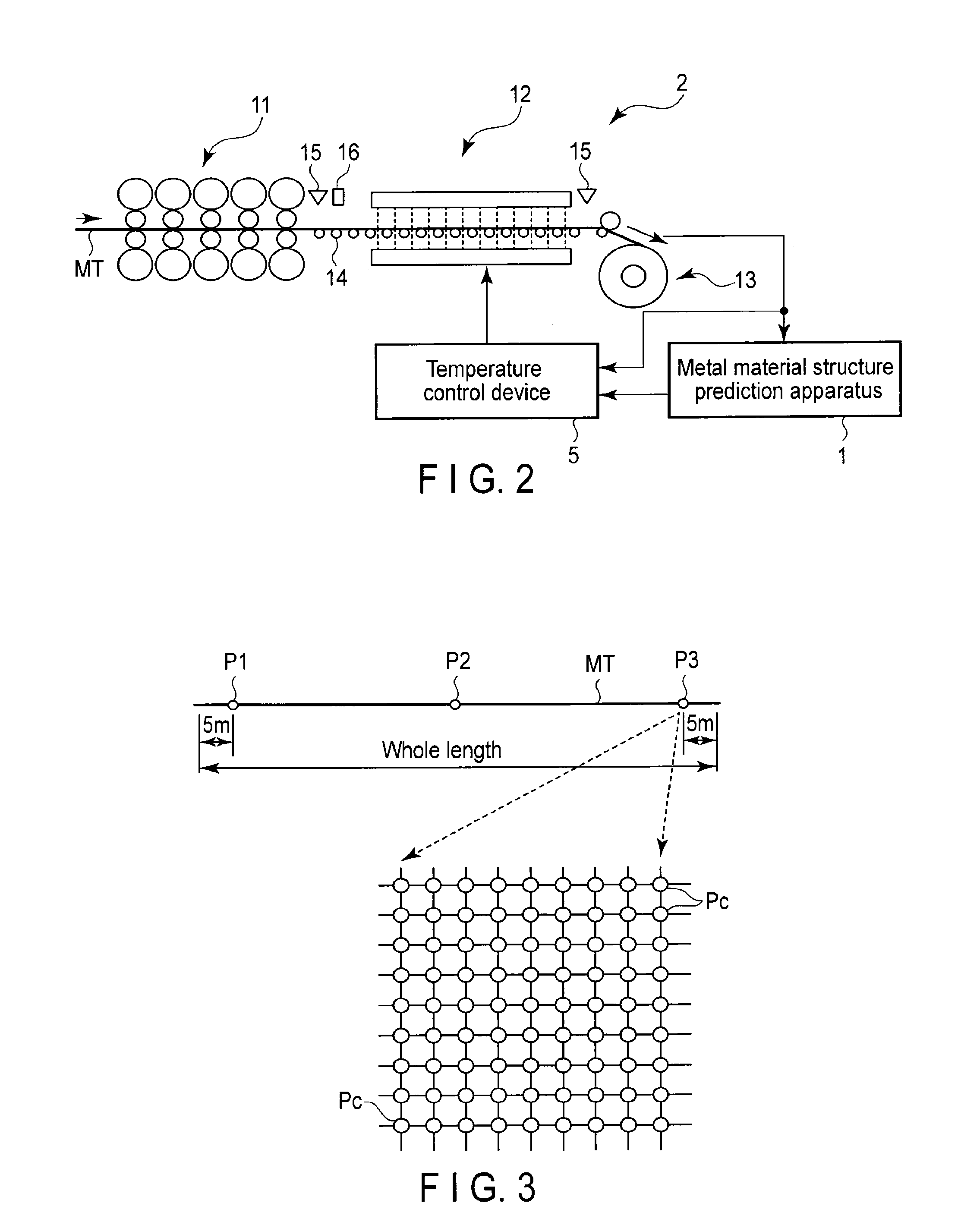

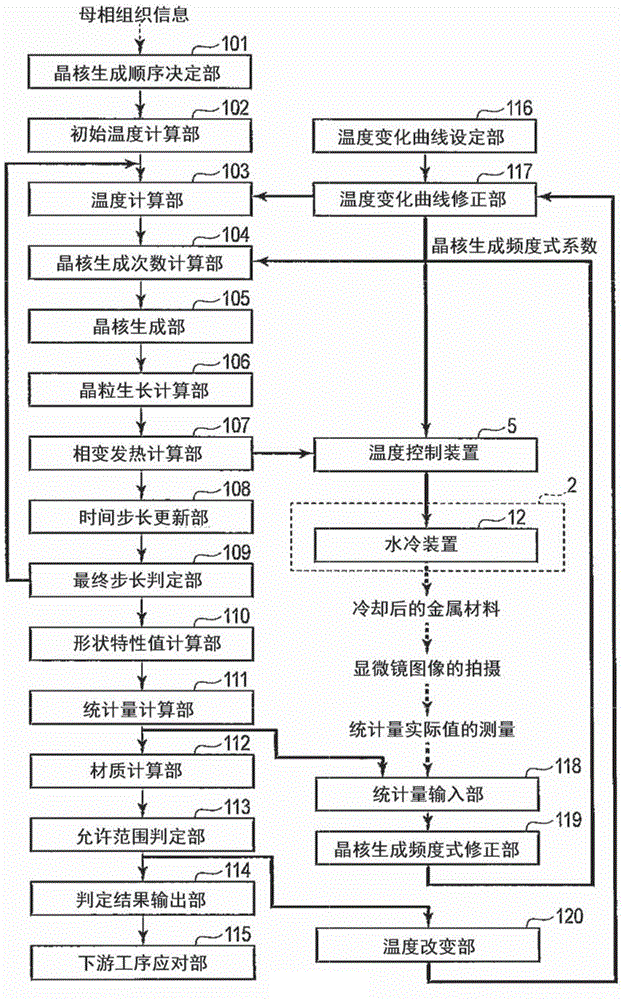

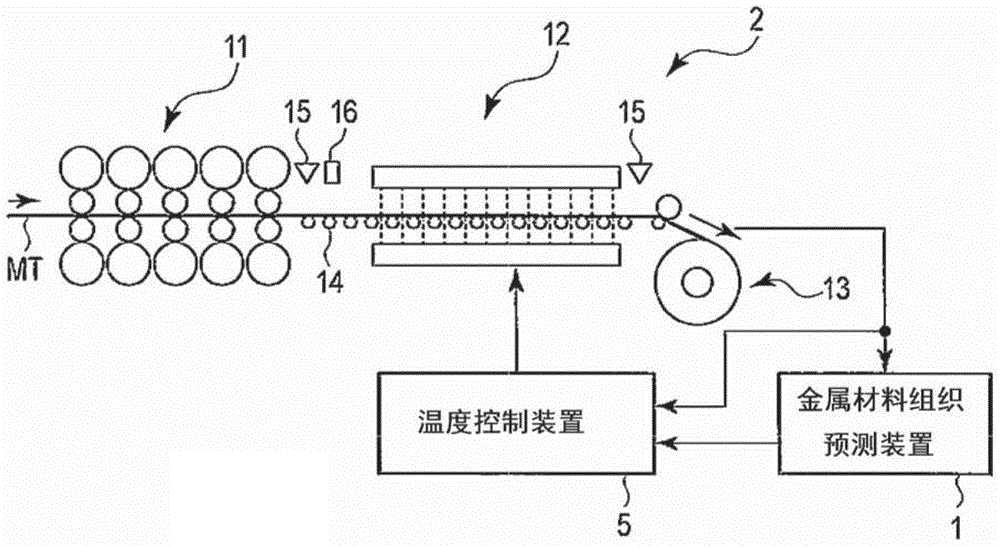

Material structure prediction apparatus, product manufacturing method and material structure prediction method

The material structure prediction apparatus includes a temperature calculator calculating temperatures at calculation points, based on a temperature condition, a nucleation count calculator calculating a nucleation count in the calculation target region, a precipitated phase generation point determining module determining, from the calculation points, a precipitated phase generation point, a grain growth calculator calculating a grain growth of the precipitated phase at the precipitated phase generation point, and a material structure prediction module predicting the structure of the material, based on the grain growth of the precipitated phase.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

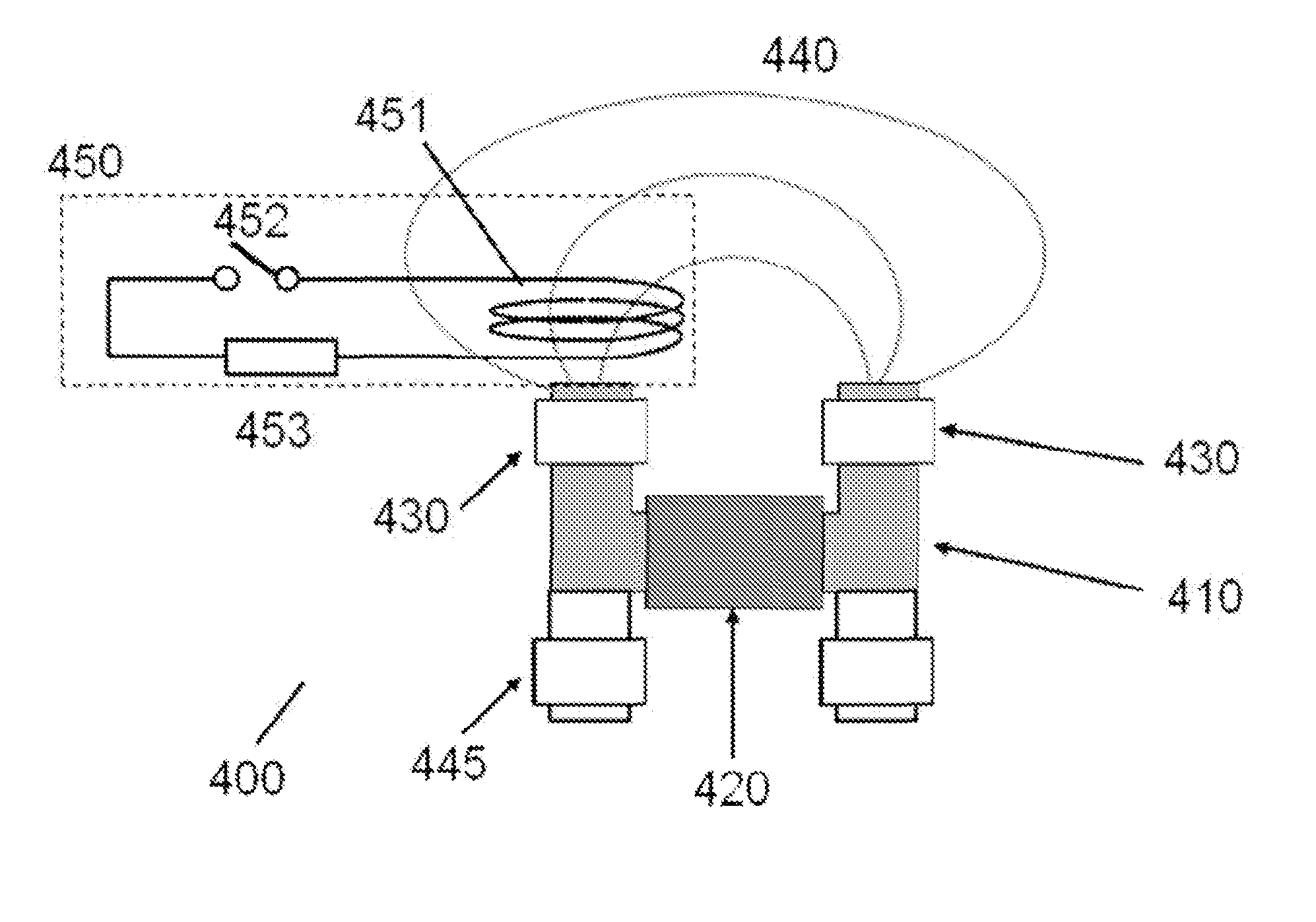

Sensors

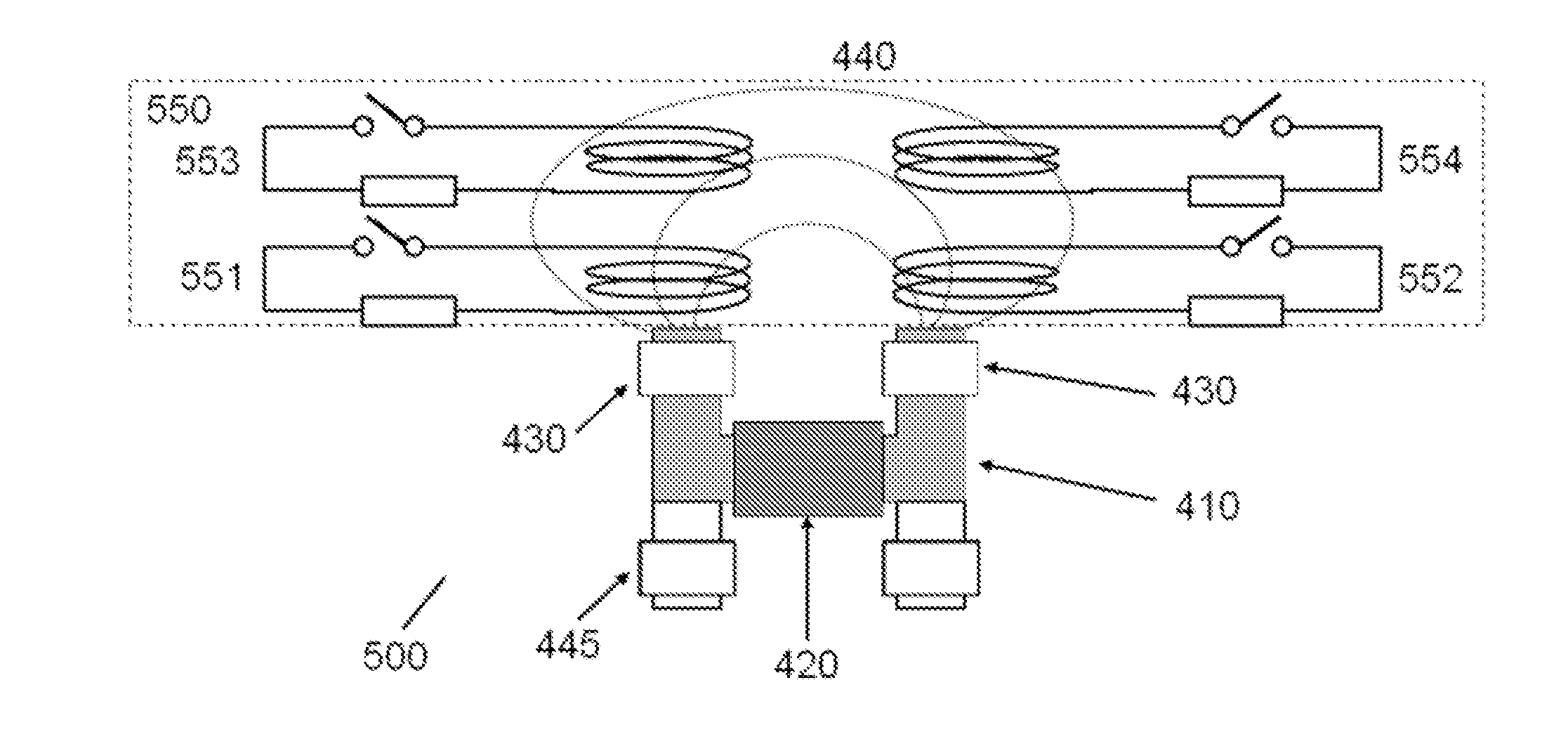

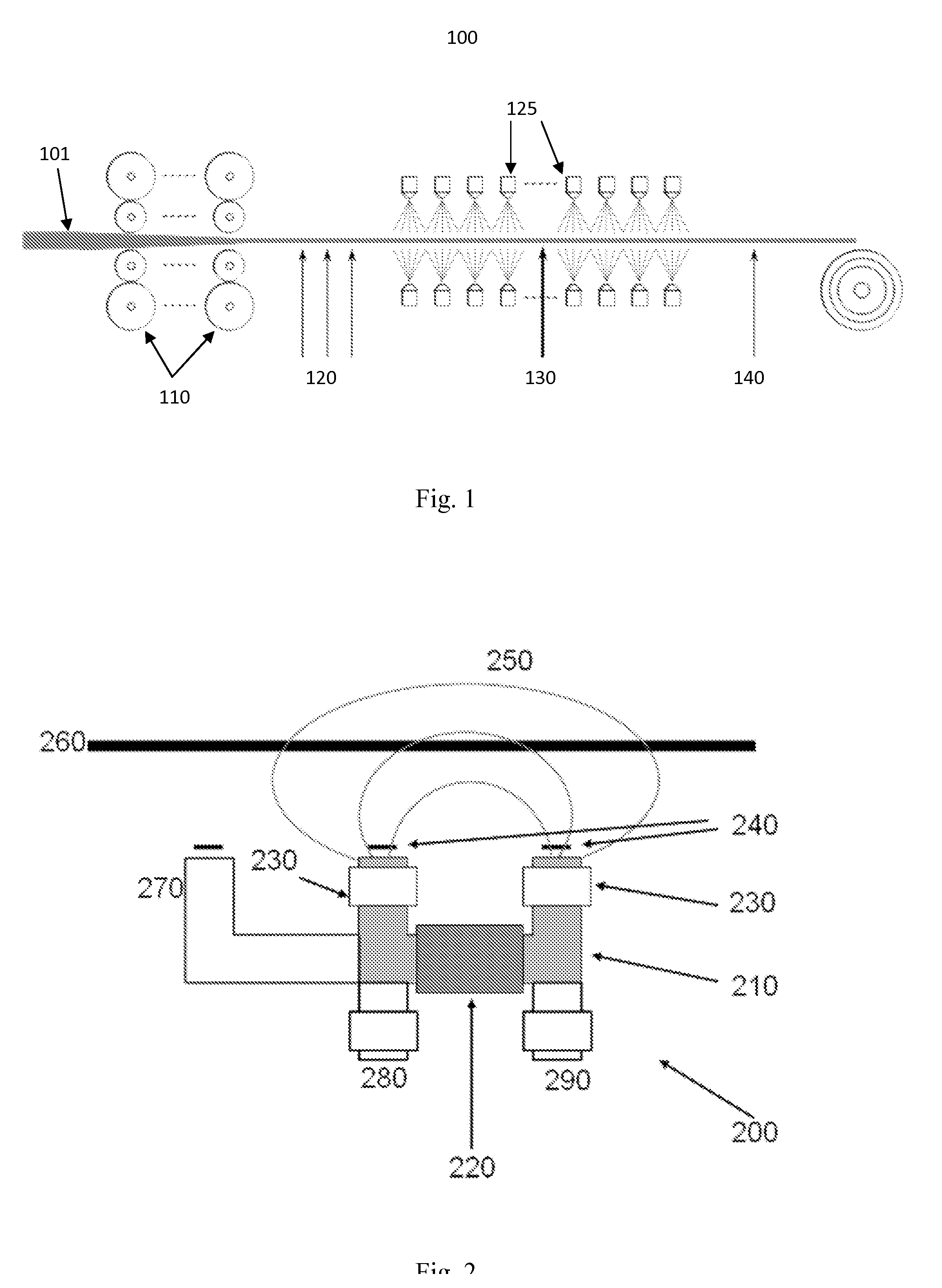

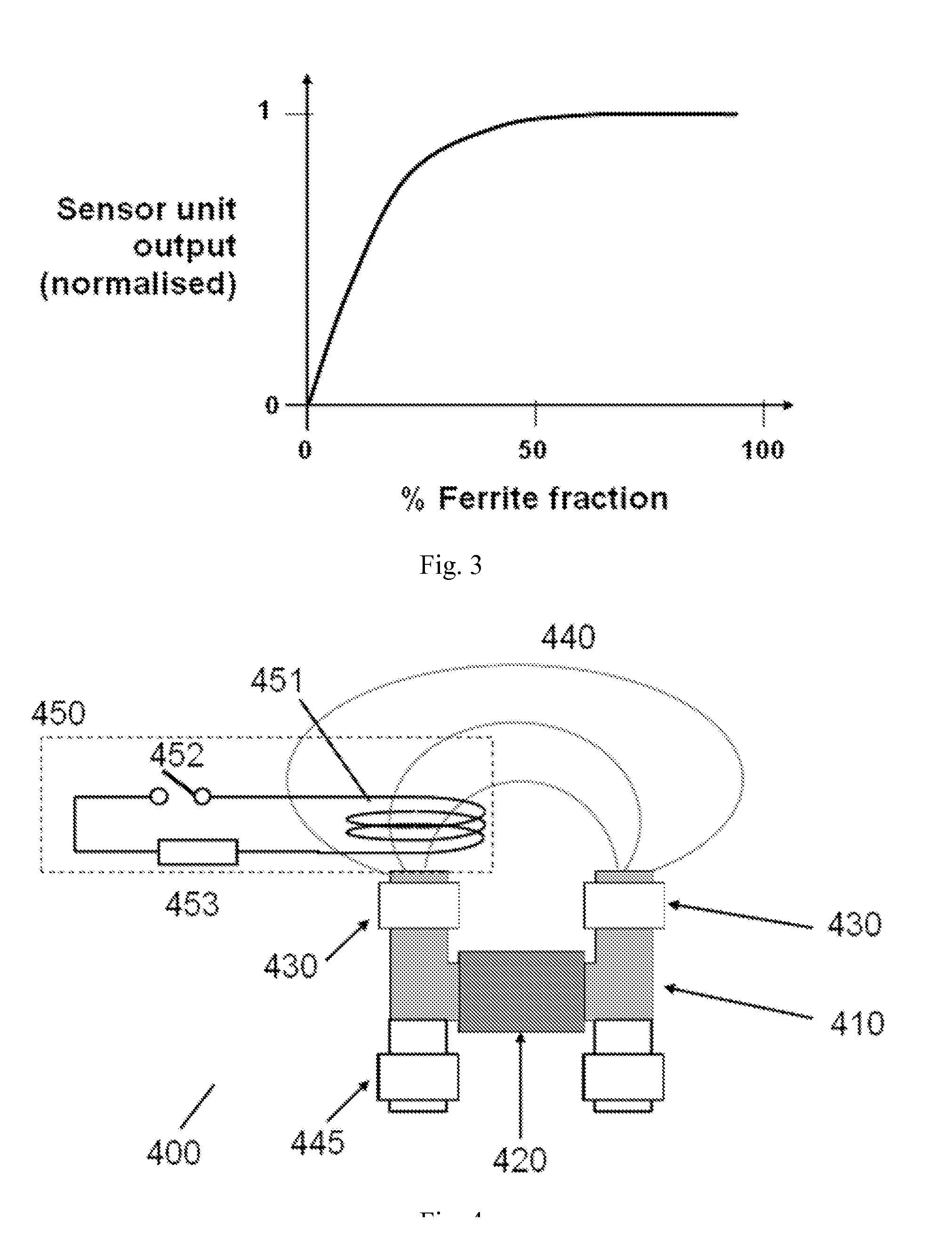

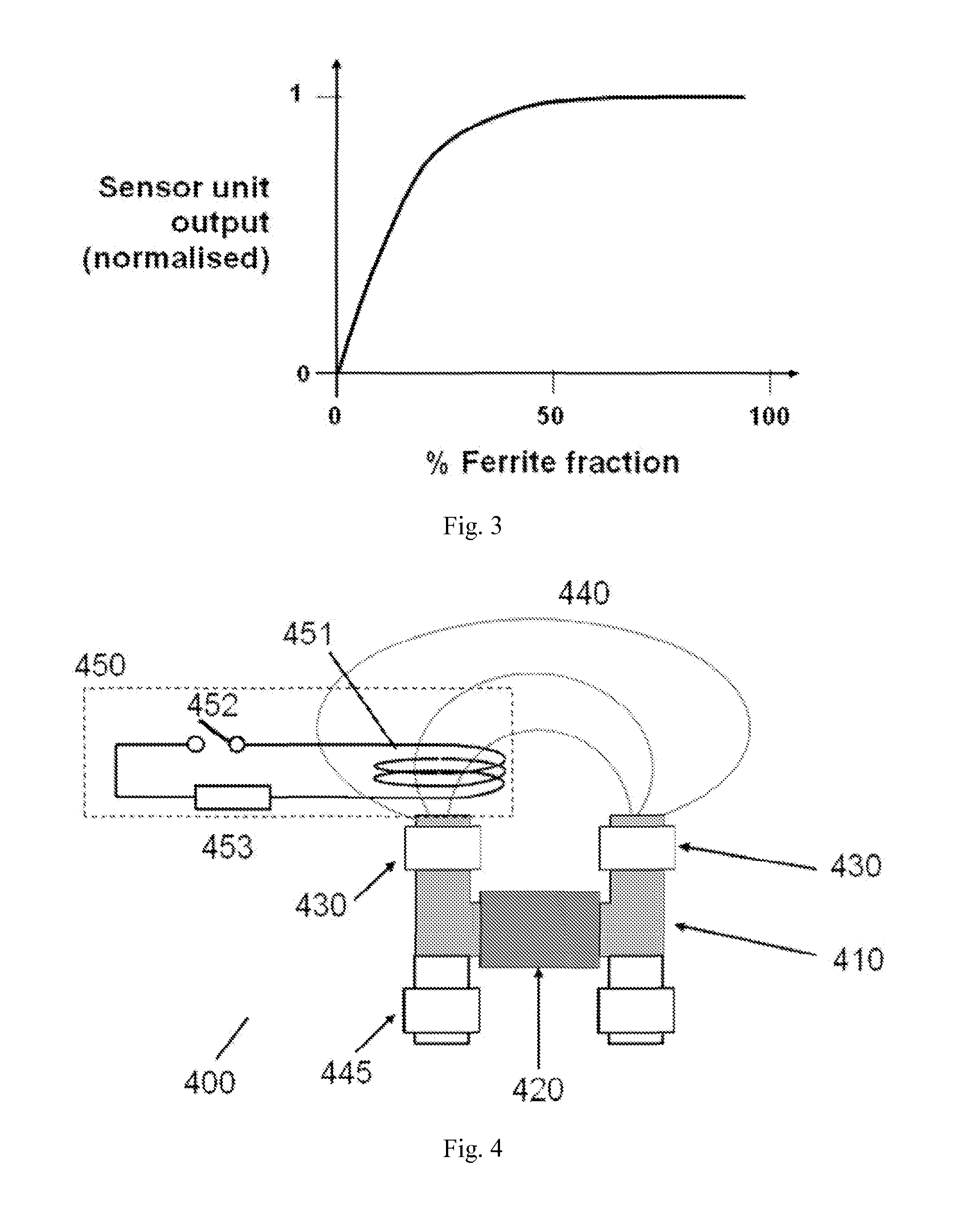

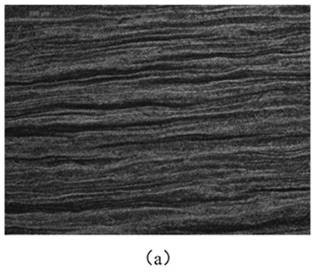

ActiveUS20140049251A1Permeability measurementsTemperature control devicePower flowElectromagnetic shielding

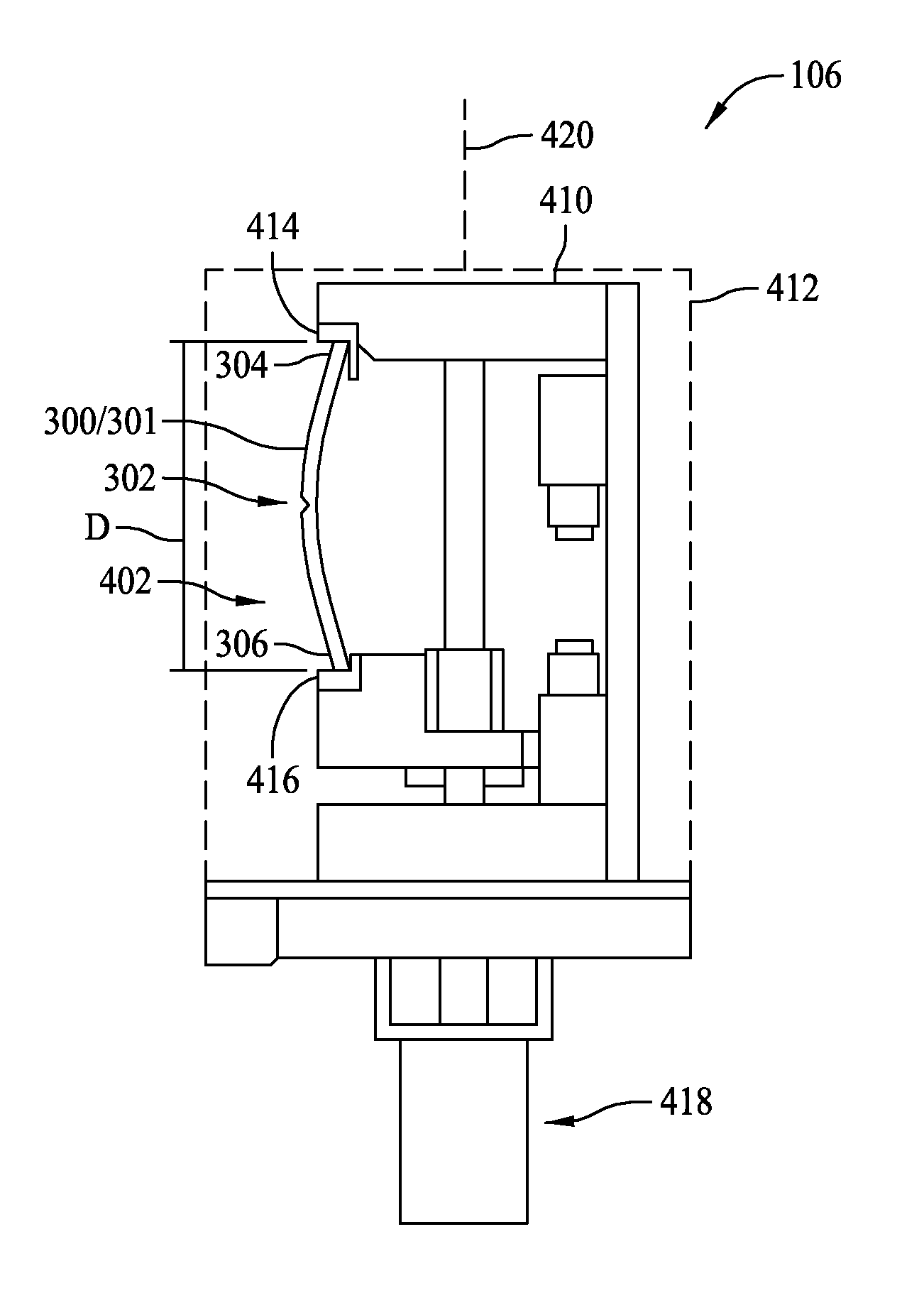

Embodiments of the present invention provide an electromagnetic sensor (400) for detecting a microstructure of a metal target, comprising: a magnetic device (410, 420) for providing an excitation magnetic field; a magnetometer (430) for detecting a resultant magnetic field induced in a metal target; and a calibration circuit (450, 551, 552, 553, 554) for generating a calibration magnetic field for calibrating the electromagnetic sensor, wherein the calibration reference magnetic field is generated by an electrical current induced in the calibration circuit by the excitation magnetic field.

Owner:UNIV OF MANCHESTER

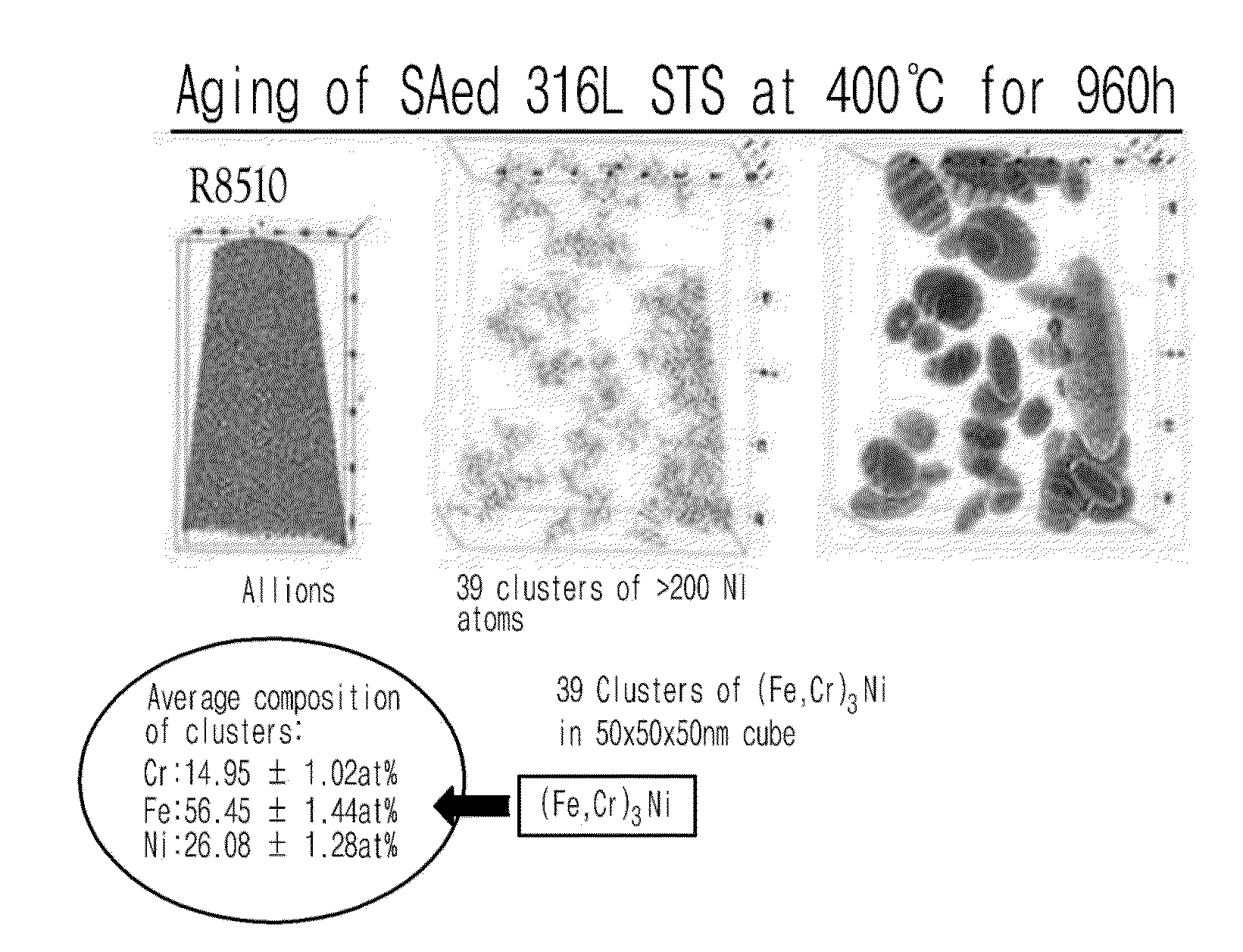

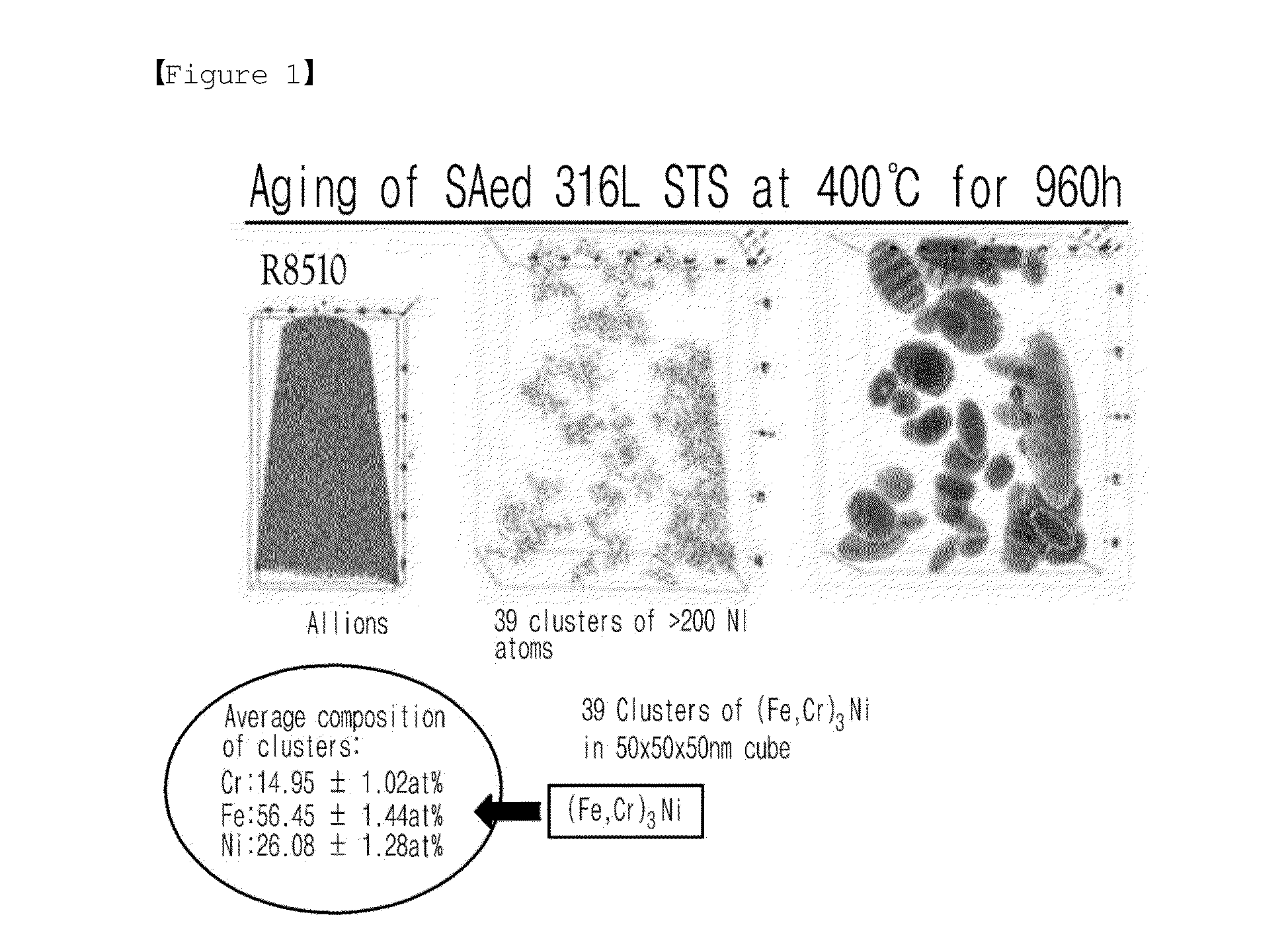

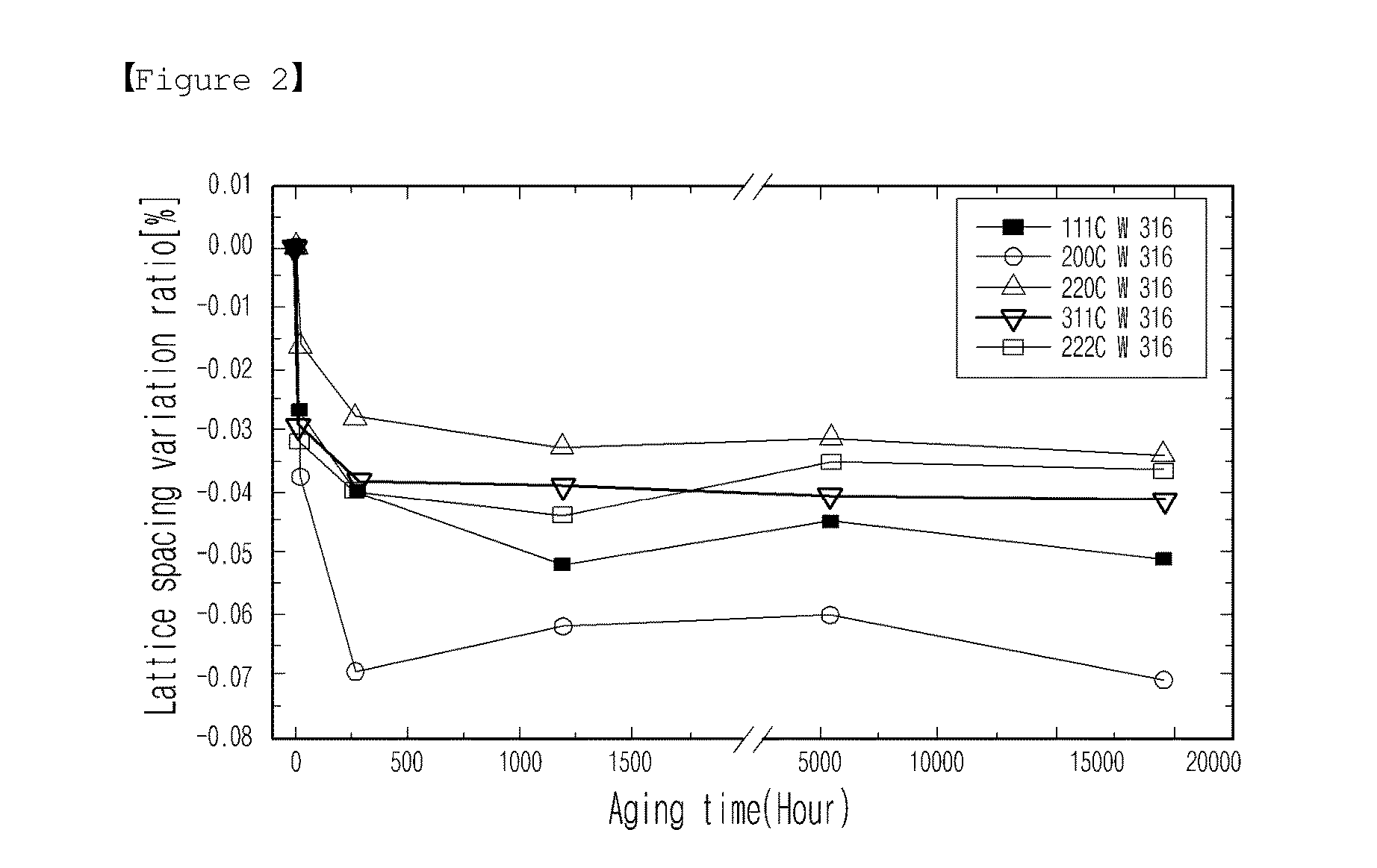

Method of non-destructive evaluation of intergranular stress corrosion cracking (IGSSC) in structural components made of metal alloys, and the method of lifetime evaluation of the structural components

ActiveUS20160161395A1Reliably evaluate remaining lifetimeSafety is assuredAnalysing solids using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceNon destructiveNuclear power

A method of non-destructive evaluation of stress corrosion cracking of structural components made of metal alloys, and a method of evaluation of the remaining lifetime of the structural component made of metal alloys are provided, in which a change in properties of the structural components made of metal alloys being used in operating nuclear power plants is measured according to the degree of atomic ordering (or short range ordering) of alloying atoms, and stress corrosion cracking of the structural components made of metal alloys is thus evaluated. The properties to be measured may be one or more selected from a group consisting of hardness, electrical resistivity and thermal conductivity.

Owner:KOREA ATOMIC ENERGY RES INST

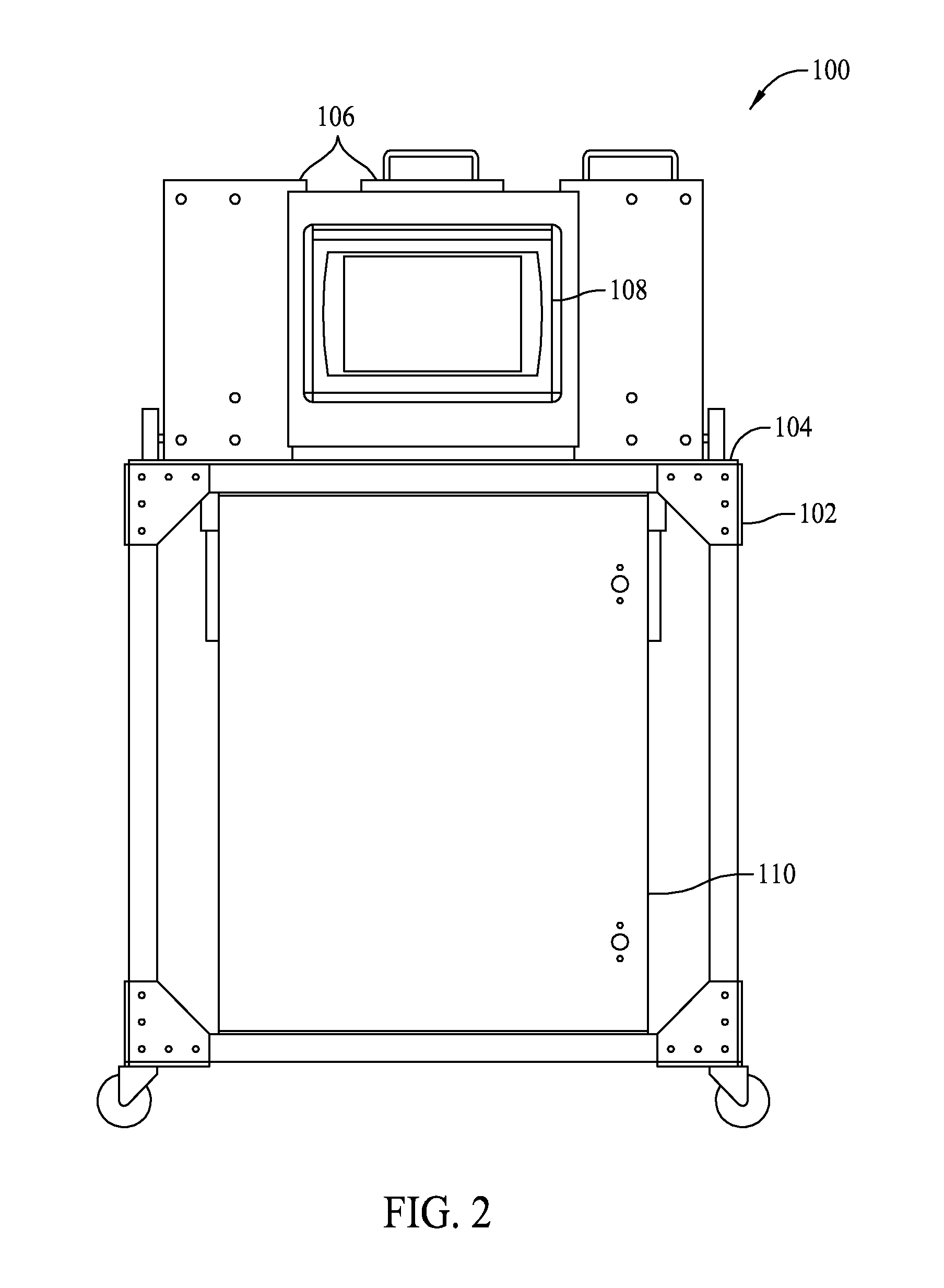

Conditioning chamber for metallurgical surface science

InactiveUS8001853B2Promote sportsRisk of contaminationWeather/light/corrosion resistancePreparing sample for investigationUltra-high vacuumSurface science

The present invention provides a conditioning chamber device and a conditioning method for metallurgical samples which can be directly connected to an instrument having an examination chamber operable in an ultra high vacuum (UHV) condition at a selected pressure below 10−7 Torr. The conditioning chamber comprises at least one vacuum pump means to reduce the conditioning chamber to the selected UHV condition corresponding to the selected pressure of the examination chamber; sample retaining means; at least one fracturing means to prepare an analysis surface on the sample; sample drying means for slow drying the sample in the selected UHV condition; a sealable outlet constructed and arranged to be operatively connected to the inlet of the examination chamber; and transporting means to transport the sample after surface preparation through a connecting means into the examination chamber without leaving the selected ultra high vacuum condition.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

Method and systems for determining hydrogen embrittlement

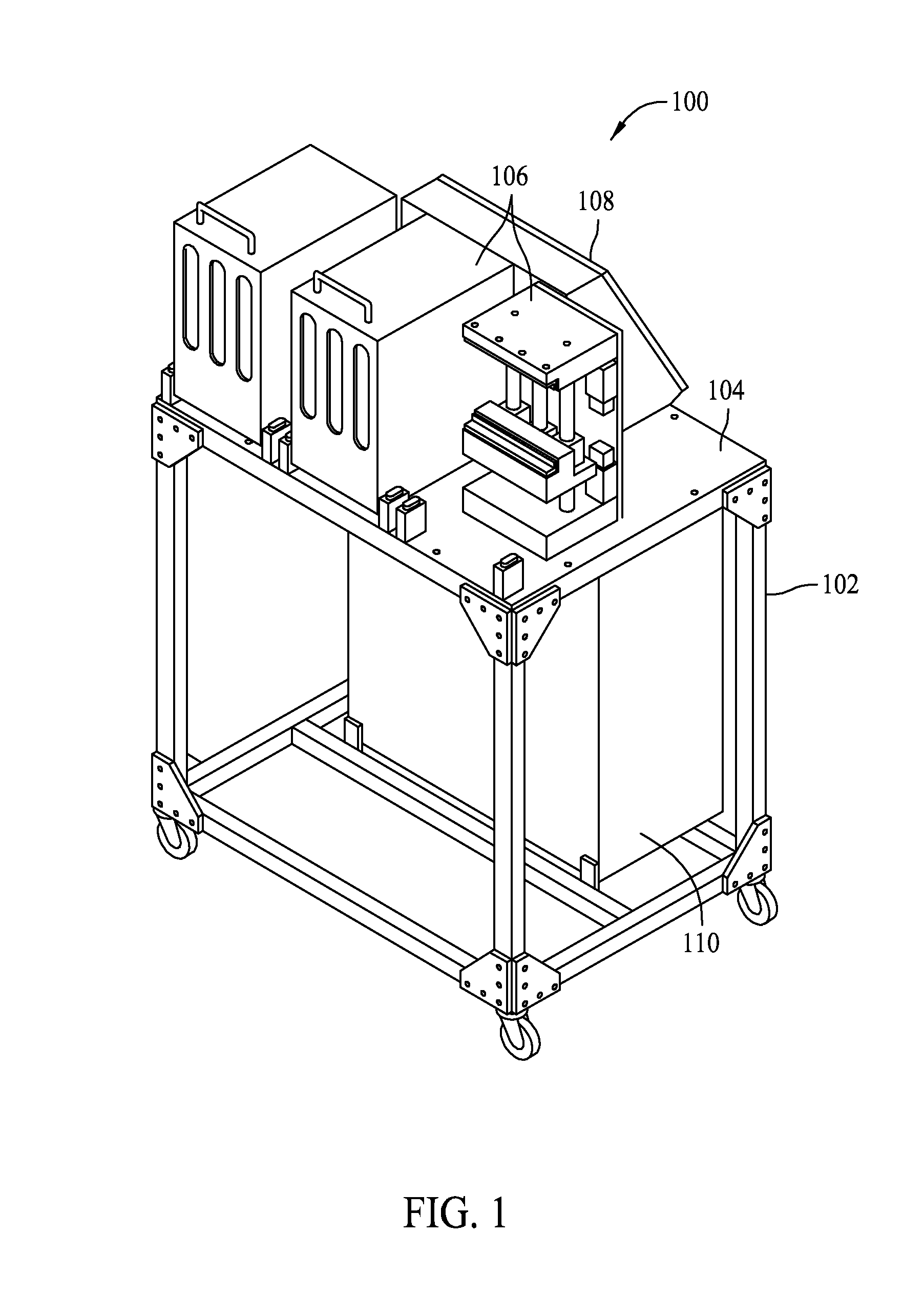

ActiveUS9176039B2Weather/light/corrosion resistanceMaterial strength using steady bending forcesEngineeringUltimate failure

A method for use in determining hydrogen embrittlement in a plated sample is provided. The method includes positioning the plated sample between a first holding member and a second holding member, moving the second holding member towards the first holding member to bend the plated sample, and applying a static load to the plated sample for a predetermined duration of time. The static load is applied by bending the plated sample to a distance between the first and second holding members that is a predetermined percentage of a baseline ultimate failure distance of the plated sample.

Owner:THE BOEING CO

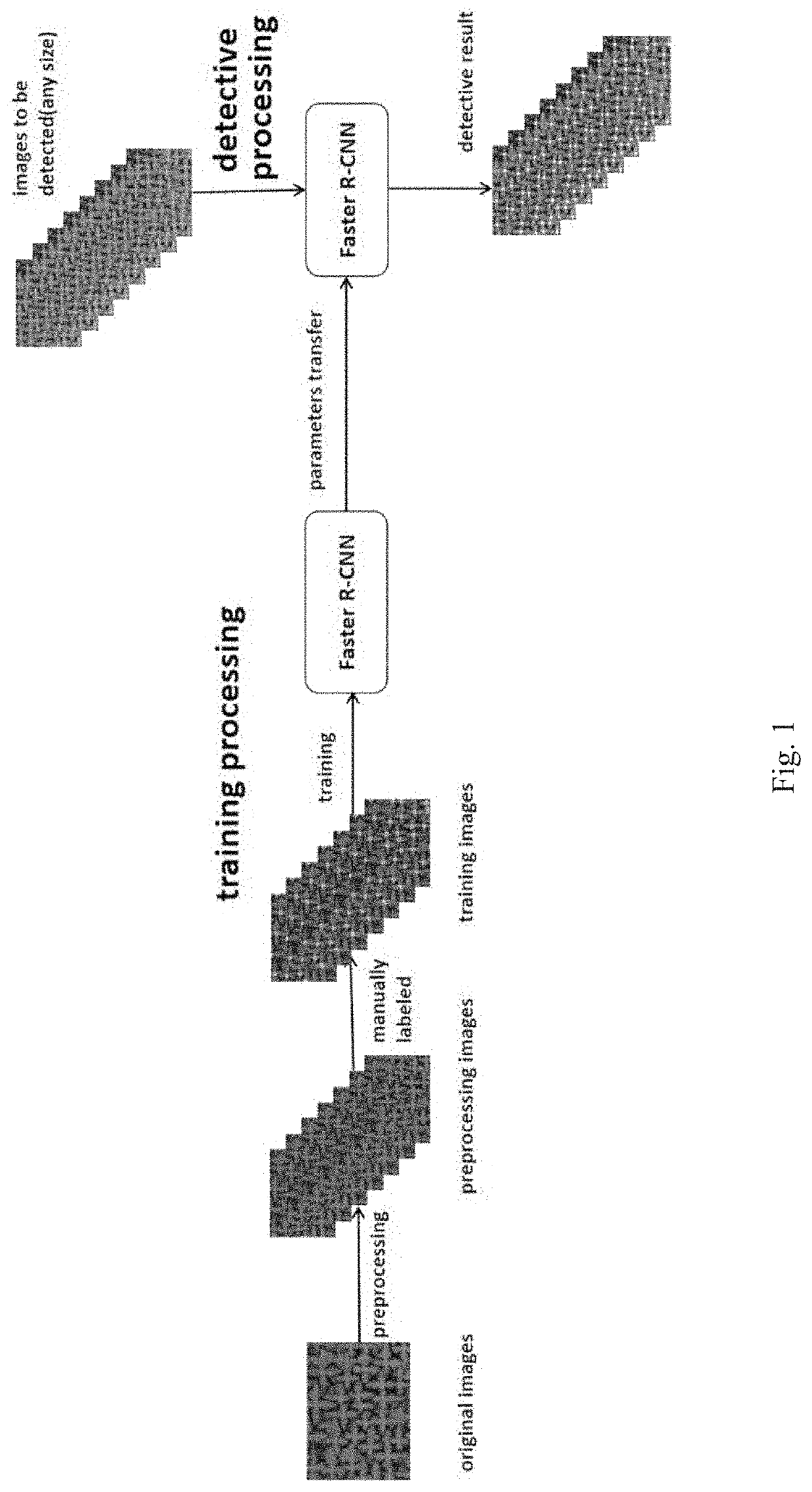

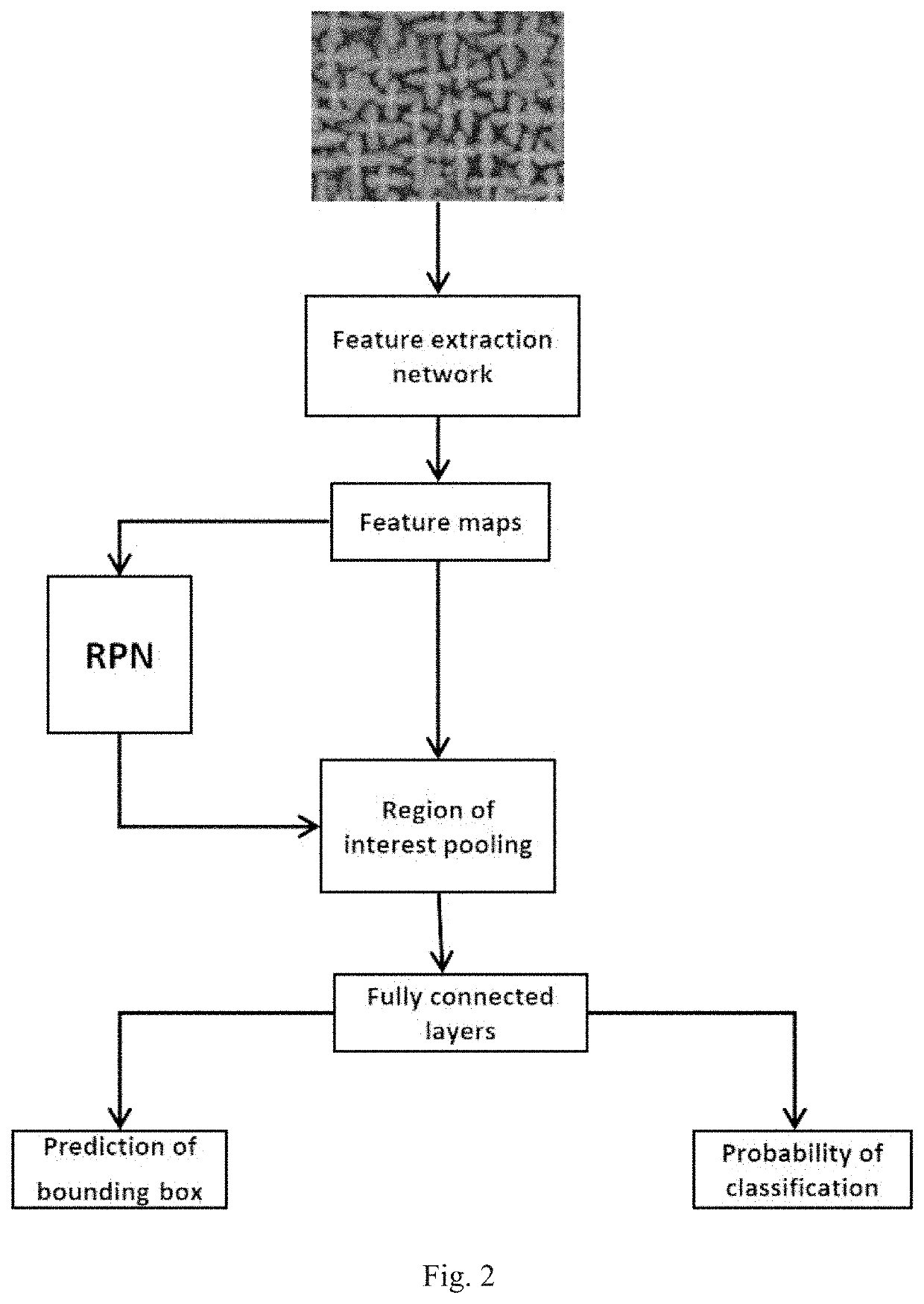

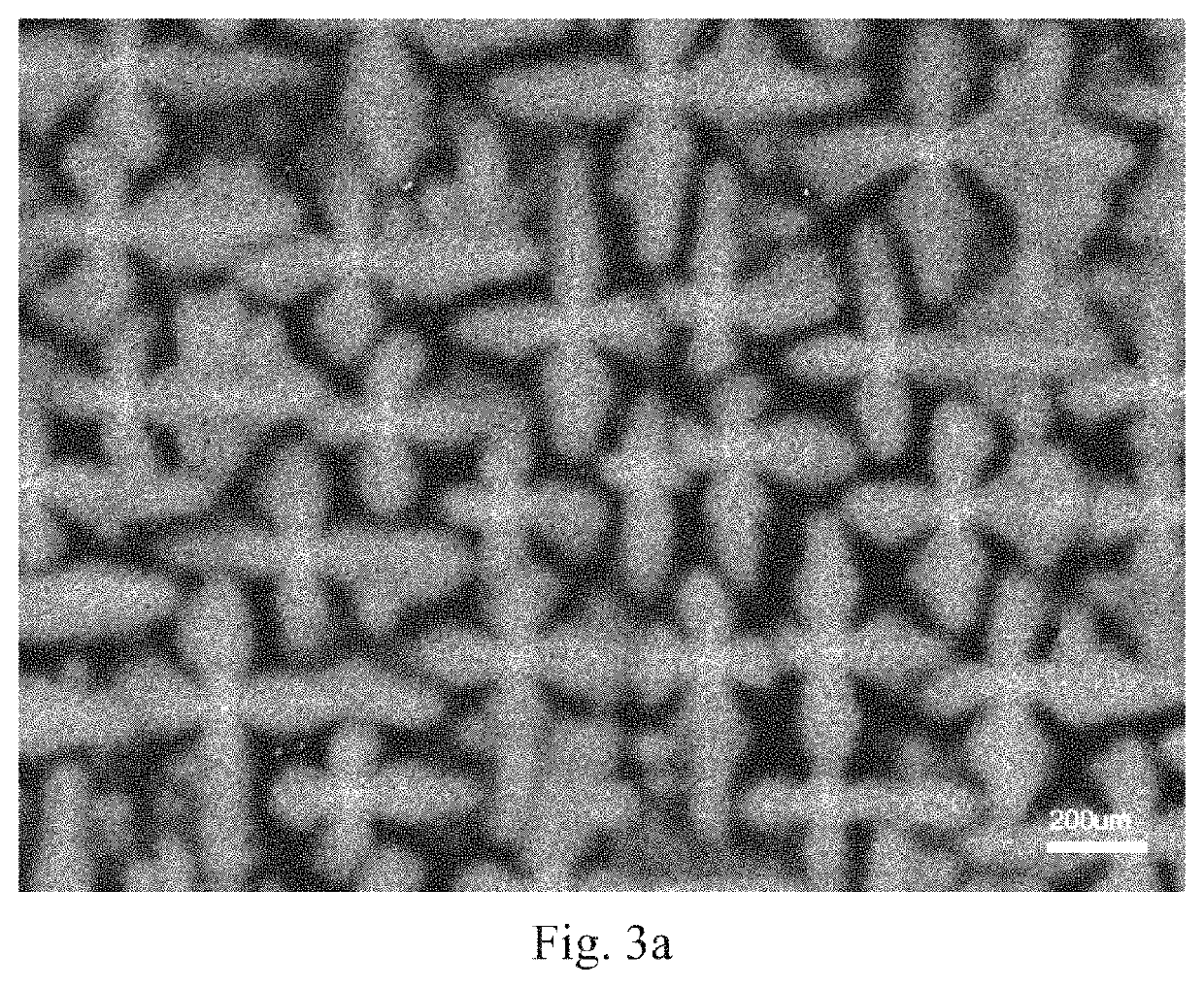

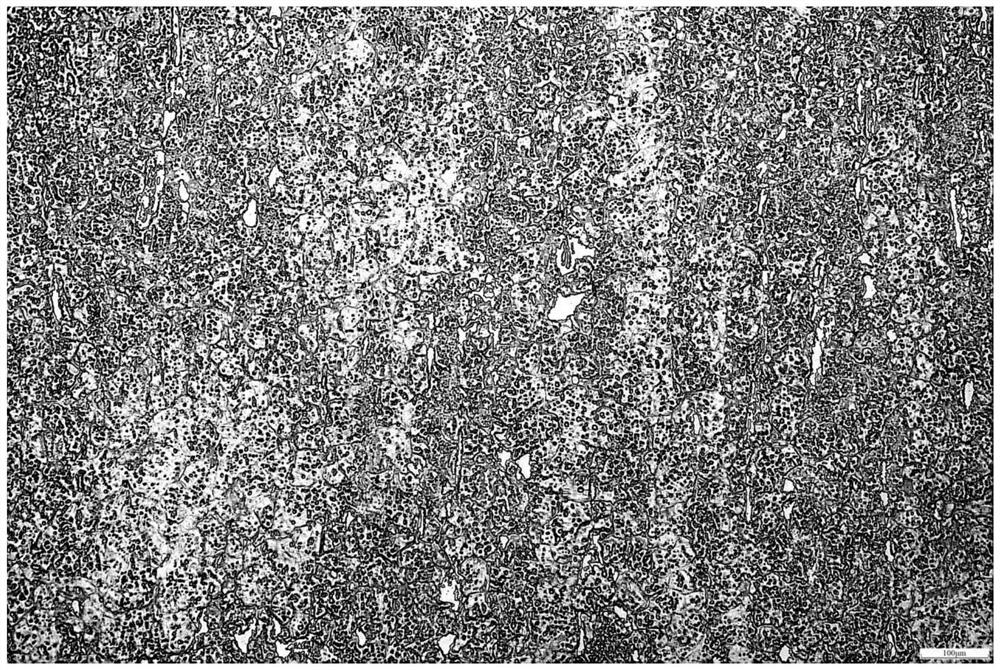

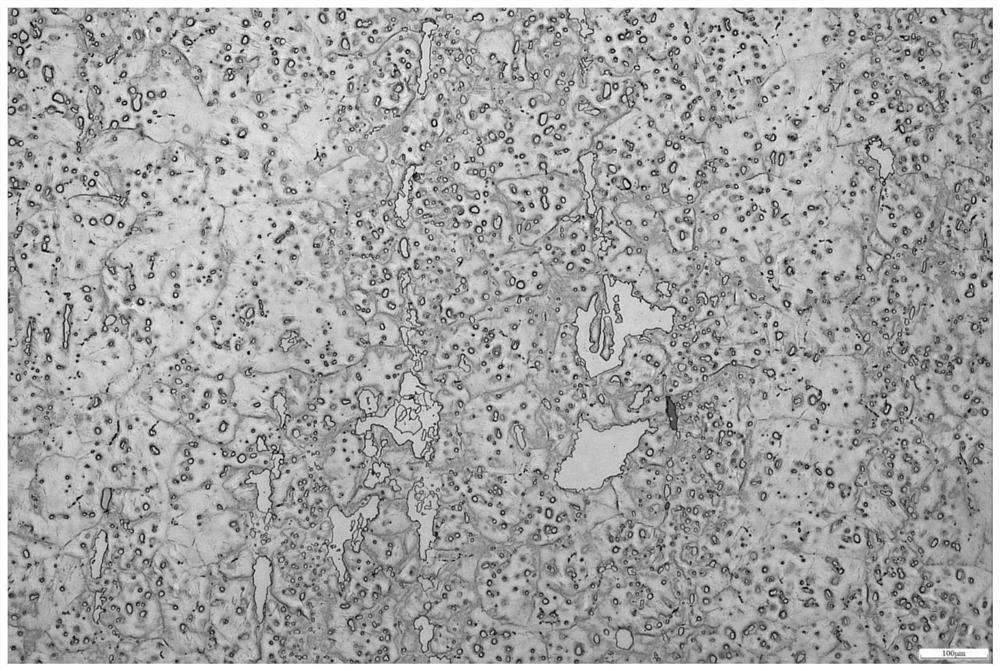

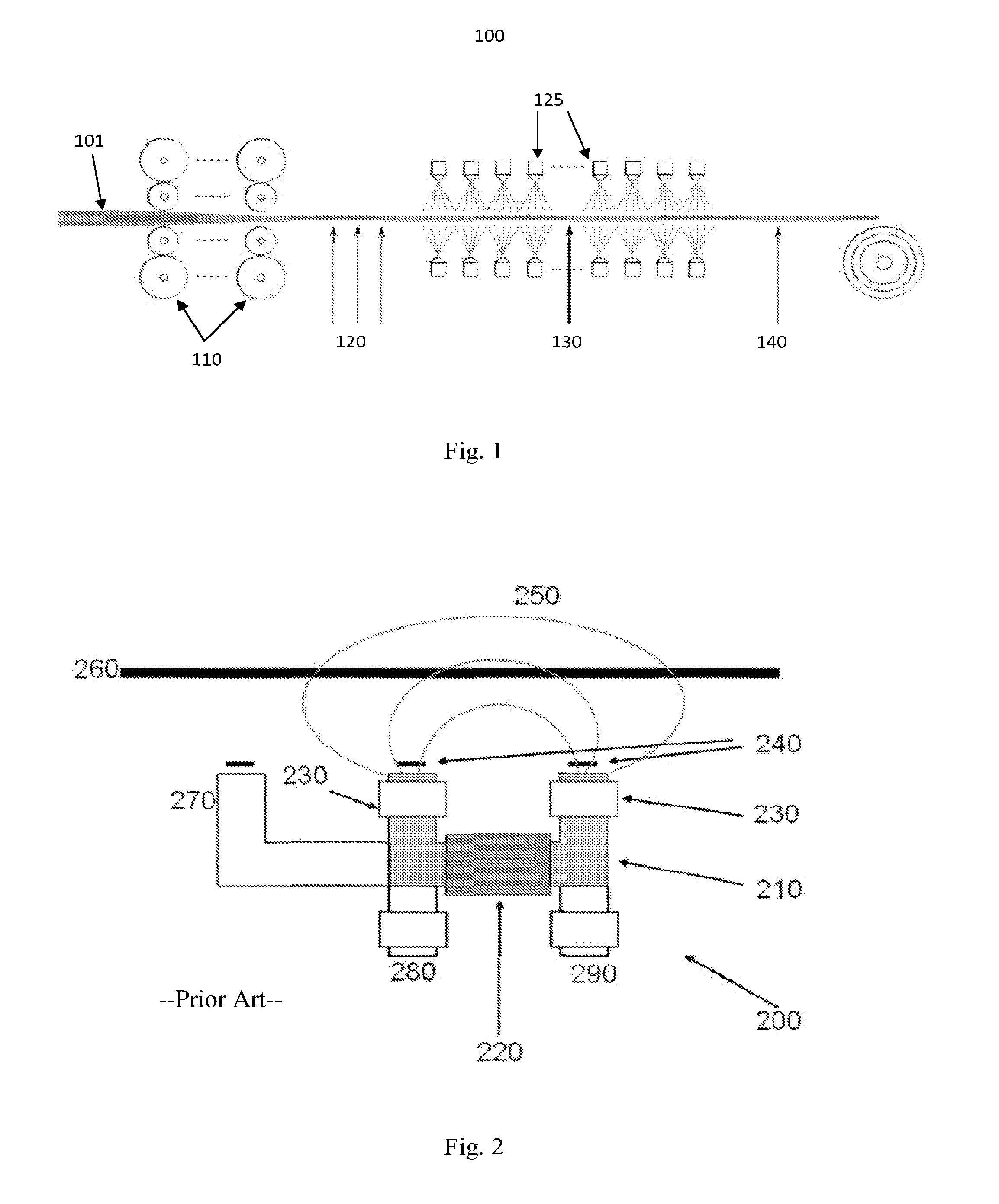

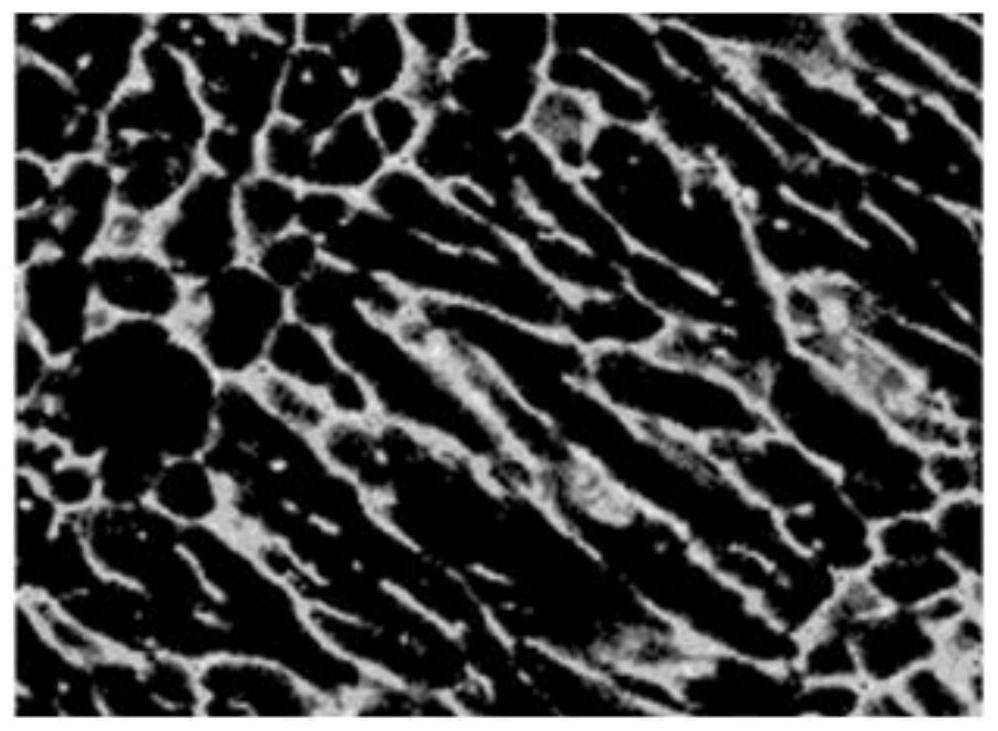

Method for automatic quantitative statistical distribution characterization of dendrite structures in a full view field of metal materials

ActiveUS20210063376A1Improve detection efficiencyHeavy workloadImage enhancementImage analysisFeature DimensionImaging processing

The invention belongs to the technical field of quantitative statistical distribution analysis for micro-structures of metal materials, and relates to a method for automatic quantitative statistical distribution characterization of dendrite structures in a full view field of metal materials. According to the method based on deep learning in the present invention, dendrite structure feature maps are marked and trained to obtain a corresponding object detection model, so as to carry out automatic identification and marking of dendrite structure centers in a full view field; and in combination with an image processing method, feature parameters in the full view field such as morphology, position, number and spacing of all dendrite structures within a large range are obtained quickly, thereby achieving quantitative statistical distribution characterization of dendrite structures in the metal material. The method is accurate, automatic and efficient, involves a large amount of quantitative statistical distribution information, and is statistically more representative as compared with the traditional measurement of feature sizes of dendrite structures in a single view field.

Owner:THE NCS TESTING TECH CO LTD

Etchant for displaying 690 nickel-base alloy deposited metal grain boundary and etching method thereof

ActiveCN110389129ALow costComposition is stableInvestigating crystalsPreparing sample for investigationLiquid wasteProcess quality

The invention discloses an etchant for displaying a 690 nickel-base alloy deposited metal grain boundary and an etching method thereof. The etchant comprises ferric chloride, EDTA, deionized water andconcentrated hydrochloric acid. The surface of the 690 nickel-based alloy deposited metal surface is successively wiped with the etchant and a nitric acid ethanol solution. Thus, it is possible to intuitively observe that the surface of a sample changes from bright to frosty during an etching process, and the weld bead can be clearly observed by naked eyes in order to better control the degree ofcorrosion, completely and clearly show the grain boundaries of the deposited metal sample grains, and avoid the covering by corrosion products. The etched different grains have different shades due to different orientations. The columnar crystal structure can be clearly observed and the grain boundaries are clear and complete. The etchant is made of simple raw materials, nontoxic, environmentallyfriendly, convenient in liquid waste disposal, low in cost, and stable and easy to control in a reaction process. The etching method is simple and easy to use, and provides detection basis for the process quality control, the process plan and the quality analysis of nuclear welding deposited layer, and has very important practical significance.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

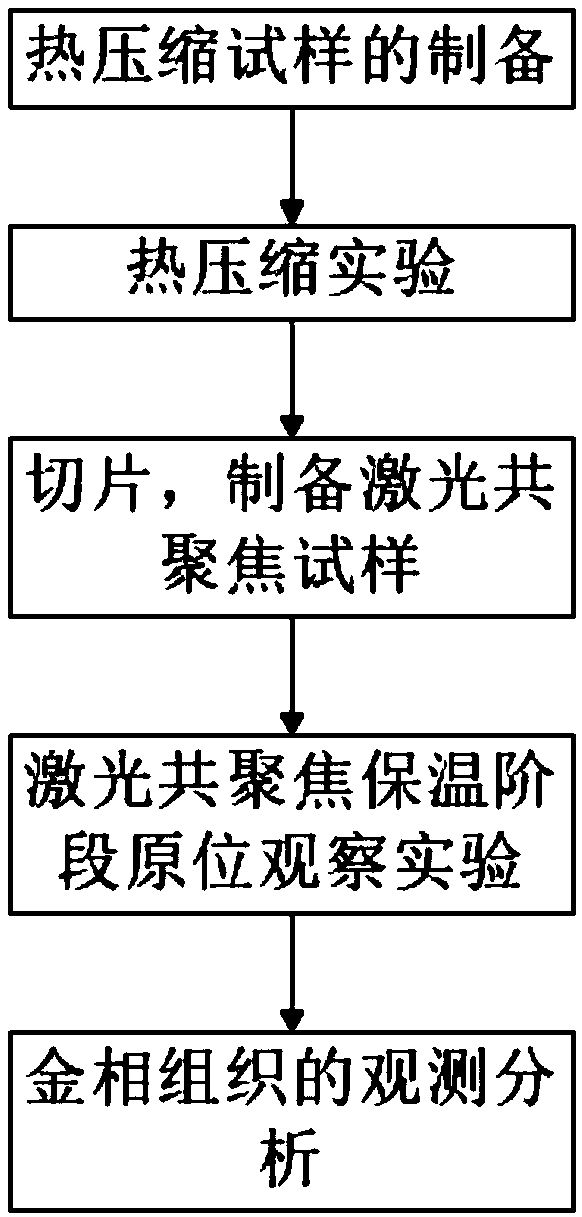

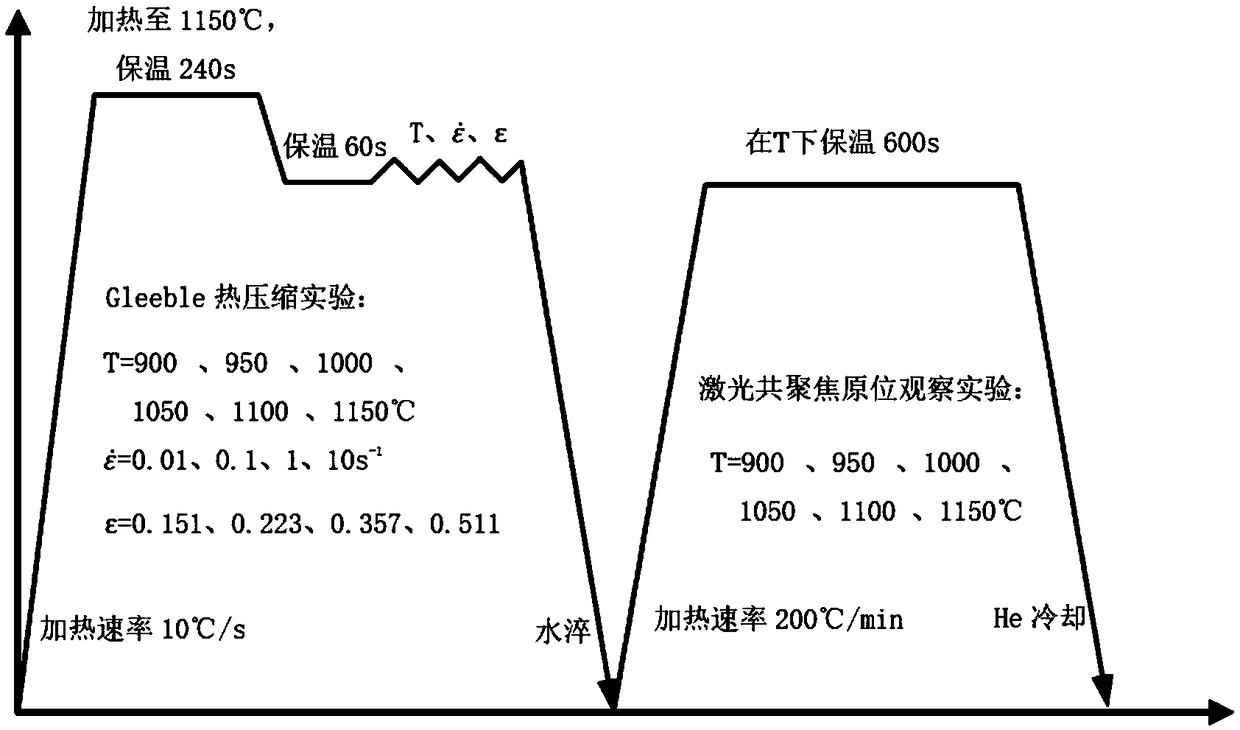

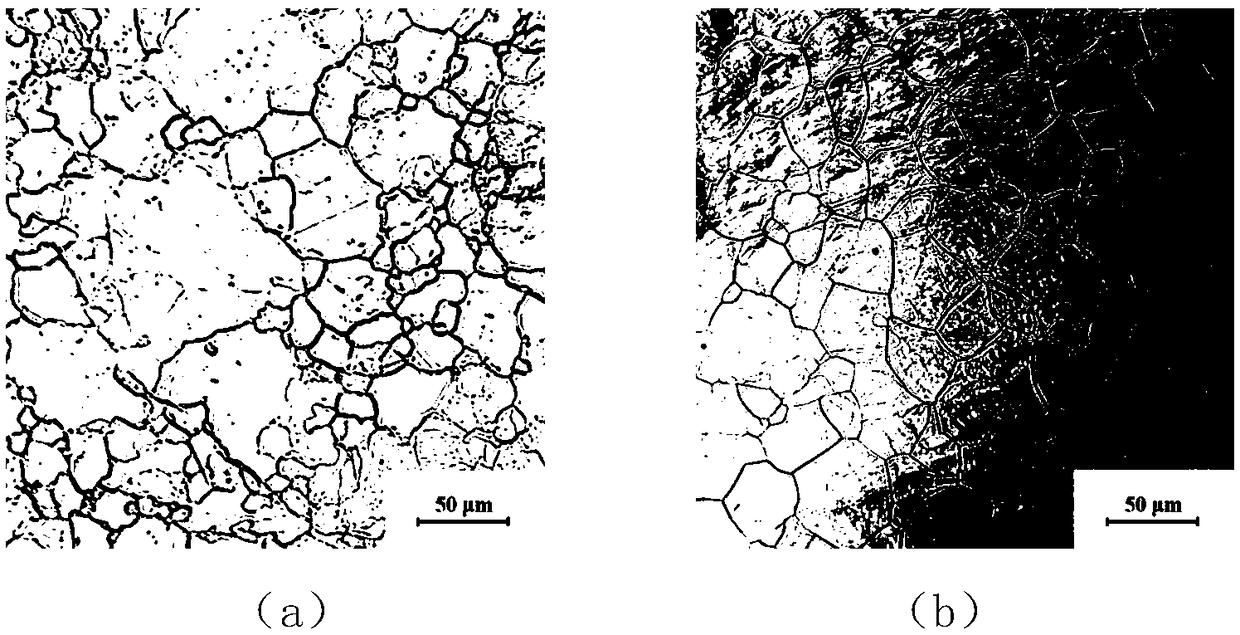

Method for analyzing post-dynamic recrystallization process of high-strength steel

ActiveCN109406747ASave time and costSave materialTesting metal structuresAnalysis methodTime dynamics

The invention discloses a method for analyzing the post-dynamic recrystallization process of high-strength steel and belongs to the field of plastic forming. The method comprises the following steps that 1, a cylindrical sample is prepared; 2, a single-pass compression experiment is conducted at different deformation temperatures, strain states and deformation, and after the deformation of the sample reaches a preset value, the sample is quenched immediately; 3, the quenched sample is sliced in the axis direction of the sample; 4, slices are subjected to infrared heating to the target temperature in a high-temperature laser confocal in-situ observation experiment and then subjected to heat preservation, real-time in-situ observation is conducted, and metallograph in the metallographic structure changing process is shot; and 5, the grain sizes and dynamic recrystallization volume fractions at different time are obtained through the metallograph, and then the influence of different parameters on the post-dynamic recrystallization process is analyzed. According to the method for analyzing the post-dynamic recrystallization process of the high-strength steel, a thermocompression experiment method and an in-situ observation experiment method are combined, real-time dynamic observation can be achieved, experiment precision is improved, materials are saved, the period is shortened, and the cost is lowered.

Owner:HUAZHONG UNIV OF SCI & TECH

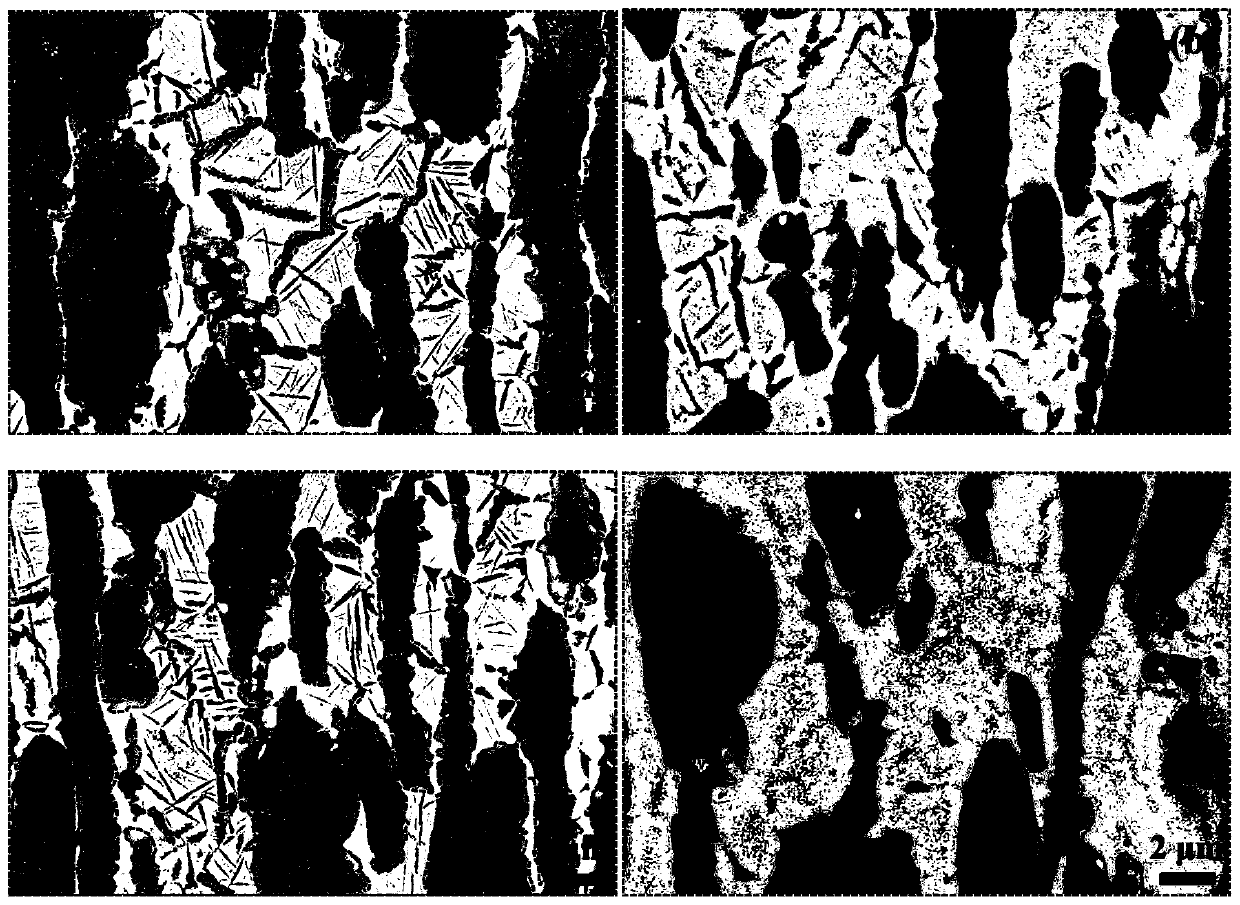

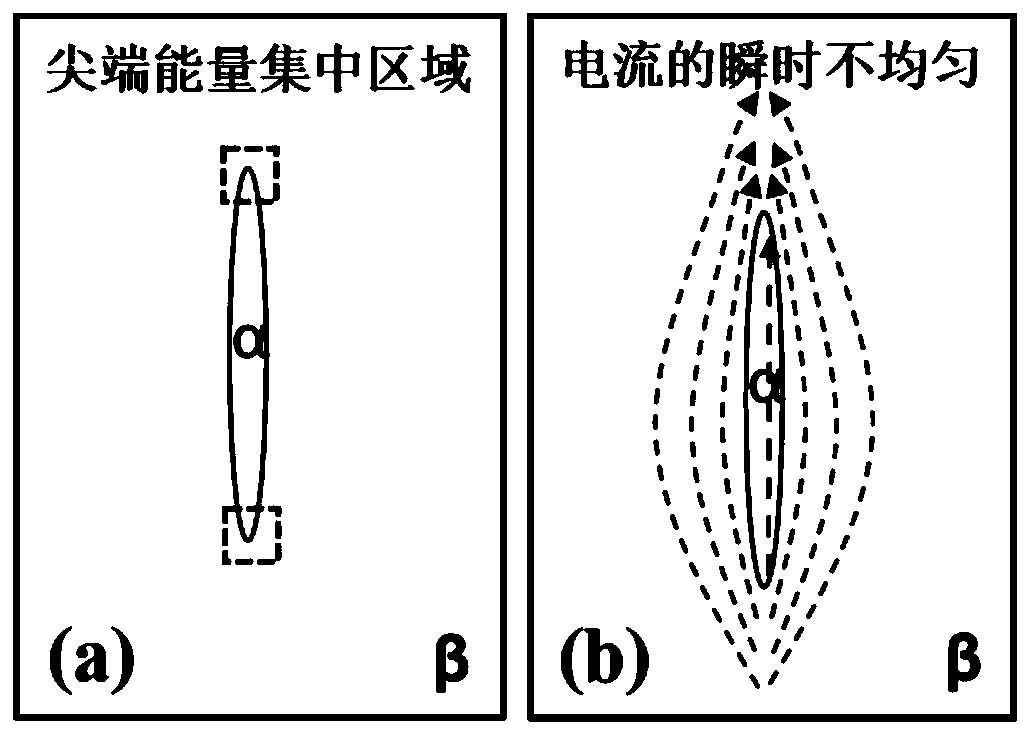

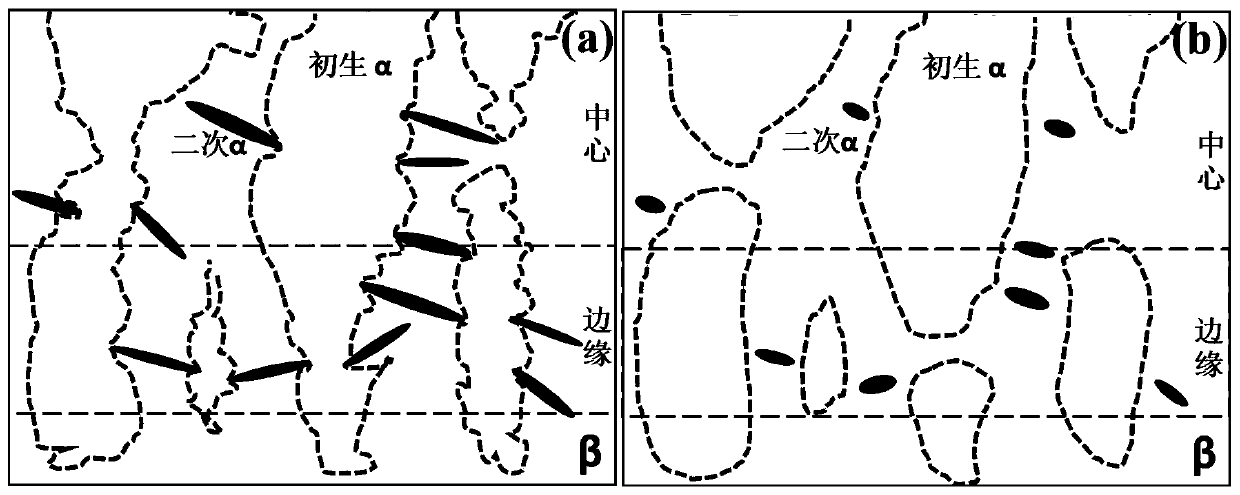

Experiment method for adjusting local sate of titanium alloy Alpha/Beta phase interface

InactiveCN110426410AShort timeImprove efficiencyMaterial analysis using wave/particle radiationTesting metal structuresBeta phaseScanning electron microscope

The invention discloses an experiment method for adjusting a local sate of a titanium alloy Alpha / Beta phase interface. The experiment method comprises the steps of processing a titanium alloy experiment sample to form a cylindrical shape, additionally arranging electrodes at two ends of a part of sample, and performing pulse current impact processing, wherein no pulse current impact processing isperformed on the other part of sample; cutting the sample along a middle line, and processing a cutting surface to obtain a sample which can be observing a gold phase; observing morphology of a Alphaphase and a Beta phase and change of the Alpha / Beta phase interface of the titanium alloy which is subjected to pulse current impact processing or is not subjected to pulse current impact processingby a scanning electron microscope under high power, and performing contrast to obtain an evolution rule of the titanium alloy Alpha / Beta phase after pulse current impact processing; and analyzing thestate change of the titanium alloy Alpha / Beta phase after the pulse current impact processing by a pulse current impact thermal effect and non-thermal effect action mechanism so as to obtain experiment conclusion. According to the method, the local state of the titanium alloy Alpha / Beta phase interface is adjusted by pulse current impact, the experiment method is low in time consumption and high in efficiency, and the change effect can be observed and verified.

Owner:WUHAN UNIV OF TECH

Metallographic corrosion method for high-carbon martensitic stainless steel grain boundary

PendingCN111811912ADoes not affect grain size evaluationShort corrosion timePreparing sample for investigationTesting metal structuresAlcoholPolishing

The invention belongs to the field of metallographic analysis and detection of stainless steel, and particularly relates to a metallographic corrosion method for high-carbon martensitic stainless steel grain boundary. The problem that a metallographic corrosion method which aims at high-carbon martensitic stainless steel, is easy and convenient to operate and low in cost is lacked is solved. The invention provides the metallographic corrosion method of a high-carbon martensitic stainless steel grain boundary, wherein the method comprises the following steps: carrying out coarse grinding, finegrinding, polishing, cleaning and drying on a high-carbon martensitic stainless steel metallographic sample to obtain a bright scratch-free polished surface; and corroding the polished surface for 5-30 s at room temperature by adopting a metallographic corrosive agent, cleaning and drying. The metallographic corrosive agent is composed of 1 g to 4 g of picric acid, 5 ml of concentrated hydrochloric acid, 100 ml of ethyl alcohol and 2 ml to 5 ml of dishwashing liquid. The method aims at the high-carbon martensitic stainless steel, the grain boundary display effect is good, normal-temperature corrosion is adopted without pre-heating the sample, the corrosion time is short, operation is easy, and application and popularization are easy.

Owner:什邡新工金属材料有限公司

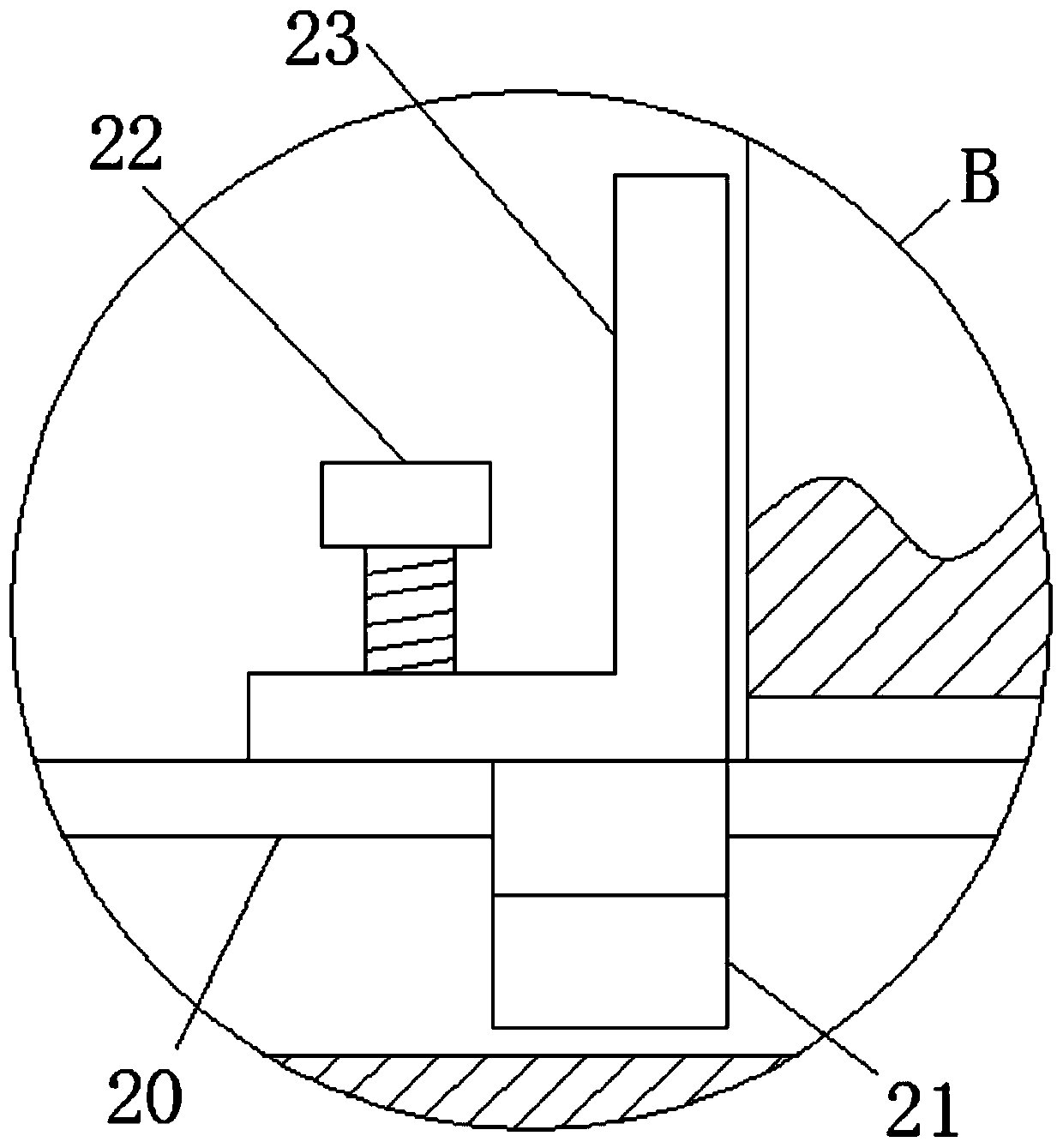

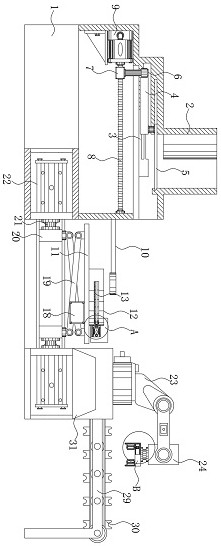

Hardware crimping quality probing device capable of carrying out nondestructive testing

InactiveCN111272967AQuick fixFast and uniform detectionTesting metal structuresElectric machineryEngineering

The invention discloses a hardware fitting crimping quality probing device capable of carrying out nondestructive testing. The device comprises a mounting plate and a detector, the upper end of the mounting plate is fixedly connected with a portal frame; the opposite sides of the two vertical parts of the portal frame are connected with the detector through a moving mechanism. The side wall of onevertical part of the portal frame is slidably sleeved with a rectangular rod through a rectangular through hole; one end of the rectangular rod penetrates through the rectangular through hole and isrotationally connected with a fixed plate through a first rolling bearing; a T-shaped sliding groove is formed in the rod wall of the rectangular rod, a limiting mechanism is arranged in the T-shapedsliding groove, a motor is fixedly connected to the side wall of the other vertical part of the portal frame, a rotating shaft is fixedly connected to the output end of the motor, and one end of the rotating shaft penetrates through the side wall of the vertical part of the portal frame and is fixedly connected with a rectangular block. According to the invention, workers can conveniently and rapidly fix hardware fittings, the surfaces of the hardware fittings can be rapidly and uniformly detected, and meanwhile, the hardware fittings with different lengths can be detected.

Owner:马鞍山市华能电力线路器材有限责任公司

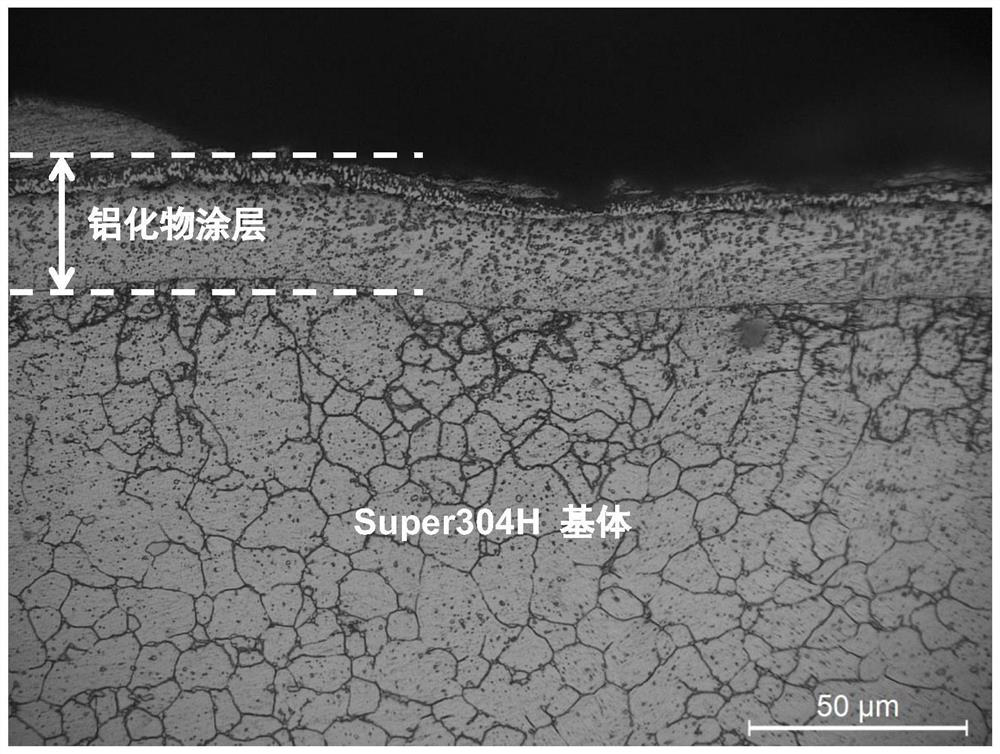

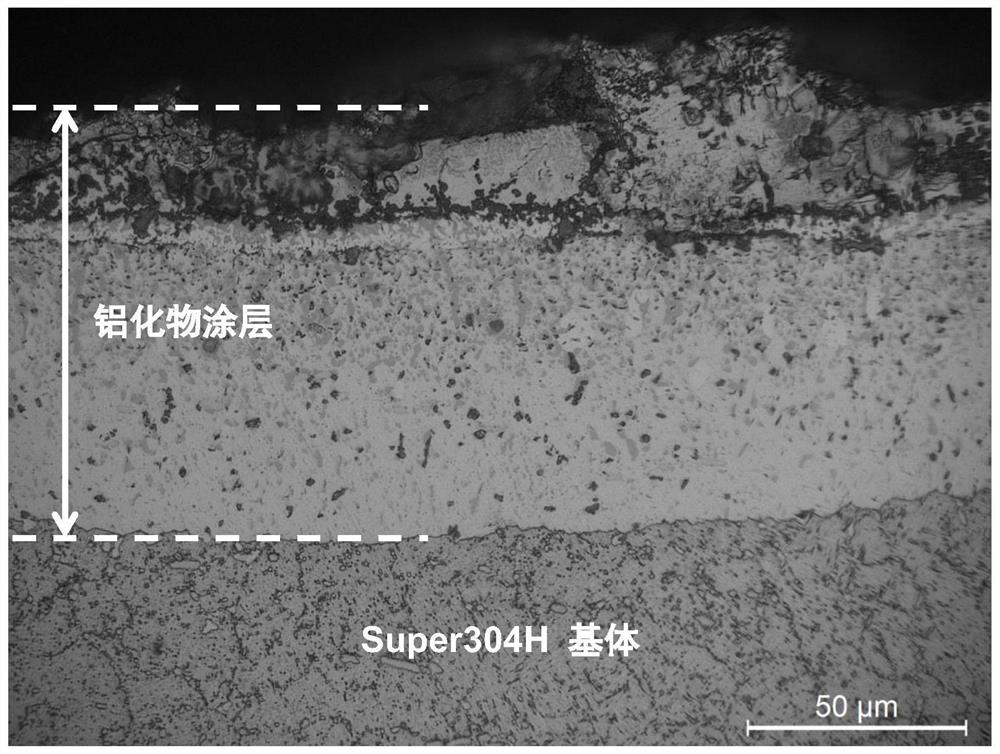

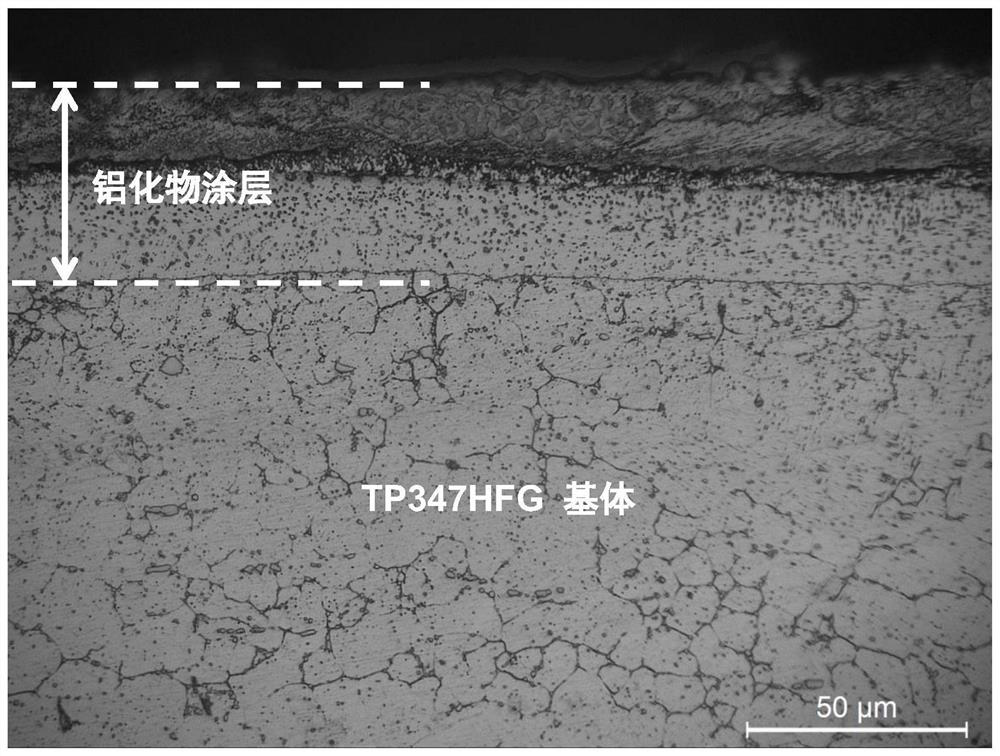

Metallographic corrosion method for simultaneously displaying austenitic stainless steel and aluminide coating organization structure on surface of austenitic stainless steel

ActiveCN111982645ASimultaneous imaging effect is remarkableCorrosion method is simple and effectiveMaterial analysis using wave/particle radiationNuclear energy generationSS - Stainless steelCopper sulfate

The invention provides a metallographic corrosion method for simultaneously displaying austenitic stainless steel and an aluminide coating tissue structure on the surface of the austenitic stainless steel. The method comprises the following steps: mixing 40-55% of hydrochloric acid, 37-48% of ultrapure water and 8-12% of glycerol in percentage by volume to obtain a liquid phase, and then adding copper sulfate and ferric trichloride to obtain a metallographic corrosive agent; uniformly dripping the prepared metallographic corrosive agent on the surface of the coating sample to corrode for 15-25seconds; after the surface gradually loses the finish degree, immediately using a large amount of ultrapure water for washing, finally, sucking absolute ethyl alcohol or acetone to clean residual water spots and impurities on the surface of the sample, using a blower used for blow-drying so that the austenite steel and the organization structure of the aluminide coating on the surface of the austenite steel can be developed at the same time. The corrosion method is mainly used for simultaneously developing organizational structures of the austenitic stainless steel and the aluminide coating on the surface of the austenitic stainless steel, and has a remarkable effect of simultaneously developing a matrix and a coating structure in an original state and a service state.

Owner:XIAN THERMAL POWER RES INST CO LTD

Corrosive agent and corrosion method for dendritic tissue of CoCrMo alloy used in artificial joint

InactiveCN109342688ASimple compositionEasy to prepareWeather/light/corrosion resistanceTesting metal structuresArtificial jointsMetallic materials

The invention belongs to the field of metallographic tissue characterization of metallic materials, and relates to a corrosive agent and a corrosion method for dendritic tissue of CoCrMo alloy used inartificial joint. The corrosion solution used in the invention is an evenly mixture of equivalent potassium permanganate and sodium hydroxide solution. When the corrosive agent is heated to boiling,the specimen after mechanically polishing is immersed in the corrosion solution in boiling state to corrode the dendrite tissue. Because of the different corrosion resistance of cast specimen and heat-treated specimen, the corrosion time of the specimen in different states is stipulated in the present invention. The corrosive agent of the invention has simple composition, only consisting of potassium permanganate and sodium hydroxide. The preparation ratio is 1:1, and the preparation process is simple. The CoCrMo alloy dendritic tissue corroded by this method is clear and accurate, and the dendrite area of the solid-soluble reinforcing element is corroded.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Square billet center macrosegregation analysis method

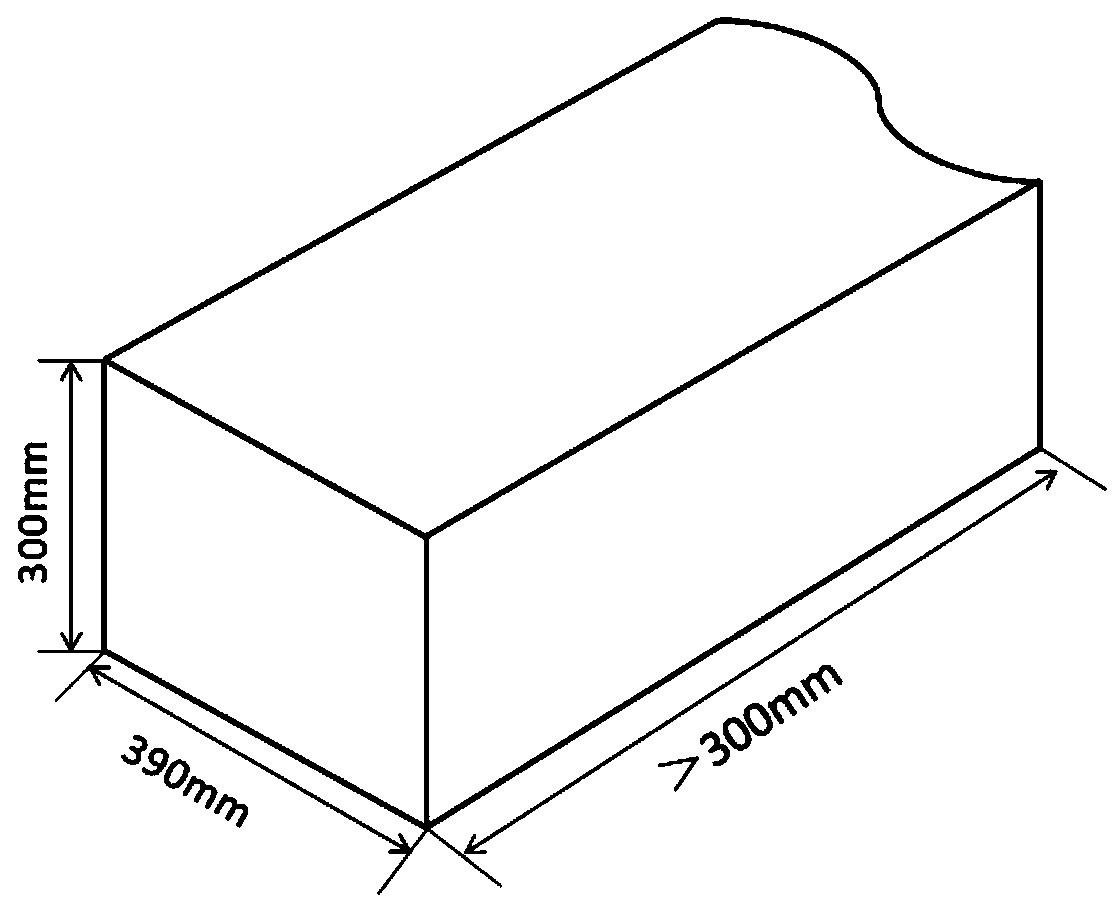

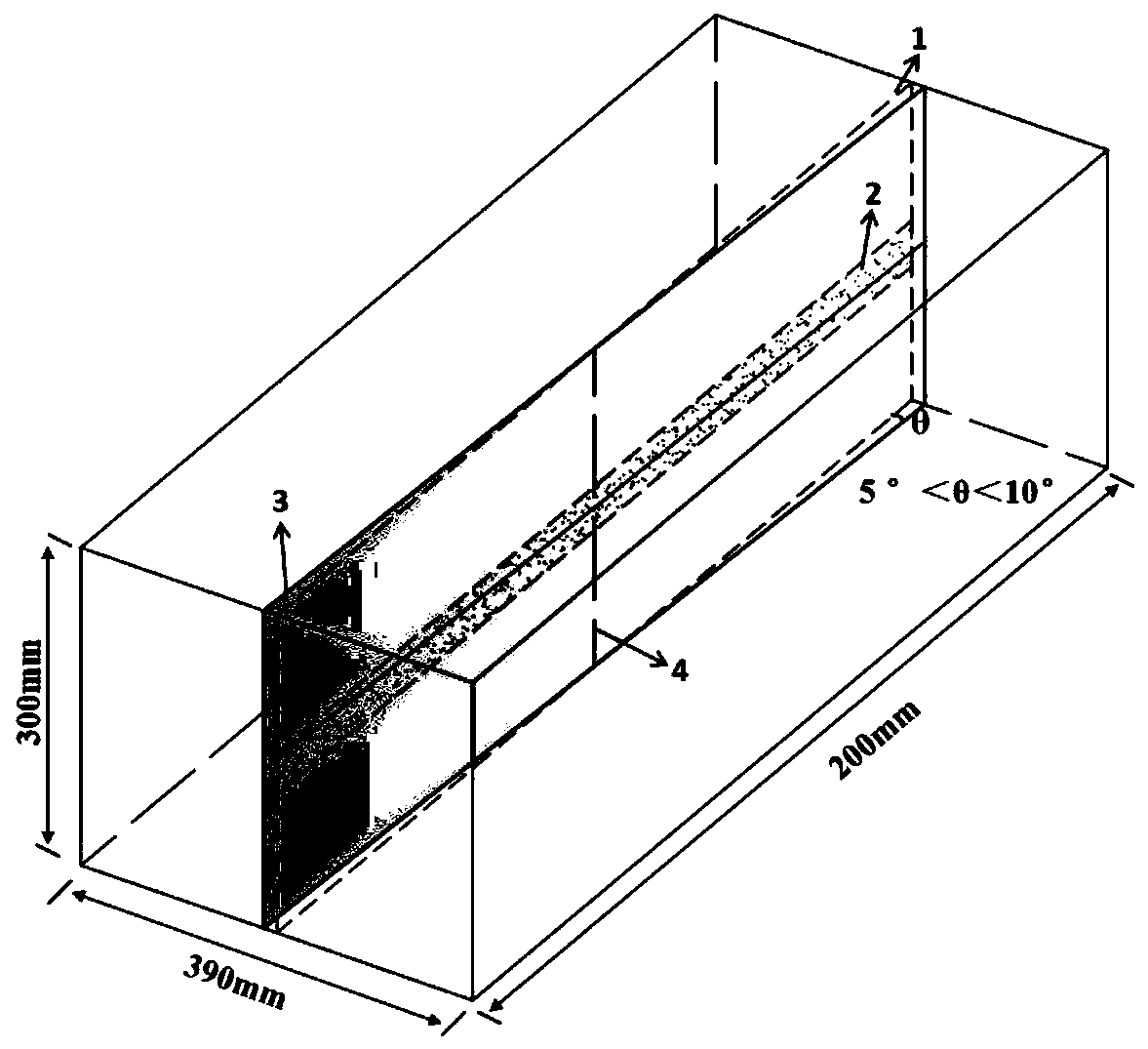

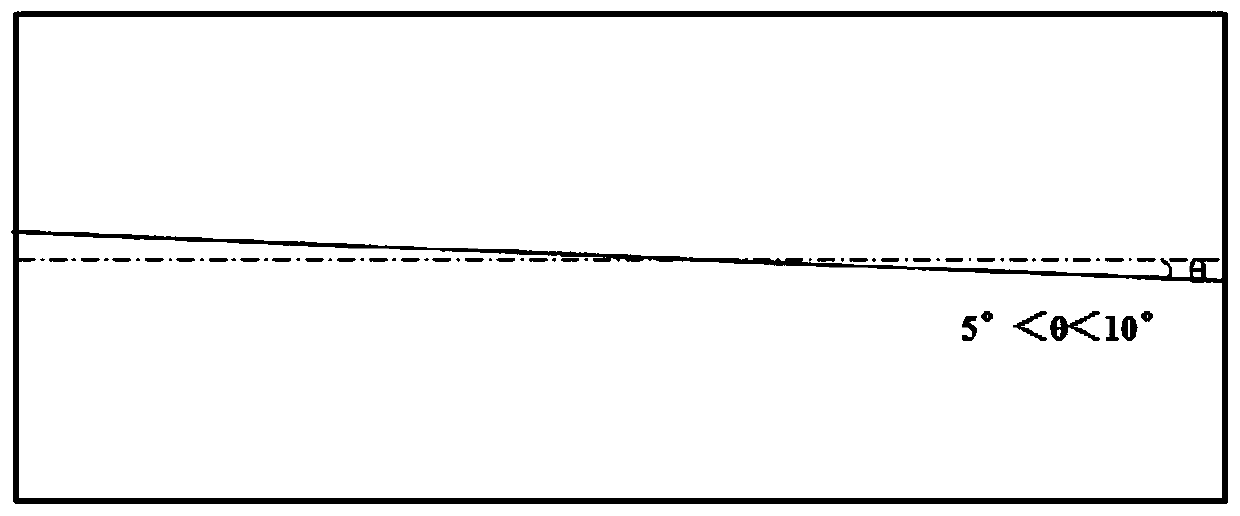

ActiveCN111537691AImprove representationReduce biasWithdrawing sample devicesPreparing sample for investigationMetallurgical assayVertical plane

The invention discloses a square billet center macrosegregation analysis method, and belongs to the technical field of metallurgical analysis. The method comprises the following steps: carrying out sampling, sample processing, macroscopic examination and drilling chemical analysis on a square billet continuous casting billet by using a vertical plane forming an included angle with the central longitudinal section. According to the invention, the vertical sample cutting method forming a certain included angle with the central longitudinal section is creatively applied to the sample preparationmethod in the center macrosegregation analysis process of the square billet continuous casting billet; the deviation of a casting blank center segregation analysis result caused by a sample cutting position factor can be reduced, the accuracy of casting blank center segregation condition analysis is improved, and accurate reference information is provided for casting blank quality monitoring or process improvement.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Martensite aging stainless steel dendritic crystal corrodent and corrosion method

InactiveCN110749718ASimple recipeEasy to operateMaterial analysis using wave/particle radiationPreparing sample for investigationEtchingElectrolysis

The invention relates to a martensite aging stainless steel dendritic crystal corrodent and corrosion method, and belongs to the technical field of metallographic analysis of iron and steel. The corrodent provided by the invention is an analytical pure nitric acid aqueous solution, which is prepared from an analytical pure nitric acid and water. The dendritic crystal corrosion method comprises thesteps of: a. cutting an as-cast sample for grinding and polishing; b. preparing the dendritic crystal corrodent; and c. using a stainless steel sheet as a cathode, using the sample as an anode, and placing the as-cast sample in the corrodent to perform electrolytic etching at room temperature. The corrodent provided by the invention has a simple formula, simple operation steps, and clear and accurate detection results of dendritic crystal corrosion, data such as interdendritic spacing can be accurately calculated through clear morphology of the dendritic crystal, and segregation degrees between dendritic crystals and dendritic crystal stems can be measured by using an energy spectrum for evaluating quality of the as-cast structures and assisting in evaluating the elimination of dendriticsegregation by the homogenization heat treatment.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

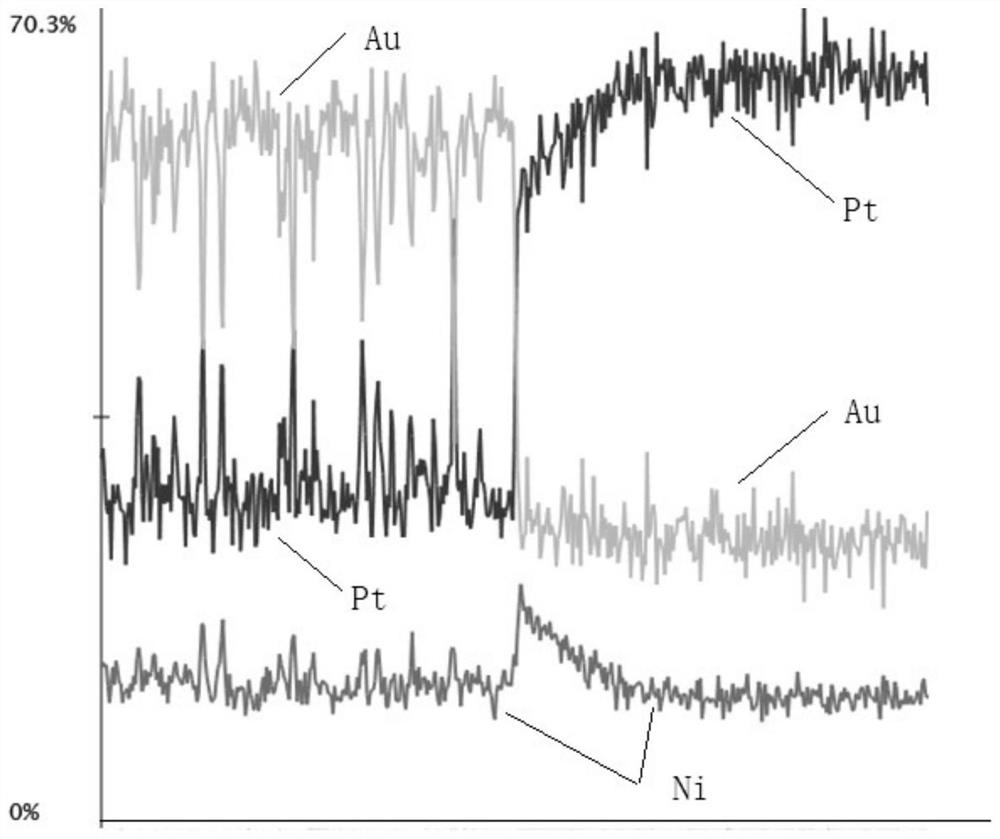

Method for preparing high-melting-point metal ternary diffusion couple

ActiveCN113189127AEasy to prepareReduce the amount of metalMaterial analysis using wave/particle radiationSolid state diffusion coatingTube furnaceMetallic materials

The invention discloses a method for preparing a high-melting-point metal ternary diffusion couple. The method is mainly used for preparing the diffusion couple composed of three kinds of high-melting-point metal. The method comprises the following steps: paving a B metal block or sheet with the lowest melting point in three kinds of high-melting-point metal above an A metal block, then putting A-B metal into a tubular furnace protected by argon, heating to be above the melting point of the B metal, melting the B metal to form metallurgical bonding with the A, and performing diffusion annealing to form an A-B diffusion couple; and then coating the C metal sheet at the interface of the A-B diffusion couple, fixing the C metal sheet by using a clamp, and performing diffusion annealing to prepare the A-B / C ternary diffusion couple. The method is simple, the amount of needed metal is small, the preparation process is easy to control, diffusion couple combination is flexible and controllable, the effect is excellent, and the success rate is high. The method is suitable for preparation of metal material diffusion couples, especially for preparation of precious metal and high-temperature alloy material diffusion couples, and the prepared diffusion couples can be used for research of phase diagrams, diffusion kinetics and thermodynamics.

Owner:KUNMING INST OF PRECIOUS METALS

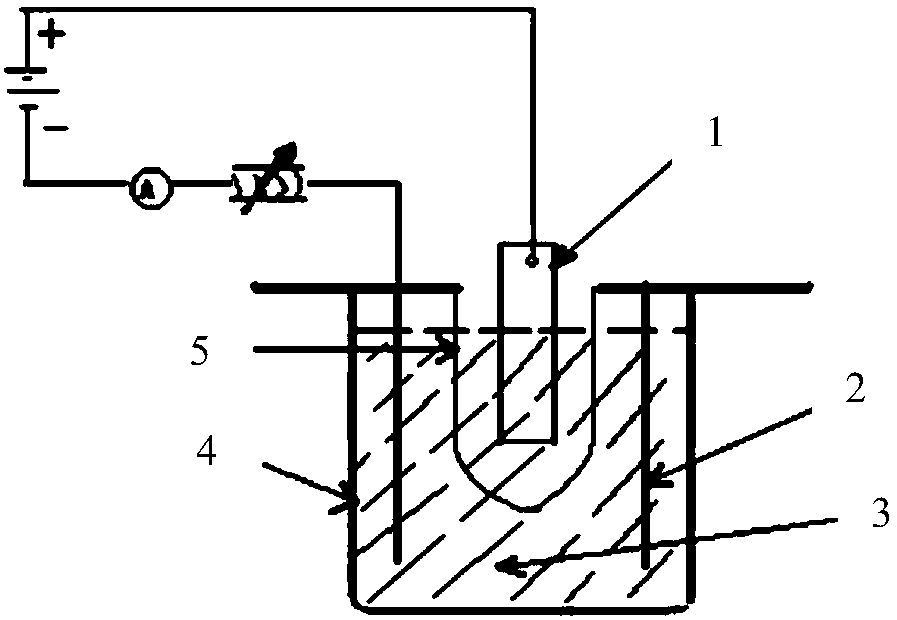

Apparatus and method for the non-destructive measurement of hydrogen diffusivity

ActiveUS20180313779A1Ensure concentricityPrevent leakageFluid pressure measurement using elastically-deformable gaugesMaterial analysis by electric/magnetic meansNon destructiveMetal

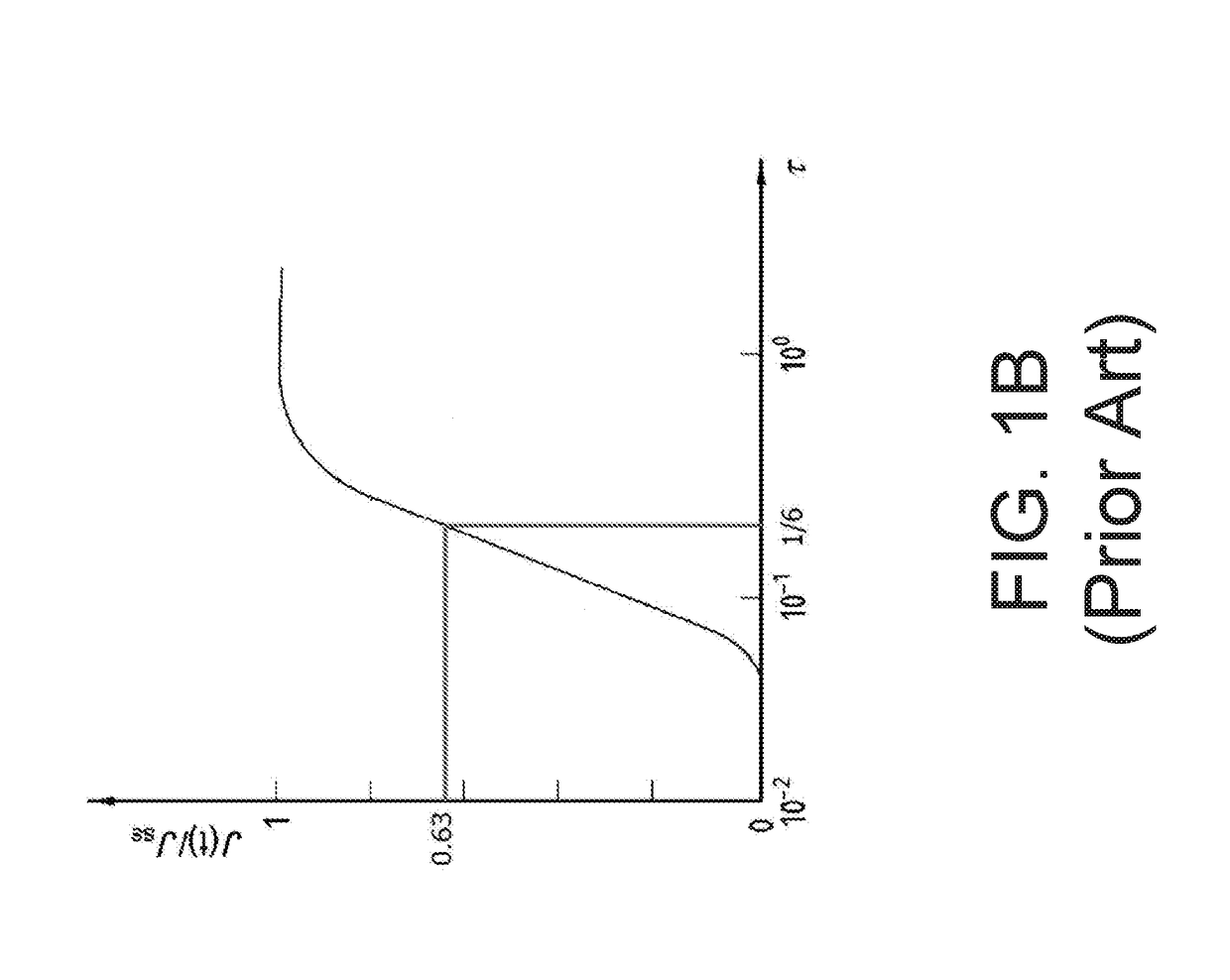

A method of measuring a hydrogen diffusivity of a metal structure is provided. The method includes providing a hydrogen charging surface at a first location on an external surface of the structure, and a hydrogen oxidation surface at a second location adjacent to the first location on the external surface of the structure. A hydrogen flux is generated and directed into the metal surface at the charging surface. At least a portion of the hydrogen flux generated by the charging surface and diverted back toward the surface is detected, and a transient of the diverted hydrogen flux is measured. The hydrogen diffusivity of the metal structure is then determined based on the measured transient.

Owner:SAUDI ARABIAN OIL CO

Method for detecting the contamination of two-phase titanium alloys with an alpha phase and a beta phase

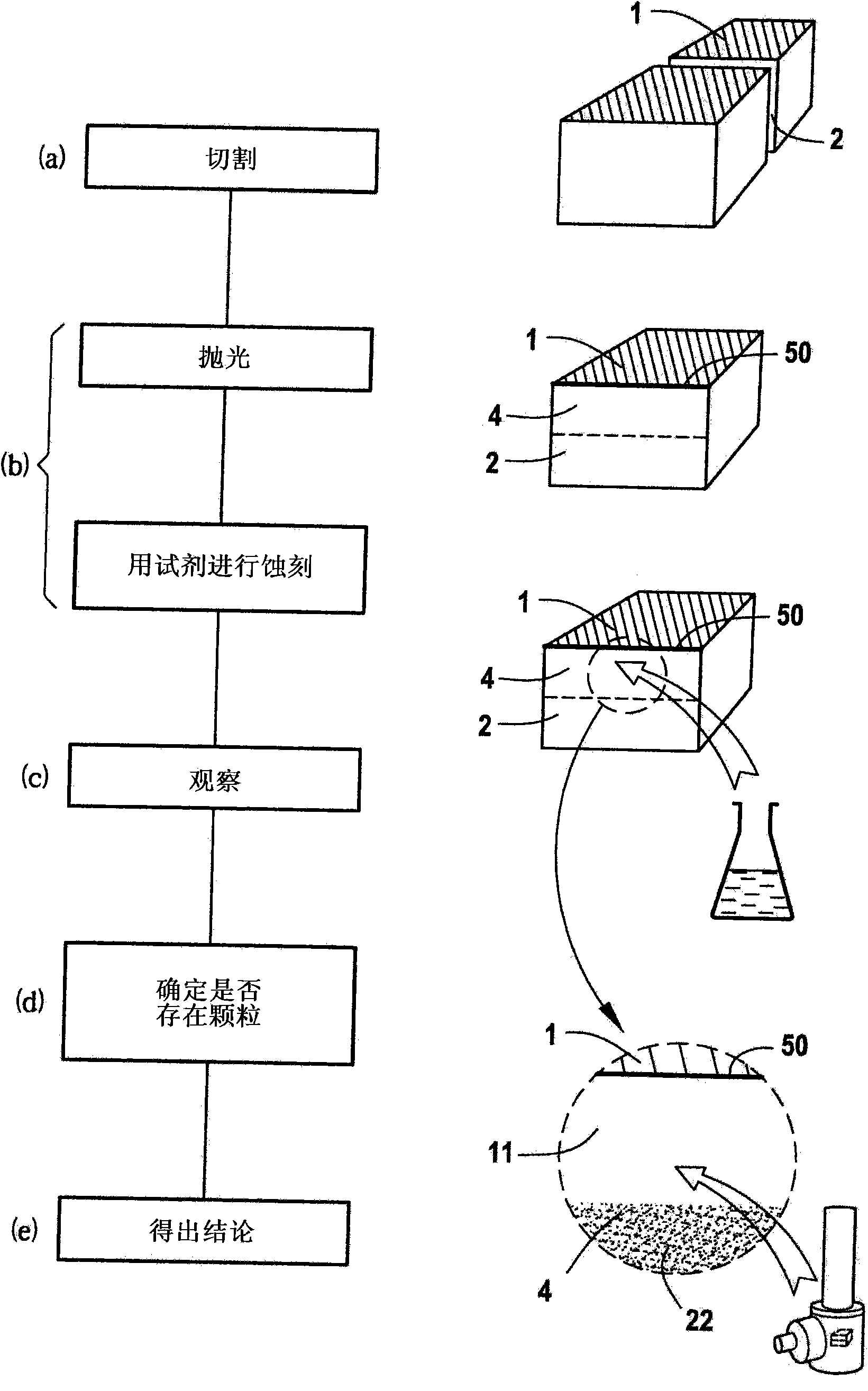

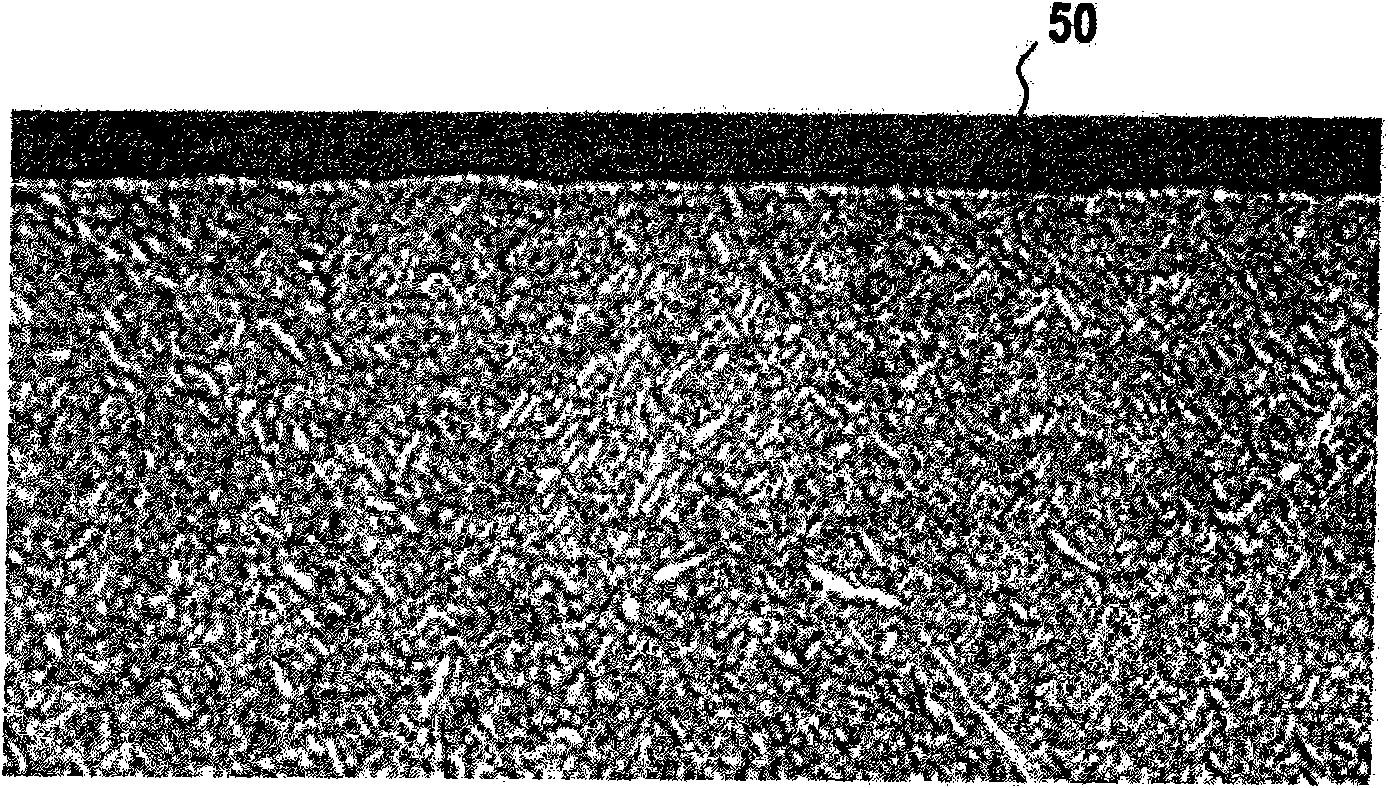

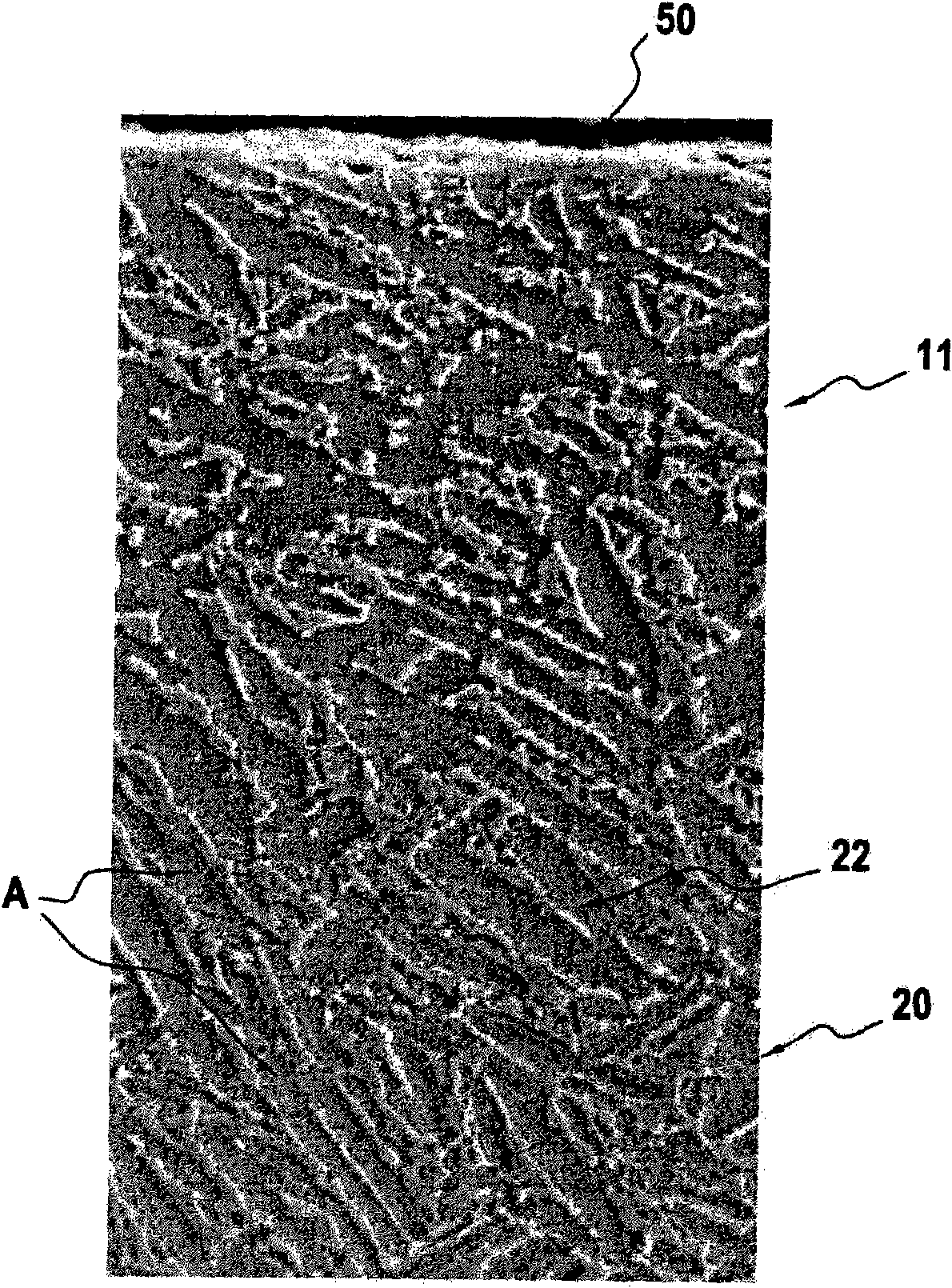

The invention relates to a method for examining a two-phase titanium alloy with an alpha phase and a beta phase. The method comprises the following steps consisting in: (a) cutting a sample from a part made from the alloy; (b) preparing a region (4) of the cut surface of the sample close to the edge (50) thereof, said edge (50) being shared with the outer surface (1) of the part so that the region (4) can be observed; (c) observing the alpha phase of the region (4) at a magnification of more than 5000x; (d) determining whether or not grains are present in the alpha phase of a first area (11) adjacent to the edge (50) of the sample; and (e) when grains are absent from the alpha phase of the adjacent area (11) but grains (22) are present in the alpha phase outside said adjacent area (11), concluding that the alloy is contaminated by a gas.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

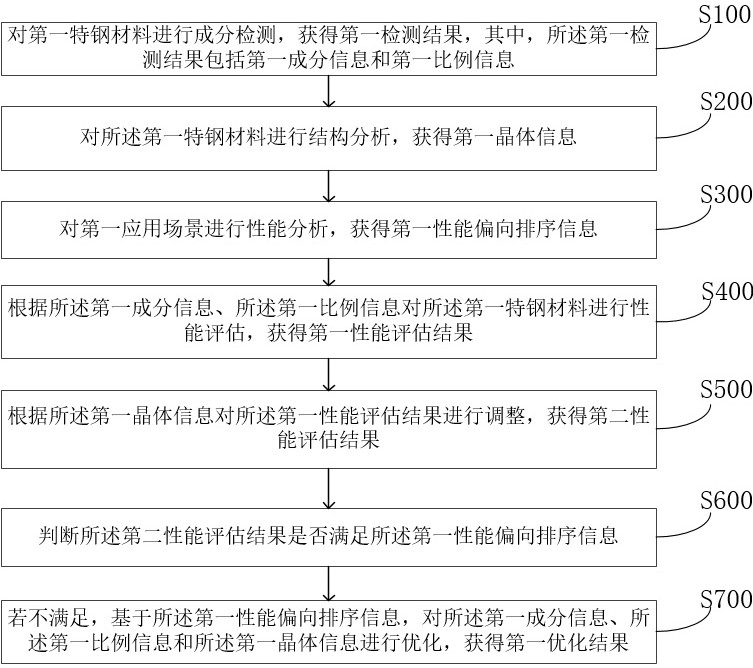

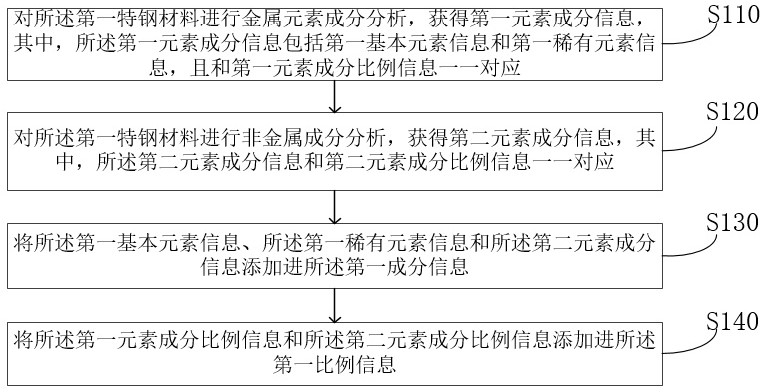

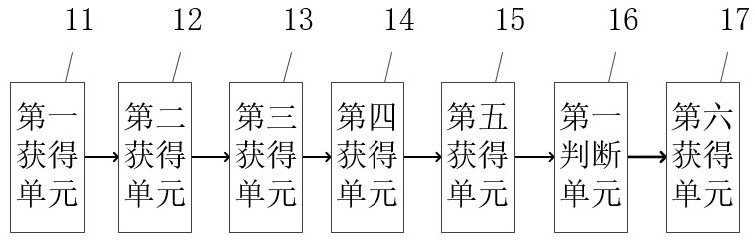

Component-based special steel performance evaluation method and system

ActiveCN114742481AImprove bindingResourcesManufacturing computing systemsEvaluation resultStructure analysis

The invention provides a component-based special steel performance evaluation method and system, and relates to the technical field of artificial intelligence, and the method comprises the steps: carrying out the component detection of a first special steel material, and obtaining first component information and first proportion information; performing structural analysis on the first special steel material to obtain first crystal information; performing performance analysis on the first application scene to obtain first performance deviation sorting information; performing performance evaluation on the first special steel material according to the first component information and the first proportion information to obtain a first performance evaluation result; adjusting the first performance evaluation result according to the first crystal information to obtain a second performance evaluation result; and when the first performance deviation sorting information is not met, the first component information, the first proportion information and the first crystal information are optimized, so that the technical problem that the combination degree of special steel preparation process parameters and application scenes is difficult to guarantee due to judgment depending on personnel experience is solved. And the technical effect of obtaining the special steel process parameters with high combination degree with the application scene is achieved.

Owner:SUZHOU XIANGLOU METAL PROD

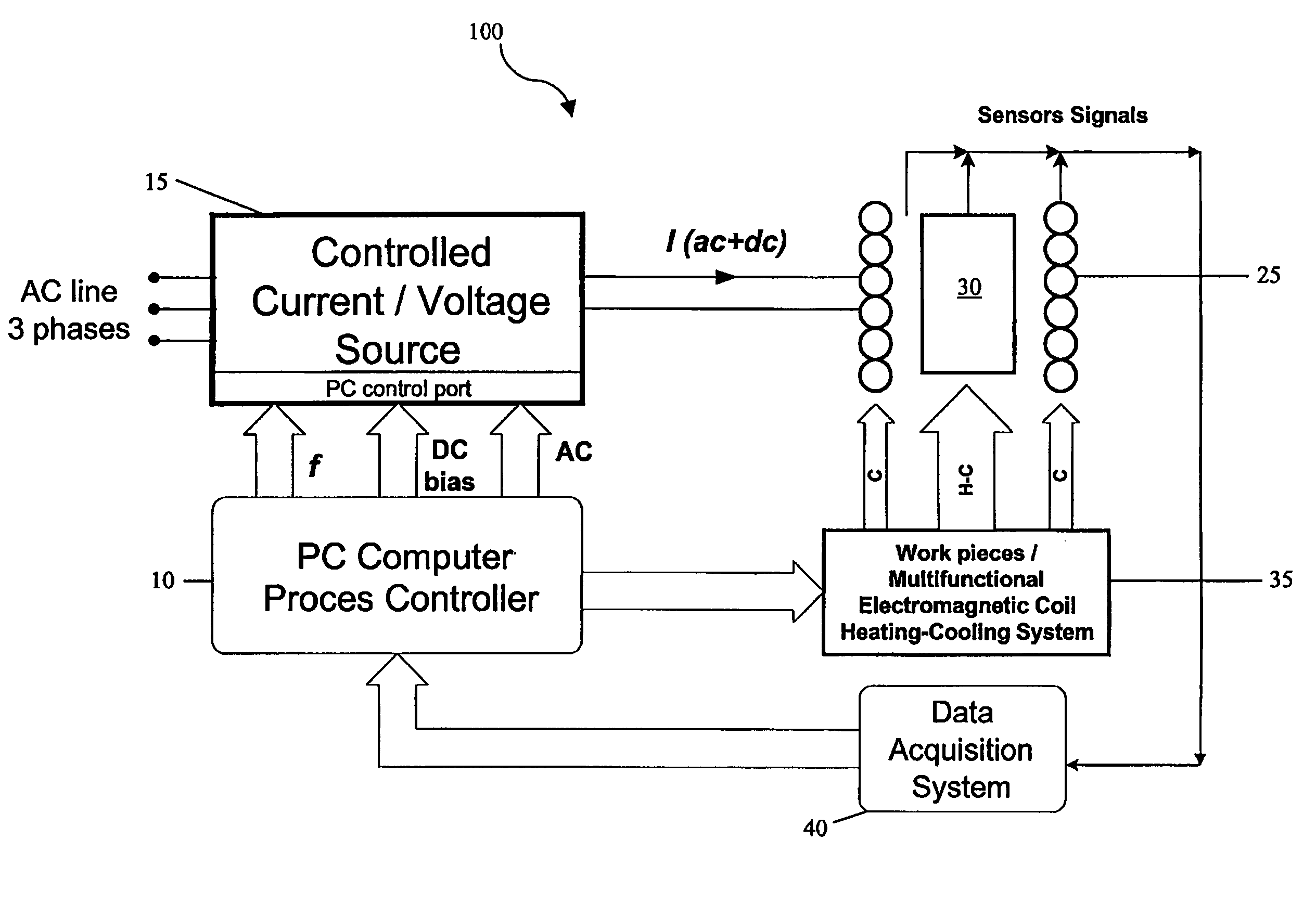

Electromagnetic method and apparatus for treatment of engineering materials, products, and related processes

InactiveUS7255828B2High degree of accuracyHigh precisionBlast furnace detailsHeat treatment process controlControl systemWaste management

A method and apparatus for performing electromagnetic treatment on engineering materials and products and for improving processing technologies and service characteristics of the materials. The apparatus integrates electromagnetic treatment with a thermal analyzer and a control system. The apparatus allows for precise control of the operating parameters of an electromagnetic treatment process in order to render significant improvement in the materials and products metallurgical characteristics.

Owner:KASPRZAK MARCIN STANISLAW +2

Material organization predict device, product fabrication method, and material organization predict method

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

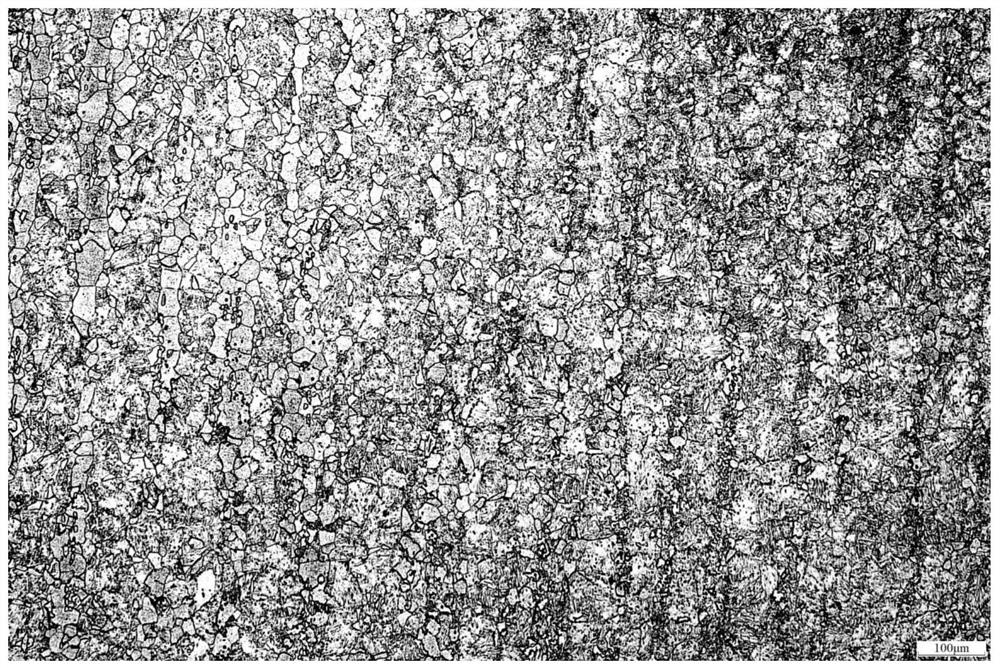

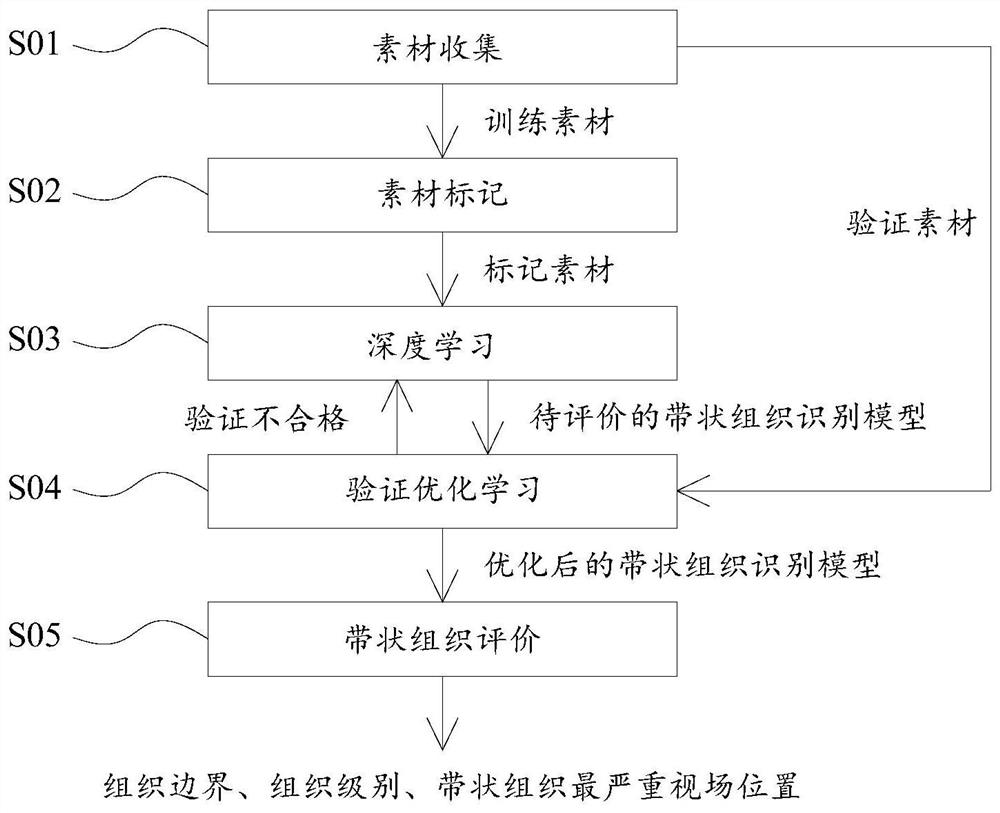

Method for evaluating banded structure in steel

PendingCN112634200AAvoid uncertaintyGood repeatabilityImage enhancementImage analysisMarking outEngineering

The invention provides a method for evaluating a banded structure in steel, and belongs to the technical field of steel structure detection. The method for evaluating the banded structure in the steel comprises the steps of material marking, deep learning and banded structure evaluation. Material marking: selecting a plurality of banded tissue pictures as training materials; and marking the ferrite banded structure in each training material, including marking the structure boundary and marking the structure level in combination with the size information. And deep learning: carrying out recognition learning on each marked training material in sequence by adopting a deep neural network model, including initializing by utilizing the size information, the organization boundary information and the organization level information of each training material to obtain a banded organization recognition model. And banded structure evaluation: taking the banded structure picture as a to-be-evaluated material, and analyzing the ferrite banded structure of the to-be-evaluated material by adopting the banded structure identification model. The evaluation method is high in repeatability and can effectively avoid uncertainty of subjective judgment.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

Sensors

ActiveUS9404992B2Permeability measurementsTemperature control deviceElectromagnetic shieldingElectrical current

Embodiments of the present invention provide an electromagnetic sensor (400) for detecting a microstructure of a metal target, comprising: a magnetic device (410, 420) for providing an excitation magnetic field; a magnetometer (430) for detecting a resultant magnetic field induced in a metal target; and a calibration circuit (450, 551, 552, 553, 554) for generating a calibration magnetic field for calibrating the electromagnetic sensor, wherein the calibration reference magnetic field is generated by an electrical current induced in the calibration circuit by the excitation magnetic field.

Owner:UNIV OF MANCHESTER

Metallographic corrosive agent and metallographic display method for primary banded structure of steel

ActiveCN111830229AEasy to prepareAccelerated corrosionMaterial analysis using wave/particle radiationInvestigating crystalsWater methanolCopper chloride

The invention belongs to the technical field of metallographic detection, and relates to a metallographic corrosive agent and metallographic display method for the primary banded structure of steel. The metallographic corrosive agent comprises water, methanol, copper chloride and hydrochloric acid; the ratio of the volume of the water to the volume of the methanol to the mass of the copper chloride to the volume of the hydrochloric acid is (25-35)ml to (25-35)ml to (20-30)g to (1-3)ml. The metallographic corrosive agent and the metallographic display method are mainly suitable for hot-rolled steel products subjected to rolling deformation, can also be used for steel products subjected to heat treatment after rolling, are convenient to operate and stable in corrosion effect, can clearly display a primary banded structure of a steel sample, and can be used for evaluating the quality and performance of the steel products.

Owner:SHOUGANG CORPORATION

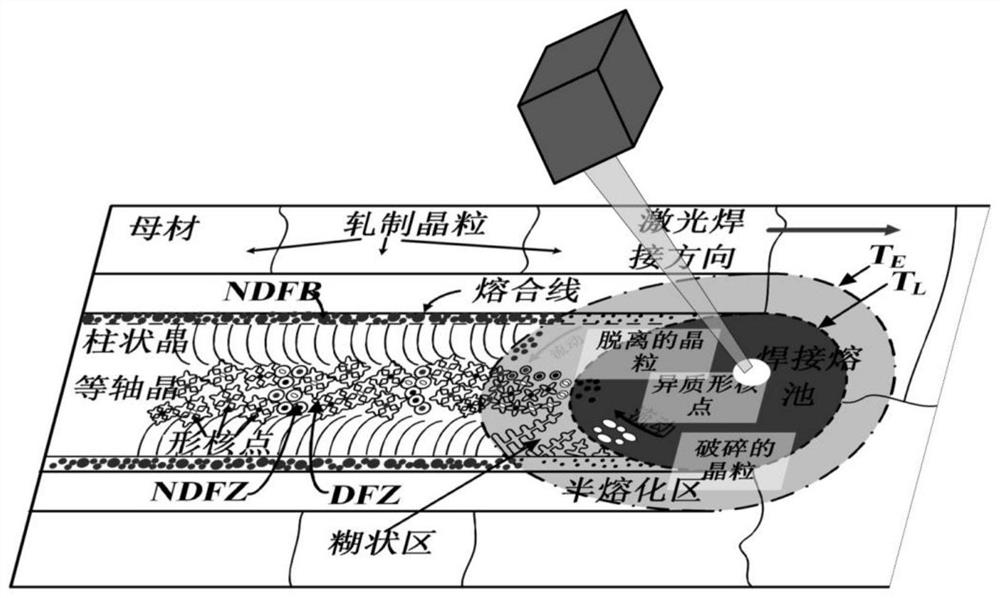

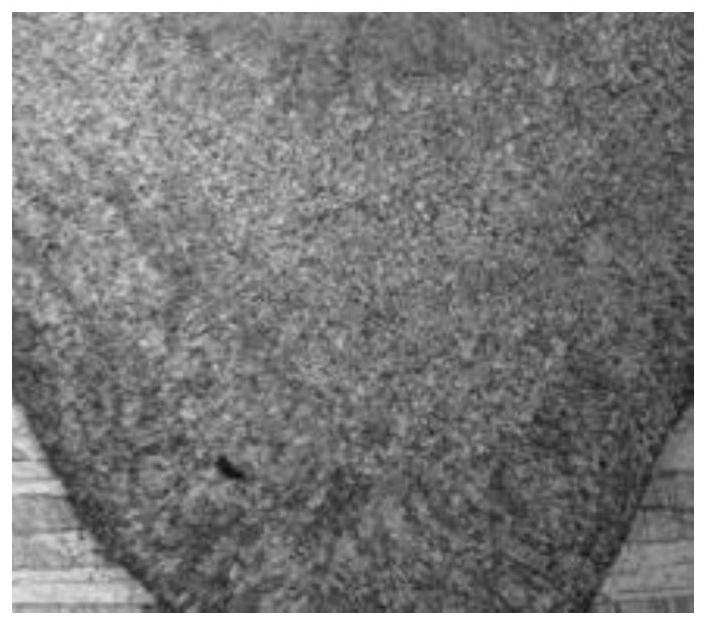

Method for analyzing microstructure nucleation mechanism of laser welding seam

ActiveCN111982618AGood repeatabilityImprove accuracyPreparing sample for investigationTesting metal structuresEquiaxed crystalsWeld seam

The invention belongs to the technical field related to laser welding, and discloses a method for analyzing a microstructure nucleation mechanism of a laser welding seam. The method comprises the following steps: (1) performing laser welding, namely test welding, on a sample 1, and analyzing the microstructure morphology and distribution of the obtained laser welding seam; meanwhile, using TIG welding for conducting one-pass pre-welding and n-pass pre-welding on the sample 2-1 and the sample 2-2 correspondingly, then conducting test welding on weld joints formed through pre-welding correspondingly, and conducting metallographic representation on the obtained overlapped weld joints correspondingly; wherein the sample 1, the sample 2-1 and the sample 2-2 are made of the same material; wherein n is a positive integer greater than or equal to 3; (2) comparing the equiaxed crystal quantity and distribution of the laser weld joint and the overlapped weld joint area of the sample 1, and pre-identifying the nucleation mechanism of the weld joint according to the comparison result; and (3) performing confirmation according to the pre-identification result so as to analyze and obtain a nucleation mechanism. According to the invention, the accuracy and repeatability of a nucleation mechanism are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Production and processing equipment with automobile shifting fork welding assembly detection function

InactiveCN112296495AEasy to moveEasy to reinforceWelding/cutting auxillary devicesAuxillary welding devicesControl engineeringElectric machinery

The invention discloses production and processing equipment with an automobile shifting fork welding assembly detection function. The production and processing equipment comprises a shifting fork feeding case, and a shifting fork feeding bin is fixedly welded on the right side of the upper surface of the top of the shifting fork feeding case; an arc-shaped sliding groove is fixedly welded on the right side of the surface of a control console; a motor controller is arranged at the bottom of a small arm of a rotary mechanical arm, and a second conveyor belt is arranged on the surface of the right side of the rotary mechanical arm; and a discharging port is formed in the bottom of the front side of the rotary mechanical arm. According to the production and processing equipment, the control console is arranged between the shifting fork feeding case and the rotary mechanical arm; single-column pneumatic cylinders are arranged at the bottoms of the shifting fork feeding case and the rotary mechanical arm separately, thereby facilitating pushing of a driven sliding block to enable a control console to rise upwards; meanwhile, through arrangement of the arc-shaped sliding groove, a weldinghead is easy to move along the arc-shaped sliding groove, and the problem of low precision during manual welding is solved; and thus, automatic welding is facilitated, and the welding precision is improved.

Owner:东莞市夯实科技有限公司

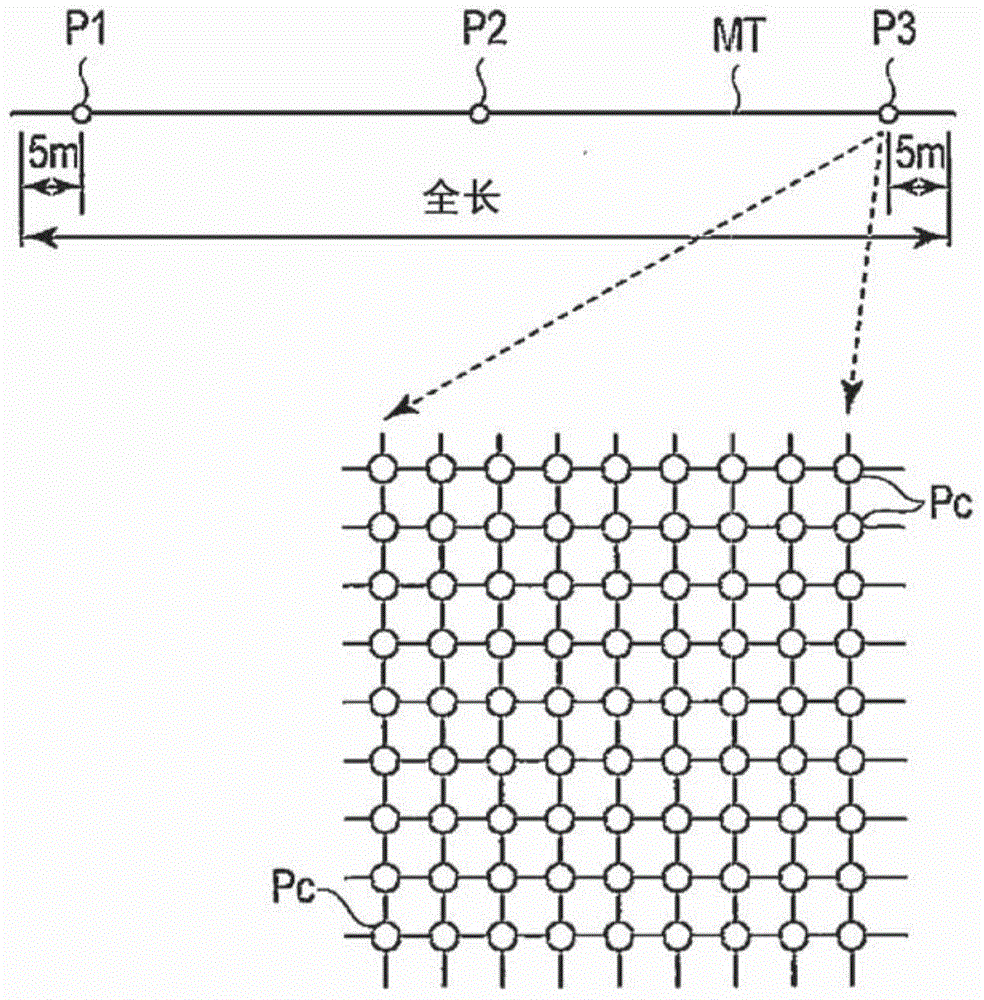

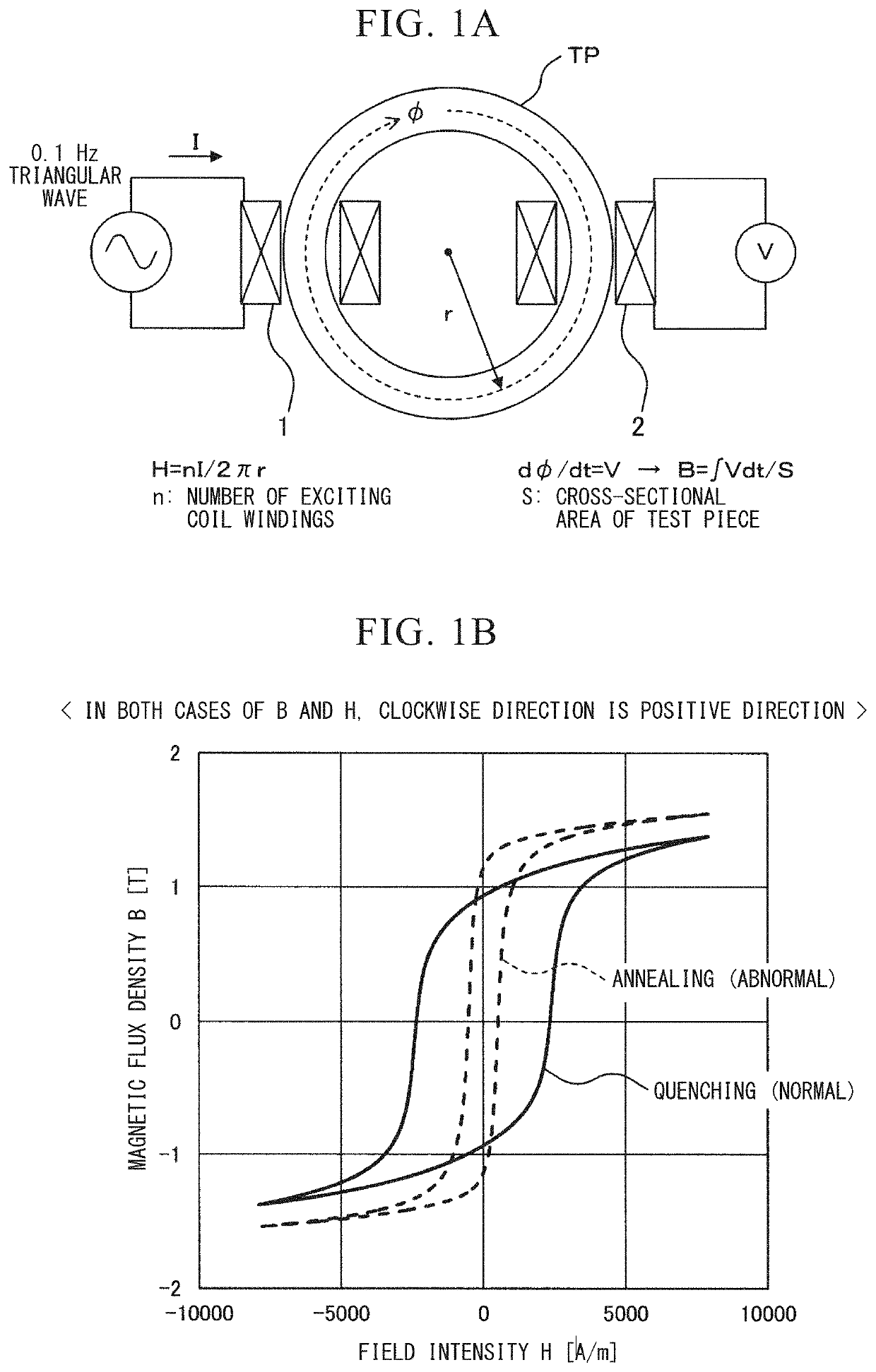

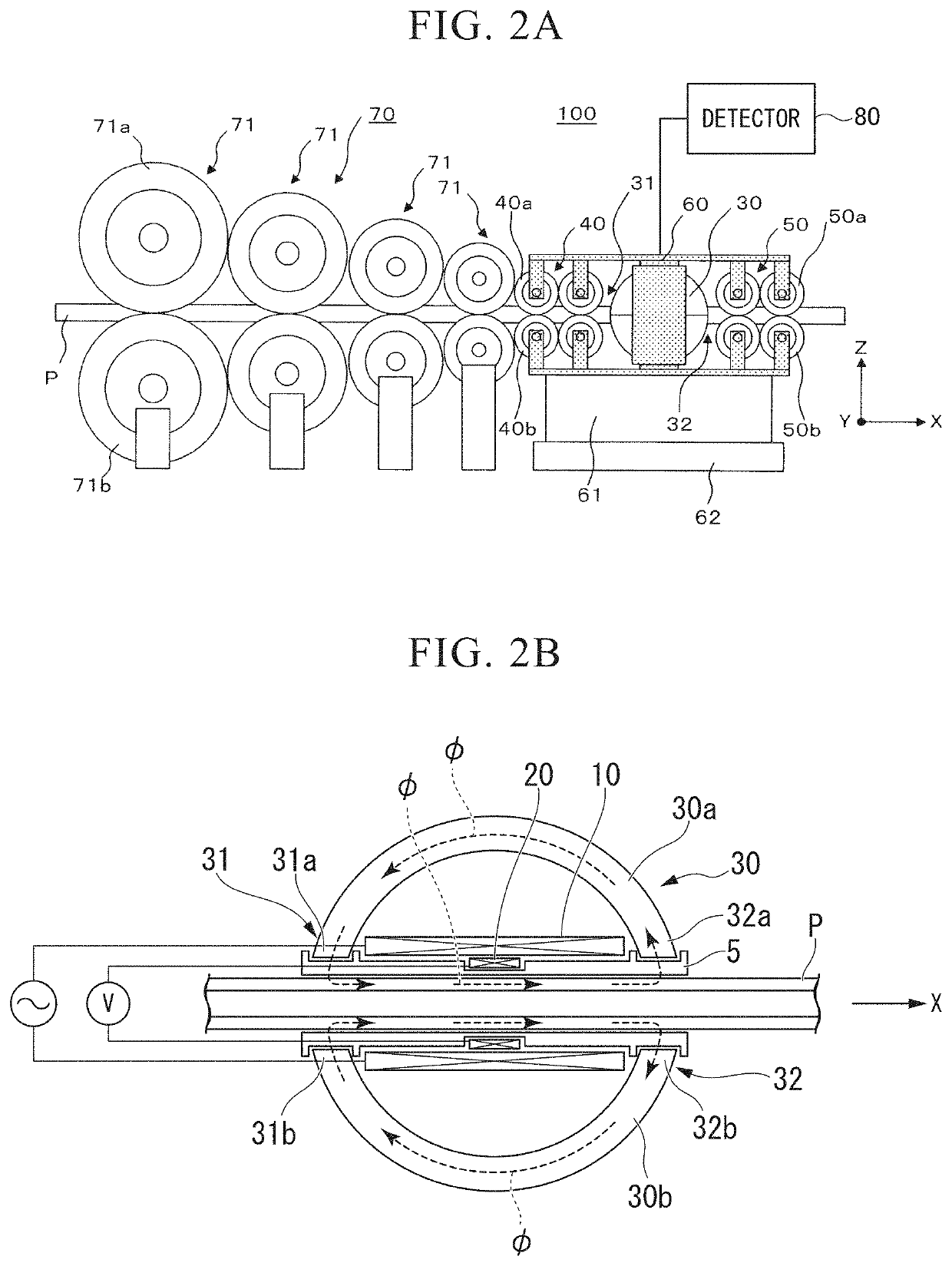

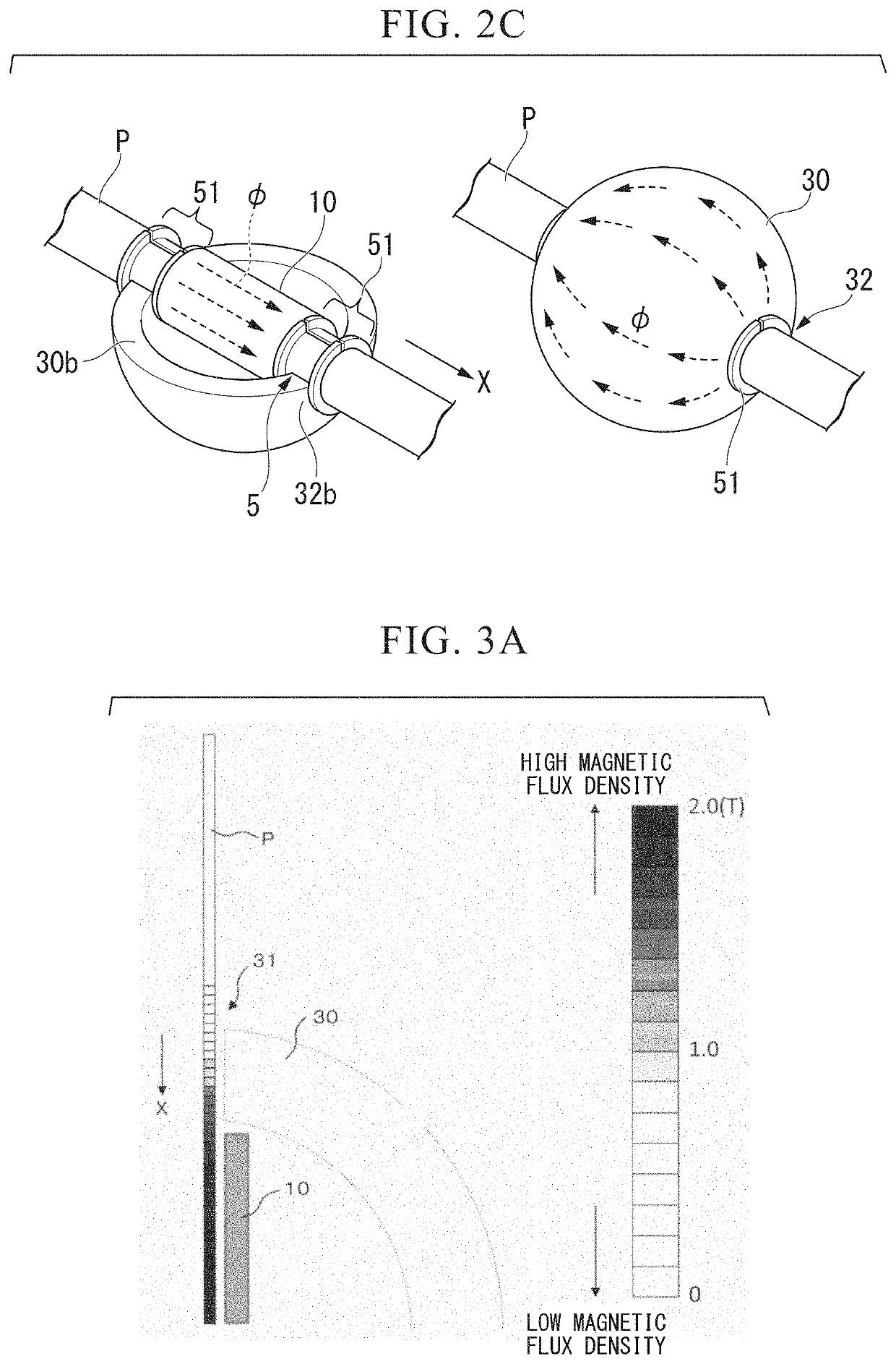

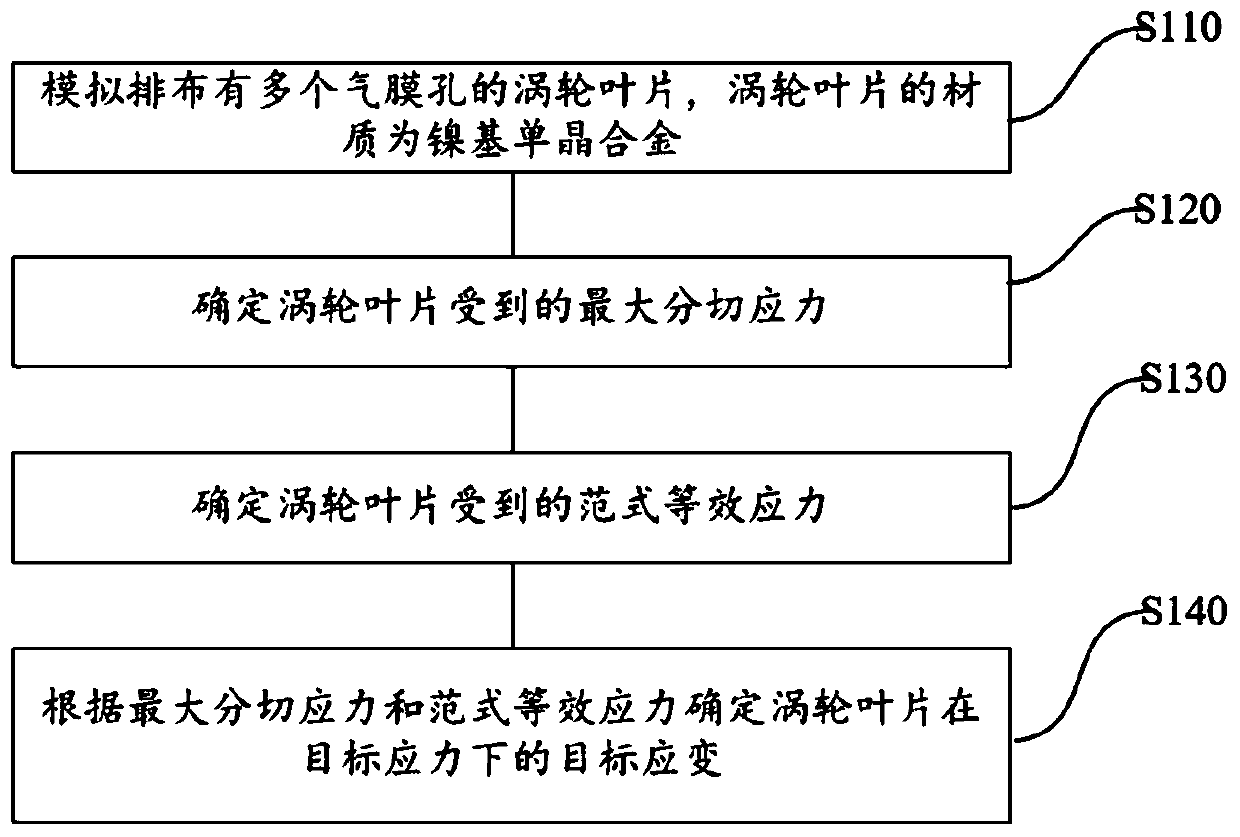

Device and method of detecting magnetic characteristic change for long material

ActiveUS20200284758A1Accurate detectionReduce dead zoneHysteresis curve measurementsTesting metal structuresMagnetizationMagnetic characteristic

A device of detecting magnetic characteristic change for a long material includes: an exciting coil into which the long material is inserted and which magnetizes the long material in a longitudinal direction; a detecting coil into which the long material is inserted and which detects a magnetic flux generated in the long material due to magnetization by the exciting coil; and a yoke member which has a first opening portion which is positioned on one side of the long material in the longitudinal direction and into which the long material is inserted and a second opening portion which is positioned on the other side of the long material in the longitudinal direction and into which the long material is inserted, and has a shape which is substantially axially symmetrical about an axis passing the first opening portion and the second opening portion, and the exciting coil and the detecting coil are surrounded by the yoke member, the first opening portion, and the second opening portion.

Owner:NIPPON STEEL CORP

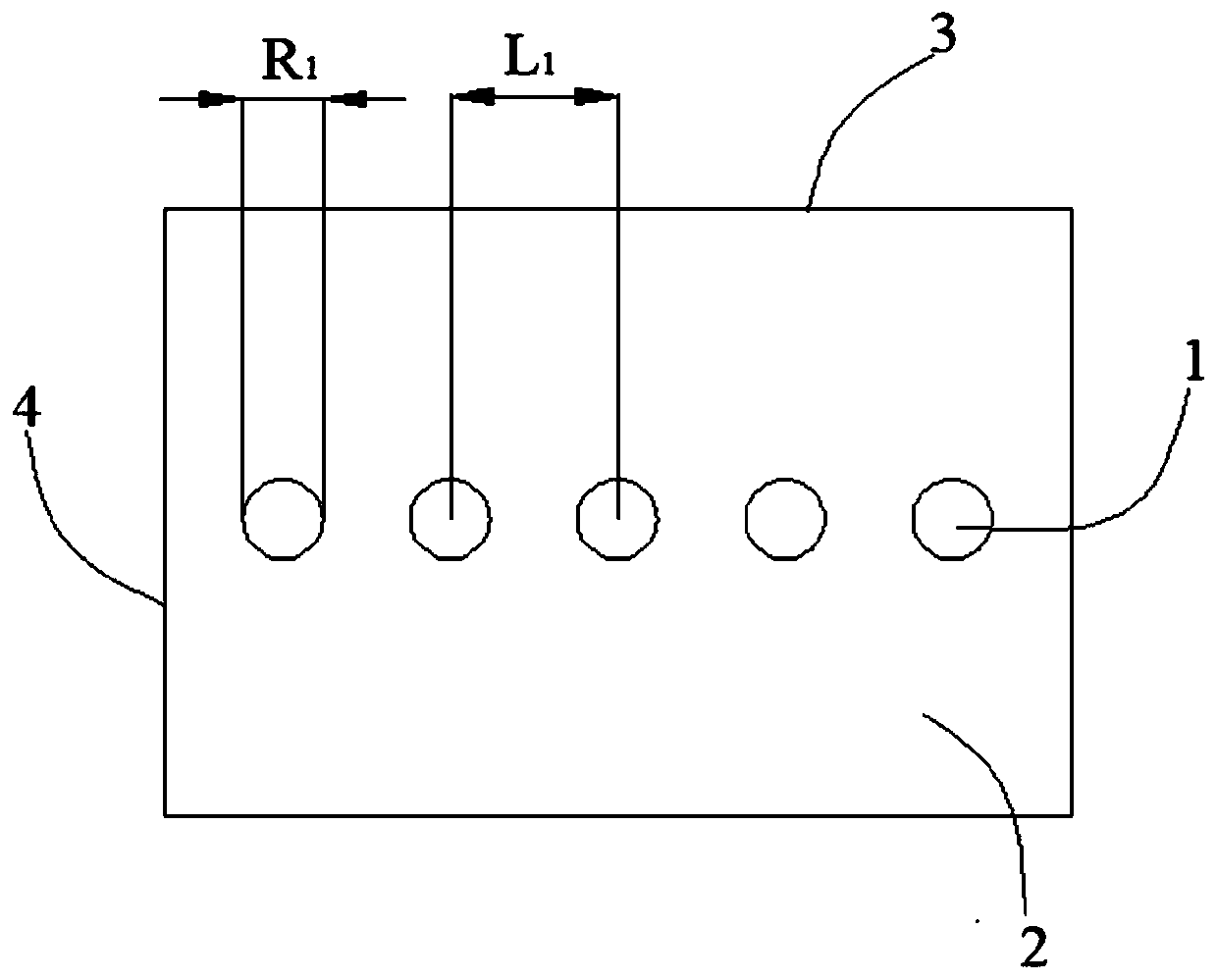

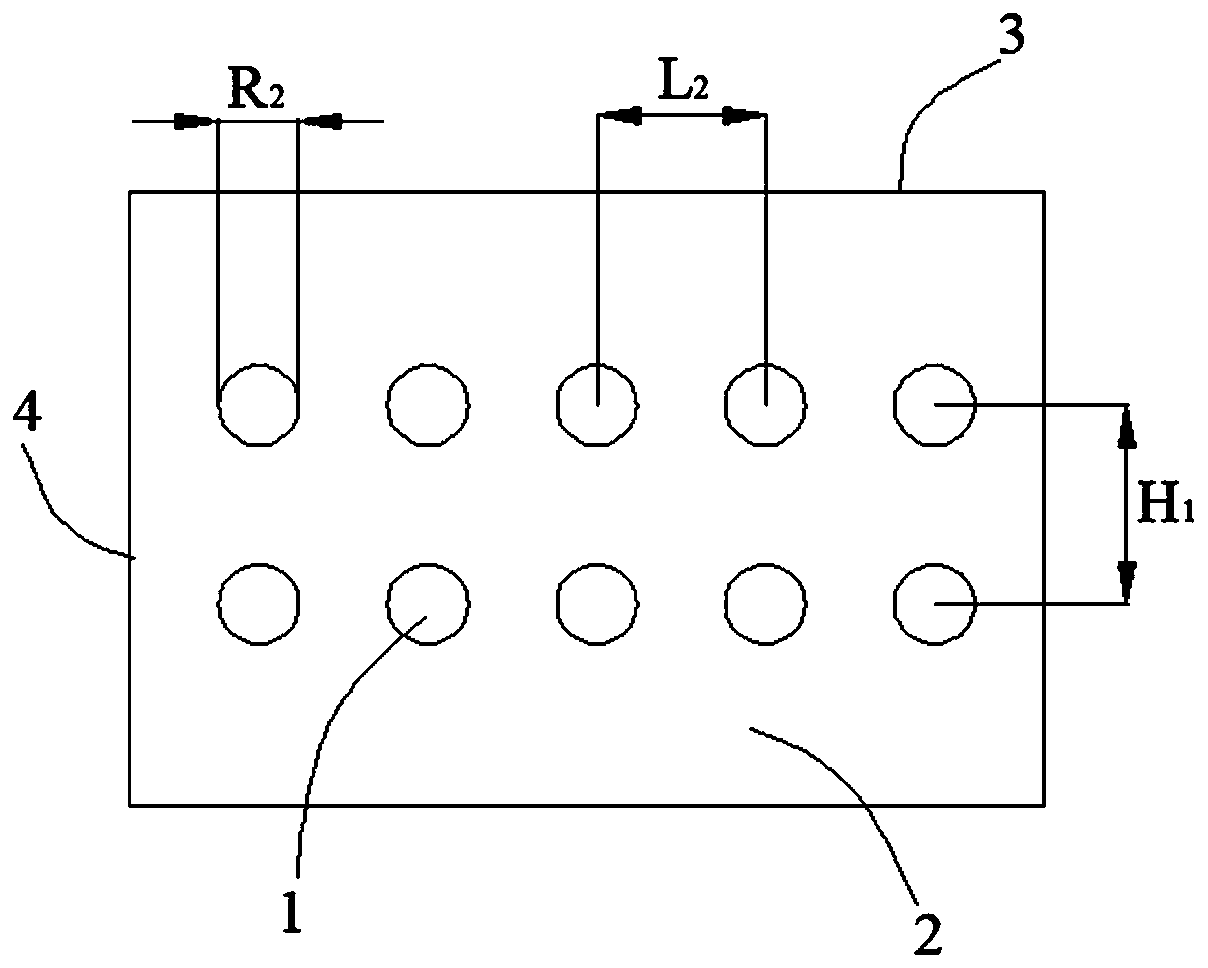

Method for predicting influence of air film hole arrangement mode on performance of nickel-based single crystal alloy

InactiveCN110032789AImprove accuracyGeometric CADMachine part testingTurbine bladePredictive methods

The invention relates to the technical field of turbine blades, and provides a method for predicting the influence of an air film hole arrangement mode on the performance of a nickel-based single crystal alloy. The method for predicting the influence of the air film hole arrangement mode on the performance of the nickel-based single crystal alloy comprises the following steps of simulating a turbine blade provided with a plurality of air film holes, wherein the turbine blade is made of the nickel-based single crystal alloy; determining the maximum slitting stress borne by the turbine blade; determining the normal form equivalent force borne by the turbine blade; and determining the stress-strain distribution of the turbine blade according to the maximum cutting stress and the normal form equivalent force, so that the accuracy of performance prediction can be improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com