Martensite aging stainless steel dendritic crystal corrodent and corrosion method

A technology of stainless steel and martensite, which is applied in the field of maraging stainless steel dendrite corrosion agent and corrosion, can solve the problems of complex configuration method, unsatisfactory erosion effect, and inability to clearly display dendrite morphology, etc., to achieve simple formula, The effect of simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment selects a PH13-8Mo as-cast sample, and the main components of the steel are shown in Table 1.

[0032] Table 1 Chemical composition of PH13-8Mo steel

[0033] C Si mn P S Cr Mo Ni Al 0.045 0.019 0.024 0.0057 0.0025 12.58 2.23 8.16 1.1

[0034] (1) Prepare the sample: cut the above-mentioned cast sample, mechanically grind one plane of the sample on 180#, 500#, and 1000# sandpaper, and then polish it with 2.5μ diamond polishing paste until it is scratch-free Rinse and dry after scratching;

[0035] (2) Preparation of corrosion solution: take 50ml of analytically pure nitric acid with a mass fraction of 65-68%, add 50ml of deionized water, stir gently with a glass rod, and configure it as a 50% aqueous solution of nitric acid by volume;

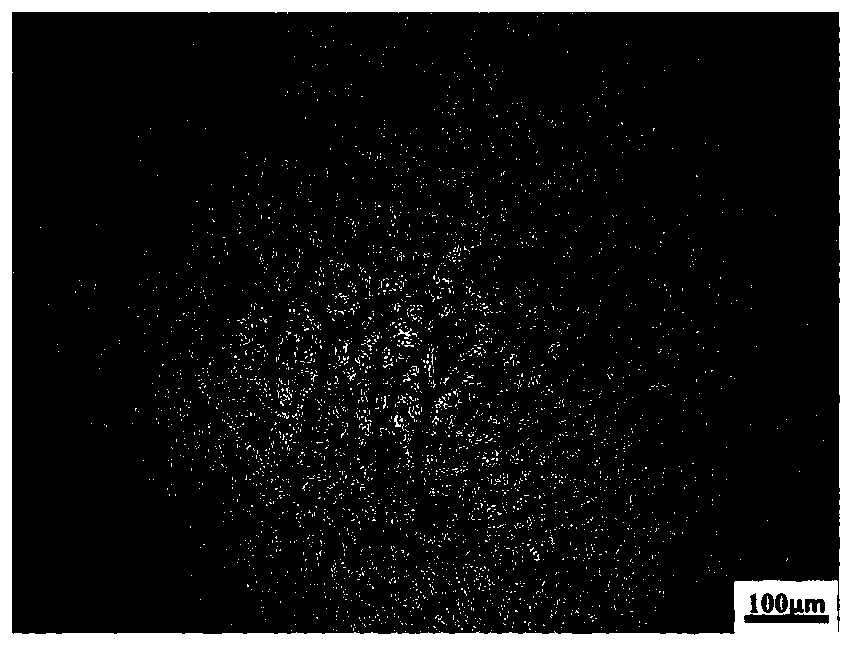

[0036] (3) Sample corrosion: at normal temperature, the polished sample is carried out electrolytic etching, with the stainless steel sheet as the cathode, the sample as the anode, t...

Embodiment 2

[0040] In this embodiment, a PH13-8Mo as-cast sample is selected, and the main components of the steel are shown in Table 2.

[0041] Table 2 Chemical composition of PH13-8Mo steel

[0042] C Si mn P S Cr Mo Ni Al 0.04 0.057 0.108 0.009 0.0032 12.8 2.3 8.05 1.1

[0043] (1) Prepare the sample: cut the above-mentioned cast sample, mechanically grind one plane of the sample on 180#, 500#, and 1000# sandpaper, and then polish it with 2.5μ diamond polishing paste until it is scratch-free Rinse and dry after scratching;

[0044] (2) Preparation of corrosion solution: take 40ml of analytically pure nitric acid with a mass fraction of 65-68%, add it to 60ml of deionized water, stir gently with a glass rod, and configure it as an aqueous solution of nitric acid with a volume fraction of 40%;

[0045] (3) Sample corrosion: at normal temperature, the polished sample is carried out electrolytic etching, with the stainless steel sheet as the cathode,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com