Method for detecting the contamination of two-phase titanium alloys with an alpha phase and a beta phase

A titanium alloy and inspection method technology, applied in the direction of testing metals, material inspection products, testing metal structures, etc., can solve problems such as inaccuracy and inapplicability of titanium alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

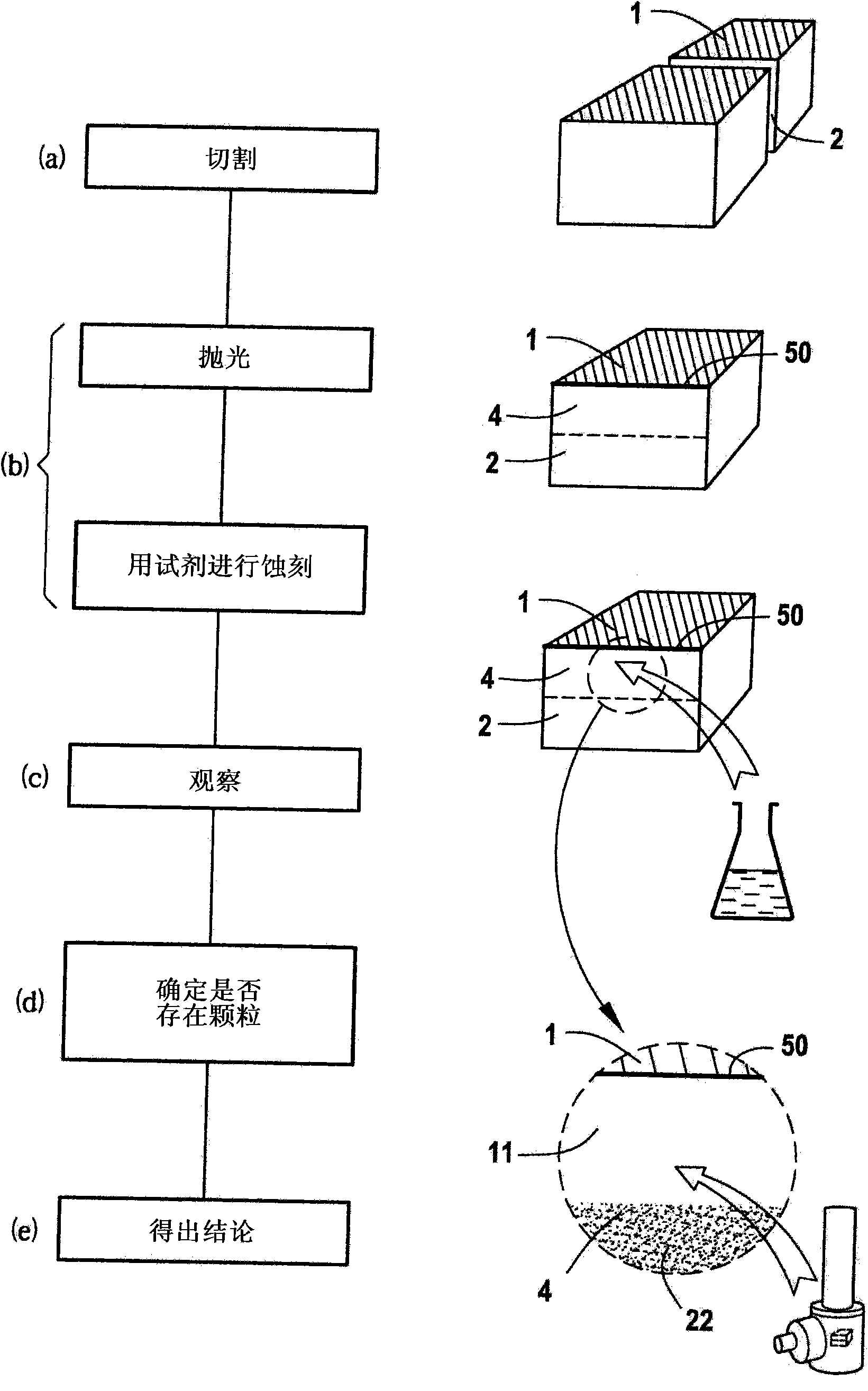

[0032] Until now, when observing parts made of duplex titanium alloys with alpha and beta phases, it was concluded that the part had not been damaged if no white fringe could be seen along the edge shared by the sample with the surface of the part in question. pollute. Therefore, if the mechanical properties of the part are found to be unsatisfactory, it is concluded that the poor performance is due to causes such as manufacturing defects, poor surface condition, work hardening or poor operating conditions. Either of these circumstances could explain the poor mechanical properties.

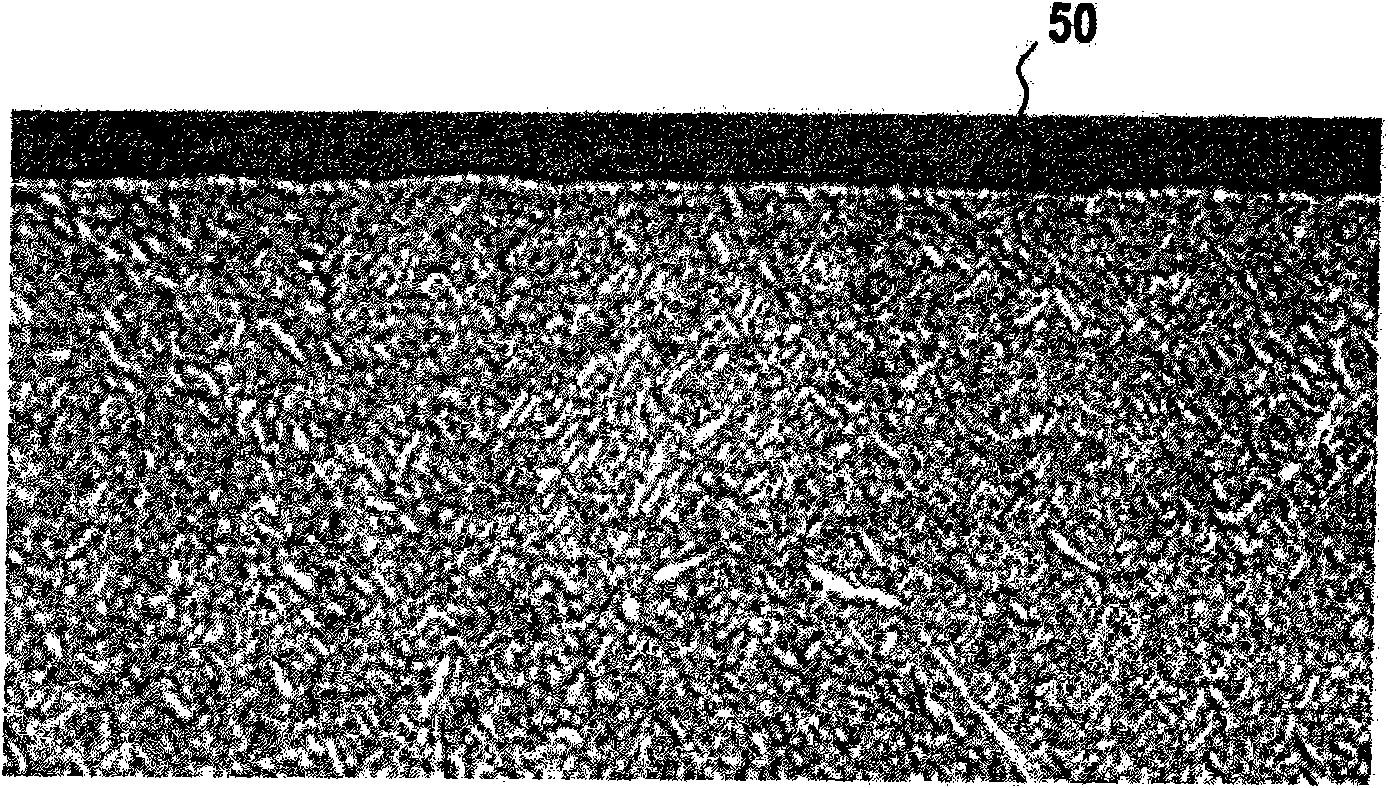

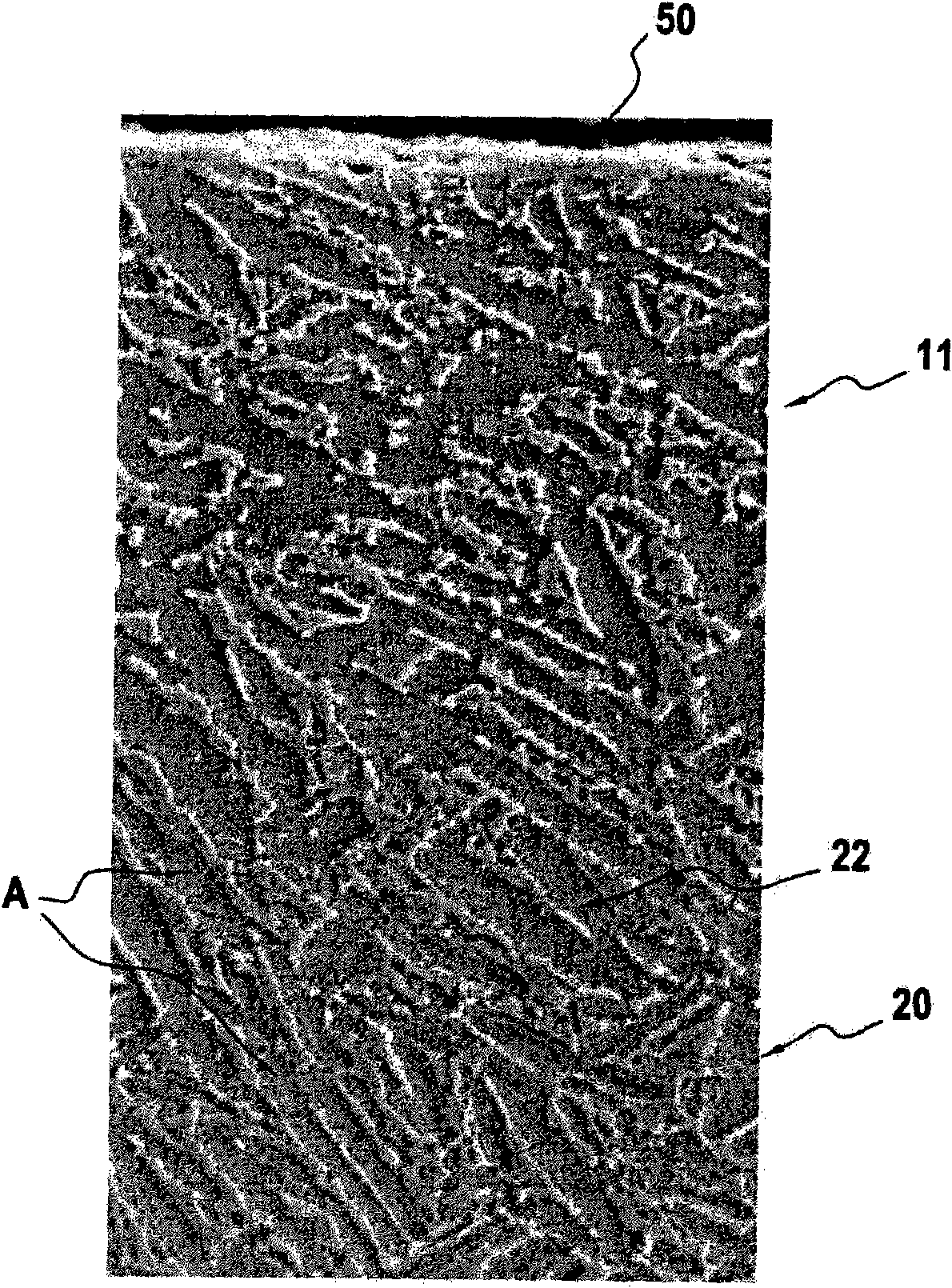

[0033] The inventors of the present invention have collected a large number of samples of various duplex-type titanium alloys with α-phase and β-phase, and in a non-obvious manner considered the To observe these samples, it is sufficient to observe the white edge of the alloy contaminated with gaseous elements. Thus, using a magnification greater than or equal to x5000, the inventors of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com