Thermal treatment method for TC18 titanium alloy

A TC18 and titanium alloy technology, applied in the field of heat treatment of metal materials, can solve the problems of low alloy strength and alloy plasticity and toughness, and achieve the effect of improving plasticity and toughness, increasing temperature and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

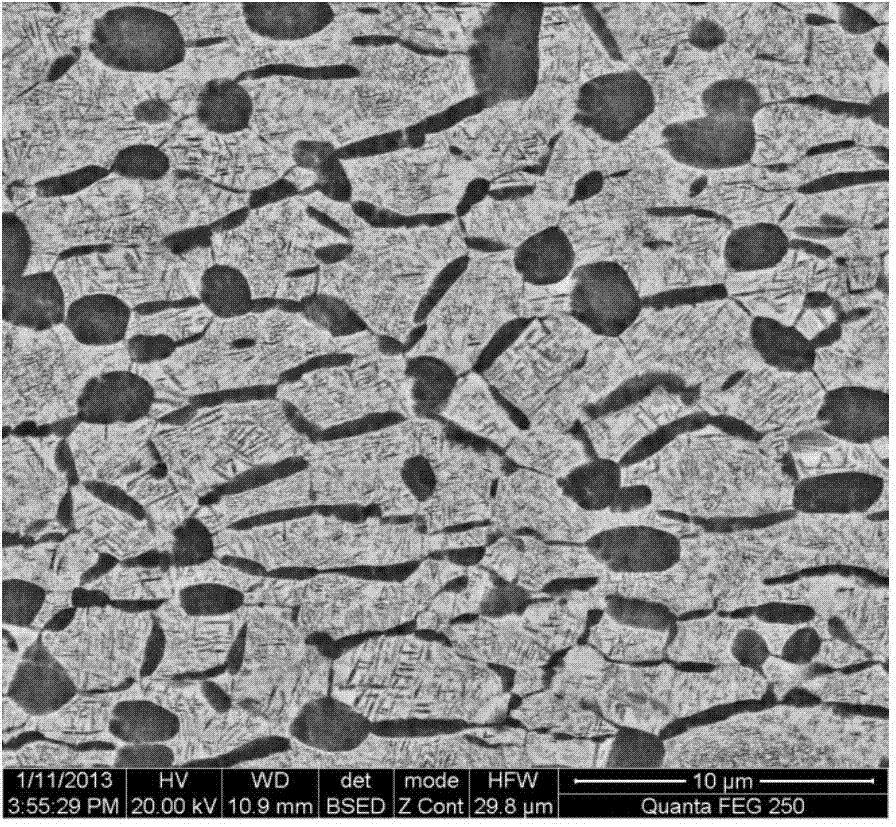

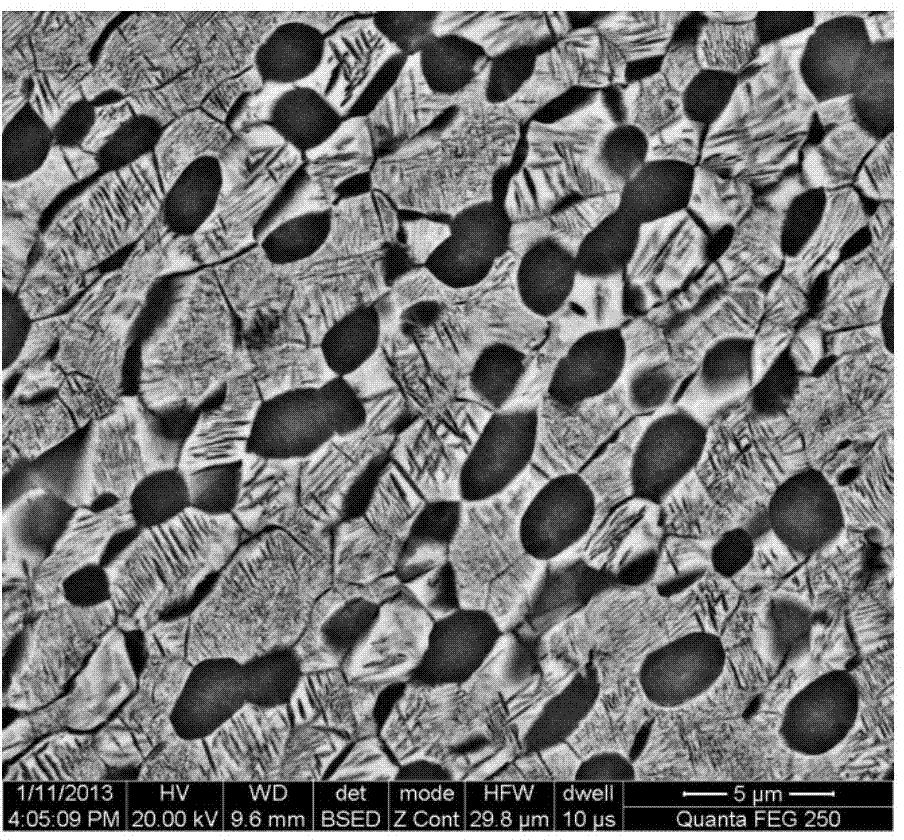

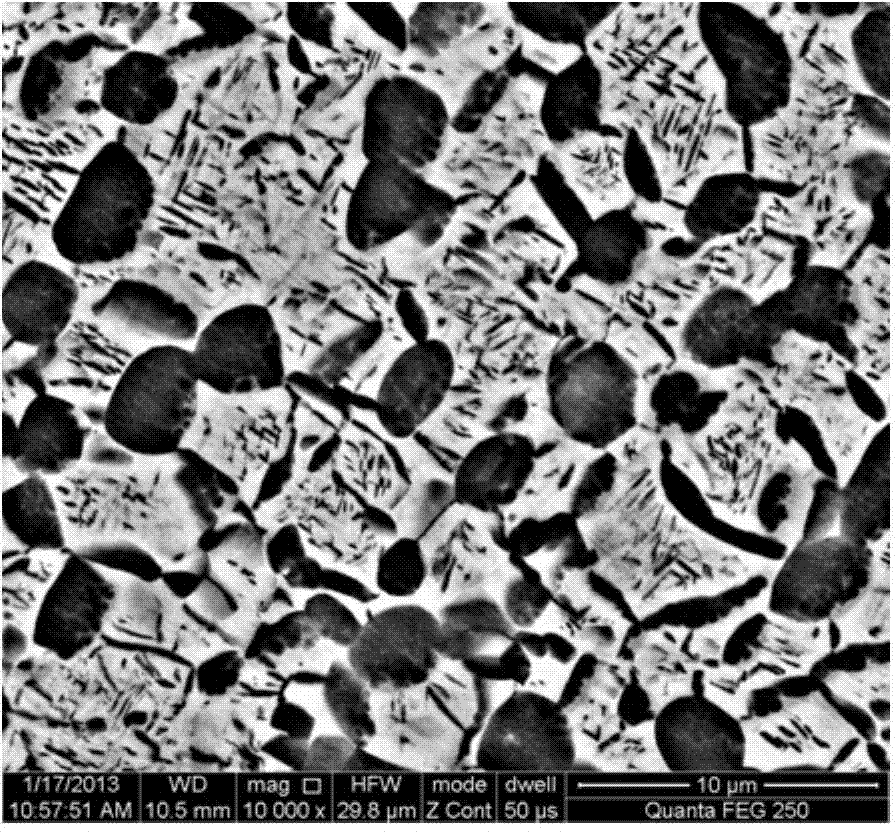

[0034] The TC18 titanium alloy hot-forged bar with Φ120mm×150mm is used, and its microstructure is composed of β phase and equiaxed α phase; the volume fraction of equiaxed α phase is 31%, and the average size is 3-5 μm.

[0035] The β-transition temperature of the TC18 titanium alloy hot-forged bar was determined to be 865±5°C. In the first step, heat the alloy rod to 760°C for 6 hours, control the cooling rate to 2-3°C / s, and force air cooling to room temperature; in the second step, heat the alloy rod to 540°C for 8 hours, and then air cool to room temperature.

[0036] Table 1 shows the mechanical property parameters of the TC18 titanium alloy bar treated in this example at room temperature.

[0037]Mechanical properties of TC18 bar room temperature in table 1 example 1

[0038]

Embodiment 2

[0040] The TC18 titanium alloy hot-forged bar with Φ180mm×200mm is used, and its microstructure is composed of β phase and equiaxed α phase; the volume fraction of equiaxed α phase is 29%, and the average size is 4-5μm.

[0041] The β-transition temperature of the TC18 titanium alloy hot-forged bar was determined to be 865±5°C. The first step is to heat the alloy rod to 790°C for 2 hours, then control the cooling rate to 15-20°C / s, and water-cool to room temperature; the second step is to heat the alloy rod to 570°C for 6 hours, and then air-cool to room temperature.

[0042] Table 2 shows the mechanical property parameters of the TC18 titanium alloy bar treated in this example at room temperature.

[0043] Mechanical properties of the TC18 rod at room temperature in Table 2 Example 2

[0044]

Embodiment 3

[0046] The TC18 titanium alloy hot-forged bar with Φ180mm×200mm is used, and its microstructure is composed of β phase and equiaxed α phase; the volume fraction of equiaxed α phase is 33%, and the average size is 2-4μm.

[0047] The β-transition temperature of the TC18 titanium alloy hot-forged bar was determined to be 865±5°C. In the first step, heat the alloy rod to 770°C for 4 hours, control the cooling rate to 10-15°C / s, and cool it to room temperature with water; in the second step, heat the alloy rod to 600°C for 4 hours, and then air cool to room temperature.

[0048] Table 3 shows the mechanical property parameters of the TC18 titanium alloy rods treated in this example at room temperature.

[0049] TC18 bar room temperature mechanical properties in table 3 embodiment 3

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com