MgAlZn series heat resistant magnesium alloy containing niobium

A magnesium alloy, heat-resistant technology, applied in the field of magnesium alloys, can solve problems such as the inability to meet the high temperature resistance requirements of components, the components do not work well, and cannot withstand high temperatures, achieve good fluidity and die castability, improve high temperature resistance, and delay crystallisation. The effect of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Prepare the heat-resistant magnesium alloy according to the steps described in the above-mentioned process two, the casting adopts metal mold casting, and the weight percentage of the magnesium alloy is composed of Al 1.5%, Zn 0.1%, Mn 0.1%, Y 0.0002%, Nb 0.0002%, Zr 0.001%, B 0.0002%, and the rest is Mg.

[0031] Castings are heat treated.

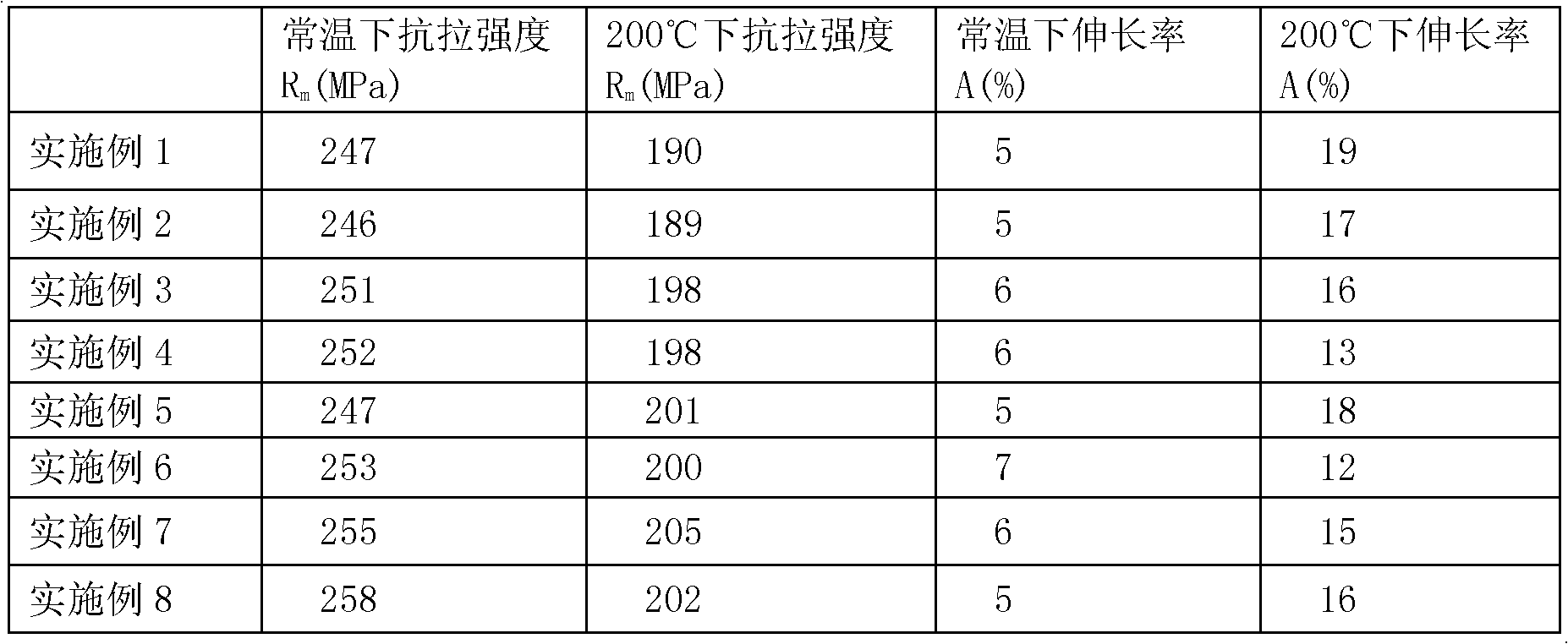

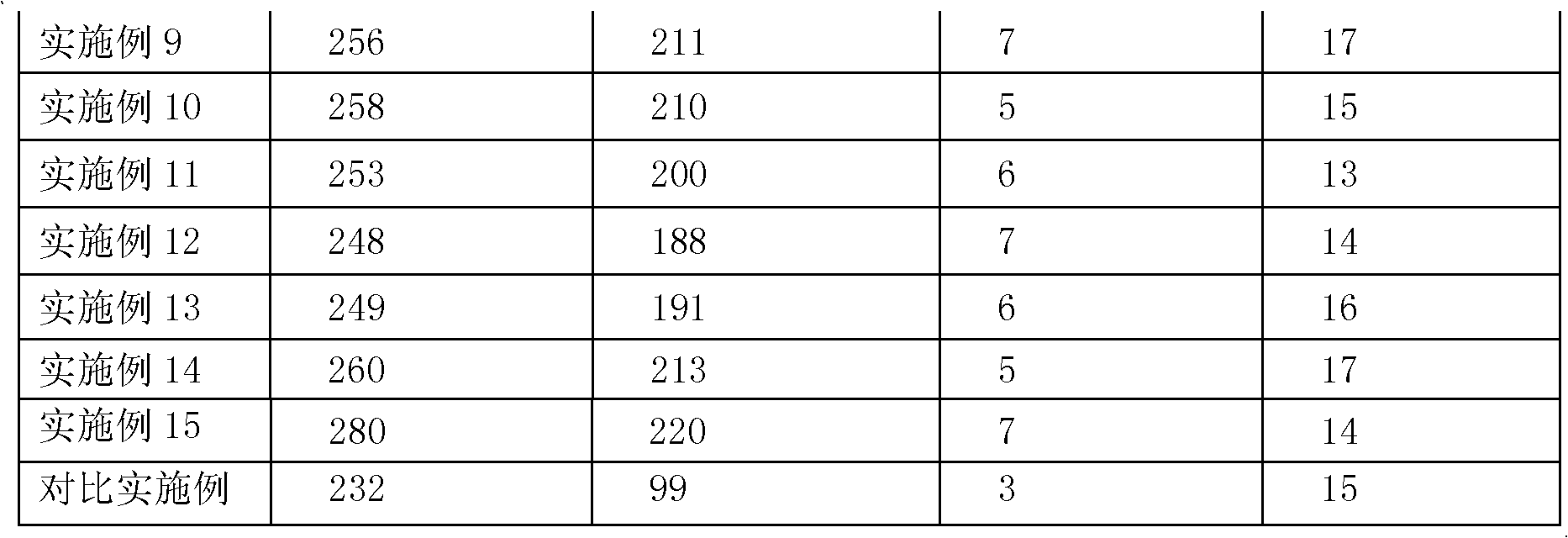

[0032]See Table 1 for the properties of the magnesium alloy castings provided in this example.

Embodiment 2

[0034] Prepare the heat-resistant magnesium alloy according to the steps described in the above-mentioned process one. The casting adopts low-pressure die-casting, and the weight percentage of the magnesium alloy is composed of Al 25%, Zn 3.5%, Mn 2.2%, Sc 16%, Nb 4%, Zr 2 %, Ca 2%, and the rest is Mg.

[0035] Castings are heat treated.

[0036] See Table 1 for the properties of the magnesium alloy castings provided in this example.

Embodiment 3

[0038] Prepare the heat-resistant magnesium alloy according to the steps described in the above-mentioned process two, the casting adopts high-pressure die-casting, and the weight percentage of the heat-resistant magnesium alloy is composed of Al 1.5%, Zn 0.3%, Mn 0.1%, Sm 0.1%, Nb 0.05%, Zr 0.2% , Sr 0.05%, and the rest is Mg.

[0039] See Table 1 for the properties of the magnesium alloy castings provided in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com