Patents

Literature

150results about How to "Improve die casting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

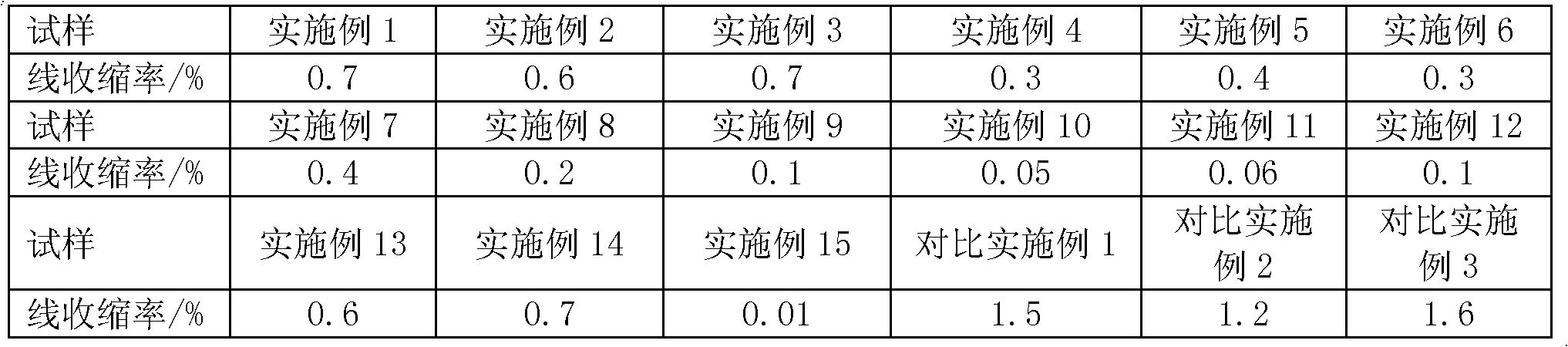

Cast magnesium alloy of low linear shrinkage

The invention discloses a cast magnesium alloy of low linear shrinkage, which belongs to the field of magnesium alloys. The magnesium alloy consists of Mg, Al, Zn, Mn, rare earth, Nb, Li and M element, wherein the materials have the following weight percentage composition: 1.5-25 percent of Al, 0.1-3.5 percent of Zn, 0.1-2.2 percent of Mn, 0.0002-16 percent of rare earth, 0.0002-4 percent of Nb, 0.0002-9 percent of Li, 0.0002-2 percent of M element and the balance Mg; and the M element is at least one of Zr, Ti, Sr, Ca, C and B. According to the heat-resistant magnesium alloy, the rare earth element and the Nb element are added into the magnesium alloy, so that the structure of beta phase is changed; the Zr element and the M element are added to refine crystal grains; due to combined action of the elements, latent heat of crystallization during alloy solidification is changed; and the magnesium alloy which has superior mold-filling capacity, low shrinkage, superior mechanical property and good machinability, fluidity and die-cast performance and is suitable for casting is obtained.

Owner:嘉兴佳斯贝特新材料有限公司

Aluminium die-cast alloy

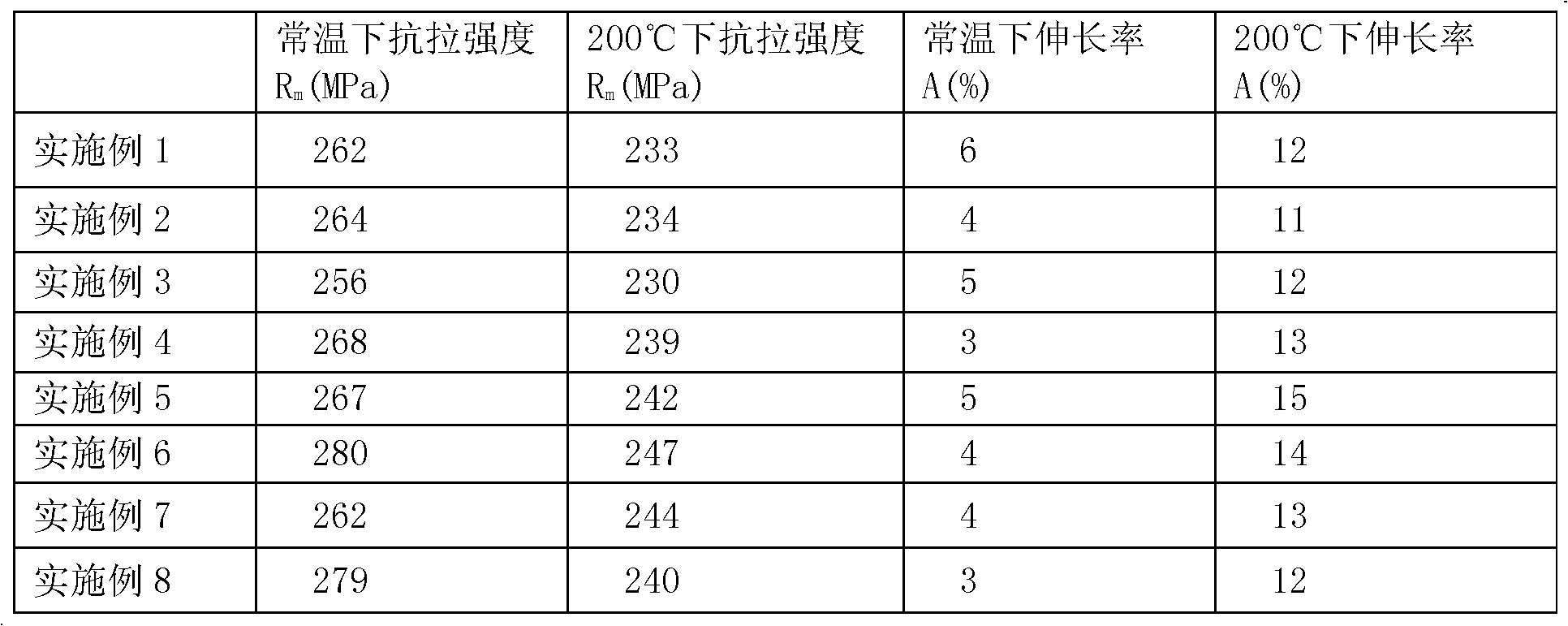

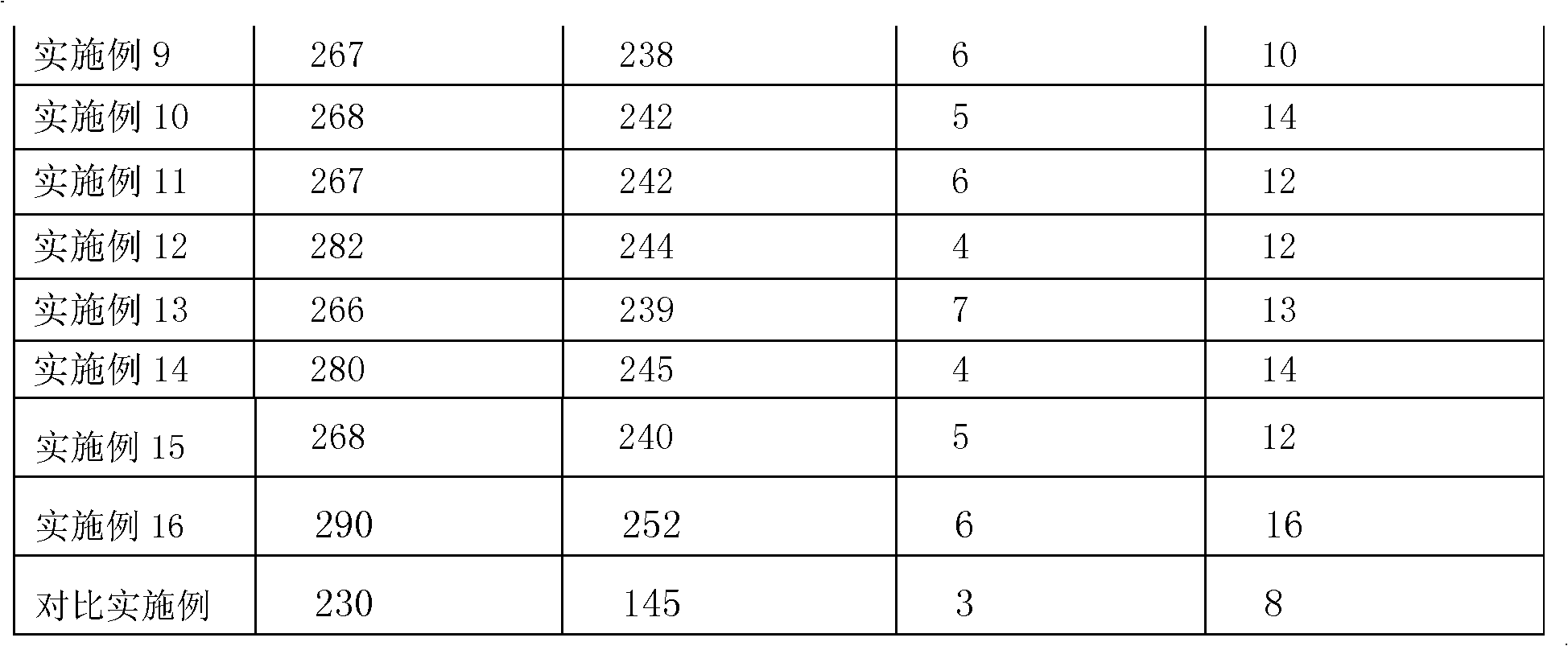

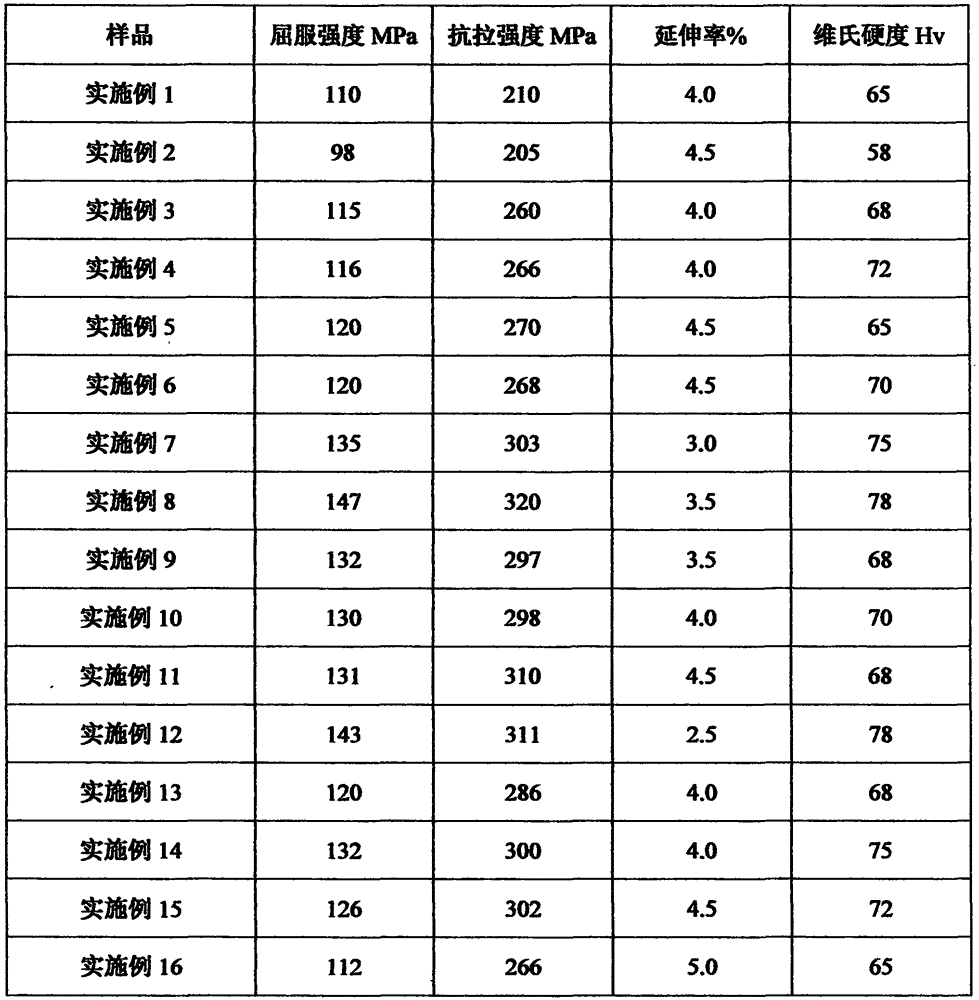

ActiveCN103343268AImprove mechanical propertiesGood anodizing effectMechanical propertyAnodic oxidation

The invention discloses an aluminium die-cast alloy which mainly contains Si, Cu, Fe, Mn, Mg, Zn, Ti and LaCe elements. The aluminium die-cast alloy is characterized in that weight content of all the elements are respectively as follows: 0.5% to 2.0% of Si, 0.1% to 0.5% of Cu, 0.3% to 0.8% of Fe, 0.5% to 1.0% of Mn, 2.0% to 4.0% of Mg, 0.8% to 2.0% of Zn, 0.15% to 0.2% of Ti and 0.6% to 0.8% of LaCe. The aluminium die-cast alloy has the good anodic oxidation ability, mechanical property and corrosion resisting property.

Owner:嘉宜科技(惠州)有限公司

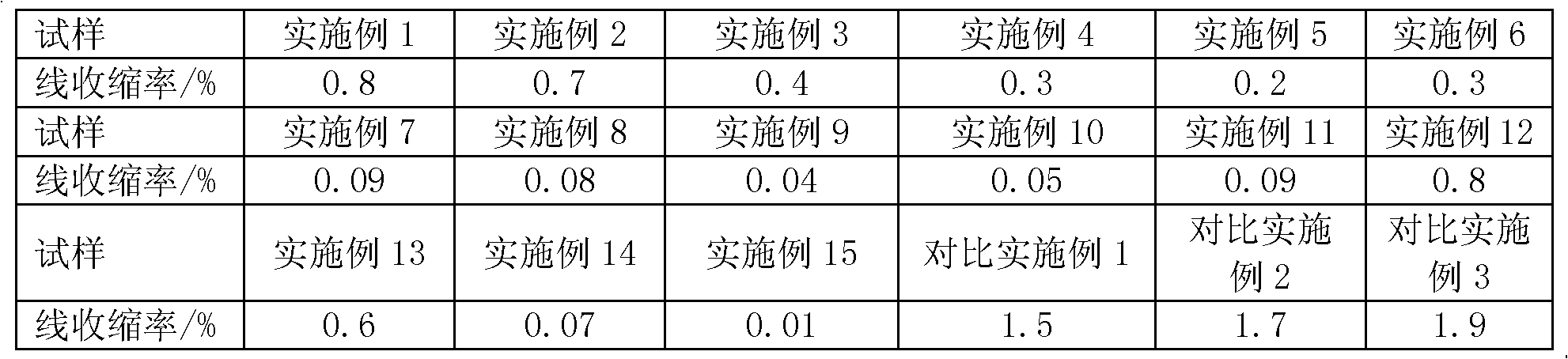

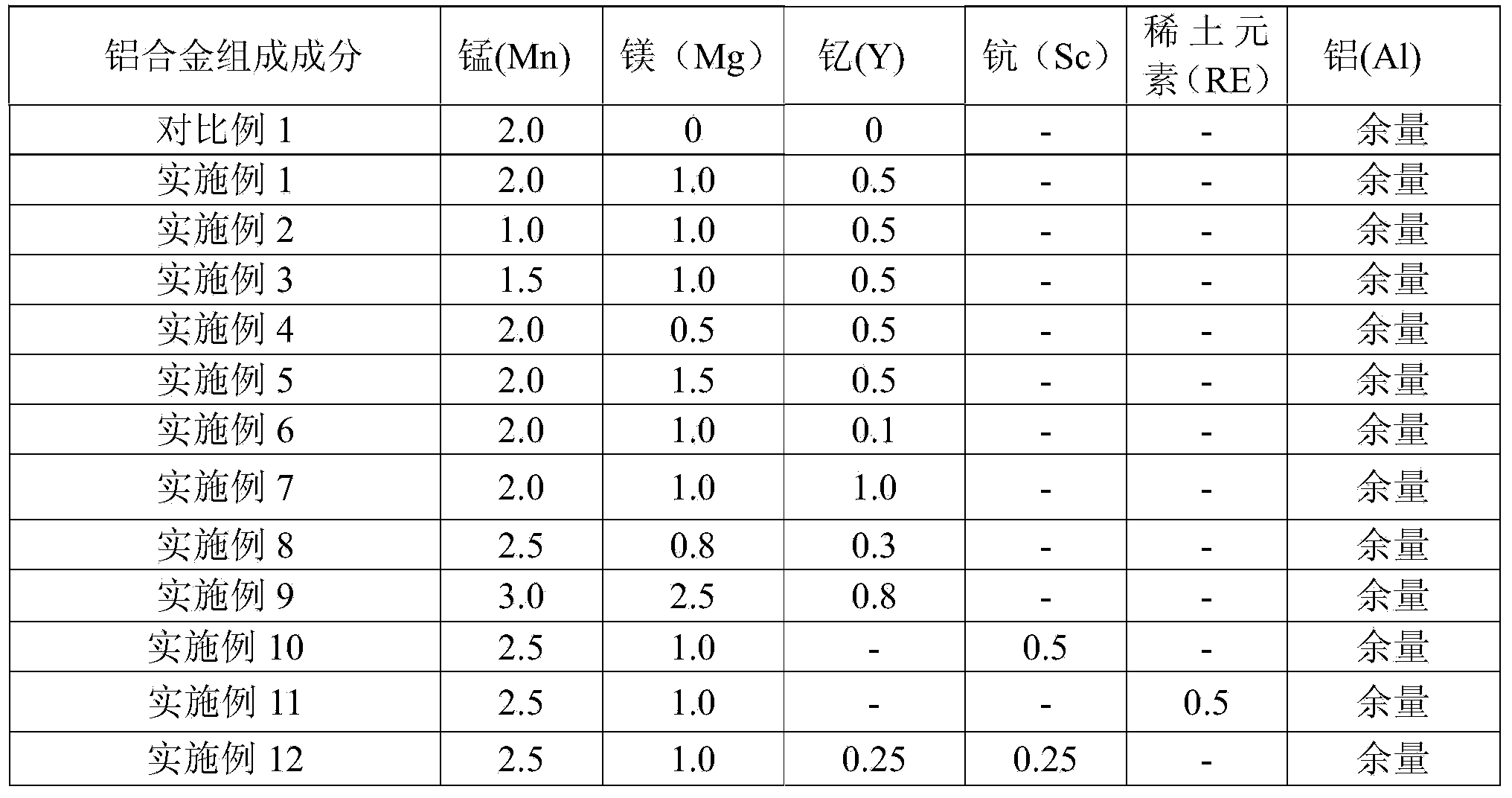

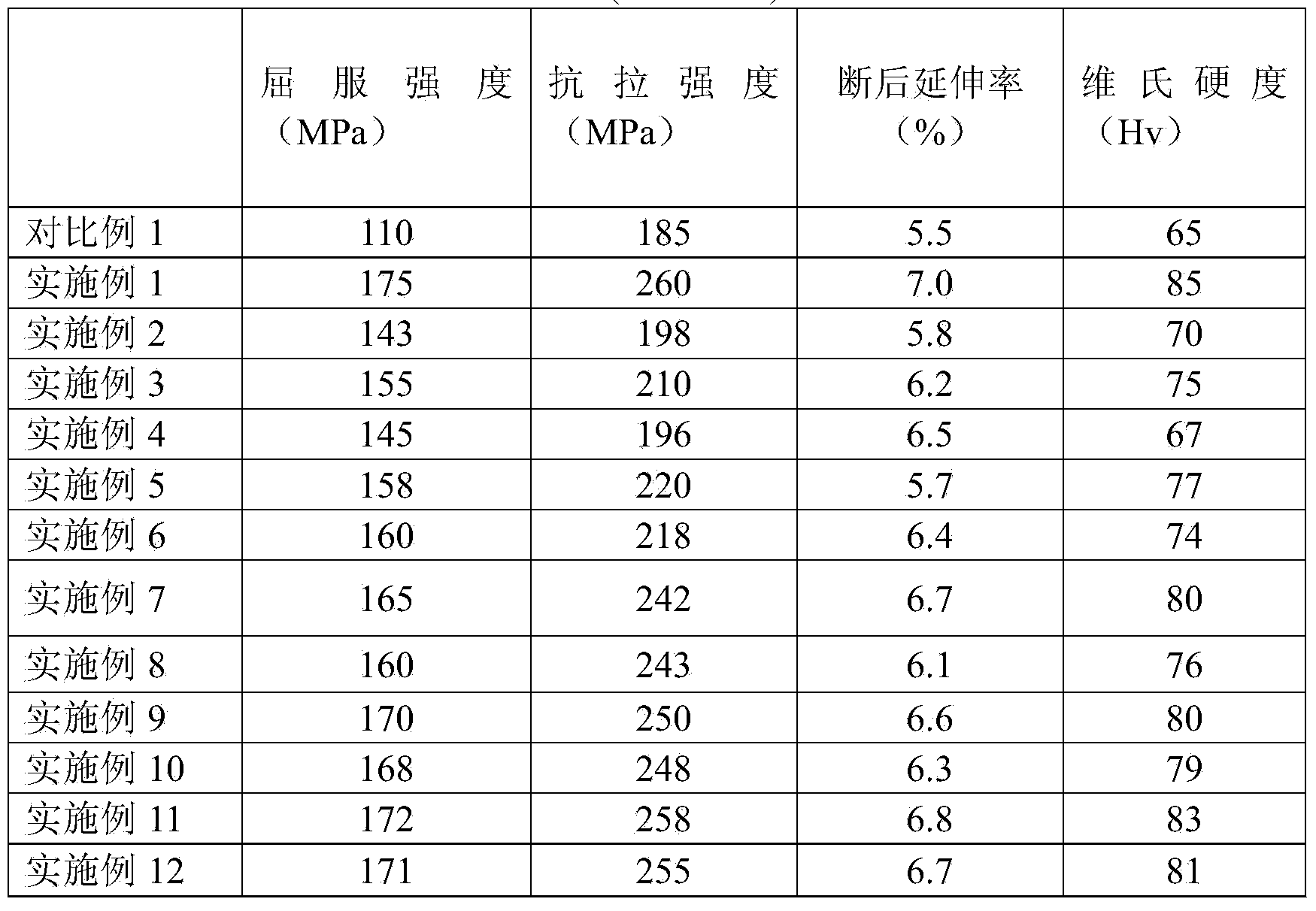

Anode-oxidable high-performance die-casting aluminum alloy and preparation method thereof

The invention provides an anode-oxidable high-performance die-casting aluminum alloy and a preparation method thereof. The die-casting aluminum alloy comprises the following components in percentage by weight: 0.5-3.0 percent of Mn, 0.5-2.50 percent of Mg, 0.1-1.0 percent of D and the balance of Al and inevitable impurities, wherein D can be one or more than two of elementary substances Y, Sc and Re; the inevitable impurities comprises the following components in percentage by weight: less than or equal to 0.10 percent of Fe, less than or equal to 0.10 percent of Si and less than or equal to 0.10 percent of Cu. The aluminum alloy is simple in composition, a high-finish surface can be obtained by means of ordinary anode oxidation and dyeing, and the comprehensive physical properties of high strength, high plasticity and the like are achieved; the anode-oxidable high-performance die-casting aluminum alloy can be colored, has high casting performance, machinability and high corrosion resistance, and can meet the use requirements of exterior parts for 3C products. The production cost is reduced, and the efficiency is increased.

Owner:SUZHOU KAI YOU ELECTRONICS SCI & TECH LTD

Die-casting aluminum alloy with anode being oxidable

The invention belongs to the technical field of aluminum alloy, in particular to die-casting aluminum alloy with the anode being oxidable. The aluminum alloy is composed of, by weight, 0.3%-0.5% of Si, 0-0.1% of Cu, 0.8%-1.5% of Mg, 0-0.05% of Zn, 0-0.35% of Fe, 1.0%-1.5% of Mn, 0.5%-2.0% of Ti, 0-0.008% of Sn, 0-0.008% of Pb and the balance Al. Compared with the prior art, all the elements are utilized reasonably, and the content of all the elements is limited within a reasonable range, so that the die-casting aluminum alloy with the anode being oxidable which is good in die-casting performance and excellent in anodic oxidation performance is obtained, and the die-casting aluminum alloy is suitable for aluminum alloy structural components with the anode being oxidable and high in surface treatment effect requirement.

Owner:DONGGUAN AO PRECISION DIECASTING CO LTD

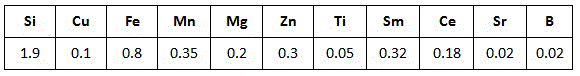

Die-casting rare earth aluminum alloy with characteristics of high fluidity and oxidability

InactiveCN104789824AImprove die casting effectImprove oxidation effectUltimate tensile strengthMaterials science

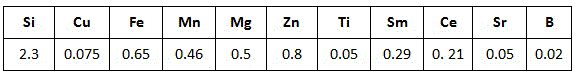

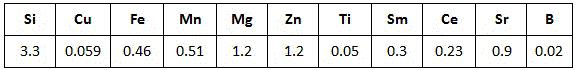

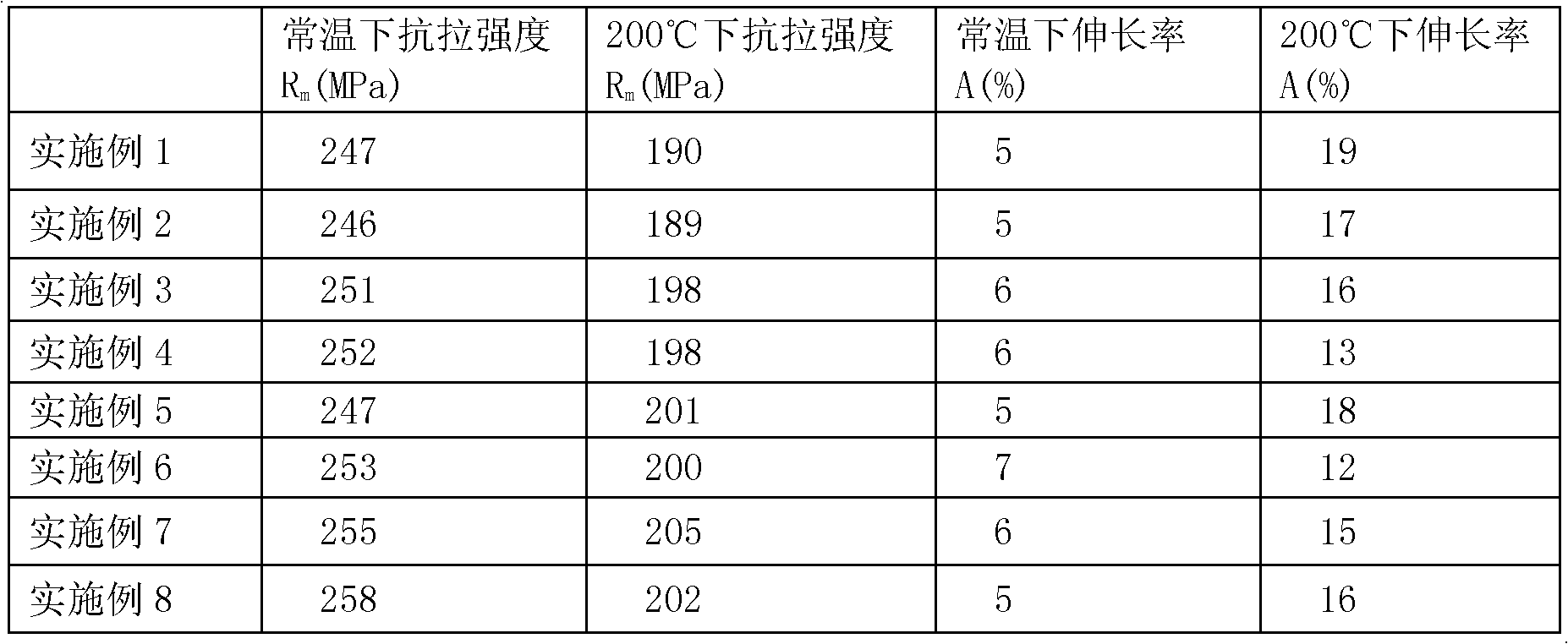

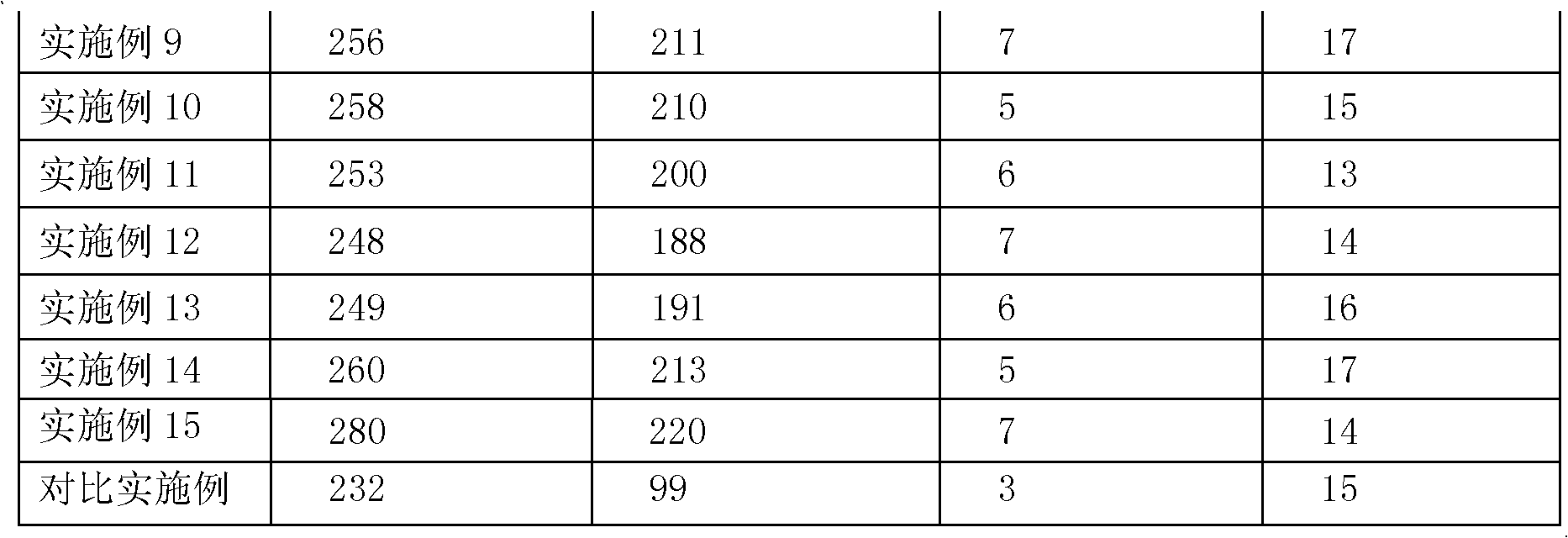

The present invention discloses a die-casting rare earth aluminum alloy with characteristics of high fluidity and oxidability. The die-casting rare earth aluminum alloy contains, by weight, 1.8-4% of Si, 0.03-0.15% of Cu, 0.2-0.9% of Fe, 0-0.7% of Mn, 0-1.8% of Mg, 0.2-1.6% of Zn, 0-0.15% of Ti, 0.2-0.45% of Sm, 0.1-0.3% of Ce, 0.01-0.15% of Sr, 0-0.1% of B, and the balance of Al and unavoidable impurities. The die-casting rare earth aluminum alloy has characteristics of high strength, good die-casting performance, good oxidation effect, good corrosion resistance, and low price, and meets the high requirements of vehicle products, household products and 3C products on the material.

Owner:苏州聚数精密铸造有限公司

MgAlZn series heat resistant magnesium alloy containing niobium

The invention discloses a MgAlZn series heat resistant magnesium alloy containing niobium, and belongs to the magnesium alloy field. The magnesium alloy is composed of elements of Mg, Al, Zn, Mn, rare earths, Nb, Zr and M, and comprises, by weight, 1.5 to 2.5 percents of Al, 0.1 to 3.5 percents of Zn, 0.1 to 2.2 percents of Mn, 0.0002 to 16 percents of rare earths, 0.0002 to 4 percents of Nb, 0.001 to 2 percents of Zr, 0.0002 to 2 percents of M element, and the balance Mg; wherein the M element is at least one of Ti, Sr, Ca, C and B. According to the magnesium alloy, the structure of Beta phase is changed and the heat resistant performance of the magnesium alloy is improved by adding rare earth elements and the Nb element into the magnesium alloy; and grains are refined by adding the Zr and M elements, so that the heat resistant magnesium alloy which has good mechanical properties, machinability, mobility and die-casting properties and is suitable for casting in particular to die-casting is obtained.

Owner:南通图海机械有限公司

Heatproof magnesium alloy

InactiveCN102994835AGrain refinementRetard grain growthTemperature resistanceMechanical properties of carbon nanotubes

The invention discloses a heatproof magnesium alloy, which belongs to the magnesium alloy field. The magnesium alloy is composed of Mg, Zn, Zr, rare earth, Nb, Al and M, and comprises the following components by weight: 0.2-9% of Zn, 0.1-2% of Zr, 0.0002-16% of rare earth, 0.0002-4% of Nb, 0.001-1.49% of Al, 0.001-2% of M and the balance of Mg. The M element is at least one selected in Ti, Sr, Ca, C and B. The rare earth and an Nb element are added in the magnesium alloy, and a structure of a beta phase is changed; the combined action of Zr and the M element can strongly refine the crystal grain, and Zr and M are reacted with certain impurity element (such as Si) in an alloy liquid and deposited, and the alloy liquid is purified. The combined effect of the elements enhances the high temperature resistance performance of the magnesium alloy, the heatproof magnesium alloy has excellent mechanical property and machinery processability, and good fluidity and die casting performance, and is suitable for casting the heatproof magnesium alloy and die casting of the heatproof magnesium alloy.

Owner:孙俊亚 +8

Hpdc Magnesium Alloy

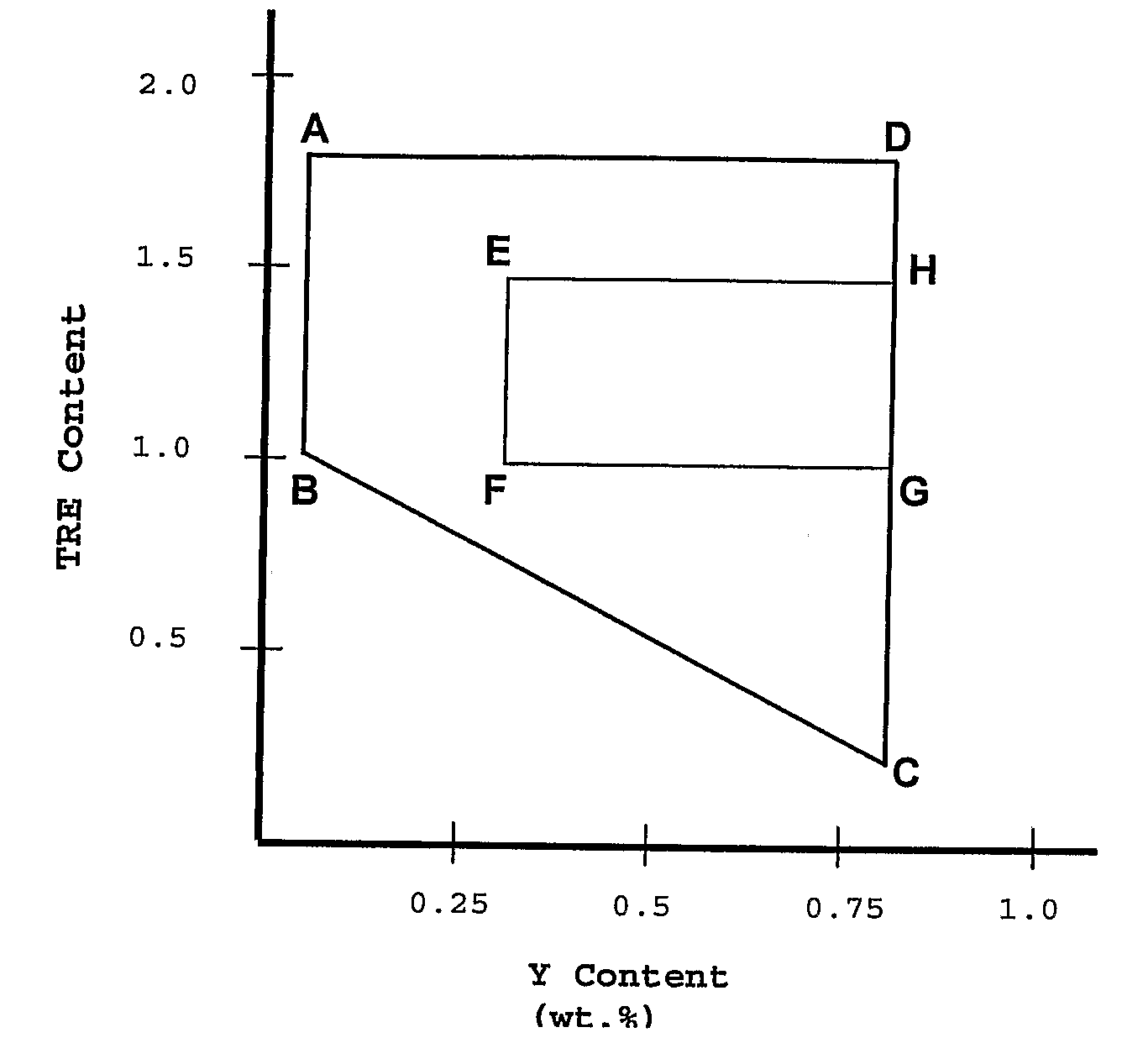

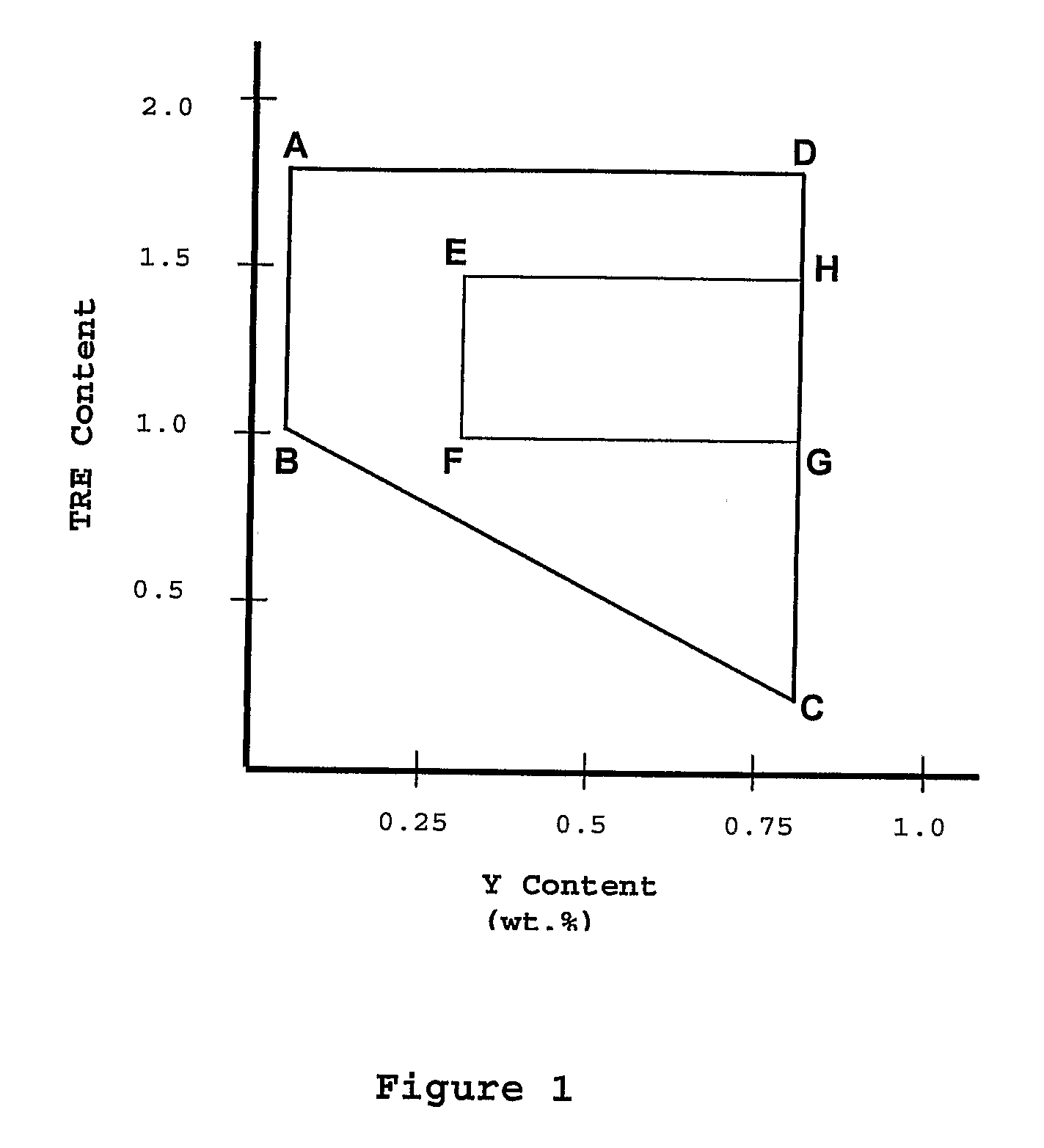

A magnesium-rare earth-yttrium-zinc alloy consists of 0.2-1.5% by weight zinc and rare earth(s) (RE) and yttrium in amounts which fall within a quadrangle defined by lines AB, BC, CD and DA wherein: A is 1.8% RE-0.05% Y, B is 1.0% RE-0.05% Y, C is 0.2% RE-0.8% Y, and D is 1.8% RE-0.8% Y.

Owner:CAST CENT PTY LTD

Die-casting heat resisting magnesium alloy and preparation thereof

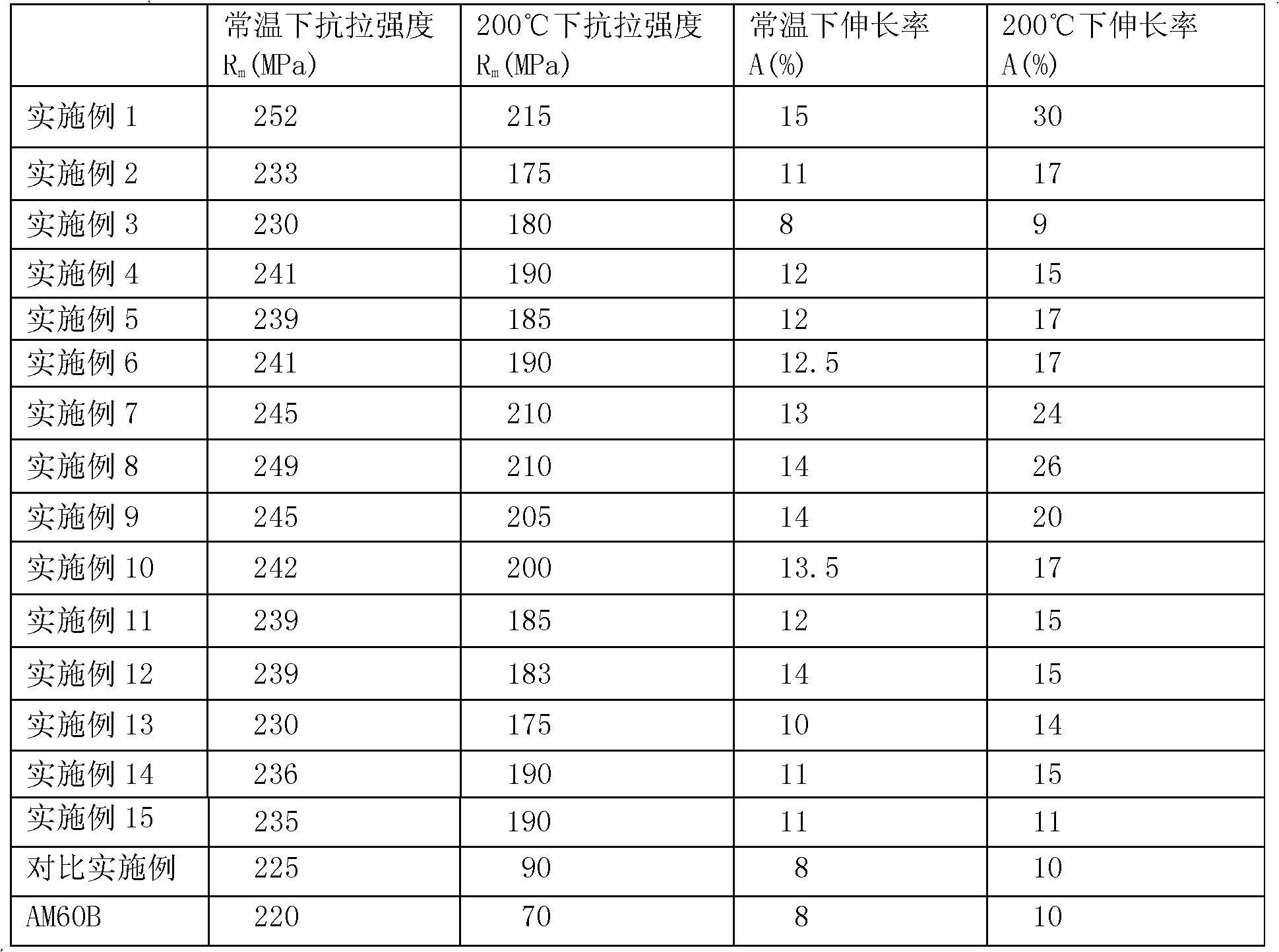

ActiveCN101353747AImprove high temperature strengthImprove plasticityMetallic materialsMagnesium alloy

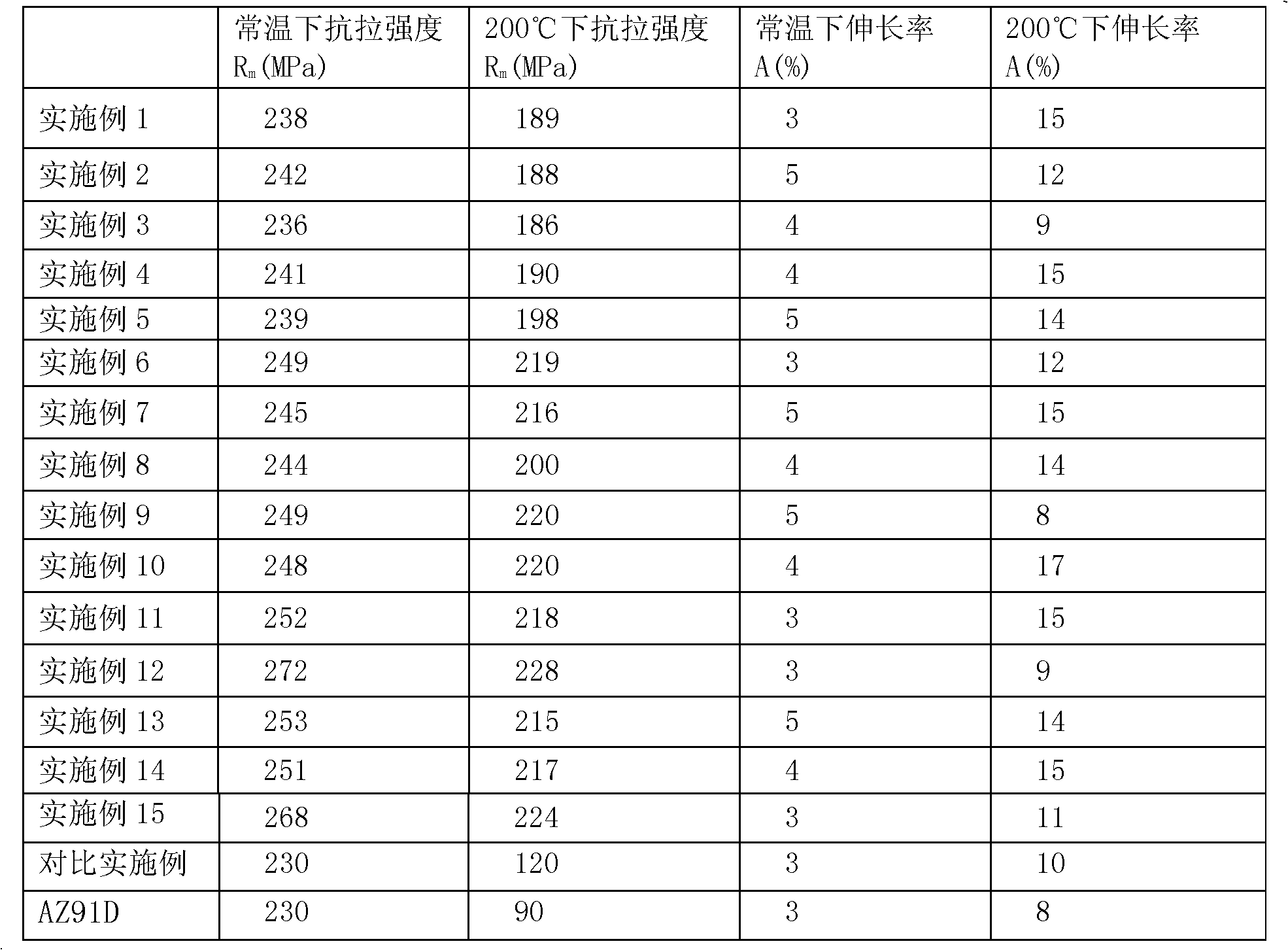

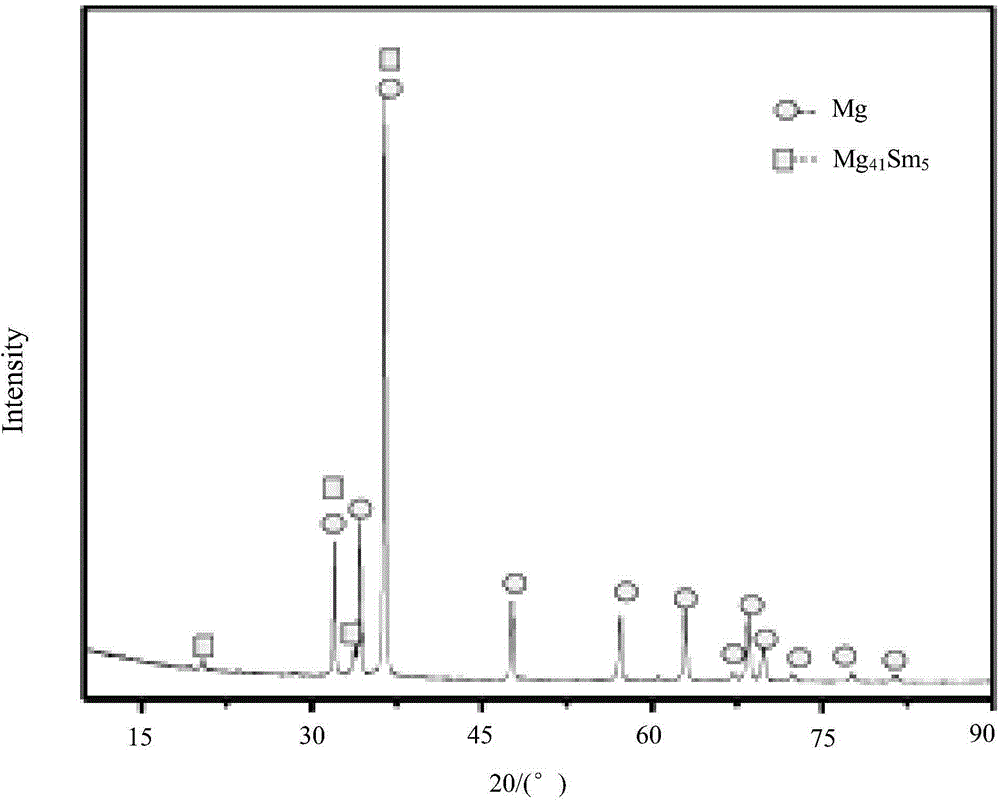

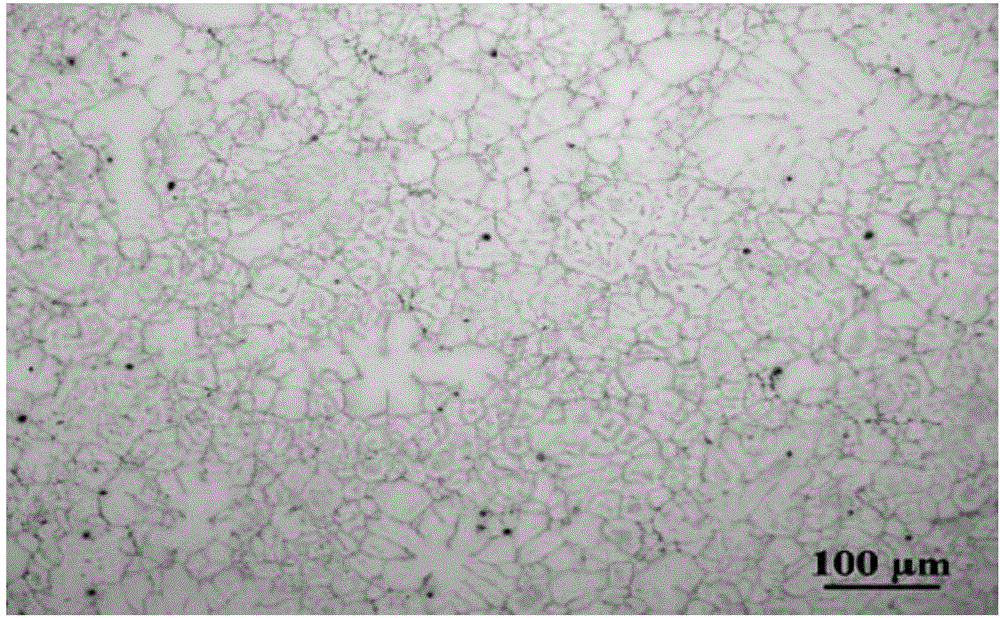

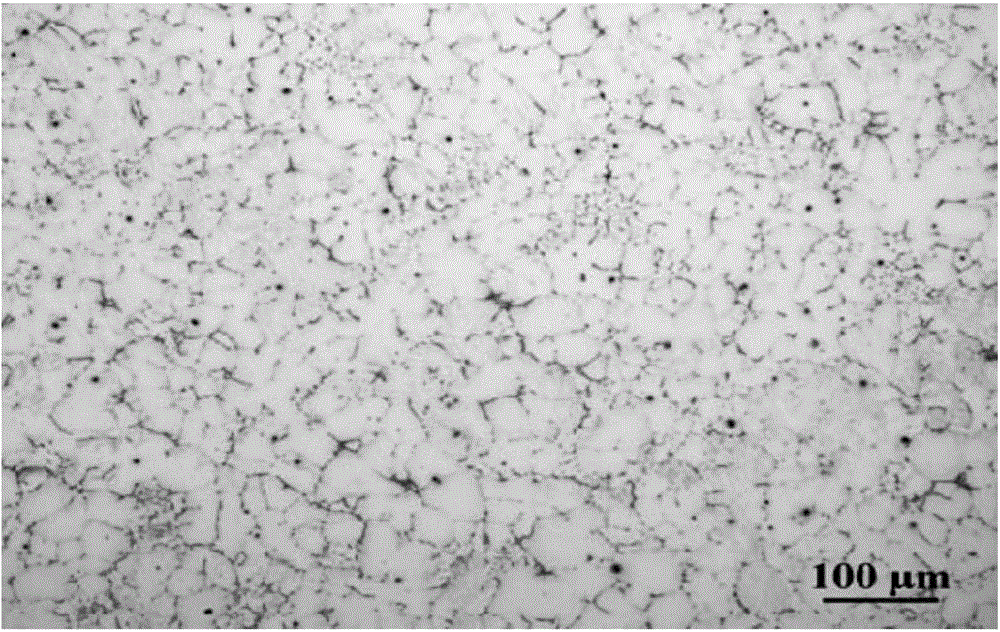

The invention relates to a die-casting heat resistant magnesium alloy and a preparation method thereof, pertaining to the metal material technology field. The components and weight percentage thereof of the alloy are as follows: 1.5 to 6.0 percent of Sm, 0 to 3.0 percent of Nd, 0 to 2.5 percent of Ca, 0.1 to 2.0 percent of Zn, 0.2 to 0.8 percent of Zr, lower than 0.02 percent of impurity elements, and the rest is Mg. The preparation method of the alloy comprises the following steps: the materials are weighed, and industrial pure Mg is heated under the protection of the mixed gas of N2 and SF6; after Mg is wholly melted, industrial pure Zn, industrial pure Ca and Mg-Sm interalloy and Mg-Nd interalloy are added at the temperature of 650 to 680 DEG C, Mg-Zr interalloy is added at the temperature of 760 DEG C, the temperature is maintained and the mixture is stirred, then the temperature is increased to 780 to 800 DEG C and maintained, after that the temperature is adjusted to 750 to 760 DEG C for refining and maintained for 30min, and when the Mg liquid is cooled to 680 to 700 DEG C, the mixture carries out die casting. The alloy of the invention has excellent tensile strength, yield strength and elongation and creep resistance simultaneously, and has good die-casting performance.

Owner:SHANGHAI JIAO TONG UNIV

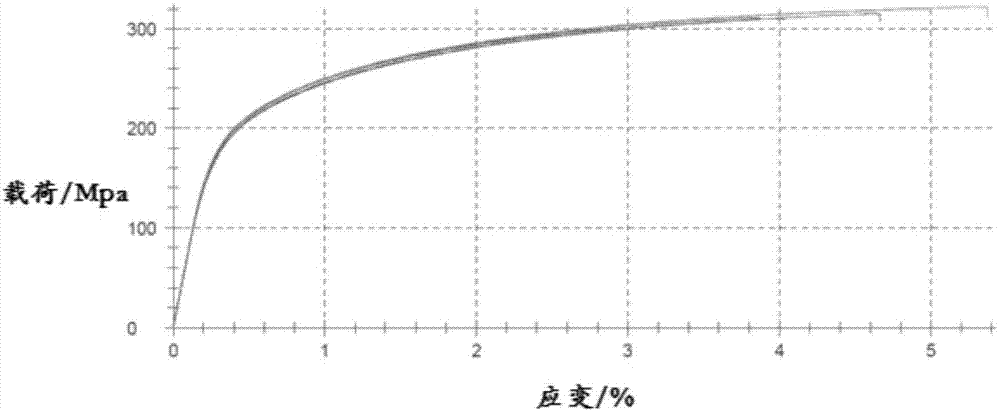

Die casting aluminum alloy with high strength and toughness as well as preparation method thereof

The invention relates to die casting aluminum alloy with high strength and toughness and a preparation method thereof. The die casting aluminum alloy with the high strength and toughness is prepared from the following components in percentage by weight: 9.0 percent to 11.0 percent of Si, 0.1 percent to 0.5 percent of Mg, 0.5 percent to 0.8 percent of Mn, 50ppm to 400ppm of Sr, 1.0 percent to 3.0 percent of Zn, 0.05 percent to 0.35 percent of Re, and less than or equal to 0.16 percent of Fe, less than or equal to 0.25 percent of other impurities, and the balance of Al. According to the Al-Si-Mn-Mg series die casting aluminum alloy, an enhancing element Zn is added, and modification is carried out by adopting an Sr / rare earth compound modifying agent, so that tissues of the alloy is improved, and the die casting aluminum alloy with high strength and high toughness, of which the yield strength is up to 160MPa, the tensile strength is up to 270MPa and an elongation ratio is up to 7 percent, can be obtained under die casting and non-heat treatment states; and moreover, the die casting aluminum alloy has high die casting performance, and application demands of parts in automobile industries can be greatly met.

Owner:SHANGHAI WANTAI AUTO PARTS +1

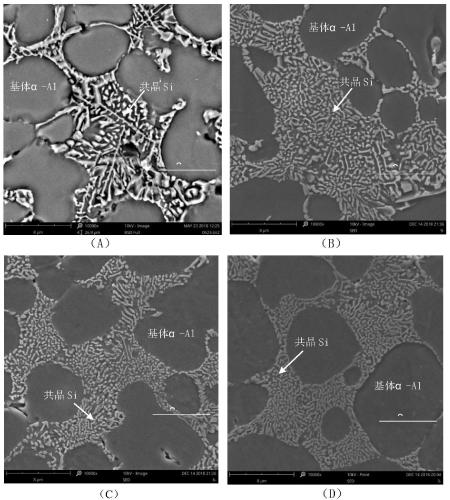

Magnesium alloy with hot cracking resistance and low linear shrinkage

The invention discloses a magnesium alloy with hot cracking resistance and low linear shrinkage, and belongs to the magnesium alloy field. The magnesium alloy is composed of elements of Mg, Al, Zn, Mn, rare earths, Nb and Li, and comprises, by weight, 1.5 to 25 percents of Al, 0.1 to 3.5 percents of Zn, 0.1 to 2.2 percents of Mn, 0.0002 to 16 percents of rare earths, 0.0002 to 4 percents of Nb, 0.0002 to 9 percents of Li, and the balance Mg. According to the magnesium alloy, the structure of Beta phase is changed by adding rare earth elements and the Nb element into the magnesium alloy; grains are refined by adding the Li element; and crystallization latent heat is changed when the magnesium alloy is solidified by the combined action of the elements, so that the heat resistant magnesium alloy which has good mold-filling capacities, low shrinkage rate, good mechanical properties, machinability, mobility and die-casting properties and is suitable for casting is obtained.

Owner:JIANGHAN UNIVERSITY

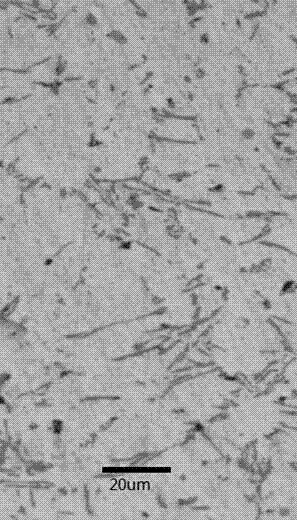

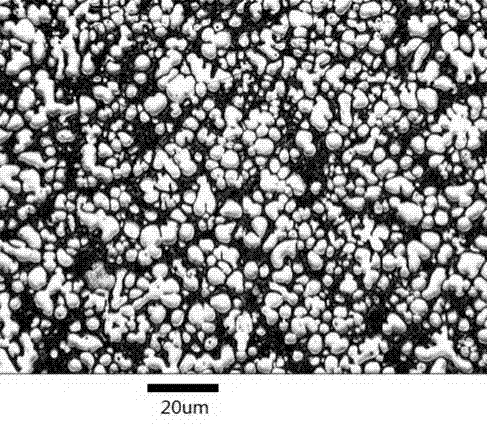

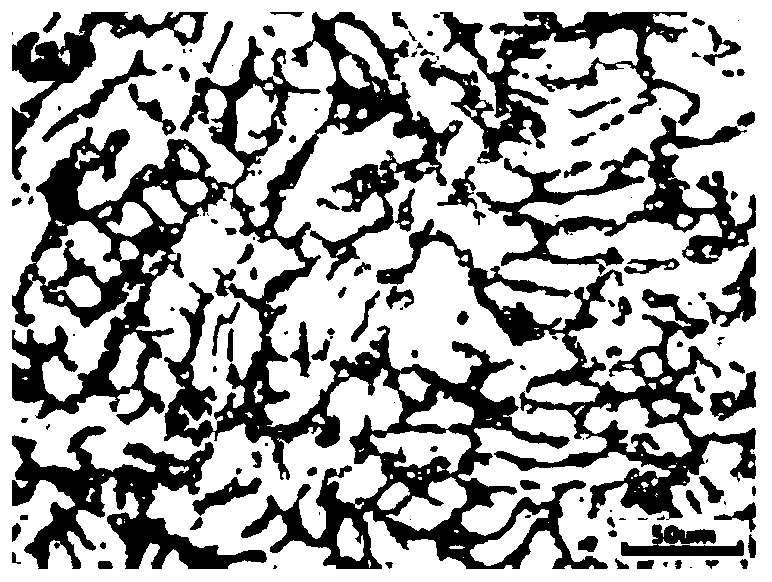

Alloy modificator for preparing metal semi-solid slurry

The invention discloses an alloy modificator for preparing metal semi-solid slurry, an alloy modificator preparation method and an alloy modificator use method. After the alloy modificator is added into the molten semi-solid slurry, the solid-to-liquid ratio of the semi-solid slurry and the content of globular crystals can be greatly increased, the preparation efficiency and the quality of the semi-solid slurry can be improved, and the quality of final die-cast products is ensured. The preparation method is simple and easy to operate, and the alloy modificator can be prepared on a large scale in simple equipment. The alloy modificator has excellent use effect and popularization significance.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL

Scandium-containing oxidable die-casting aluminium alloy, preparation method and structural part

The invention discloses a scandium-containing oxidable die-casting aluminium alloy and a preparation method thereof. The aluminium alloy comprises the following components by mass: 1-2 percent of Mn, 1-2 percent of Ni, 1-3 percent of Zn, 0.8-2 percent of Mg, 0.05-0.3 percent of Sc, 0.05-0.2 percent of Zr, 90-95 percent of Al and less than 0.15 percent of Fe and Si impurities. The invention further discloses a structural part containing the aluminium alloy. The aluminium alloy provided by the invention has the advantages of high strength, good anodic oxidation property and good die-casting property, and can be used for manufacturing thin-walled casing members meeting high appearance and performance requirements.

Owner:GUANGDONG JANUS SMART GRP CO LTD +1

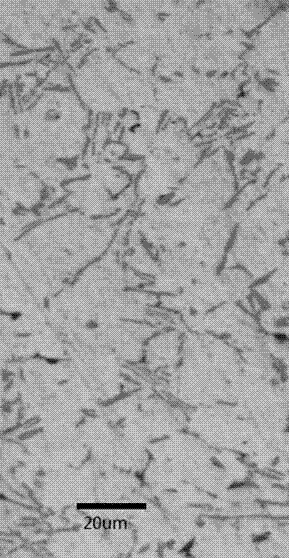

High-strength inflaming retarding pressure casting magnesium alloy and preparing method thereof

InactiveCN108385006AImprove die casting effectImprove mechanical propertiesPressure castingRare earth

The invention discloses a high-strength inflaming retarding pressure casting magnesium alloy. The high-strength inflaming retarding pressure casting magnesium alloy comprises, by weight percent, 4 to10% of Al, 0.20 to 2.0% of Ca, 0.05 to 0.90% of Zn, 0.10 to 0.50% of Y, 0.10 to 0.60% of Mn, 0 to 1.0% of La, Ce, Pr and Nd mixed rare earth, smaller than 0.003% of Fe, and the balance Mg and inevitable impurities. The magnesium alloy has the excellent pressure casting performance and mechanical performance, the tensile strength of a stretching sample reaches 300 MPa, the yield strength is 230 MPa, the ductility is 10%, the ignition point is high, 800 DEG C flame contact combustion is carried out for 180 s, observing is carried out for 60 s, the surface is softened and is not combusted, and noserious oxidation phenomenon exists; the production cost is low, toxicity and radioactivity are avoided, and the alloy can be applied to fields of car light weight, home decoration, 3C products and the like.

Owner:WENXI COUNTY REGAL MAGNESIUM

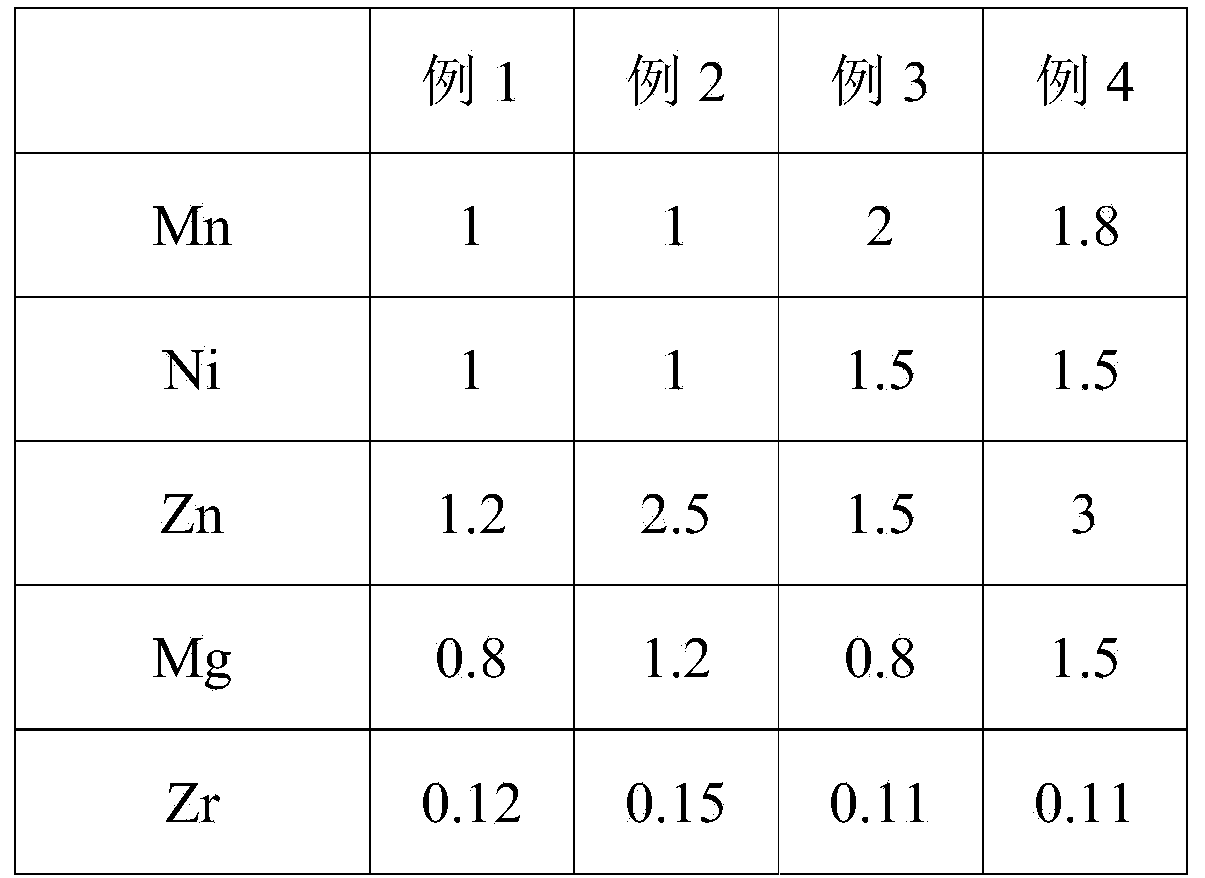

Aluminum alloy for die-casting, metal case for portable electrical device and method of manufacturing the metal case

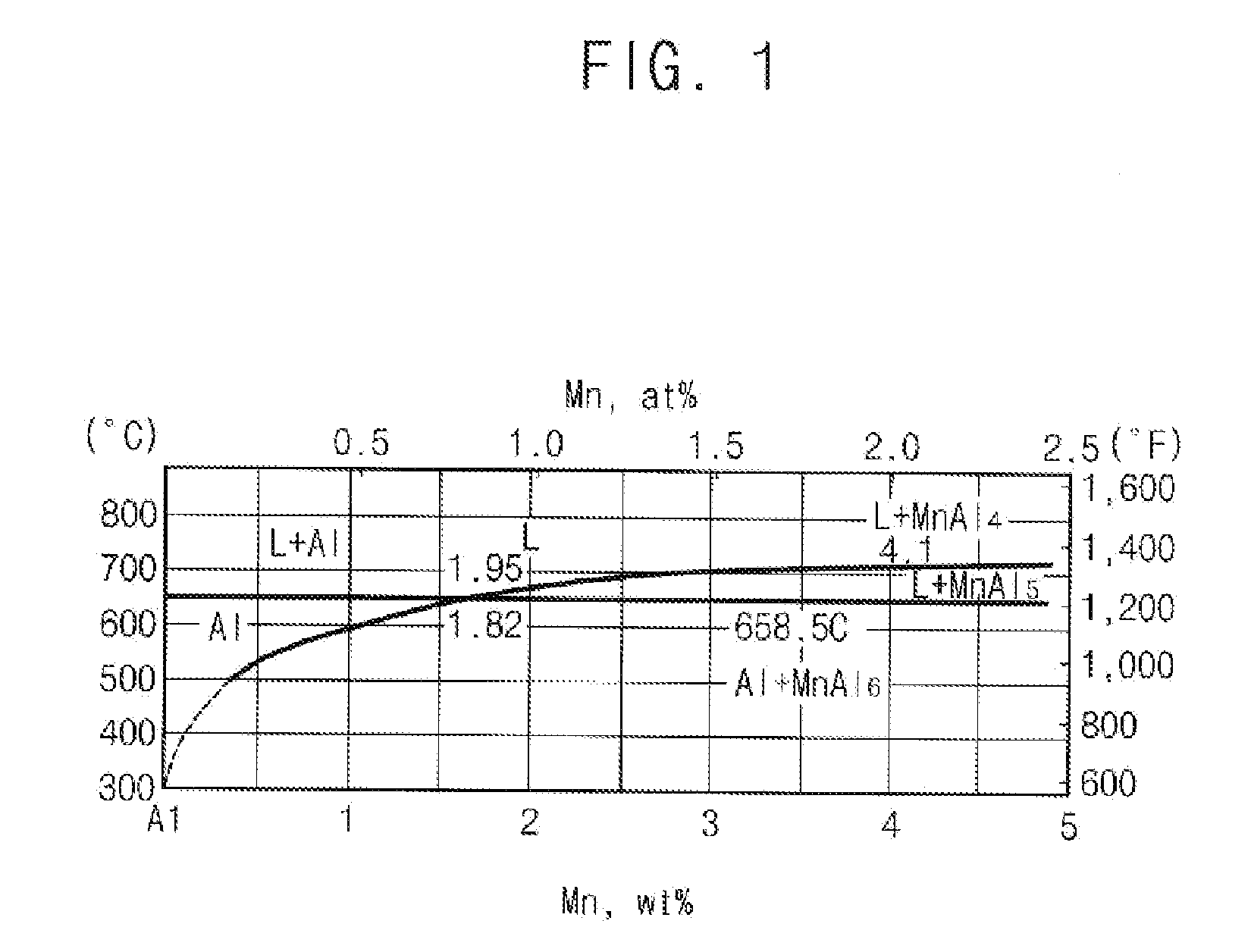

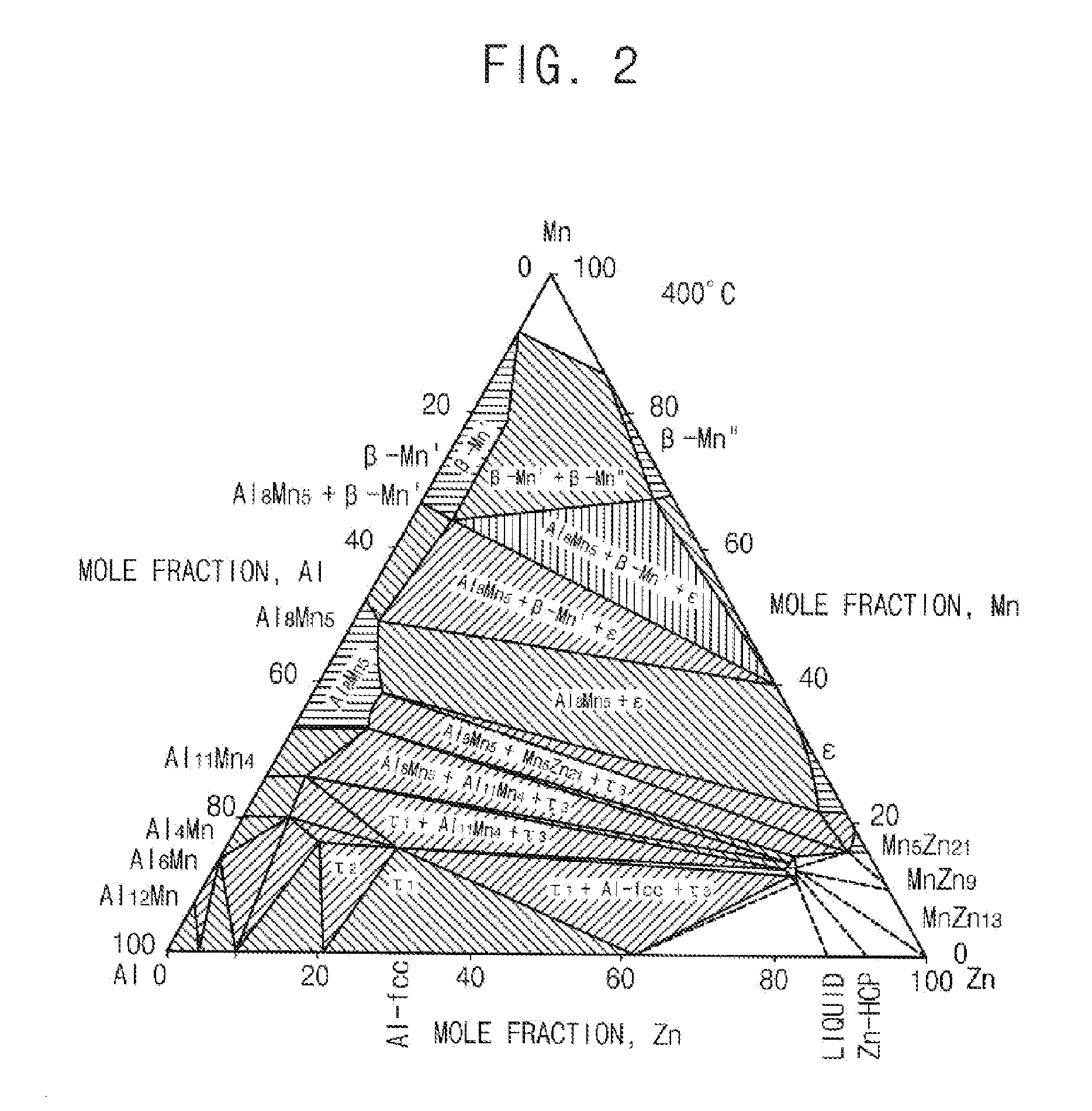

InactiveUS20150096893A1Improve die casting effectHigh strengthAnodisationDigital data processing detailsDie castingManganese

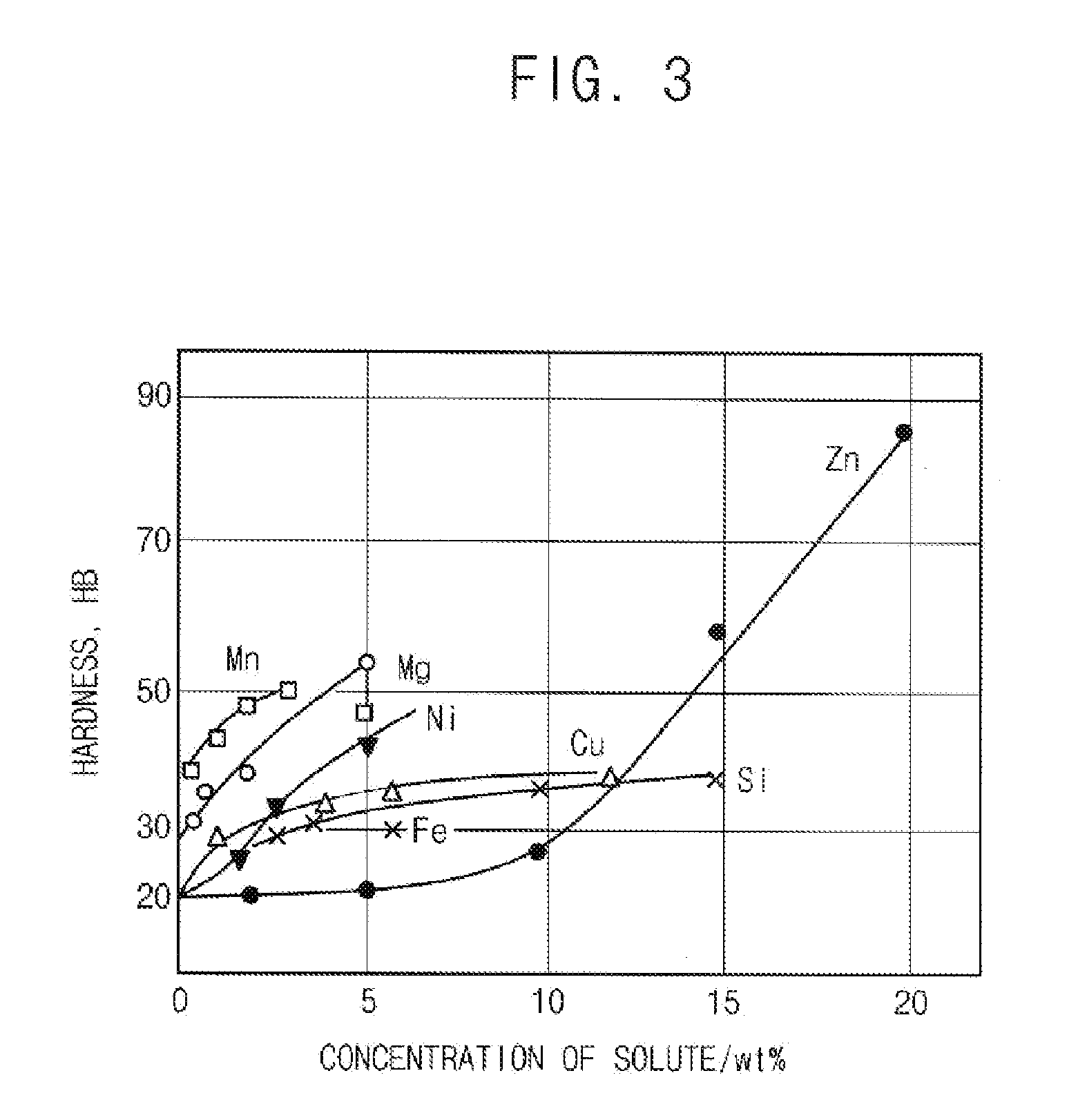

An aluminum alloy for die-casting, a metal case for a portable electrical device, and a method of manufacturing the metal case are disclosed. The aluminum alloy for die-casting includes about 1.95% to about 4.10% by weight of manganese, about 0.1% to about 2.0% by weight of zinc, about 0.3% to about 0.8% by weight of zircon, about 0.03% to about 0.09% by weight of titanium, and a remainder of aluminum. Thus, the aluminum alloy may provide a mechanical property and a glossiness that are appropriate for a case of a portable electrical device.

Owner:GK

Magnesium based alloy

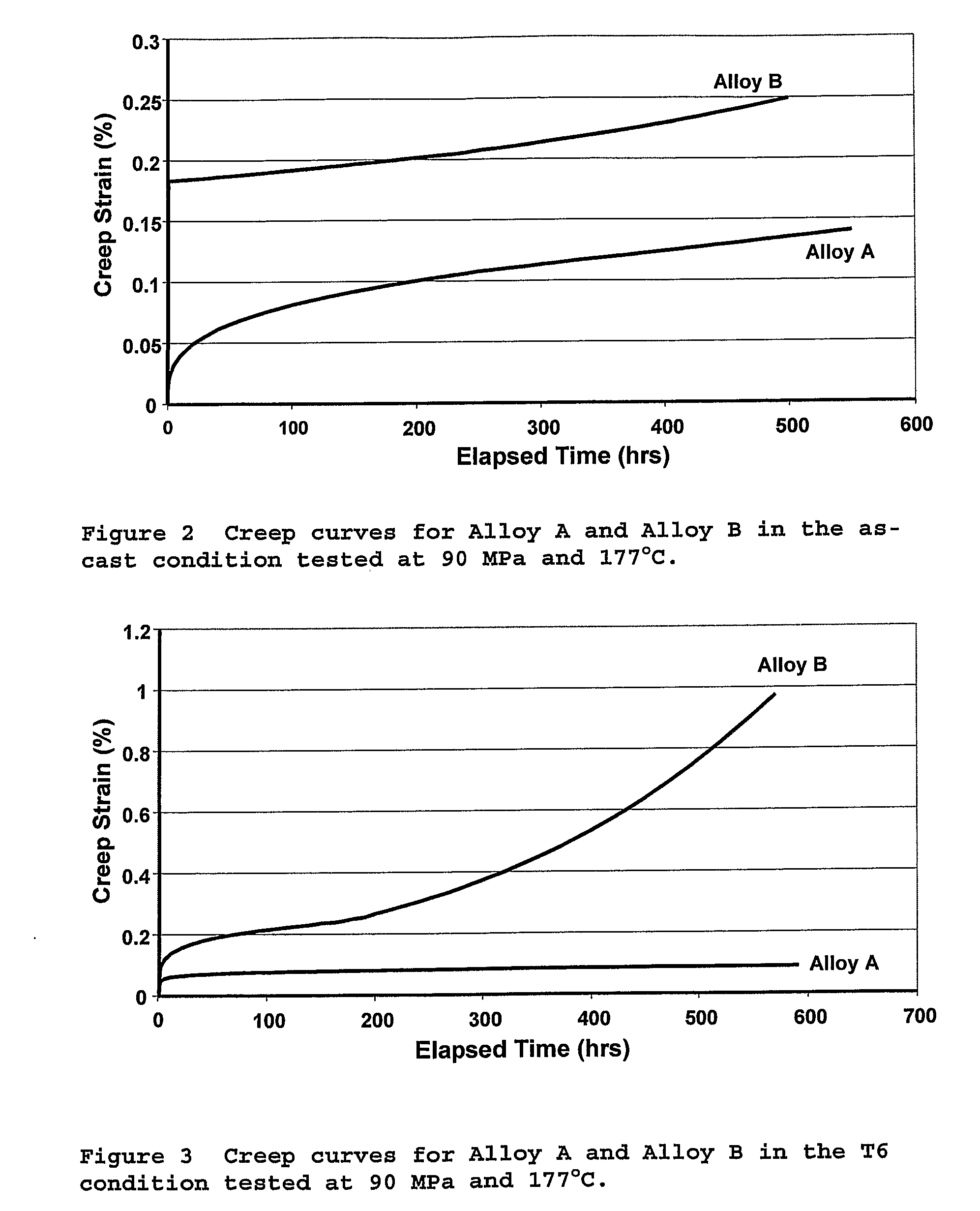

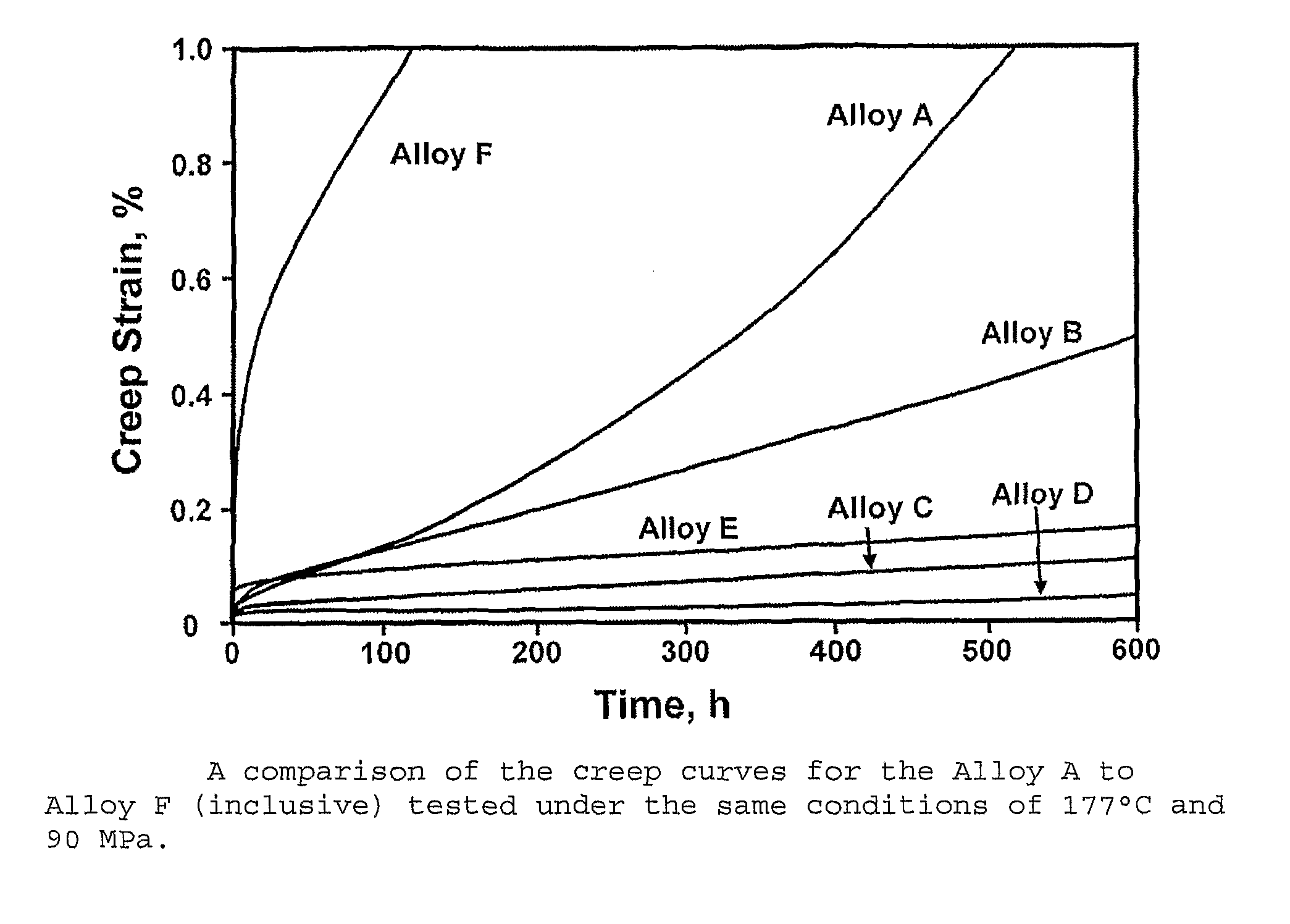

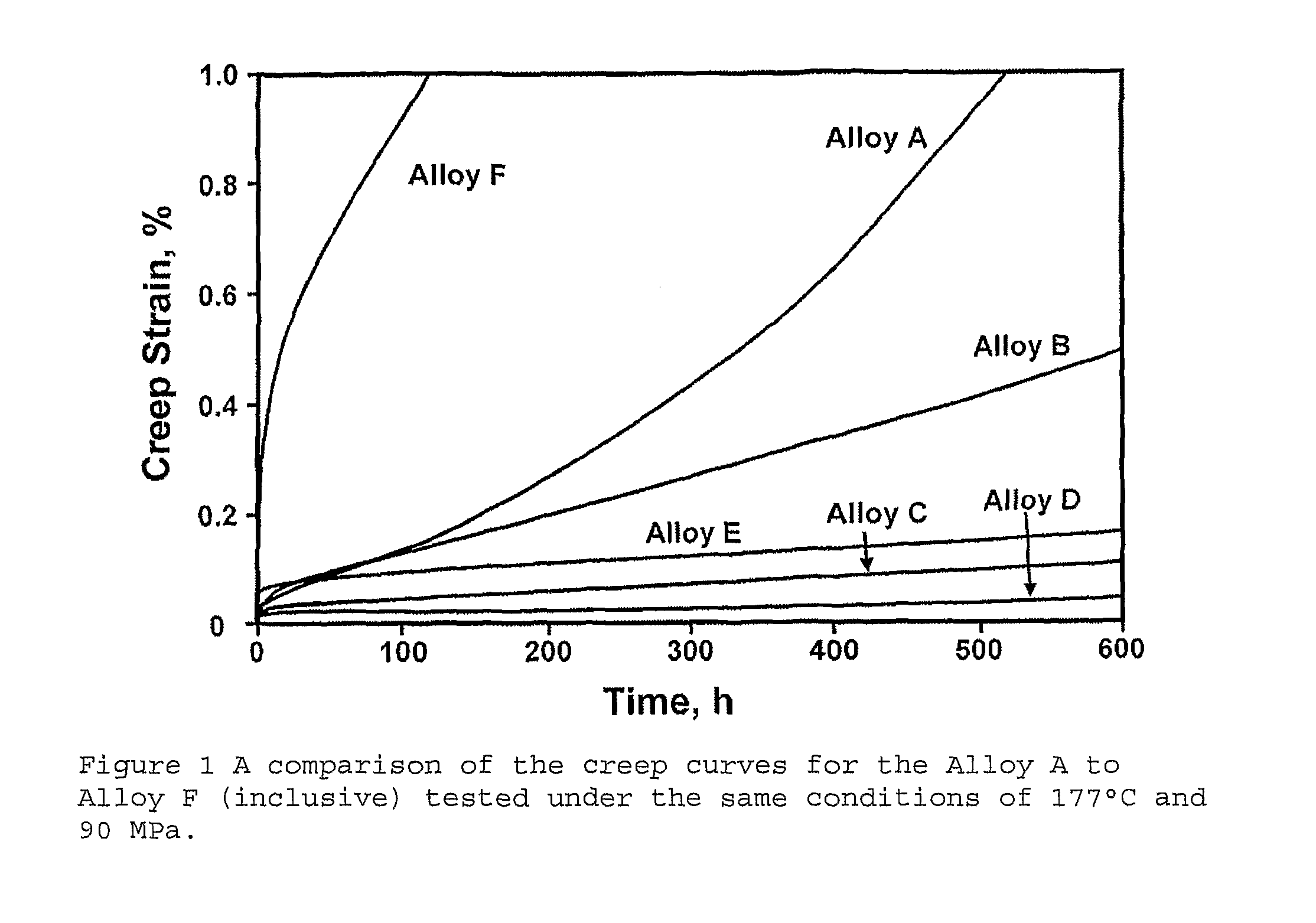

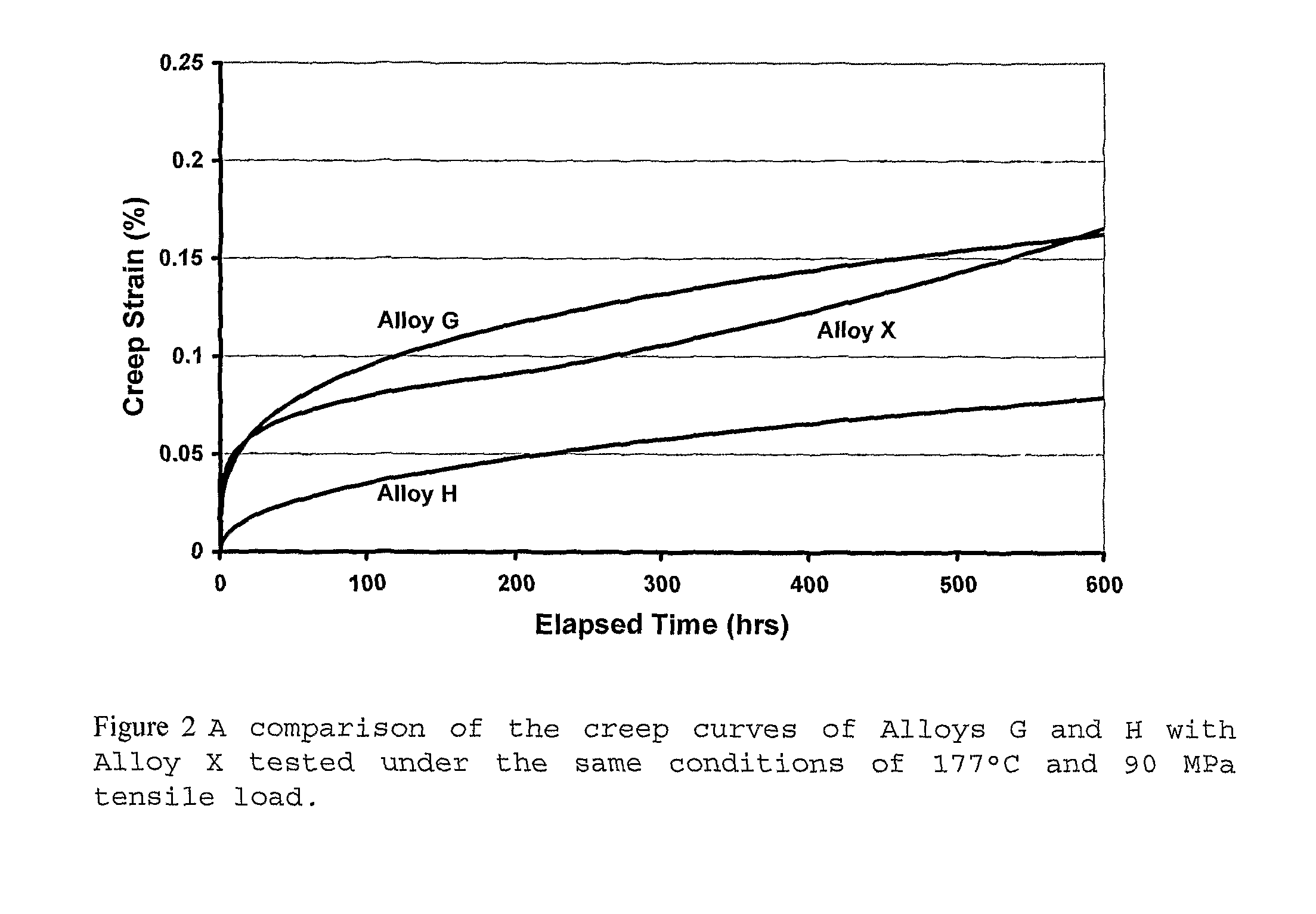

InactiveUS20100310409A1Excellent creep propertiesImprove die casting effectRare-earth elementManganese

A magnesium based alloy consisting of, by weight: 2-5% rare earth elements, wherein the alloy contains lanthanum and cerium as rare earth elements and the lanthanum content is greater than the cerium content; 0.2-0.8% zinc; 0-0.15% aluminium; 0-0.5% yttrium or gadolinium; 0-0.2% zirconium, 0-0.3% manganese; 0-0.1% calcium; 0-25 ppm beryllium; and the remainder being magnesium except for incidental impurities.

Owner:CAST CRC

High-thermal-conductivity die-casting magnesium alloy and preparation technology thereof

The invention discloses high-thermal-conductivity die-casting magnesium alloy and a preparation technology thereof. Chemical components of the high-thermal-conductivity die-casting magnesium alloy comprise, by mass, 8-13% of Zn, 0.1-1% of Ca, 0-1% of Mn, 0-1% of La, 0-1% of Ce and the balance Mg, wherein the content of Mn, the content of La and the content of Ce are not zero at the same time. The magnesium alloy is suitable for die casting and has excellent mechanical properties and high thermal conductivity, the thermal conductivity of the magnesium alloy at room temperature can reach about two times that of commonly used die-casting AZ91, and the tensile strength of the magnesium alloy is similar to that of AZ91 magnesium alloy.

Owner:BAOSHAN IRON & STEEL CO LTD

Magnesium alloy with hot cracking resistance and low linear shrinkage

The invention discloses a magnesium alloy with hot cracking resistance and low linear shrinkage, and belongs to the magnesium alloy field. The magnesium alloy is composed of elements of Mg, Zn, rare earths, Nb, Al and Li, and comprises, by weight, 0.2 to 9 percents of Zn, 0.0002 to 2 percents of Zr, 0.0002 to 16 percents of rare earths, 0.0002 to 4 percents of Nb, 0.001 to 1.49 percents of Al, 0.0002 to 9 percents of Li, and the balance Mg. According to the magnesium alloy, the structure of Beta phase is changed by adding rare earth elements and the Nb element into the magnesium alloy; grains are refined by adding the Li and Zr elements; and the crystallization latent heat is changed when the magnesium alloy is solidified by the combined action of the elements, so that the heat resistant magnesium alloy which has good mold-filling capacities, low shrinkage rate, good mechanical properties, machinability, mobility and die-casting properties and is suitable for casting is obtained.

Owner:嘉兴佳斯贝特新材料有限公司

Aluminum alloy pressure-cast door plank and preparation method thereof

The invention belongs to the field of machining of alloy materials and discloses an aluminum alloy pressure-cast door plank. The aluminum alloy pressure-cast door plank is prepared from the following raw materials in percentage by weight: 4.1%-4.3% of magnesium, 1.8%-2.1% of manganese, 0.8%-0.9% of zinc, 0.6%-0.7% of copper, 0.3%-0.4% of nickel, 0.1%-0.2% of white graphite, 0.04-0.05% of cerium, 0.04%-0.05% of yttrium, 0.02%-0.03% of samarium, 0.01%-0.02% of silicon dioxide and the balance of aluminum. The aluminum alloy pressure-cast door plank is high in mechanical strength, can resist corrosion and is unlikely to be oxidized and change color; the preparation method is simple, feasible and suitable for large-scale production.

Owner:宋守宝

Heatproof magnesium alloy

InactiveCN102994847AImprove high temperature resistanceGood mechanical propertiesBeta phaseRare earth

The invention discloses a heatproof magnesium alloy, which belongs to the magnesium alloy field. The magnesium alloy is composed of Mg, Zn, Zr, rare earth, Nb and Al, and comprises the following components by weight: 0.2-9% of Zn, 0.1-2% of Zr, 0.0002-16% of rare earth, 0.0002-4% of Nb, 0.001-1.49% of Al and the balance of Mg. The rare earth and an Nb element are added in the magnesium alloy, and a structure of a beta phase is changed; the Zr can strongly refine the crystal grain, and is reacted with certain impurity element (such as Si) in an alloy liquid and deposited, and the alloy liquid is purified. The combined effect of the elements enhances the high temperature resistance performance of the magnesium alloy, the heatproof magnesium alloy has excellent mechanical property and machinery processability, and good fluidity and die casting performance, and is suitable for casting the heatproof magnesium alloy and die casting of the heatproof magnesium alloy.

Owner:YANGZHOU JINCHEN STAINLESS STEEL MFR

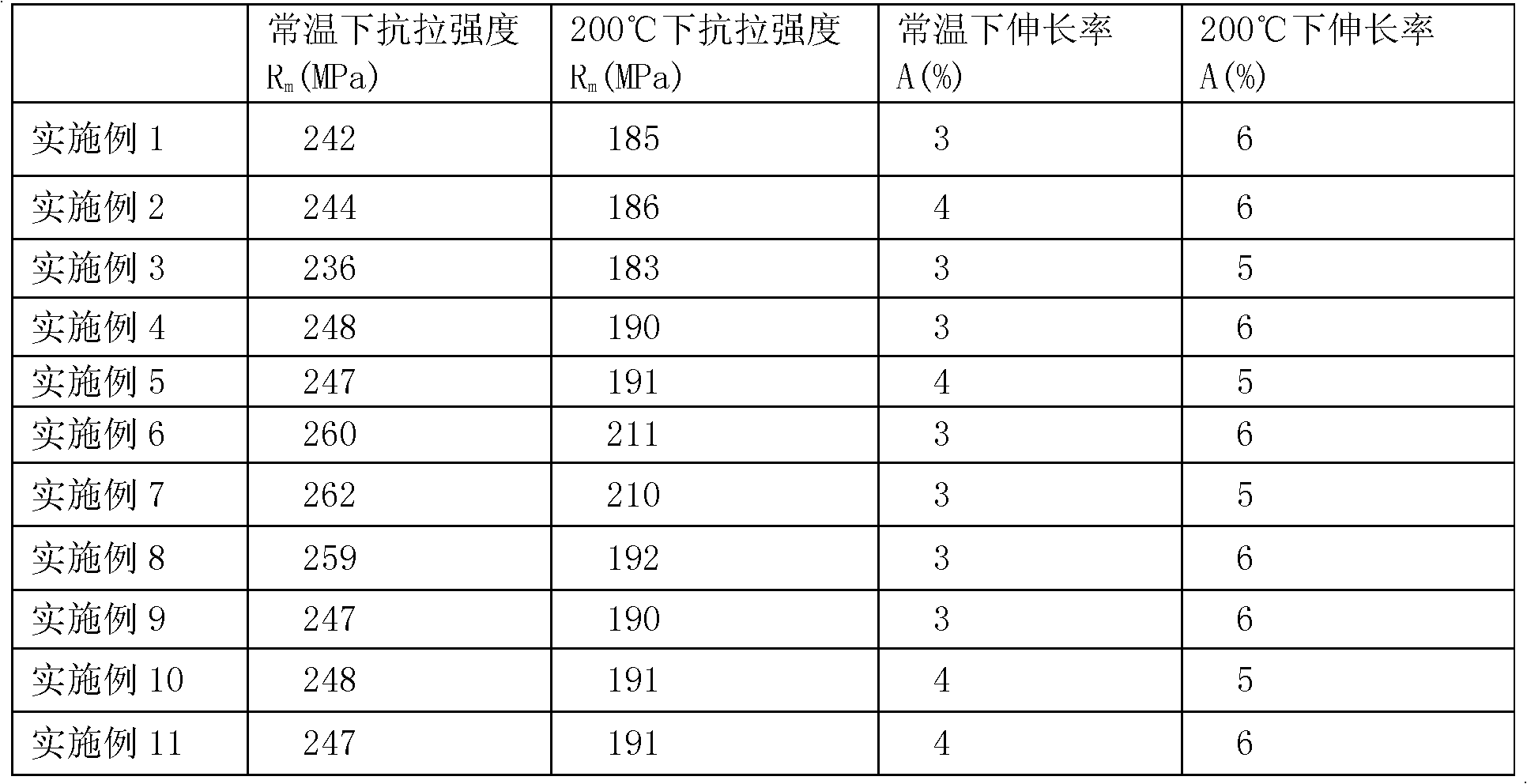

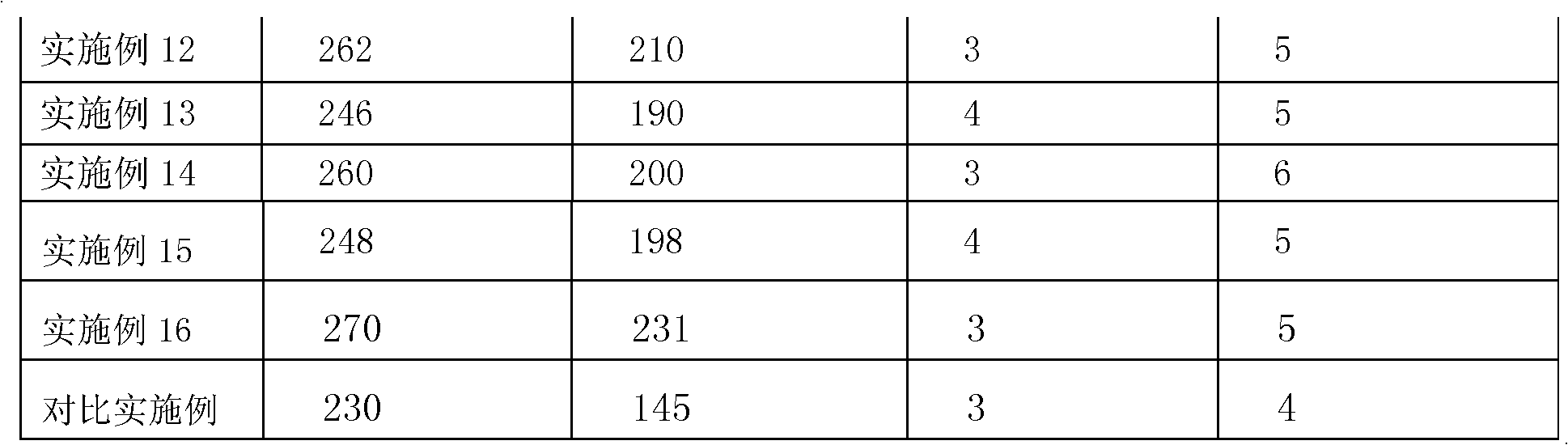

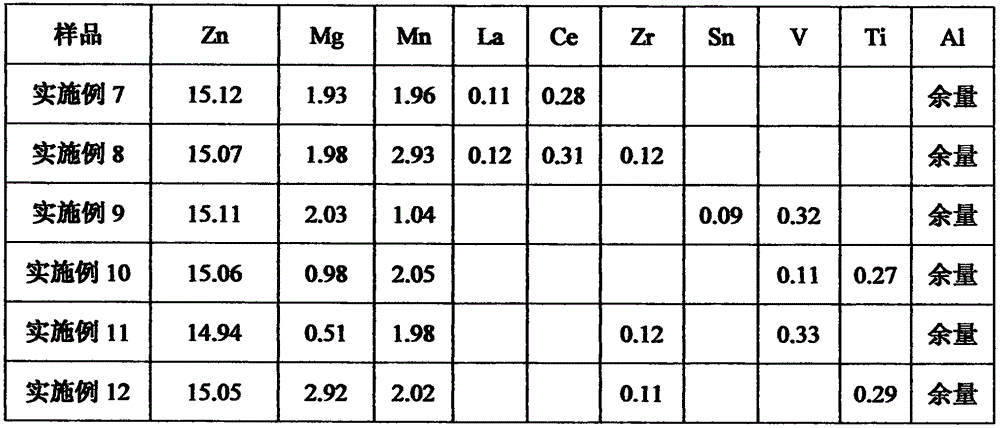

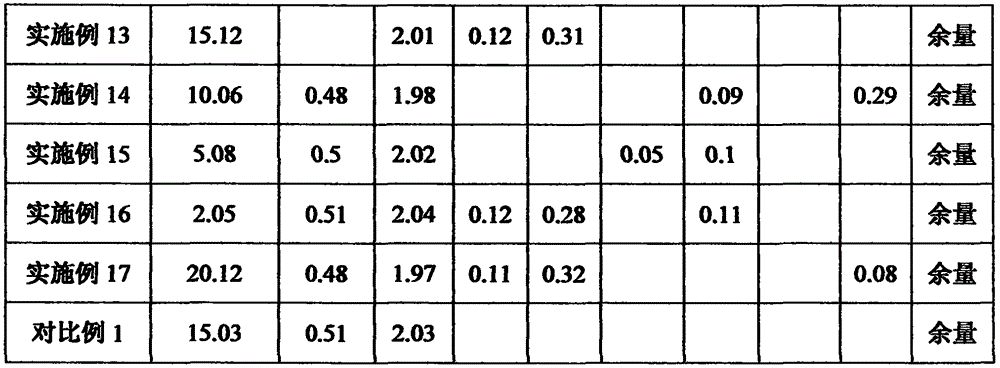

Aluminum alloy capable of being subjected to pressure casting and anodizing

The invention discloses an aluminum alloy capable of being subjected to pressure casting and anodizing. The mass ratio formula of the aluminum alloy is ZnMgMn<c>M<d>Al<e>, wherein M is one or more of Cr, Zr, Cu, Ti, rare earth elements, V, Co, Ni, Sn, Nb, Mo, Fe, Si, B, In, Ca and Be, a is not smaller than 0.1% but not larger than 20%, b is not smaller than 0% but not larger than 4%, c is not smaller than 0.1% but not larger than 4%, d is not smaller than 0% but not larger than 5%, and the balance e. The aluminum alloy capable of being subjected to pressure casting and anodizing is good in fluidity and pressure casting performance and can be easily machined in the later period; a semi-finished product obtained after pressure casting can be subjected to anodizing and colored with various colors, and the aluminum alloy is a high-quality aluminum alloy applied to products with high appearance requirements. By adjusting the ratio, it is guaranteed that while the alloy can be subjected to anodizing, comprehensive performance of the alloy can meet the pressure casting technique, and thin-wall products can be produced.

Owner:金利合金制造工业(宁波)有限公司

High-strength anodizing die-casting aluminium alloy and preparation method thereof

ActiveCN107447134ATo promote floatingImprove filtration efficiency5005 aluminium alloy6061 aluminium alloy

The invention belongs to the technical field of aluminium alloy and particularly relates to high-strength anodizing die-casting aluminium alloy and a preparation method thereof. Mg, Mn, Fe, Zn, Mo, Zr, Cr and Al constitute die-casting alloy elements, and the high-strength anodizing die-casting aluminium alloy is prepared by a smelting procedure and a die-casting procedure. The types, the contents and the adding modes of all the alloy elements are strictly controlled, so that lots of the elements mainly exist in a matrix in a solid solution format under the die-casting (fast cooling) condition; Zr and Mo ensure more uniform alloy tissue and refined crystal grains, so that the alloy has high strength and favorable die-casing performance and excellent anodizing performance; on a die-casting machine, die-casting molding can be performed by a die to directly obtain the required product without heat treatment or deformation, so that the production cost is greatly lowered; and the high-strength anodizing die-casting aluminium alloy is suitable for thin-walled shell members demanding much on the strength, the die-casting performance and the anodizing demand of the aluminium alloy.

Owner:苏州慧驰轻合金精密成型科技有限公司

MgAlZn heat resistance magnesium alloy

The invention discloses an MgAlZn heat resistance magnesium alloy, which belongs to the magnesium alloy field. The magnesium alloy is composed of Mg, Al, Zn, Mn, rare earth and Nb with the mass percentage: 1.5-18% of Al, 0.1-3.5% of Zn, 0.1-2.2% of Mn, 0.0002-8% of rare earth, 0.0002-2.2% of Nb and the balance of Mg. According to the invention, rare earth and Nb element are added in the magnesium alloy, a structure of a beta phase is changed, thereby the high temperature resistance performance of the magnesium alloy can be enhanced, so that the heat resistance magnesium alloy which is suitable for casting, especially suitable for die casting with characteristics of excellent mechanical property, good machinery processability, fluidity and die casting performance can be acquired.

Owner:WUHAN TIEMENG MACHINERY & ELECTRICITY

Magnesium alloy and preparing method thereof

The invention discloses a magnesium alloy. The magnesium alloy comprises, by weight percentage, 0-0.1% of Zn, 2%-4% of Sm, 0.1%-0.8% of Zr, 0-0.2% of impurities and the balance Mg. The invention further discloses a preparing method for the magnesium alloy. The thermal conductivity of the magnesium alloy at 25 DEG C is larger than 110 W (m.k)<1>, and the magnesium alloy has the excellent heat-conducting property; in addition, only a small amount of Sm, Zr and Zn are added in the magnesium alloy, the types and the using amounts of the added metal elements are fewer, and the cost is greatly reduced; moreover, at 25 DEG C, the strength of extension of the magnesium alloy ranges from 175 MPa to 230 MPa, the yield strength ranges from 102 MPa to 130 MPa, the ductility ranges from 6% to 11%, and the mechanical property is good; and the rate of finished products of castings ranges from 85% to 95%, and the pressure casting performance is good.

Owner:ZTE CORP +1

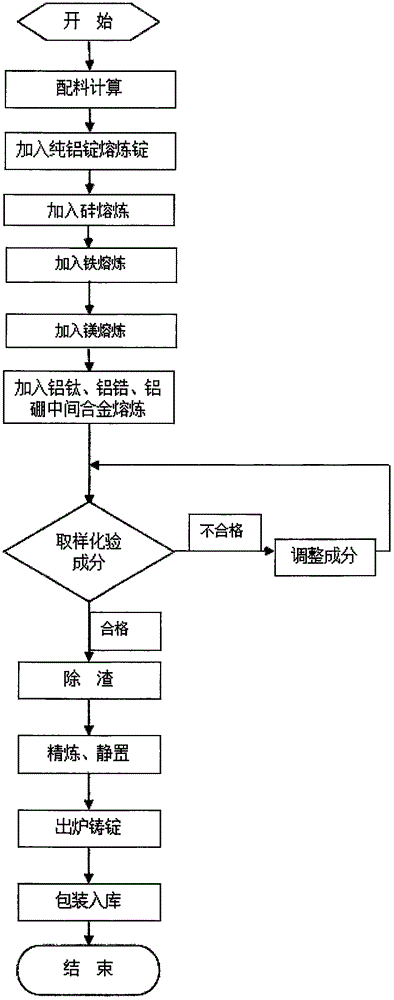

High thermal conductivity aluminum alloy and preparation method thereof

The invention discloses a high thermal conductivity aluminum alloy and a preparation method thereof. The high thermal conductivity aluminum alloy is composed of the following components in percentages by weight: 9-9.5% of silicon, 0.35-0.55% of magnesium, 0.35-0.55% of ferrum, 0.35-0.5% of manganese, less than or equal to 0.005% of copper, 0.01-0.02% of boron, 0.01-0.02% of titanium, 0.01-0.02% of zirconium, less than 0.03% of zinc and the balance of aluminum. The preparation method comprises the following steps: mixture calculation; smelting by a smelting furnace; refining and degassing; and modification. Compared with the prior art, the high thermal conductivity aluminum alloy disclosed by the invention has the advantages that the aluminum-titanium alloy disclosed by the invention has the advantages of good flowability, excellent mechanical property, high thermal conductivity coefficient, good corrosion resistance, good machining property, low cost of raw materials and the like, can be widely applied to electronic, electric, communication and mechanical and electronic industries, can effectively guarantee the radiating working performance of a heating apparatus, and plays a good role of prolonging the service lives of electronic and electric products and lowering the production cost.

Owner:马鸿斌

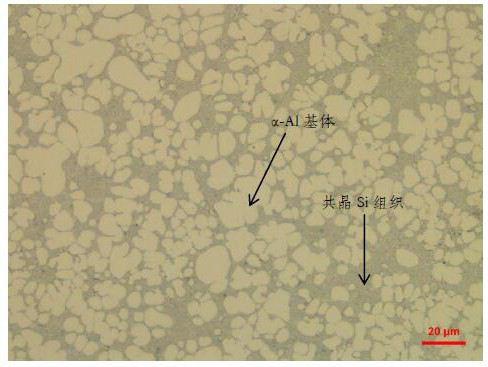

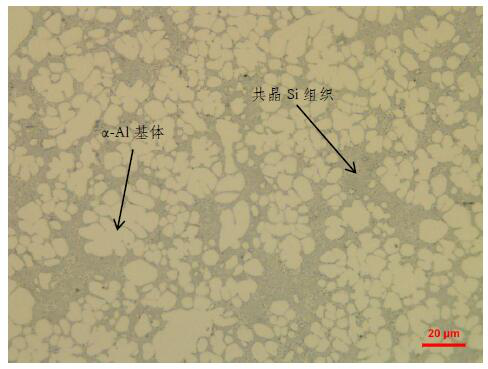

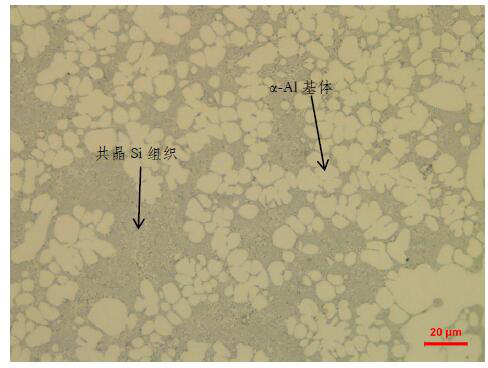

High-strength high-thermal-conductivity AlSi aluminum alloy and preparation method thereof

The invention relates to a high-strength and high-thermal-conductivity AlSi aluminum alloy and a preparation method thereof, and the high-strength and high-thermal-conductivity AlSi aluminum alloy comprises the following components in percentage by mass: 0.15%-0.65% of Cu, 8.5%-11.5% of Si, 0.35%-0.55% of Mn, 0.3%-0.55% of Mg, less than or equal to 0.25% of Fe, less than or equal to 0.15% of Zn, less than or equal to 20 ppm of Ca, less than or equal to 20 ppm of P, 0.010%-0.035% of Sr, 0.0045%-0.01% of B, 0.015%-0.035% of La + Ce and the balance of Al and impurities, and the total content of the impurities is less than or equal to 0.15%. The invention has the following advantages: on the premise of ensuring good casting performance, the die casting has excellent comprehensive mechanical properties and heat-conducting properties, thereby meeting the harsh performance requirements of motor shells and electric control shells of new energy vehicles.

Owner:南通鸿劲金属铝业有限公司

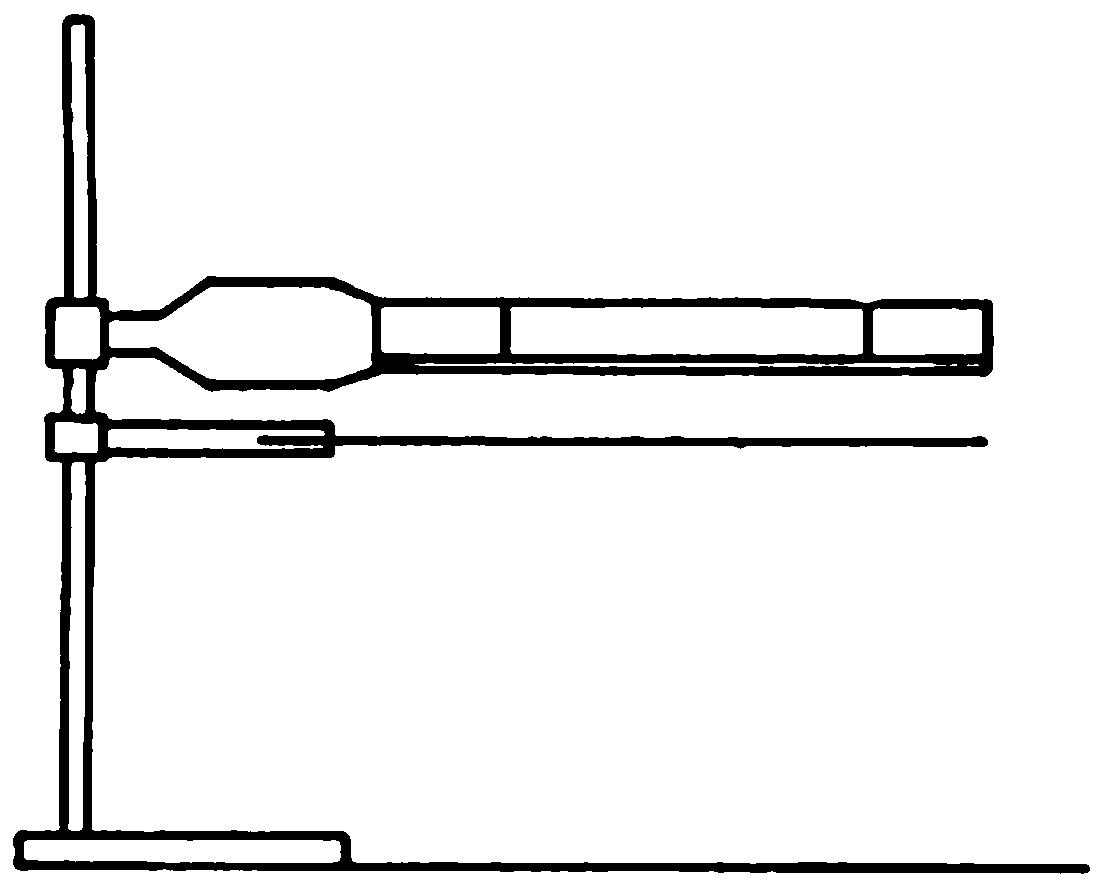

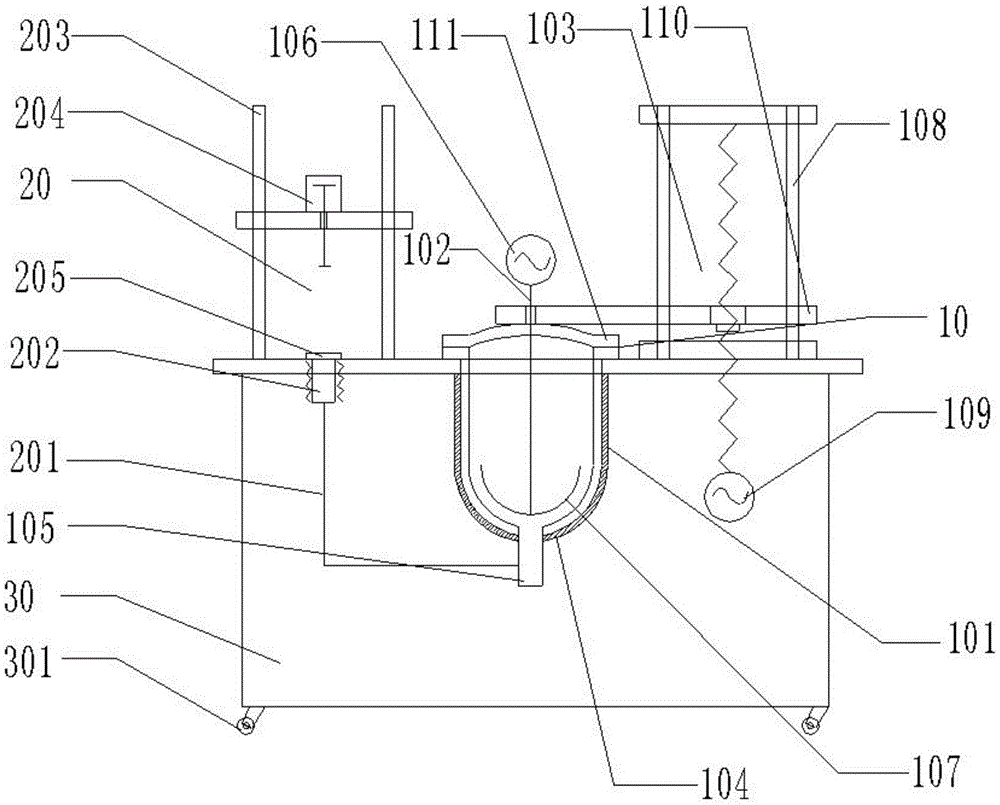

Integrated device of hot injection molding technology

ActiveCN105538481AImprove the heating effectImprove insulation effectShaping press ramCement mixing apparatusDie castingEngineering

The invention provides an integrated device of the hot injection molding technology. The integrated device of the hot injection molding technology comprises a stirring material preparing system, a die casting system and a machine shell. The stirring material preparing system comprises a stirring tank, a stirring machine and a lifting machine. A tank body of the stirring tank is arranged to have an inner layer and an outer layer, and a cavity is formed between the outer layer of tank body and the inner layer of tank body. The cavity is filled with heat conduction silicone oil, and a heater and a temperature sensor are arranged. A discharging opening is further formed in the bottom of the stirring tank. The die casting system comprises a material liquid pipeline, a material outlet, a support and a pressing device. The material liquid pipeline is arranged between the discharging opening and the material outlet. The material outlet is formed in the upper surface of the machine shell and is further formed in the central axis of the support. The support is arranged on the upper surface of the machine shell. The pressing device is arranged in the center of a beam of the support and corresponds to the material outlet. By means of the integrated device of the hot injection molding technology, it is ensured that the temperature of material liquid is uniform through oil bath heating of the stirring tank and a heating belt on the material liquid pipeline, and in addition, the automation degree of the device is relatively high.

Owner:CHINA TIANBO

Heatproof casting magnesium alloy

The invention discloses a heatproof casting magnesium alloy, which belongs to the magnesium alloy field. The magnesium alloy is composed of Mg, Al, Mn, rare earth and Nb, and comprises the following components by weight: 1.5-25% of Al, 0.13-2% of Mn, 0.001-16% of rare earth, 0.001-4% of Nb and the balance of Mg. The rare earth and an Nb element are added in the magnesium alloy, and a structure of a beta phase is changed; thereby the high temperature resistance performance of the casting magnesium alloy is enhanced, the heatproof casting magnesium alloy has excellent mechanical property and machinery processability, and good fluidity and die casting performance.

Owner:余姚市海帮五金科技有限公司

High-strength and high-toughness die-casting aluminum-silicon alloy and preparation method thereof

The invention discloses a high-strength and high-toughness die-casting aluminum-silicon alloy and a preparation method thereof. The high-strength and high-toughness die-casting aluminum-silicon alloy comprises the following components in percentage by mass: 8.5-11.5% of Si, 1.0-3.0% of Cu, 0.5-1.5% of Zn, 0.2-0.6% of Mg, 0.01-0.1% of B, 0.1-0.22% of La, 0.02-0.08% of Sr, 0.4-0.7% of Mn, not more than 0.2% of Fe, and the balance of Al and inevitable impurities. The high-strength and high-toughness die-casting aluminum-silicon alloy has relatively high strength and toughness, can be widely applied to automobiles, and especially can be applied to chassis and automobile body structural parts with high requirements for strength and toughness.

Owner:成都慧腾创智信息科技有限公司

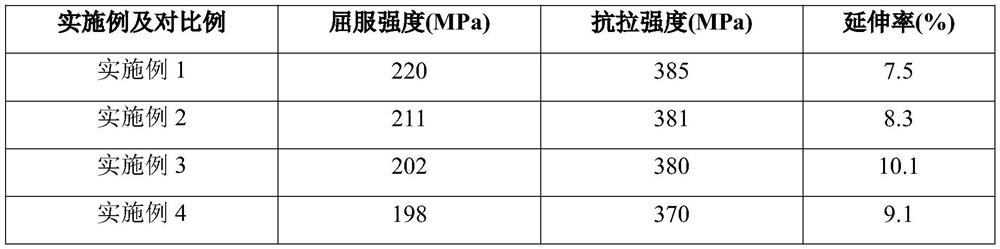

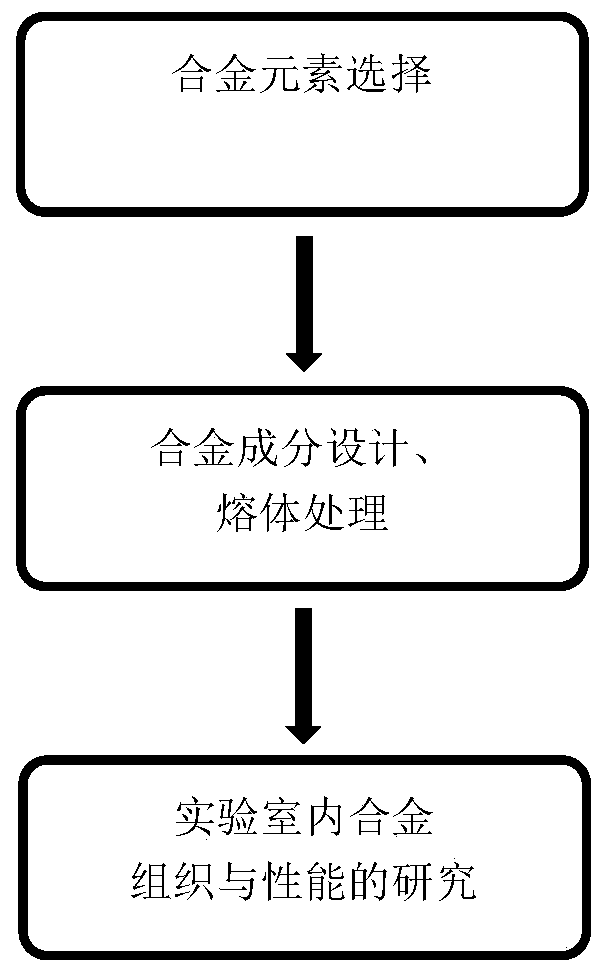

Novel high-performance die-casting zinc alloy material

The invention relates to a novel high-performance die-casting zinc alloy material, and particularly relates to a novel zinc alloy material suitable for die casting. The zinc alloy novel material comprises the following components in mass percentage by adjusting the percentage content of Al and being matched with a melt treatment process: 3.3-4.3% of Al, 0.02-0.06% of Mg, no more than 0.1% of Fe, no more than 0.005% of Pb, no more than 0.003% of Sn, no more than 0.004% of Cd and the balance Zn. The novel high-performance die-casting zinc alloy material has the higher tensile performance compared with an existing third zinc alloy, and meanwhile, the higher die-casting performance and the lower cost are achieved.

Owner:太仓宝祥有色金属制品厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com