Magnesium alloy with hot cracking resistance and low linear shrinkage

A linear shrinkage, magnesium alloy technology, applied in the field of magnesium alloys, can solve problems affecting the application of cast magnesium alloys, affect the pass rate of magnesium alloy parts, and the castings will break when the mold is opened, and achieve excellent filling ability, liquid volume and solid state. Effect of small volume change and small internal thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The magnesium alloy is prepared according to the steps described in the above-mentioned process one, and the casting adopts metal mold casting, and the weight percentage of the magnesium alloy is composed of Al 1.5%, Zn 0.1%, Mn 0.1%, Y 0.0002%, Nb 0.0002%, Li 0.0002%, The remainder is Mg.

[0028] Castings are heat treated.

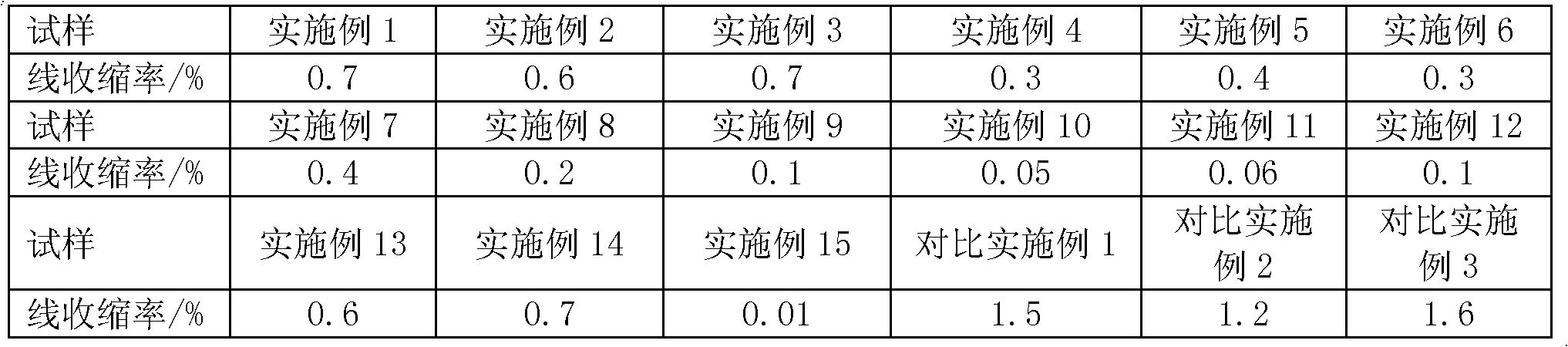

[0029] See Table 1 for the properties of the magnesium alloy castings provided in this example.

Embodiment 2

[0031] The magnesium alloy is prepared according to the steps described in the above process two, and the casting adopts semi-solid casting, and the weight percentage of the magnesium alloy is composed of Al 25%, Zn 3.5%, Mn 2.2%, Sc 16%, Nb 4%, Li 9%, The remainder is Mg.

[0032] Castings are heat treated. See Table 1 for the properties of the magnesium alloy castings provided in this example.

Embodiment 3

[0034] Prepare the magnesium alloy according to the steps described in the above-mentioned process two, the casting adopts high-pressure die-casting, the weight percentage of the magnesium alloy is composed of Al3.5%, Zn 3%, Mn 2%, Sm 5%, Nb 2%, Li 7%, and the rest is Mg;

[0035] See Table 1 for the properties of the magnesium alloy castings provided in this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com