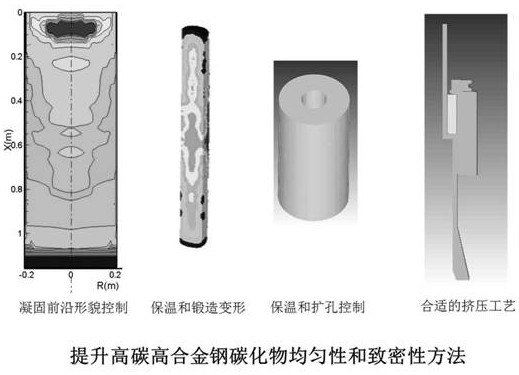

High-carbon high-alloy steel product and preparation method thereof

A high-alloy steel, high-carbon technology, applied in the field of ferrous metal preparation, can solve the problems of shortening service life and safety, cracking, carbide and matrix damage, etc., reducing local solidification time, accelerating cooling rate, and long solidification time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] On the one hand, an embodiment of the present invention provides a method for preparing a high-carbon high-alloy steel product, comprising the following steps:

[0042]1) Preparation of high-carbon and high-alloy steel low-segregation double-vacuum self-consumption blanks: adopt vacuum melting and vacuum self-consumption dual-vacuum smelting methods to manufacture high-carbon high-alloy steel blanks, and obtain low-segregation ratio casting blanks by controlling solidification parameters. The fluctuation of carbon mass fraction is controlled within ±0.02%.

[0043] Preferably, the consumable process adopts a high-carbon and high-alloy consumable billet of less than 6 tons, and controls the average molten pool depth-to-width ratio of the mushy zone of the consumable billet to be between 0.4-0.8, wherein the mushy zone has a solid fraction of 0.1-0.9 interval. Since the self-consumption process includes arc initiation, arc stabilization and arc extinguishing stages, the ...

Embodiment 1

[0059] This embodiment prepares a high-carbon high-alloy steel pipe, and the specific preparation steps are as follows:

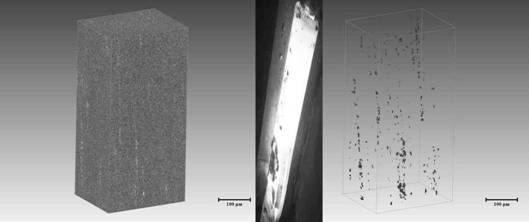

[0060] 1) Preparation of high-carbon and high-alloy steel low-segregation double-vacuum consumable billets: double-vacuum is used to prepare as-cast billets. The ingot material is M50 steel, and the consumable ingot is 6t. By controlling the average molten pool depth-width ratio in the mushy zone to 0.4, Control the carbon content fluctuation within ±0.02%, the carbide size at the 1 / 2 radius of the riser end is less than 374μm, and the hole defect size is less than 32μm;

[0061] 2) Billet high-temperature diffusion homogenization treatment and multi-fire cross-forging deformation billet opening treatment: In order to make the structure uniform, the billet is kept at a high temperature of 1130 ° C for 30 hours before forging, so that the distribution of components between dendrites is more uniform; During the forging process, the three-upsetting and three-d...

Embodiment 2

[0065] This embodiment prepares a high-carbon high-alloy steel bar, and the specific preparation steps are as follows:

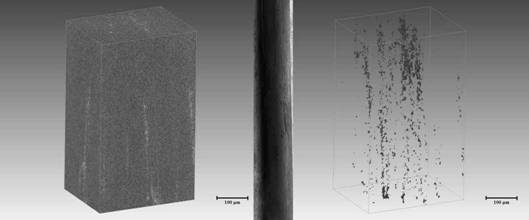

[0066] 1) Preparation of high-carbon and high-alloy steel low-segregation double-vacuum consumable billets: double-vacuum was used to prepare as-cast billets, the steel ingot material was M50 steel, and the consumable ingot was 2t. By controlling the average molten pool depth-to-width ratio in the mushy zone to 0.6, the The carbon content fluctuation is controlled within ±0.02%, the carbide size at the 1 / 2 radius of the riser end is less than 294μm, and the hole defect size is less than 24μm;

[0067] 2) Billet high-temperature diffusion homogenization treatment and multi-fire cross-forging deformation billet opening treatment: In order to make the structure uniform, the billet is kept at a high temperature of 1230°C before forging, and the holding time needs to be 20h to make the composition distribution between dendrites more uniform; In the forging proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com