Splicing frog casting system and casting method

A frog and pouring system technology, which is applied in casting equipment, casting molding equipment, casting molds, etc., can solve the problems of product shrinkage, shrinkage, failure to meet the quality level requirements of radiographic flaw detection, and limited overseas market expansion. Eliminate shrinkage cavity shrinkage, improve internal quality, and enhance market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

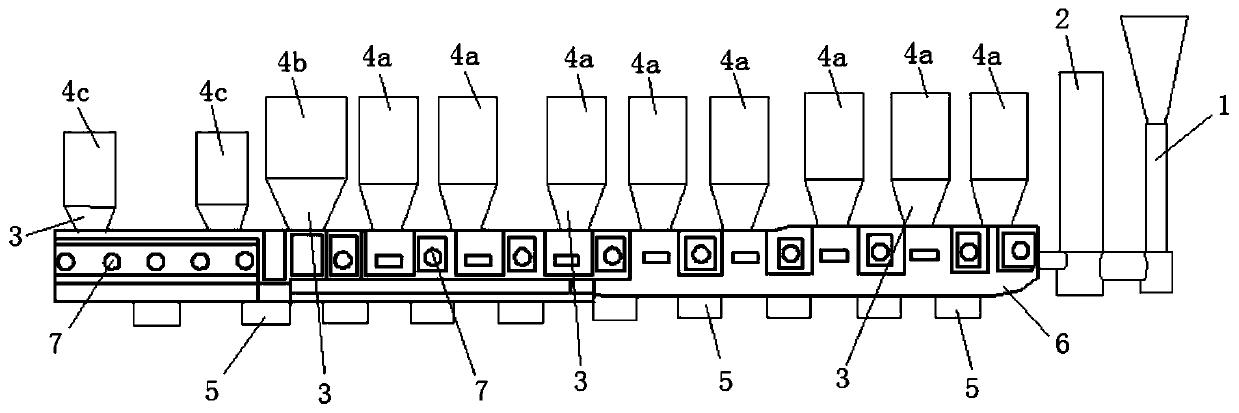

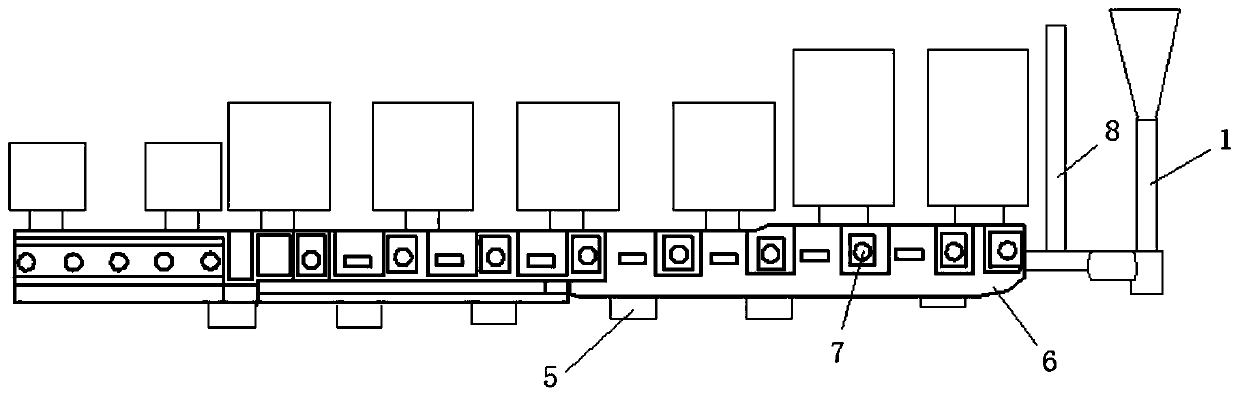

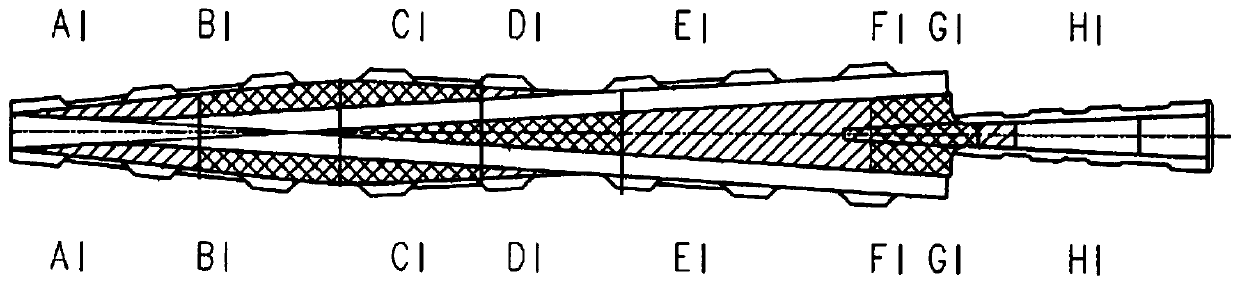

[0031] see figure 1 , an assembled frog casting system provided by an embodiment of the present invention, such as figure 1 As shown, the system includes a gating system, and the gating system communicates with the frog toe end of the frog cavity formed inside the casting mold 6; , the pouring and feeding riser assembly 2 is located between the sprue assembly 1 and the casting mold 6; further, the pouring and feeding riser assembly 2 includes a conical riser with a large upper part and a smaller lower part The mouth cavity, the slope of the riser cavity is 1:1.5. The assembled frog casting system in the prior art adopts inclined pouring, and the pouring system at the toe end only has vent holes and no feeding riser. Since the cooling of the pouring end is slow, if the subsequent molten steel supply is insufficient, the feeding amount is insufficient. There are shrinkage cavity defects on the pouring end face. In the solution provided by this application, a pouring feeding r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com