Novel high-performance die-casting zinc alloy material

A zinc alloy and new material technology, which is applied in the field of high-strength toughness performance zinc alloy die-casting new materials, can solve the problems of lower production costs, easy failure of downstream die-casting products, etc., and achieve the effects of improving competitiveness, enhancing toughness, and good die-casting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A new high-performance die-casting zinc alloy material, the main components of which are Al, Mg and Zn, and in terms of mass percentage, the new die-casting zinc alloy material includes the following main element components:

[0025] Al: 3.3%, Mg: 0.05%, Zn: 96.6412%.

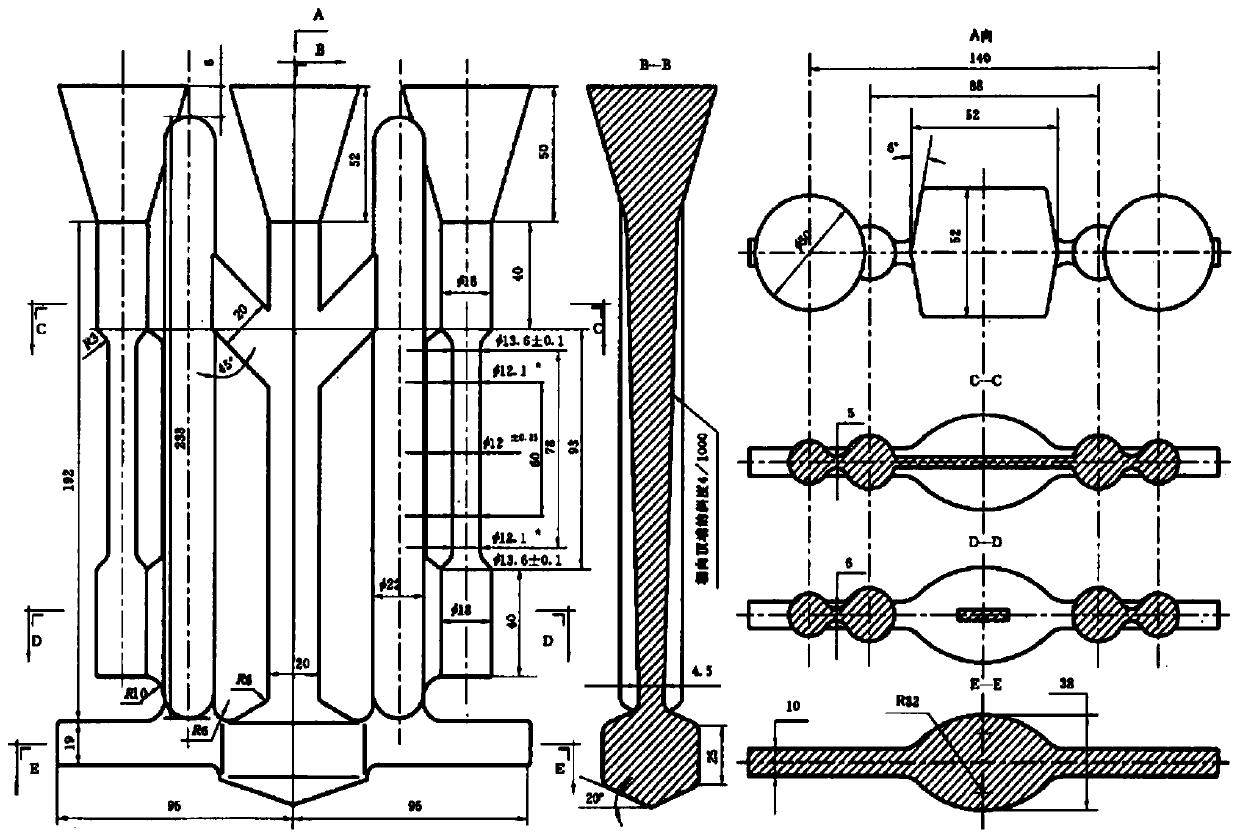

[0026] Supporting melt treatment process: raw materials include No. 0 zinc, pure aluminum, pure magnesium, ZnCl 2 Refining agent, complete refining at 500-700°C; pour the smelted alloy at 550-600°C figure 2 According to GB / T-1775-1997, the cast zinc alloy metal type standard sample and the gating riser system mold were placed, and then the tensile rod was taken out for mechanical performance testing. The results of the average value of the two test rods are shown in Table 2. According to the composition interval design composition of the new die-casting zinc alloy material, the composition of the obtained ingot is tested by a spectrometer, and the specific alloy element composition is shown in Table 1;...

Embodiment 2

[0028] A new high-performance die-casting zinc alloy material, the main components of which are Al, Mg and Zn, and in terms of mass percentage, the new die-casting zinc alloy material includes the following main element components:

[0029] Al: 3.53%, Mg: 0.05%, Zn: 96.4146%.

[0030] Supporting melt treatment process: raw materials include No. 0 zinc, pure aluminum, pure magnesium, ZnCl 2 Refining agent, complete refining at 500-700°C; pour the smelted alloy at 550-600°C figure 2 According to GB / T-1775-1997, the cast zinc alloy metal type standard sample and the gating riser system mold were placed, and then the tensile rod was taken out for mechanical performance testing. The results of the average value of the two test rods are shown in Table 2. According to the composition interval design composition of the new die-casting zinc alloy material, the composition of the obtained ingot is tested by a spectrometer, and the specific alloy element composition is shown in Table 1...

Embodiment 3

[0032] A new high-performance die-casting zinc alloy material, the main components of which are Al, Mg and Zn, and in terms of mass percentage, the new die-casting zinc alloy material includes the following main element components:

[0033] Al: 3.92%, Mg: 0.05%, Zn: 96.0213%.

[0034] Supporting melt treatment process: raw materials include No. 0 zinc, pure aluminum, pure magnesium, ZnCl 2 Refining agent, complete refining at 500-700°C; pour the smelted alloy at 550-600°C figure 2 According to GB / T-1775-1997, the casting zinc alloy metal type standard sample and the casting riser system mold were placed, and then the tensile rod was taken out for mechanical performance testing. The results of the average value of the two test rods are shown in Table 2. According to the design composition of the composition interval of the new die-casting zinc alloy material, the composition of the obtained ingot is tested by a spectrometer, and the specific alloy element composition is shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com