Die-casting rare earth aluminum alloy with characteristics of high fluidity and oxidability

A high fluidity, aluminum alloy technology, applied in the field of metal material processing, can solve the problems of poor mechanical properties, poor corrosion resistance, poor anodic oxidation performance, etc., and achieve the effect of good die casting performance, good corrosion resistance and good oxidation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

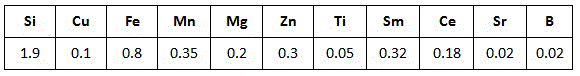

Embodiment 1

[0040] Pure aluminum (A00 aluminum), aluminum-manganese alloy (AlMn10), aluminum-silicon alloy (AlSi12), aluminum-iron alloy (AlFe20), pure magnesium (99.9), pure zinc (99.95), rare earth aluminum-titanium-boron alloy (AlTi5BRE10), magnesium Samarium-cerium alloy (MgSmCe20) and magnesium-strontium alloy (MgSr25), after batch calculation, smelting and pouring, the weight percentage content of the main elements of the final alloy is as follows: figure 1 shown.

[0041] The alloy is die-cast into a 2mm tensile specimen, and the tensile properties at room temperature are tested:

[0042] Tensile strength = 350MPa, yield strength = 270MPa, elongation = 7.6%.

[0043] Alloy oxidation effect: uniform color, bright color, smooth surface, oxide film thickness of 20-25μm.

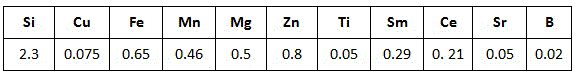

Embodiment 2

[0045] Pure aluminum (A00 aluminum), aluminum-manganese alloy (AlMn10), aluminum-silicon alloy (AlSi12), aluminum-iron alloy (AlFe20), pure magnesium (99.9), pure zinc (99.95), rare earth aluminum-titanium-boron alloy (AlTi5BRE10), magnesium Samarium-cerium alloy (MgSmCe20) and magnesium-strontium alloy (MgSr25), through batching calculation, smelting and pouring, the final alloy obtained: the weight percentage content of the main elements is as follows figure 2 shown.

[0046] The alloy is die-cast into a 0.6mm tensile specimen, and the tensile properties at room temperature are tested:

[0047] Tensile strength = 273MPa, yield strength = 180MPa, elongation = 6.2%.

[0048] Alloy oxidation effect: uniform color, bright color, smooth surface, oxide film thickness of 25μm.

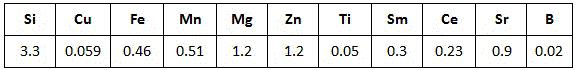

Embodiment 3

[0050] Pure aluminum (A00 aluminum), aluminum-manganese alloy (AlMn10), aluminum-silicon alloy (AlSi12), aluminum-iron alloy (AlFe20), pure magnesium (99.9), pure zinc (99.95), rare earth aluminum-titanium-boron alloy (AlTi5BRE10), magnesium Samarium-cerium alloy (MgSmCe20) and magnesium-strontium alloy (MgSr25), after batch calculation, smelting and pouring, the weight percentage content of the main elements of the final alloy is as follows: image 3 shown.

[0051] The alloy is die-cast into a 0.8mm tensile specimen, and the tensile properties at room temperature are tested:

[0052] Tensile strength = 289MPa, yield strength = 191MPa, elongation = 5.3%.

[0053] Alloy oxidation effect: uniform color, bright color, smooth surface, oxide film thickness of 30μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com