Heatproof casting magnesium alloy

A technology for casting magnesium alloys and magnesium alloys, which is applied in the field of MgAlMn series heat-resistant casting magnesium alloys, can solve the problems of low temperature resistance, uncomfortable parts, high working temperature, etc., and achieve high temperature resistance, good machinability, and excellent mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

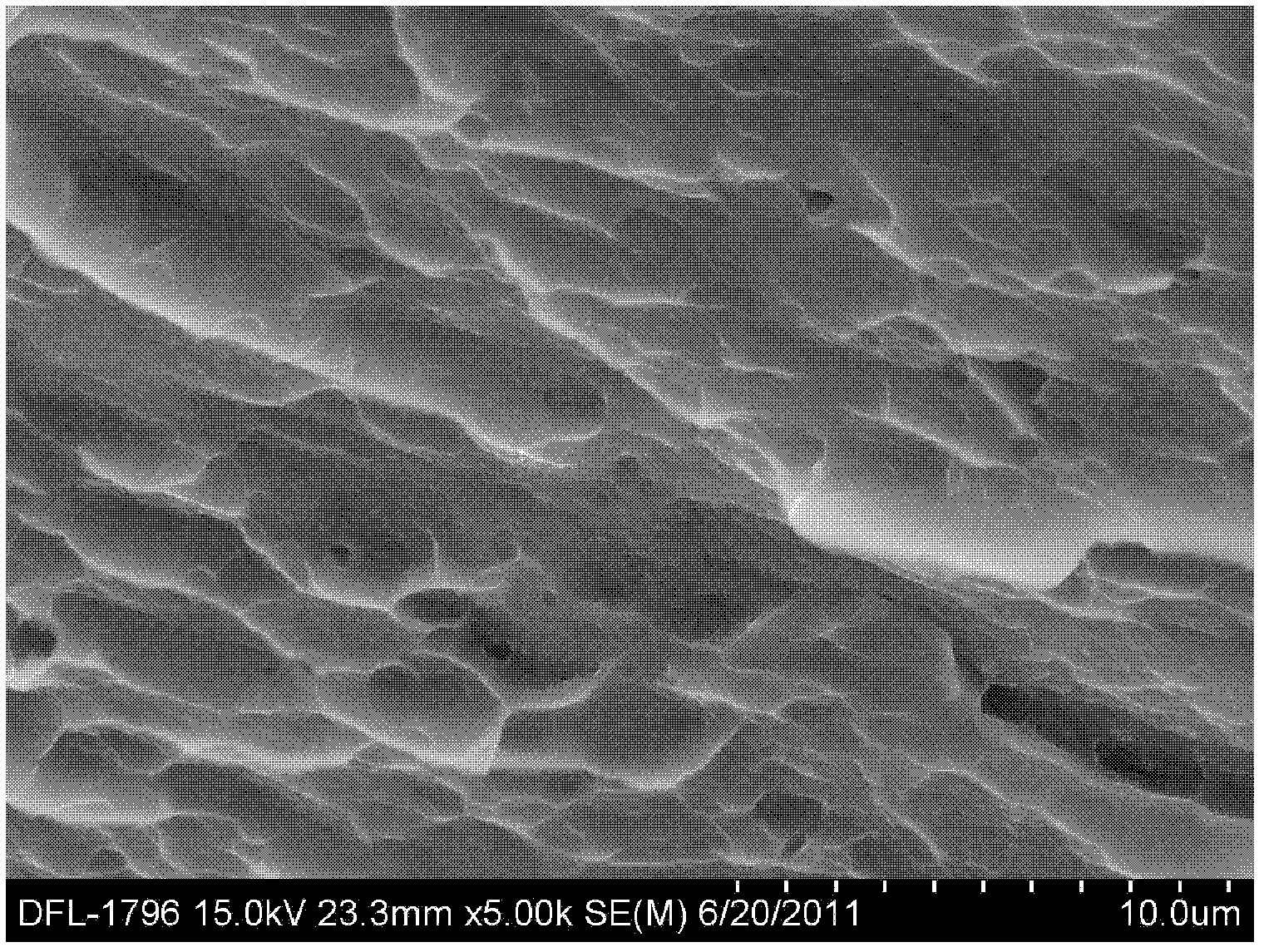

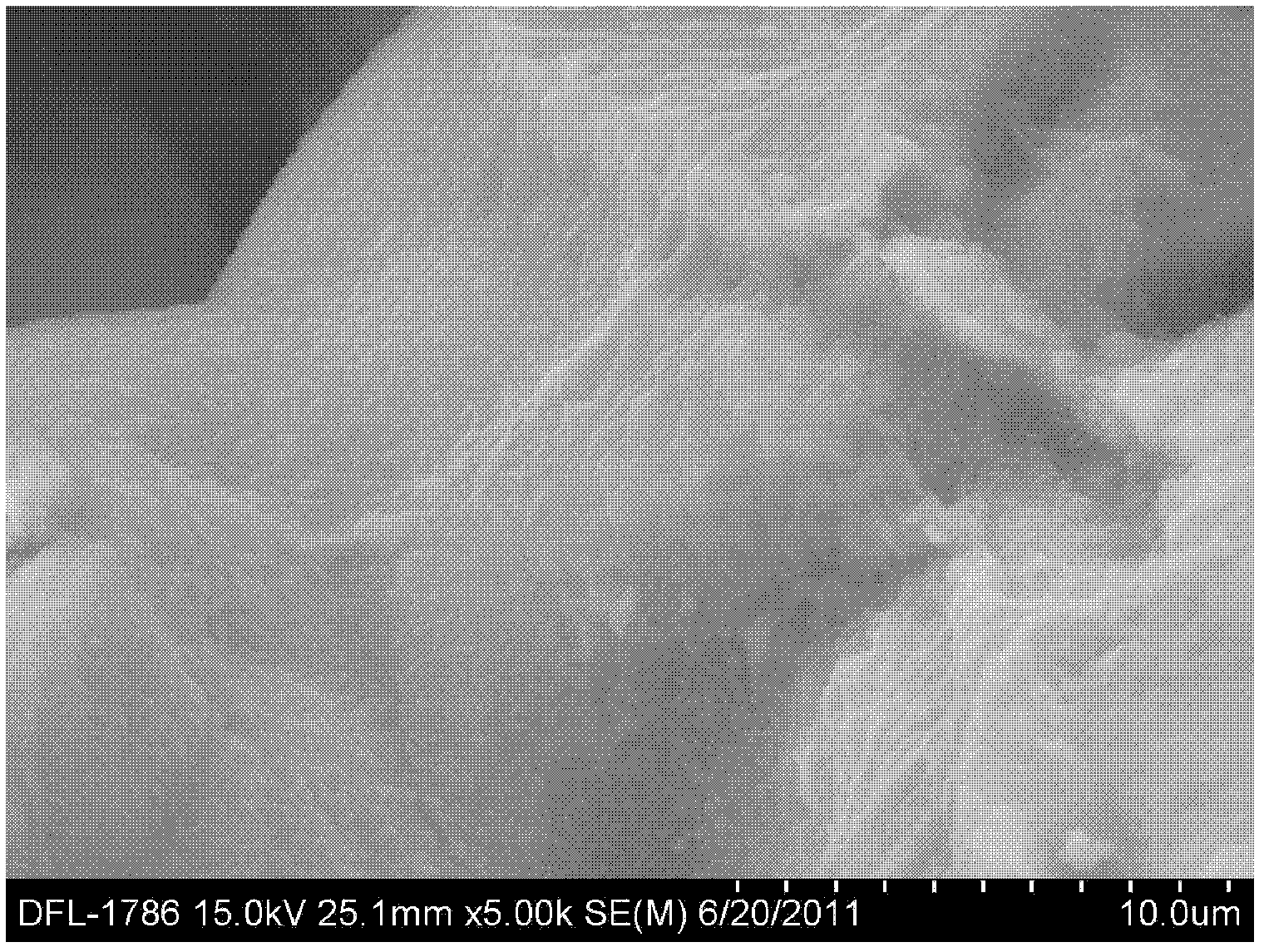

Image

Examples

Embodiment 1

[0031] The heat-resistant magnesium alloy is prepared according to the steps described in the above-mentioned process 1. The casting adopts high-pressure die-casting. The weight percentage of the magnesium alloy is composed of Al 6.2%, Mn 0.4%, Gd 0.5%, Nb 0.2%, and the rest is Mg.

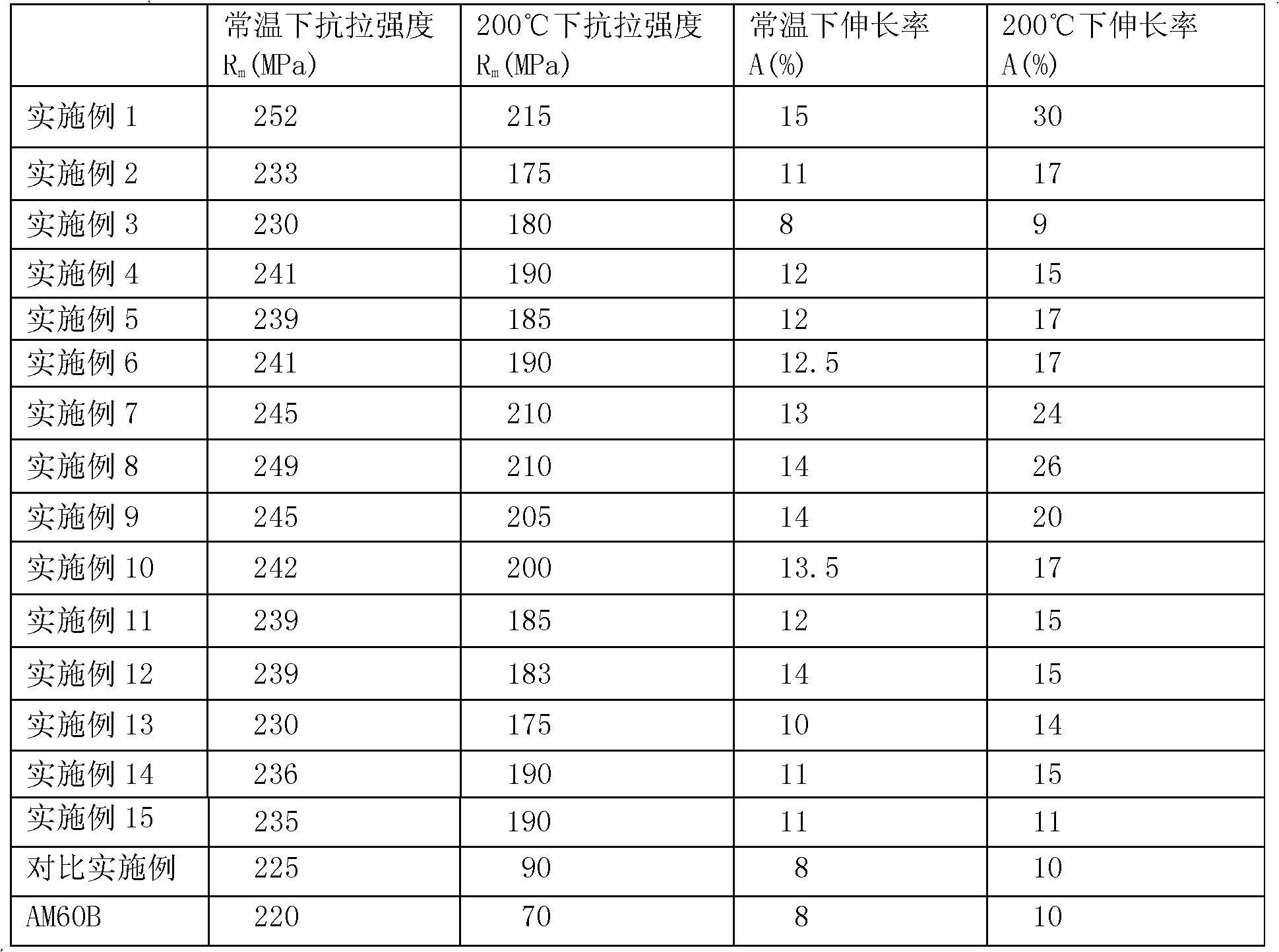

[0032] See Table 1 for the properties of the magnesium alloy castings provided in this example.

Embodiment 2

[0034] The heat-resistant magnesium alloy is prepared according to the steps described in the second process above, and the casting is cast in a metal mold. The weight percentage of the magnesium alloy is composed of Al 1.5%, Mn 0.13%, Sm 0.001%, Nb 0.001%, and the rest is Mg.

[0035] Heat treatment of castings (T4 solid solution treatment process): raise the temperature of castings to 480°C in a box-type resistance furnace, keep it warm for 1 hour, and water quench the castings after they come out of the furnace, the water temperature is 80°C.

[0036] See Table 1 for the properties of the magnesium alloy castings provided in this example.

Embodiment 3

[0038]The heat-resistant magnesium alloy is prepared according to the steps described in the second process above, and the casting is semi-solid casting. The weight percentage of the magnesium alloy is composed of Al 25%, Mn 2%, Y 16%, Nb 4%, and the rest is Mg.

[0039] Heat treatment of castings (T4 solid solution treatment process): the castings are heated to 480°C in a box-type resistance furnace and kept for 8 hours. After the castings are released from the furnace, they are water-quenched and the water temperature is 80°C.

[0040] See Table 1 for the properties of the magnesium alloy castings provided in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com