Alloy modificator for preparing metal semi-solid slurry

一种半固态浆料、变质剂的技术,应用在制备金属半固态浆料的合金变质剂,合金变质剂的制备领域,能够解决半固态浆料固液比难控制、影响铸件成型、冷隔浇不足等问题,达到提高制备效率和浆料质量、成本和能耗低、降低生产成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The technical solution adopted by the present invention is an alloy modifier for preparing metal semi-solid slurry and a preparation method thereof, the steps of the preparation method are:

[0033] (1) Add 5Kg of pure aluminum with a purity of 99.99% to the stone mold crucible, put the stone mold crucible into an electric furnace and heat up to 750°C to melt the pure aluminum;

[0034] (2) Add metal copper, aluminum-magnesium alloy, titanium alloy additives, and metal silicon to the stone mold crucible to make the components in the stone mold crucible the quality of silicon, iron, copper, manganese, magnesium, zinc, titanium, lead, and aluminum The ratio is 6.05:0.15:0.12:0.002:0.5:0.025:0.002:0.002:90.5;

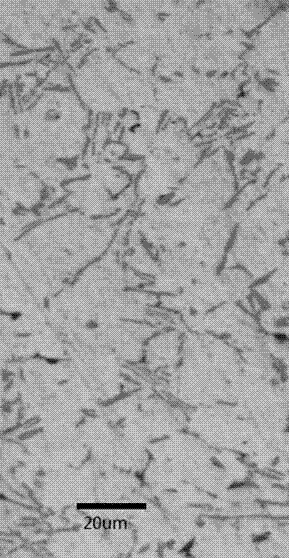

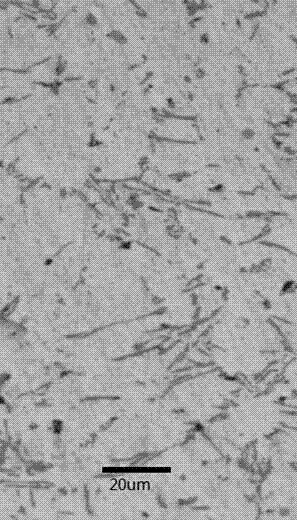

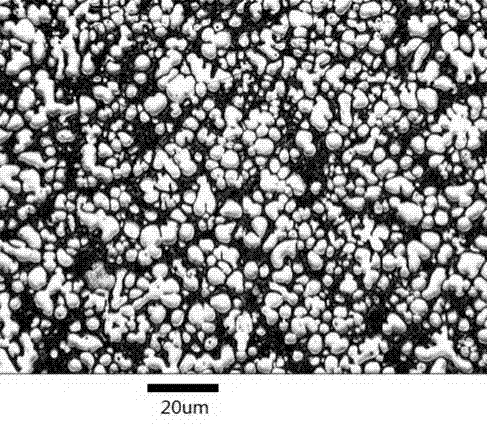

[0035] (3) Melt and refine the alloy in the stone mold crucible to obtain a liquid alloy modifier; then take a sample and analyze the chemical composition and metallographic structure of the alloy modifier;

[0036] (4) Pouring the alloy modifier in a uniform liqui...

Embodiment 2

[0042] An alloy modifier for preparing metal semi-solid slurry and a preparation method thereof, the steps of the preparation method are:

[0043] (1) Add 5Kg of pure aluminum with a purity of 99.99% to the stone mold crucible, put the stone mold crucible into an electric furnace and heat up to 765°C to melt the pure aluminum;

[0044] (2) Add metal copper, aluminum-magnesium alloy, titanium alloy additives, and metal silicon to the stone mold crucible to make the components in the stone mold crucible the quality of silicon, iron, copper, manganese, magnesium, zinc, titanium, lead, and aluminum The ratio is 6.95: 0.45: 0.65: 0.006: 0.001: 0.05: 0.08: 0.06: 93.2;

[0045](3) Melt and refine the alloy in the stone mold crucible to obtain a liquid alloy modifier; then take a sample and analyze the chemical composition and metallographic structure of the alloy modifier;

[0046] (4) Pouring the alloy modifier in a uniform liquid state into the metal model to make a bar of the all...

Embodiment 3

[0052] An alloy modifier for preparing metal semi-solid slurry and a preparation method thereof, the steps of the preparation method are:

[0053] (1) Add 5Kg of pure aluminum with a purity of 99.99% to the stone mold crucible, put the stone mold crucible into an electric furnace and heat up to 735°C to melt the pure aluminum;

[0054] (2) Add metal copper, aluminum-magnesium alloy, titanium alloy additives, and metal silicon to the stone mold crucible to make the components in the stone mold crucible the quality of silicon, iron, copper, manganese, magnesium, zinc, titanium, lead, and aluminum The ratio is 6.70: 0.20: 0.40: 0.005: 0.35: 0.04: 0.07: 0.05: 91.15;

[0055] (3) Melt and refine the alloy in the stone mold crucible to obtain a liquid alloy modifier; then take a sample and analyze the chemical composition and metallographic structure of the alloy modifier;

[0056] (4) Pouring the alloy modifier in a uniform liquid state into the metal model to make a bar of the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com