Anode-oxidable high-performance die-casting aluminum alloy and preparation method thereof

An anodic oxidation, high-performance technology, applied in the field of metal materials and die-casting aluminum alloy materials, can solve the problems of brittle products, poor die-casting performance, and inability to realize production applications, etc., to improve the strength and plasticity of the alloy, and improve the fluidity of the alloy , good coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Material preparation: Raw material ratio (mass ratio): Mn (Al-Mn master alloy ingot): 2.0%, magnesium (pure magnesium ingot with purity ≥99.9wt%): 1.0%, Y (Al-Y master alloy ingot): 0.5 %, the balance is aluminum (pure aluminum ingot with a purity ≥99.9wt%).

[0035] The flux is: covering agent SY-LF1, refining agent and modifier K 2 ZrF 6 .

[0036] Drying: Dry the prepared raw materials, in which Mg and Al are dried at 100°C±10°C, while Al-Mn master alloy ingots and Al-Y master alloy ingots are dried at 150°C±10°C Drying, the function of drying is to remove the moisture in the raw material.

[0037] Melt alloying: first preheat the crucible to 200-250°C, put the weighed aluminum ingot and Al-Mn master alloy ingot into the crucible and add a covering agent to heat and melt, and wait for the aluminum ingot, aluminum-manganese master alloy ingot After all melting, add the weighed Al-Y intermediate alloy ingot and pure magnesium ingot. When adding pure magnesium ingot...

Embodiment 2

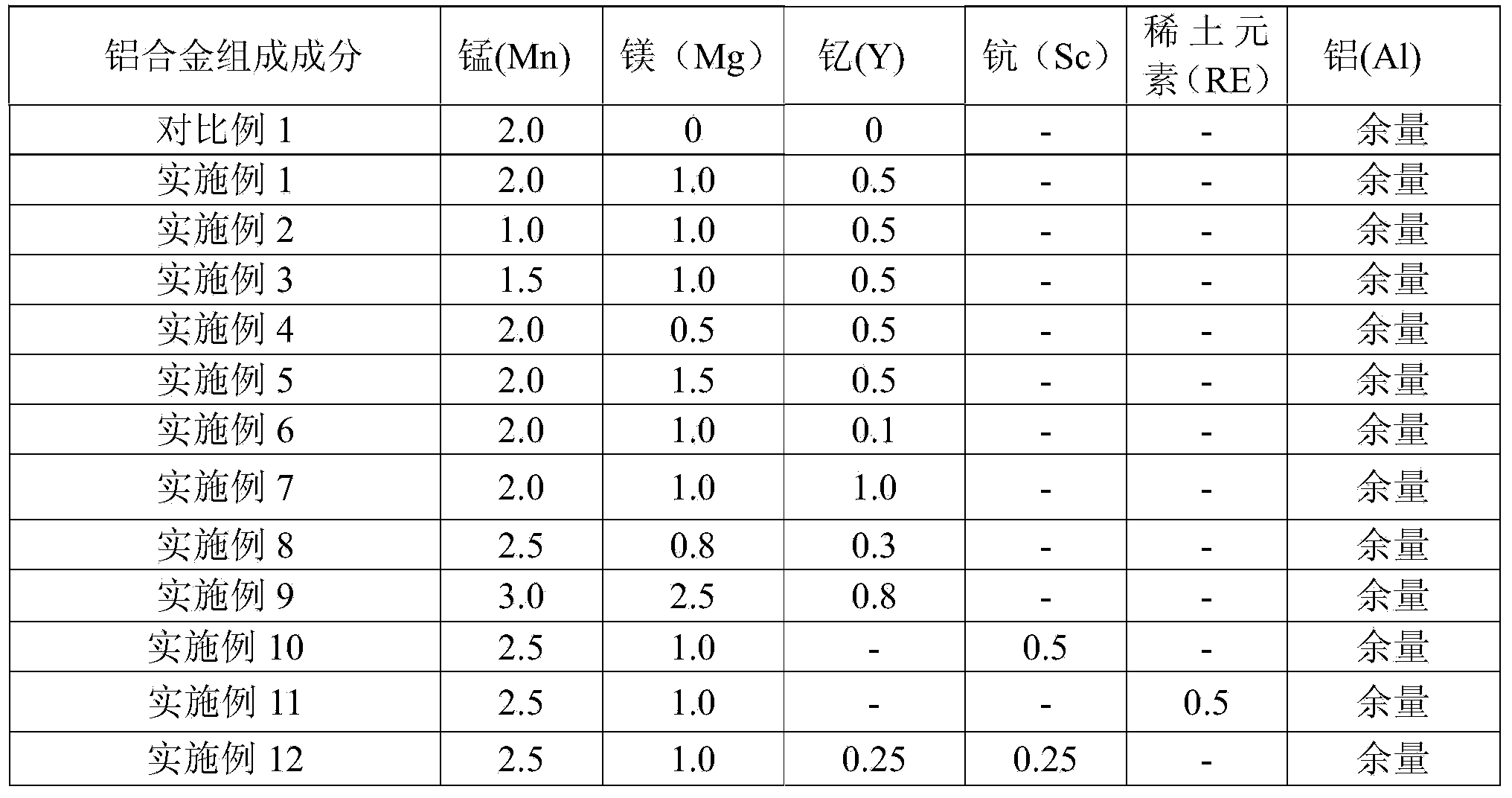

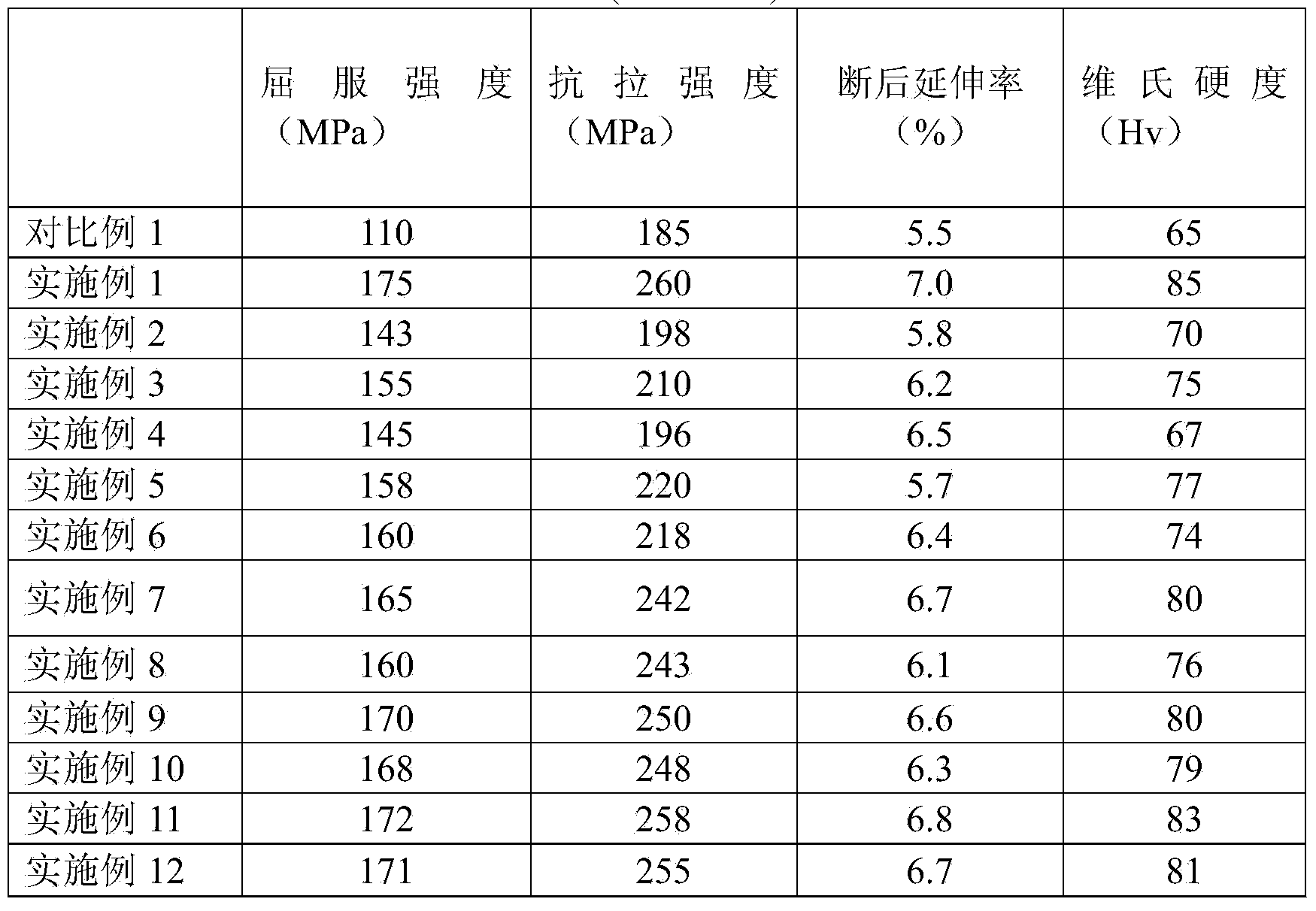

[0043] The raw materials and preparation method are basically the same as in Example 1, the only difference is: Mn (Al-Mn master alloy ingot): 1.0%, magnesium (pure magnesium ingot with a purity ≥ 99.9wt%): 1.0%, Y (Al- Y intermediate alloy ingot): 0.5% to produce aluminum alloy ingot A2. The chemical composition test results of the obtained aluminum alloy are shown in Table 1, and the strength performance test results are shown in Table 2.

Embodiment 3

[0045] The raw materials and preparation method are basically the same as in Example 1, the only difference is: Mn (Al-Mn master alloy ingot): 1.5%, magnesium (pure magnesium ingot with a purity ≥ 99.9wt%): 1.0%, Y (Al- Y intermediate alloy ingot): 0.5%, the balance is aluminum (pure aluminum ingot with a purity ≥ 99.9wt%), and the aluminum alloy ingot A3 is obtained. The chemical composition test results of the obtained aluminum alloy are shown in Table 1, and the strength performance test The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com