Hpdc Magnesium Alloy

a technology of magnesium alloy and magnesium alloy, applied in the field of magnesium alloy, can solve the problem that none of these alloys is suitable for use at elevated temperatures, and achieve the effect of improving the die castability of alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

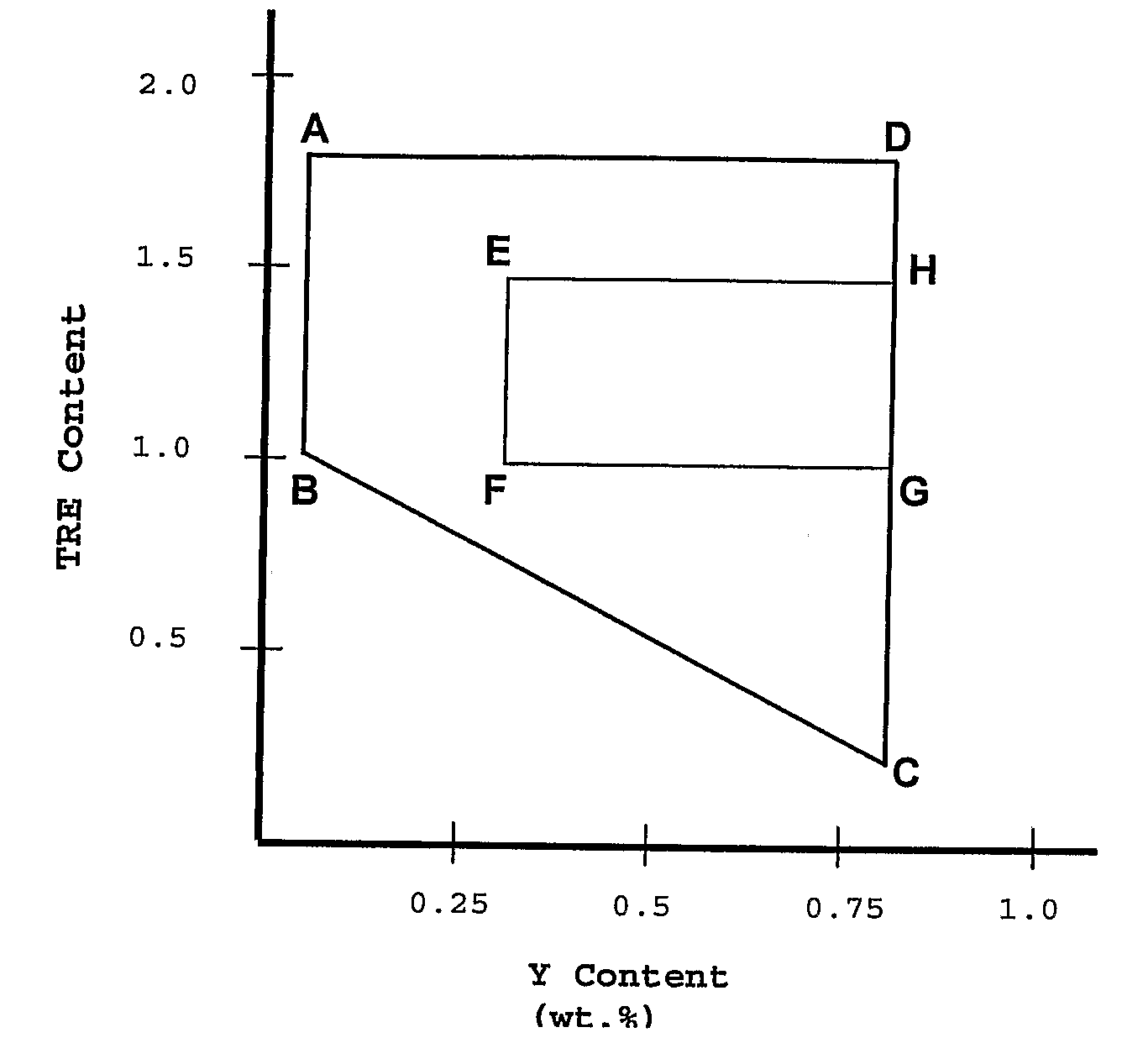

Method used

Image

Examples

example 1

[0075]Two alloys according to the present invention were prepared and chemical analyses of the alloys are set out in Table 1 below. The rare earths other than neodymium were added as a Ce-based misch metal which contained cerium, lanthanum and some neodymium. The extra neodymium and the zinc were added in their elemental forms. Standard melt handling procedures were used throughout preparation of the alloys.

TABLE 1Alloys PreparedElementAlloy AAlloy BNd (wt %)0.60.54Ce (wt %)0.370.36La (wt %)0.320.31Zn (wt %)0.40.41Y (wt %)0.50.18Mg (wt %)BalanceBalanceexcept forexcept forincidentalincidentalimpuritiesimpurities

[0076]The tensile properties of Alloys A and B at room temperature and at 177° C. are set out below in Table 2.

TABLE 2Tensile Properties21° C.177° C.0.2% Proof0.2% ProofStressUTSElong.StressUTSElong.Alloy A1201464.01061326.6Alloy B1141645.71021339.0

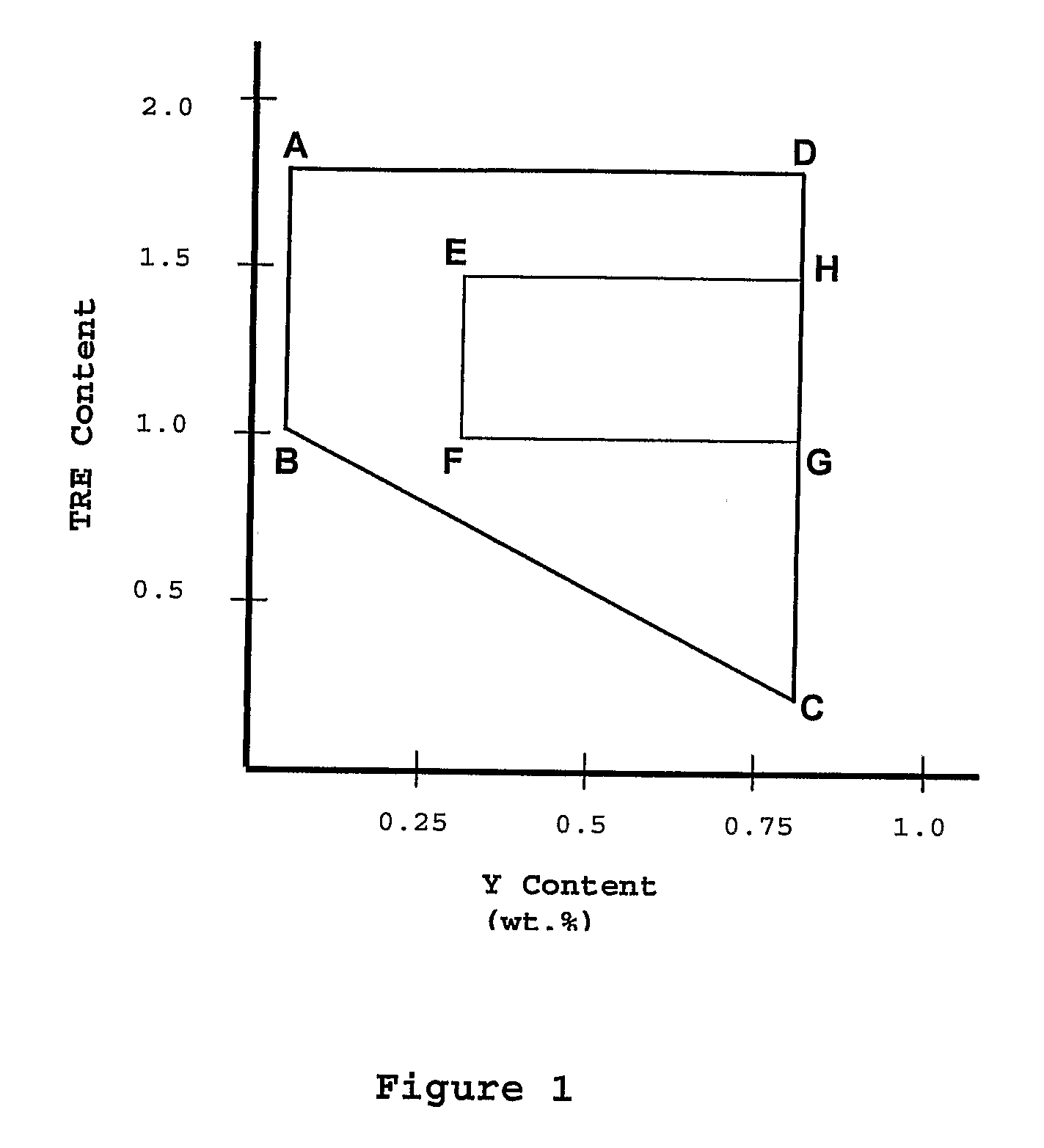

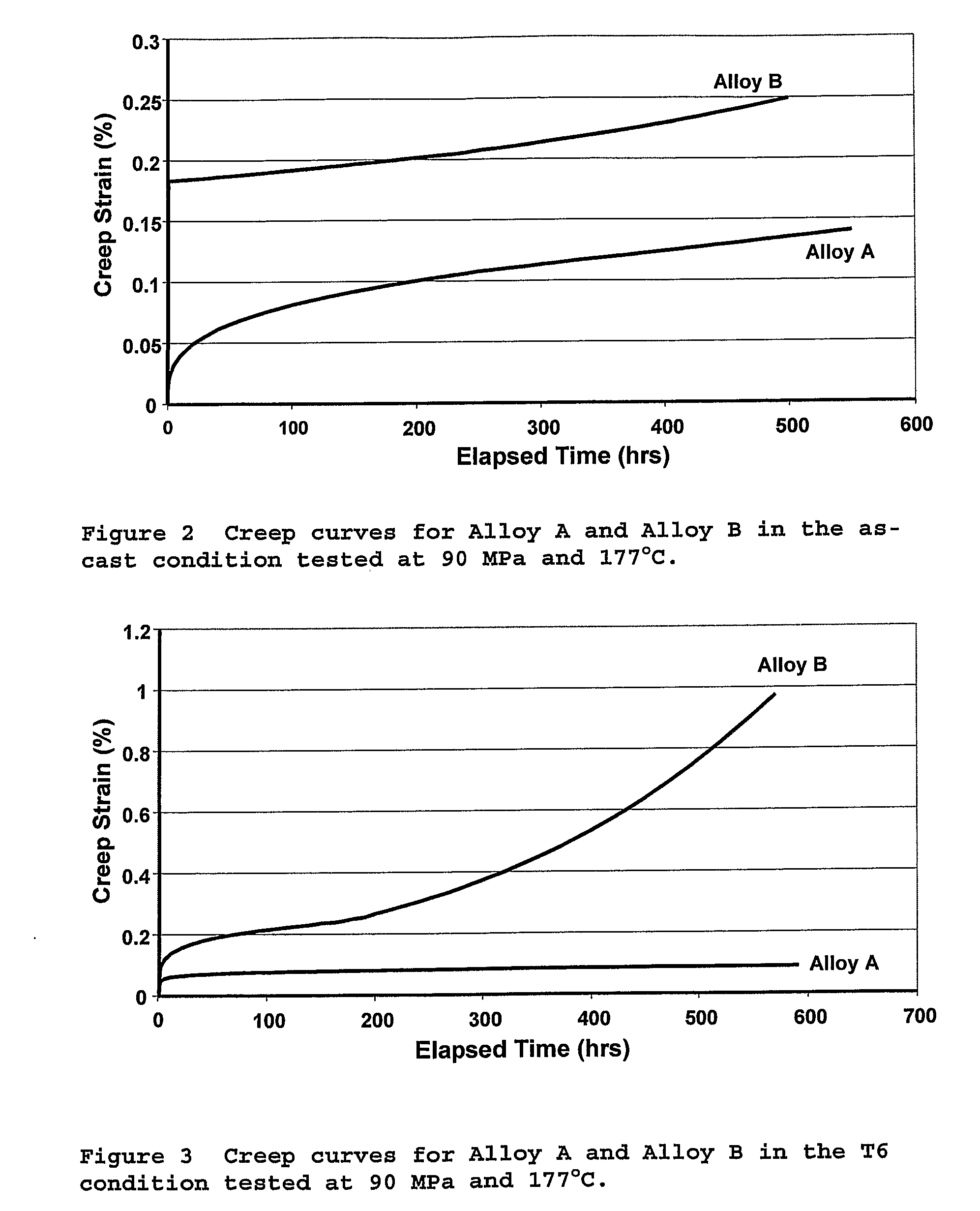

[0077]Creep tests were carried out on Alloys-A and B at a constant load of 90 MPa and at a temperature of 177° C. in the as-cast c...

example 2

[0081]A series of alloys according to the present invention were produced and their compositions are listed in Table 4 which includes Alloys A and B referred to in Example 1.

TABLE 4Chemical composition of Alloys A-VZrZrNdCeLaYZnBeAlFe(wt. %,(wt. %,Alloy(wt. %)(wt. %)(wt. %)(wt. %)(wt. %)(ppm)(wt. %)(ppm)soluble)total)A0.600.370.320.500.40—————B0.540.360.310.180.41—————C0.630.410.361.060.43150.10—0.02D0.640.420.381.520.45180.10—0.0050.035E1.180.410.380.750.42190.10—0.0050.03F0.530.630.180.950.43260.11—0.0080.08G0.541.110.180.950.42400.11—0.0180.15H0.620.480.370.270.54150.0717I0.560.440.330.260.57150.0716J0.460.360.280.250.57160.0714K0.650.490.380.370.56150.07250.009L0.580.440.340.390.57180.08270.0050.010M0.490.370.280.400.54170.08200.0050.010N0.670.500.370.540.58160.07260.006O0.580.420.330.570.54180.07220.0050.008P0.480.340.270.600.54180.07270.0050.008Q0.480.350.280.640.80200.07340.0060.010R0.460.340.270.611.12190.07280.0050.010S0.680.510.391.170.570.0134T0.710.510.401.100.5650.0433U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| atomic numbers | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com