High-strength anodizing die-casting aluminium alloy and preparation method thereof

A technology of anodizing and casting aluminum alloys, which is applied in the field of aluminum alloys, can solve the problems of waste of raw materials, high processing costs, and non-environmental protection, and achieve the effects of accelerating metallurgical physical and chemical reactions, improving kinetic conditions, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Al-1.5Mg-2.5Mn-0.6Fe-2.5Zn-0.8Mo-0.8Zr-2Cr high-strength anodic oxidation die-casting aluminum alloy (that is, the composition content is: 1.5wt% Mg, 2.5wt% Mn, 0.6wt% Fe, 2.5wt% Zn, 0.8wt% Mo, 0.8wt% Zr, 2wt% Cr, the balance being Al).

[0034] (1) First, calculate the required pure Al ingot, pure Mg ingot, pure Zn ingot, Al-10% Mn master alloy, Al-10% Fe master alloy, Al-70% Mo master alloy, Al-5%Zr master alloy, Al-10%Cr master alloy quality; Wherein the composition content of Al-10%Mn master alloy is: 10wt%Mn, balance is Al; The composition content of Al-10%Fe master alloy is : 10wt% Fe, the balance is Al; the composition content of the Al-70% Mo master alloy is: 70wt% Mo, the balance is Al; the composition content of the Al-5% Zr master alloy is: 5wt% Zr, the balance is Al; Al-10%Cr master alloy composition content is: 10wt% Cr, balance is Al. Mg yield is 75-90%, Zn yield is 70-85%, Fe yield is 90-110%, Mo yield is 70-85%, Mn yield is 80-90%, The yield of Zr is ...

Embodiment 2

[0044] Composition: Al-2.8Mg-4.0Mn-1.2Fe-3.5Zn-1.5Mo-1.5Zr-2.5Cr high-strength anodic oxidation die-casting aluminum alloy (that is, the composition content is: 2.8wt% Mg, 4.0wt% Mn, 1.2wt% %Fe, 3.5wt% Zn, 1.5wt% Mo, 1.5wt% Zr, 2.5wt% Cr, the balance being Al).

[0045] Raw material and preparation method are with embodiment 1.

Embodiment 3

[0047] Composition: Al-1.8Mg-3.0Mn-0.8Fe-2.2Zn-0.6Mo-1.2Zr-1.9Cr high-strength anodic oxidation die-casting aluminum alloy (that is, the composition content is: the content of Mg is 1.8wt%, the content of Mn is 3.0wt%, the content of Fe is 0.8wt%, the content of Zn is 2.2wt%, the content of Mo is 0.6wt%, the content of Zr is 1.2wt%, the content of Cr is 1.9wt%, and the balance is Al).

[0048] Raw material and preparation method are with embodiment 1.

PUM

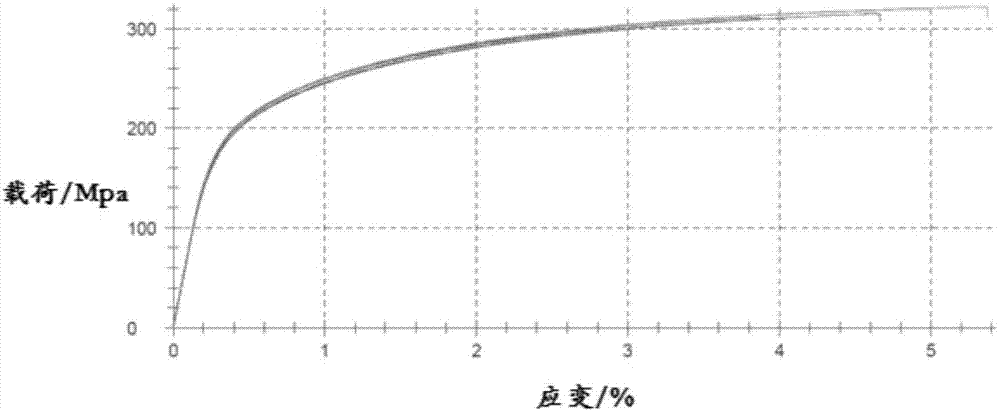

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com