Patents

Literature

34 results about "2219 aluminium alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2219 aluminium alloy is an alloy in the wrought aluminium-copper family (2000 or 2xxx series). It can be heat-treated to produce tempers with higher strength but lower ductility. The aluminium-copper alloys have high strength, but are generally less corrosion resistant and harder to weld than other types of aluminium alloys. To compensate for the lower corrosion resistance, 2219 aluminium can be clad in a commercially pure alloy such as 1050 or painted. This alloy is commonly formed by both extrusion and forging, but is not used in casting.

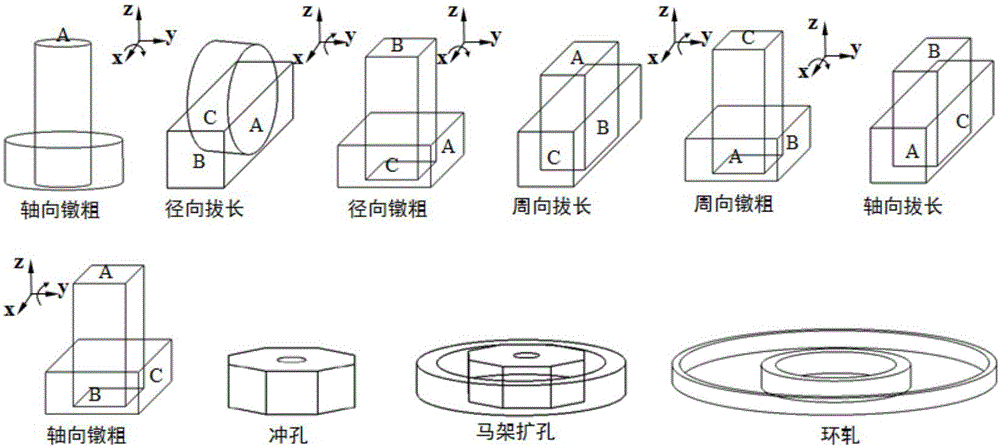

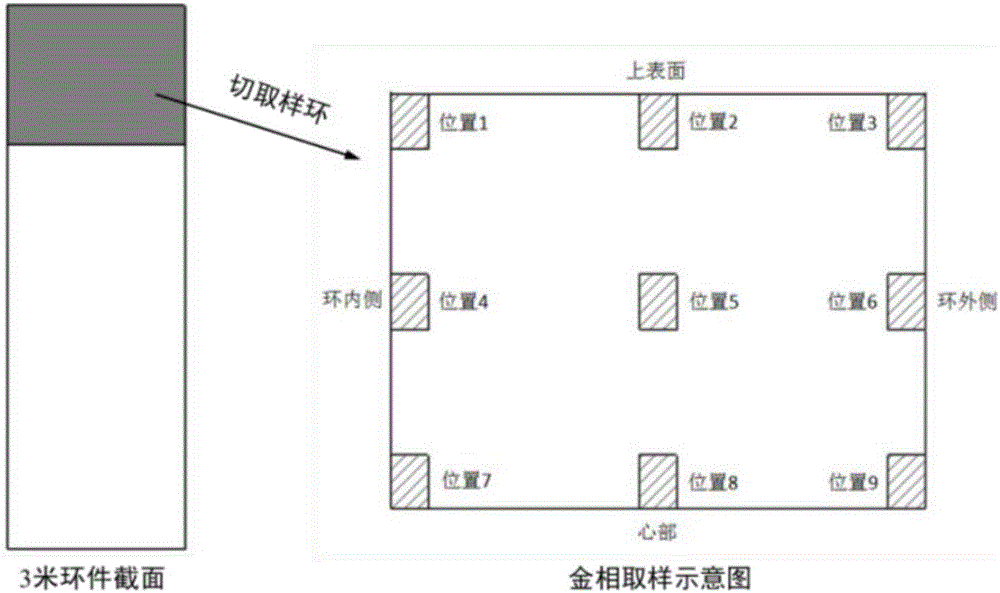

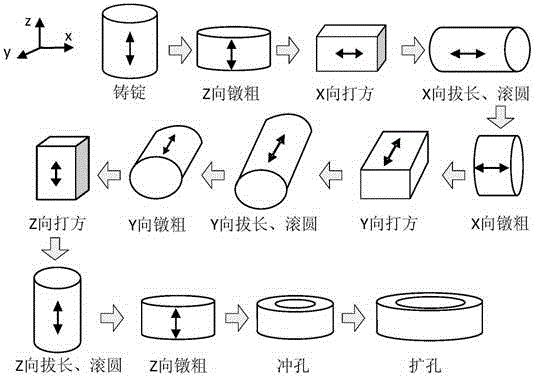

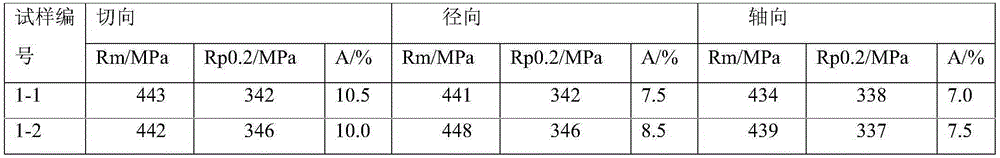

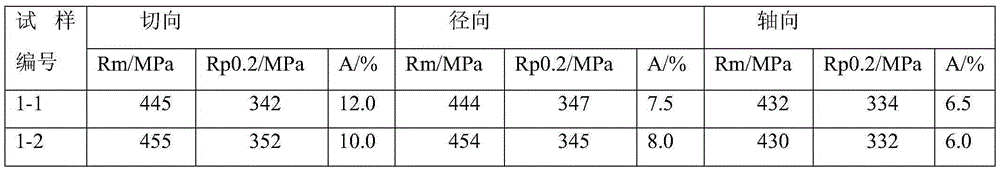

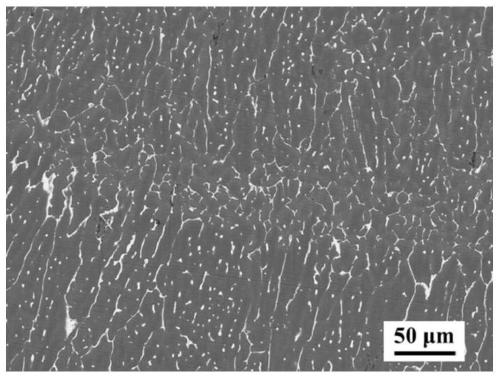

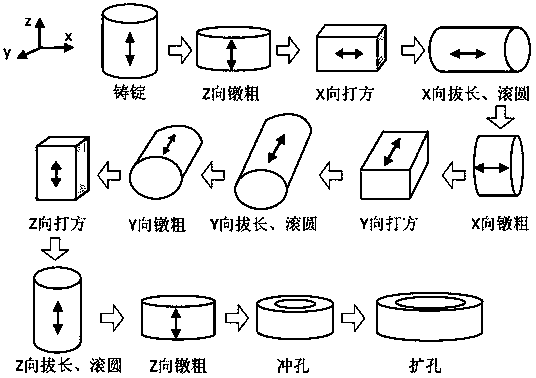

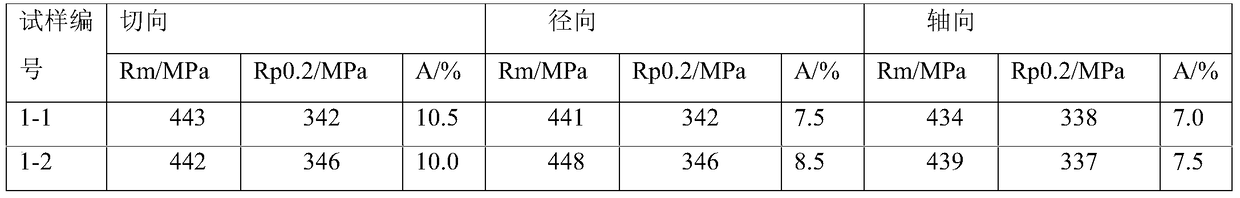

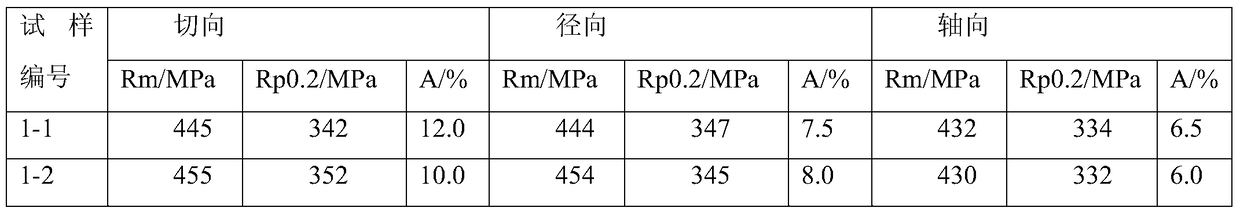

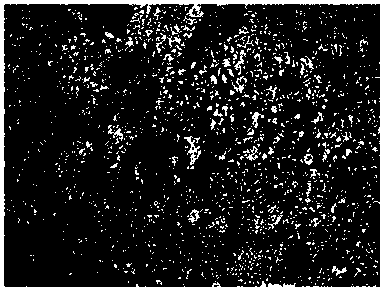

Process method for improving comprehensive mechanical property of 2219 aluminum alloy ring piece

The invention relates to the technical field of metal material deformation heat treatment processes and discloses a process method for improving the comprehensive mechanical property of a 2219 aluminum alloy ring piece so that coarse residual crystalline phases of the large-size 2219 aluminum alloy ring piece can be fully crushed and crystalline grains can be refined and equiaxed, thus, the strength and the plasticity of the 2219 aluminum alloy ring piece are improved at the same time, and the anisotropy is decreased. The process method comprises the steps of multi-directional forging, punching, mandrel supporter broaching, piecewise rolling and heat treatment. In the multi-directional forging step, the heating temperature of a blank is 500 DEG C-520 DEG C, and the final forging temperature is higher than or equal to 380 DEG C. Piecewise rolling comprises the steps that in the first stage, the ring blank is heated to 420 DEG C-460 DEG C and subjected to hot rolling on a ring rolling machine, and the hot rolling deformation quantity is 30%-40%; and in the second stage, the ring piece subjected to hot rolling is air-cooled to 240 DEG C-280 DEG C and is continuously subjected to medium and low temperature rolling on the ring rolling machine, and the deformation quantity is 15%-25%.

Owner:湖南中创空天新材料股份有限公司

Forging and cogging technique for super-sized aluminum alloy ingots

ActiveCN106541064AGrain refinementImprove organizational structureMetal-working apparatusIngotMulti directional

The invention belongs to the technical field of forging forming, in particular to a forging and cogging technique for super-sized aluminum alloy ingots. The technical scheme provides the forging and cogging technique for super-sized aluminum alloy ingots and comprises following steps: utilizing multi-directional forging technology; controlling deformation of 2219 aluminum alloy ingots through controlling forging temperature, single-time forging ratio, cumulative forging ratio, deformation rate and ratios of width to height; refining grains of material and improving structure of material such that uniformity control over structure and performance of super-large diameter 2219 aluminum alloy rolled compact can be achieved, thereby improving uniformity among product quality and product qualification ratio; and the need for developing aerospace products is satisfied.

Owner:CAPITAL AEROSPACE MACHINERY +1

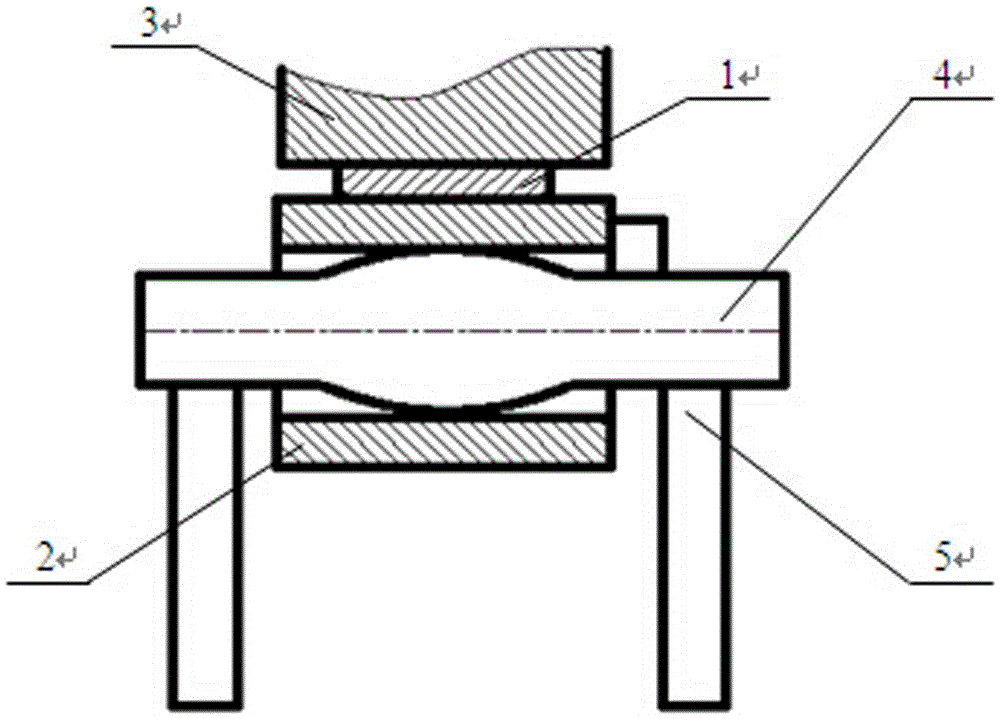

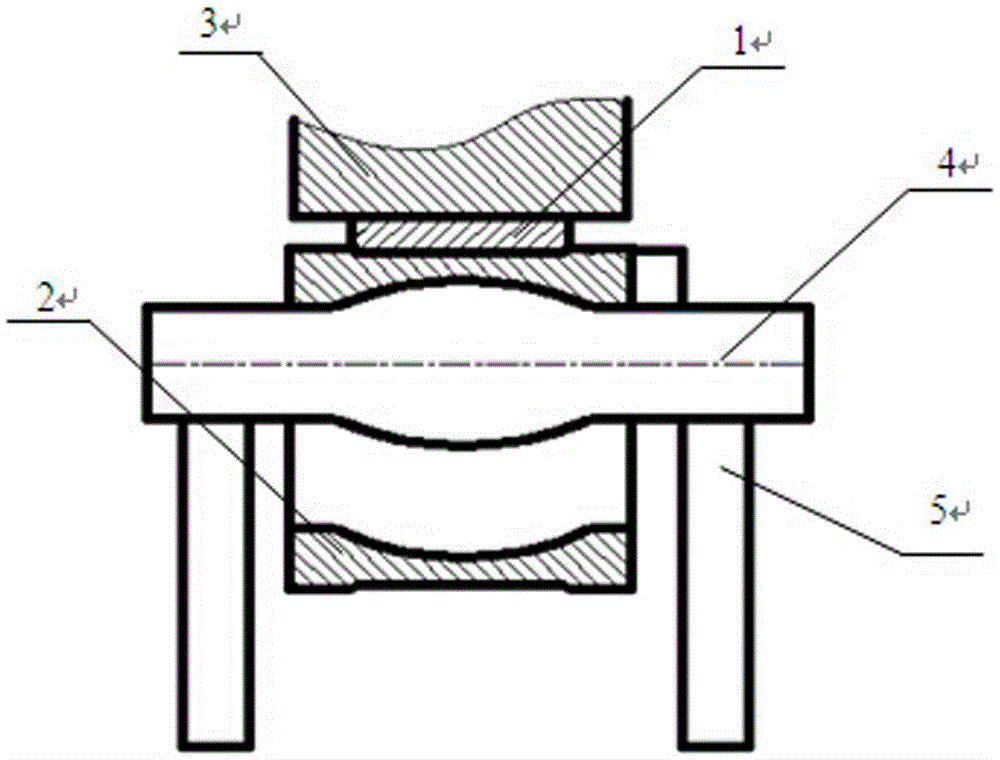

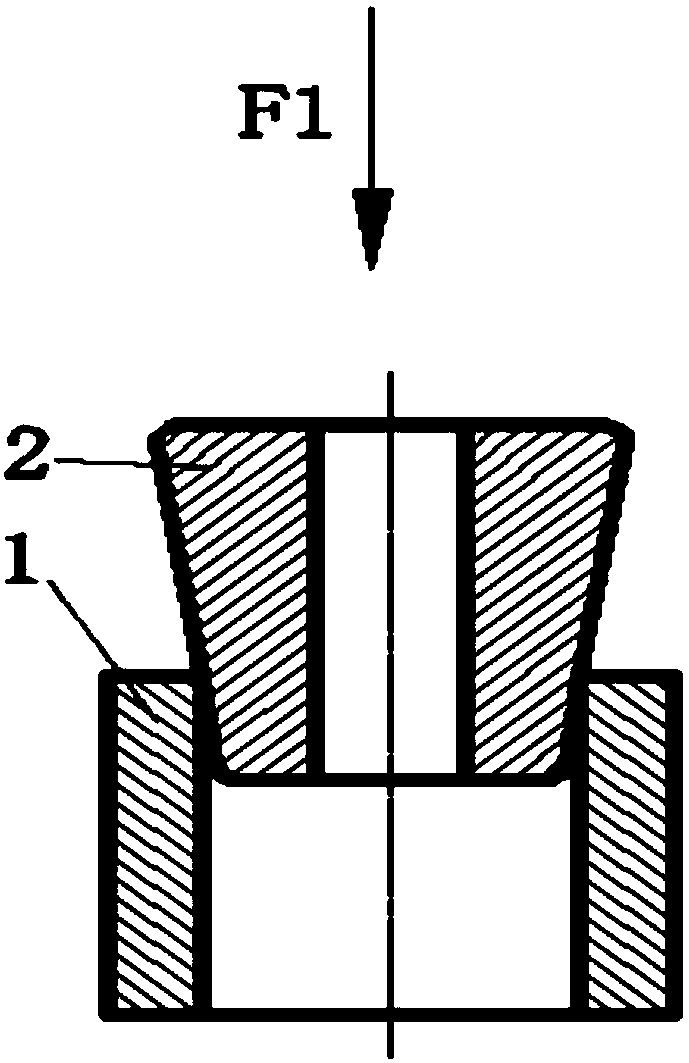

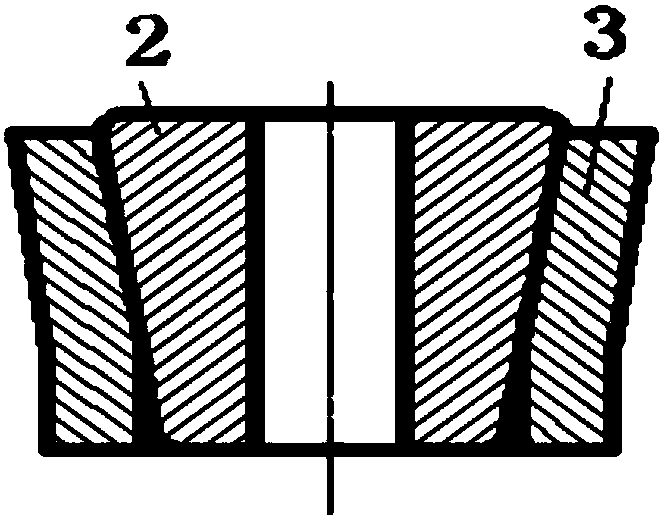

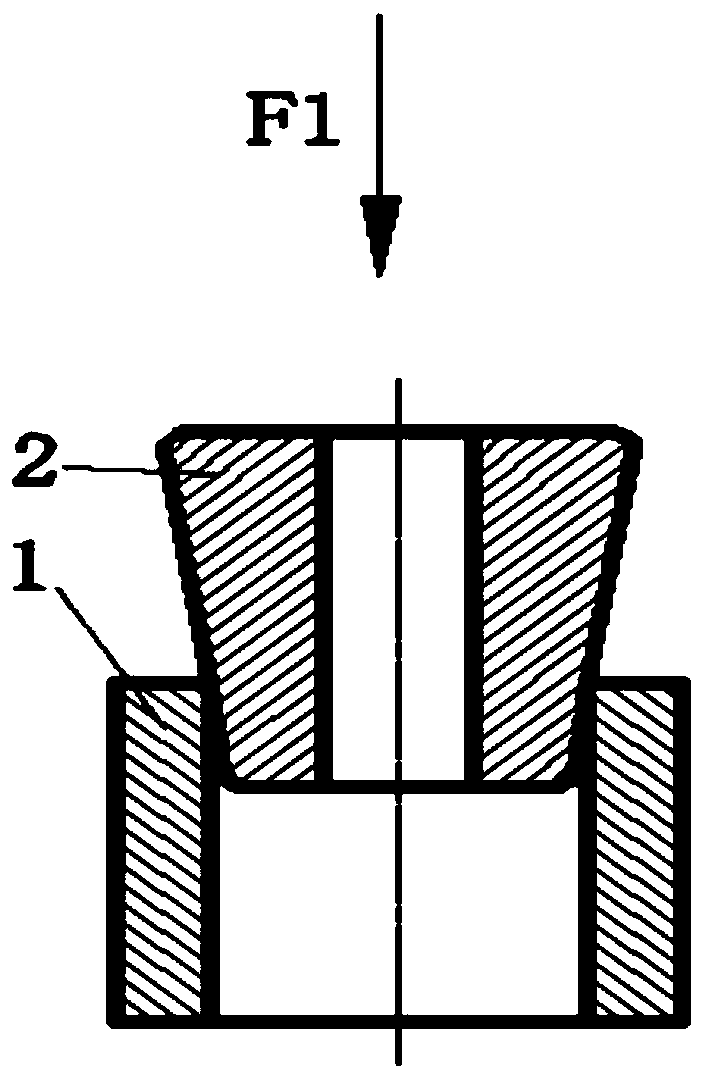

Manufacturing method and mold of 2219 aluminum alloy strap inner flange high cylinder special-shaped annular forging

InactiveCN105478637AUniform tissueReduce the difficulty of subsequent processingMetal rollingManipulatorExtrusion

The invention relates to a manufacturing method of a 2219 aluminum alloy strap inner flange high cylinder special-shaped annular forging. The manufacturing method comprises such steps as manufacturing of a rectangular annular blank, manufacturing of a special-shaped annular blank, pre-rolling of the special-shaped annular blank and manufacturing of a final forging; in the step of manufacturing the special-shaped annular blank, the rectangular annular blank coats a special-shaped lever; the special-shaped lever is flatly placed on a mandrel supporter; a beating plate is placed on the outer circle of the middle part of the rectangular annular blank; the outer circle of the rectangular annular blank is contacted with the concave lower surface of the beating plate; two ends of the annular blank are not covered by the beating plate; an upper anvil of a press is descended; the pressure is applied to the rectangular annular blank through the upper surface plane of the beating plate; meanwhile, a manipulator rotates the rectangular annular blank; under extrusion of the special-shaped lever and the beating plate, the inner diameter of the middle part of the rectangular annular blank is increased; the wall thickness is thinned; and the blank is separated to two ends to obtain the special-shaped annular blank. The beating plate is added between an upper anvil of the press and the annular blank, so that the blank is separated in the blank manufacturing phase, the shape and the size of the annular blank are more close to the shape and the size of a target forging, the subsequent processing difficulty is reduced, the period is shortened, and the efficiency is improved.

Owner:GUIZHOU AVIATION TECHN DEV

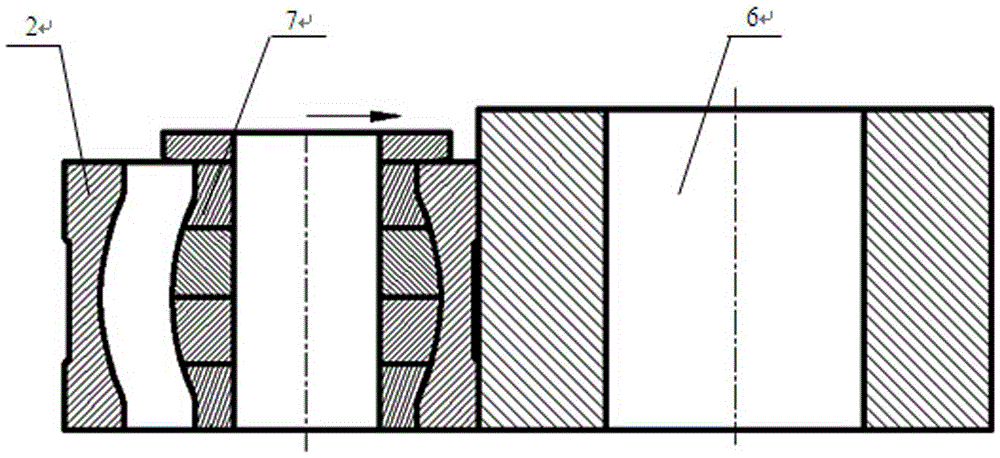

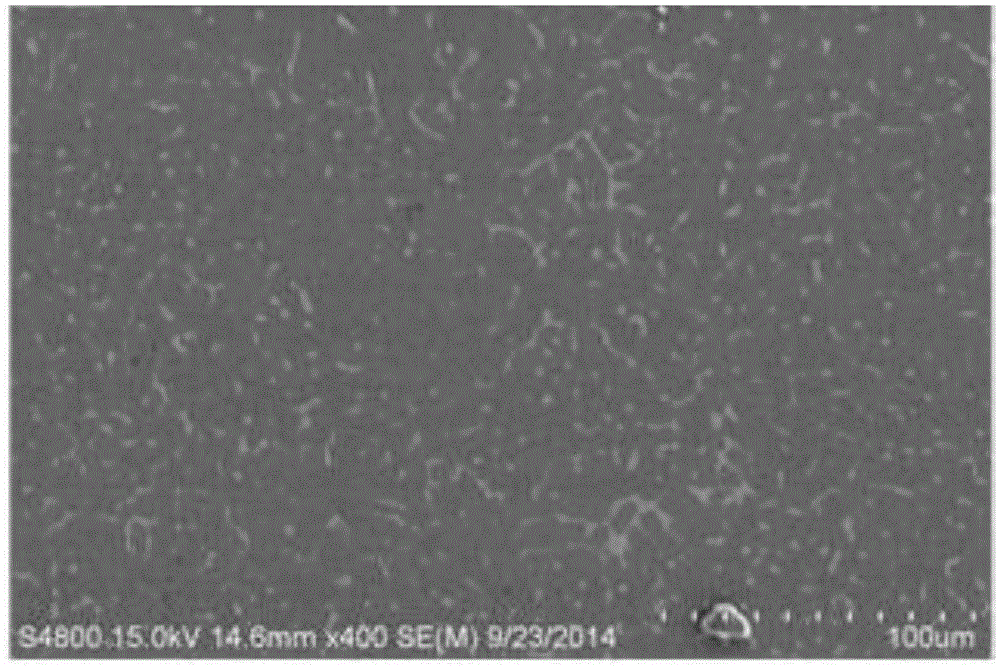

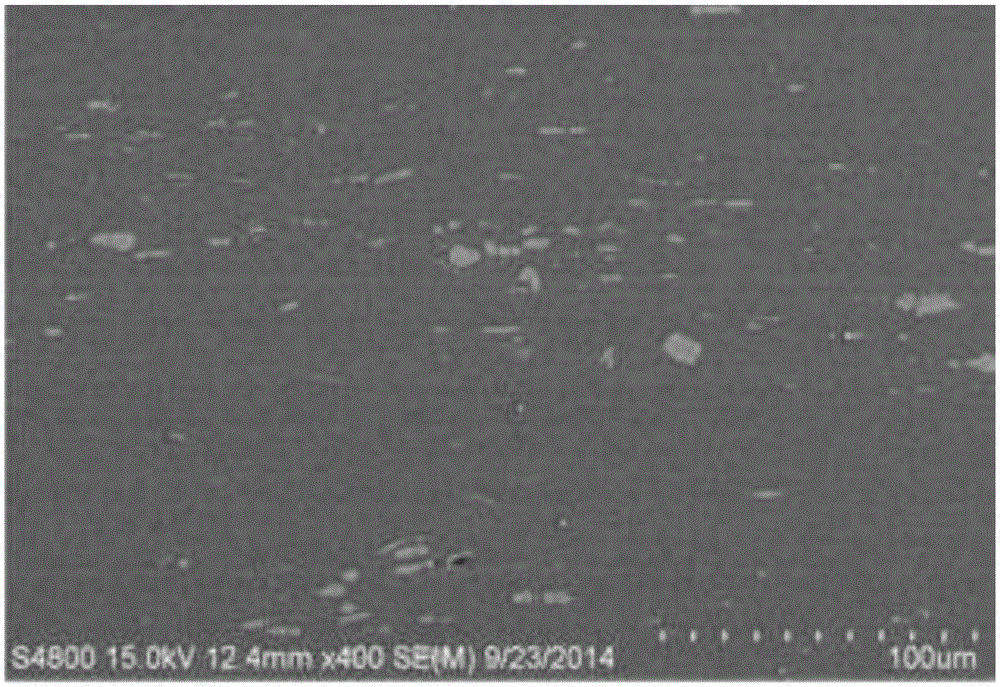

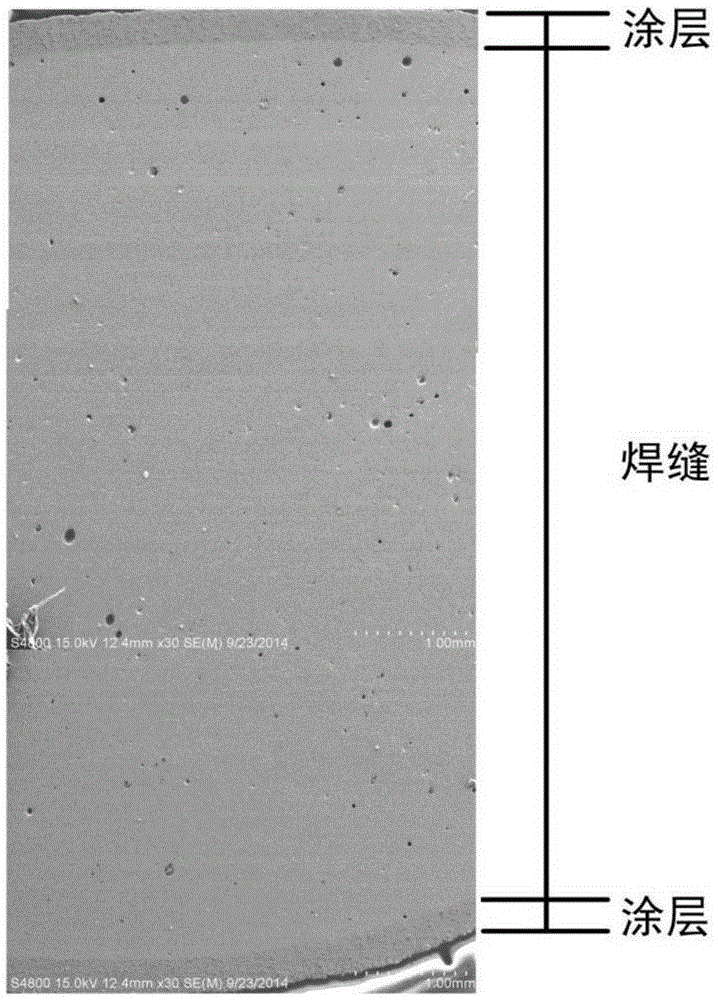

Weld surface protection method for aluminum alloy storage tank storing N2O4 for a long time

InactiveCN105420720AAchieve removalEasy to producePressure inorganic powder coatingSlagAlloy composite

The invention relates to a weld surface protection method for an aluminum alloy storage tank storing N2O4 for a long time, and belongs to the technical field of aluminum alloy weld corrosion protection. According to the method, weld surface accumulated tumors are removed through mechanical grinding; the diameters of holes with the diameters being smaller than 0.5 mm are expanded by 2-5 times; the height difference between a weld and a base body material fusion line is smaller than 0.8 mm; aluminum powder and 2024 aluminum alloy powder or 2219 aluminum alloy powder are mixed with Al2O3 powder respectively, then the powder is sent into a cold spray gun to prepare an aluminum alloy composite coating, and weld surface coarsening and oxide removal are achieved synchronously; and when welding slag and / or black gray oxidized layers exist on the weld surface, before the aluminum alloy composite coating is deposited through cold spraying, the Al2O3 powder or SiC powder is sent into the cold spray gun so as to carry out sand blasting on the weld surface, and after treatment, residual welding slag and residual black gray oxidized layers do not exist through visual inspection. By means of the method, corrosion protection on the weld of the inner wall of the aluminum alloy storage tank storing N2O4 for a long time can be achieved, and deformation of a large-size thin-wall tank body is controlled.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

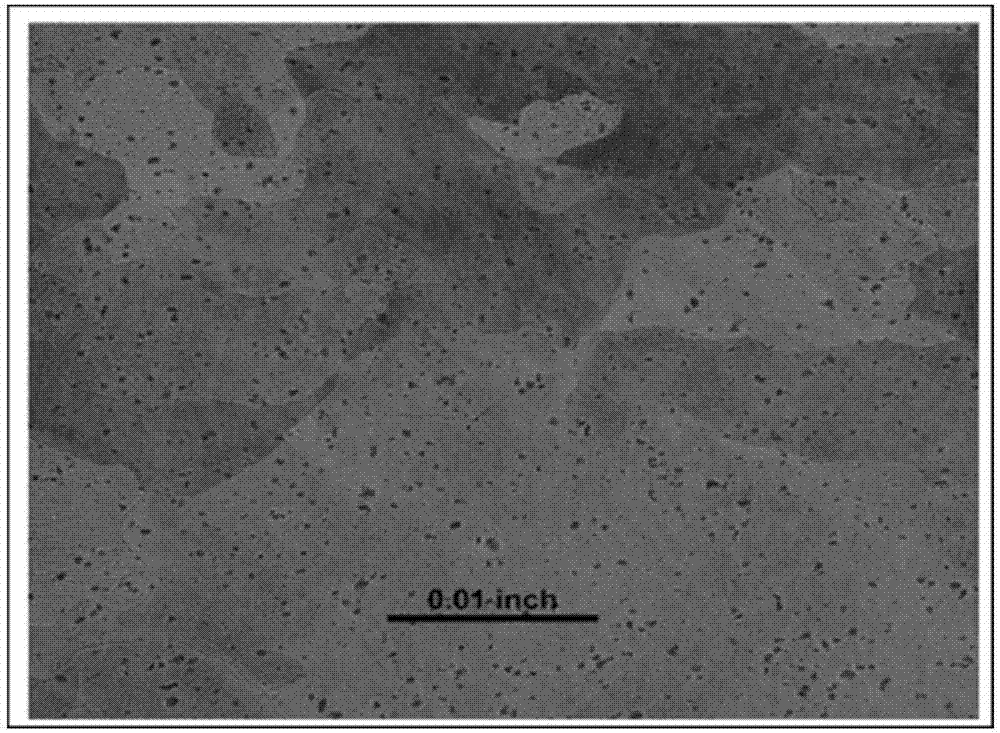

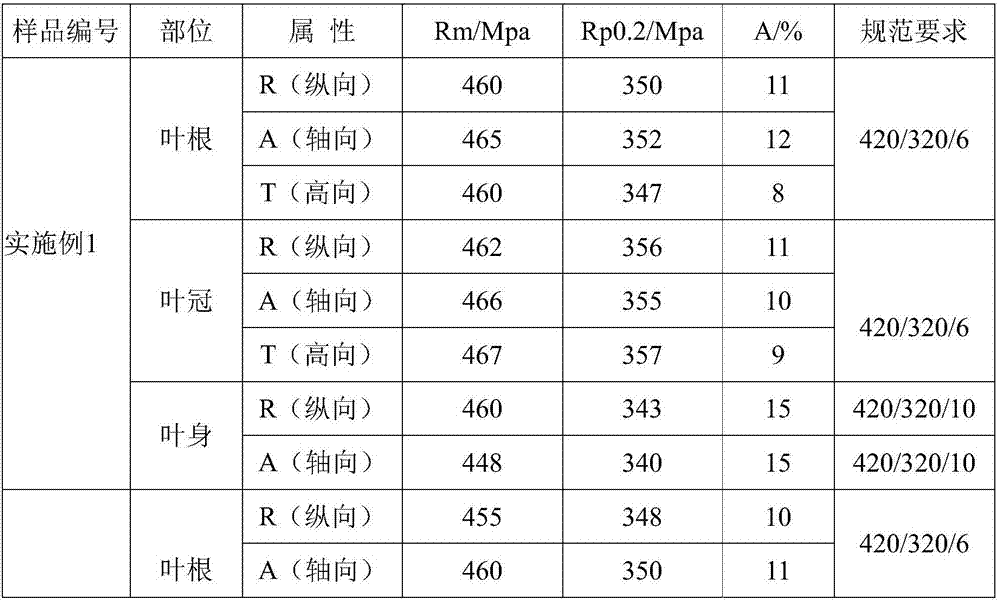

Aluminum alloy blade forged piece and manufacturing method thereof

InactiveCN107999687AHomogeneous tissue stateImprove mechanical propertiesFurnace typesEngine componentsSolid solutionThermal treatment

The invention discloses an aluminum alloy blade forged piece and a manufacturing method of the aluminum alloy blade forged piece. The manufacturing method comprises main steps of roll forging, upsetting blank making, screw press die forging, solid solution, small-deformation cold forging and aging thermal treatment. The heating parameter and the deformation parameter are reasonably set, and the cold forging deformation and the cold forging time of the forged piece are accurately controlled, so that 2219 aluminum alloy is processed. The workpiece heating temperature in the blank making step andthe die forging step ranges from 380 DEG C to 480 DEG C, the workpiece deformation in the blank making step and the die forging step ranges from 20% to 80%, the cold forging step needs to be accomplished within 3-12 hours after the solid solution step is accomplished, the workpiece deformation ranges from 1% to 5%, and finally the 2219 aluminum alloy blade forged piece with the uniform metallographic structure state and the good mechanical property is obtained. The technical requirement of a novel aero-engine for using the aluminum alloy blade forged piece can be met.

Owner:WUXI TURBINE BLADE

Ytterbium micro-alloyed aluminium-copper-magnesium-silver-manganese system high-strength deforming heat-stable aluminium alloy and preparation method thereof

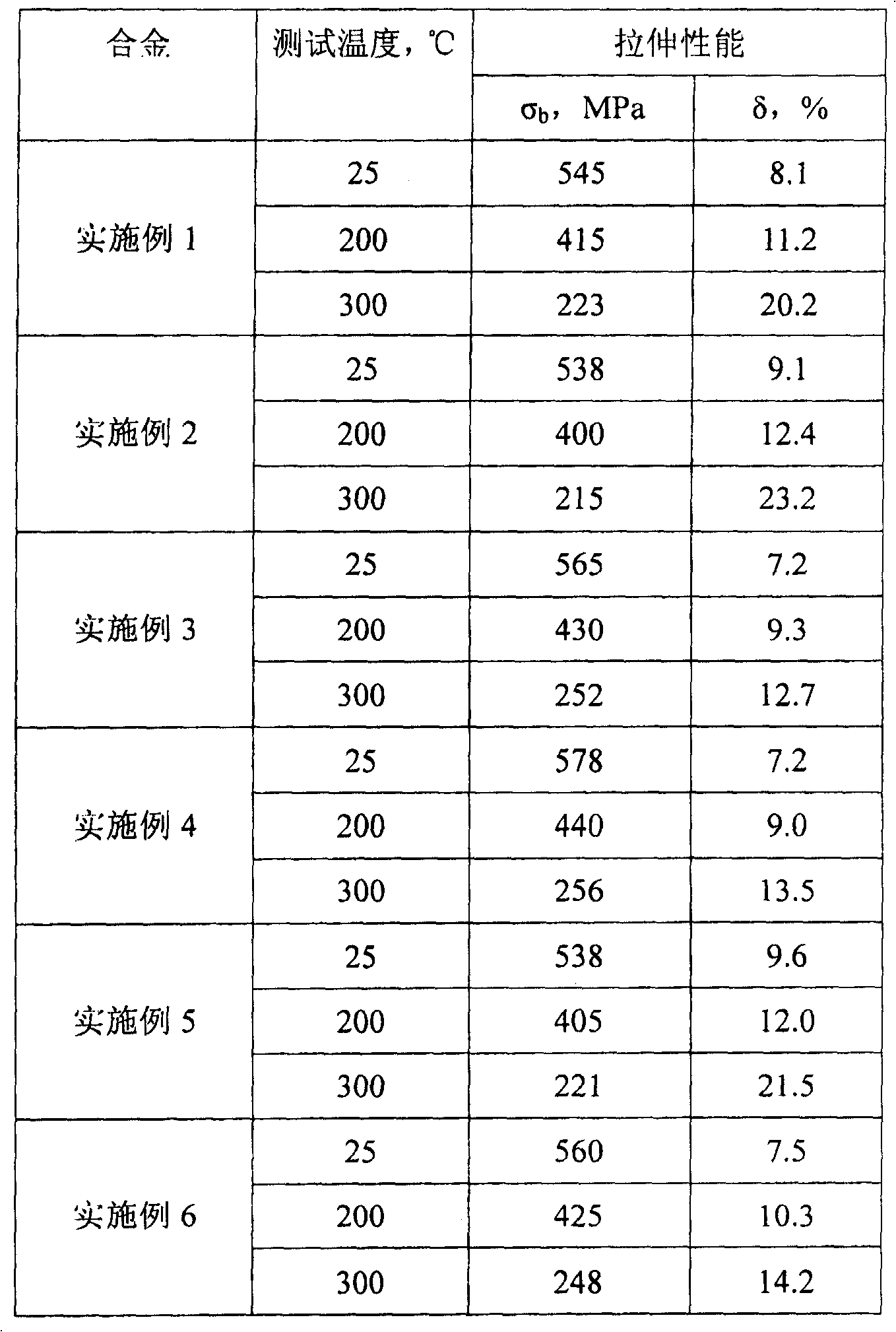

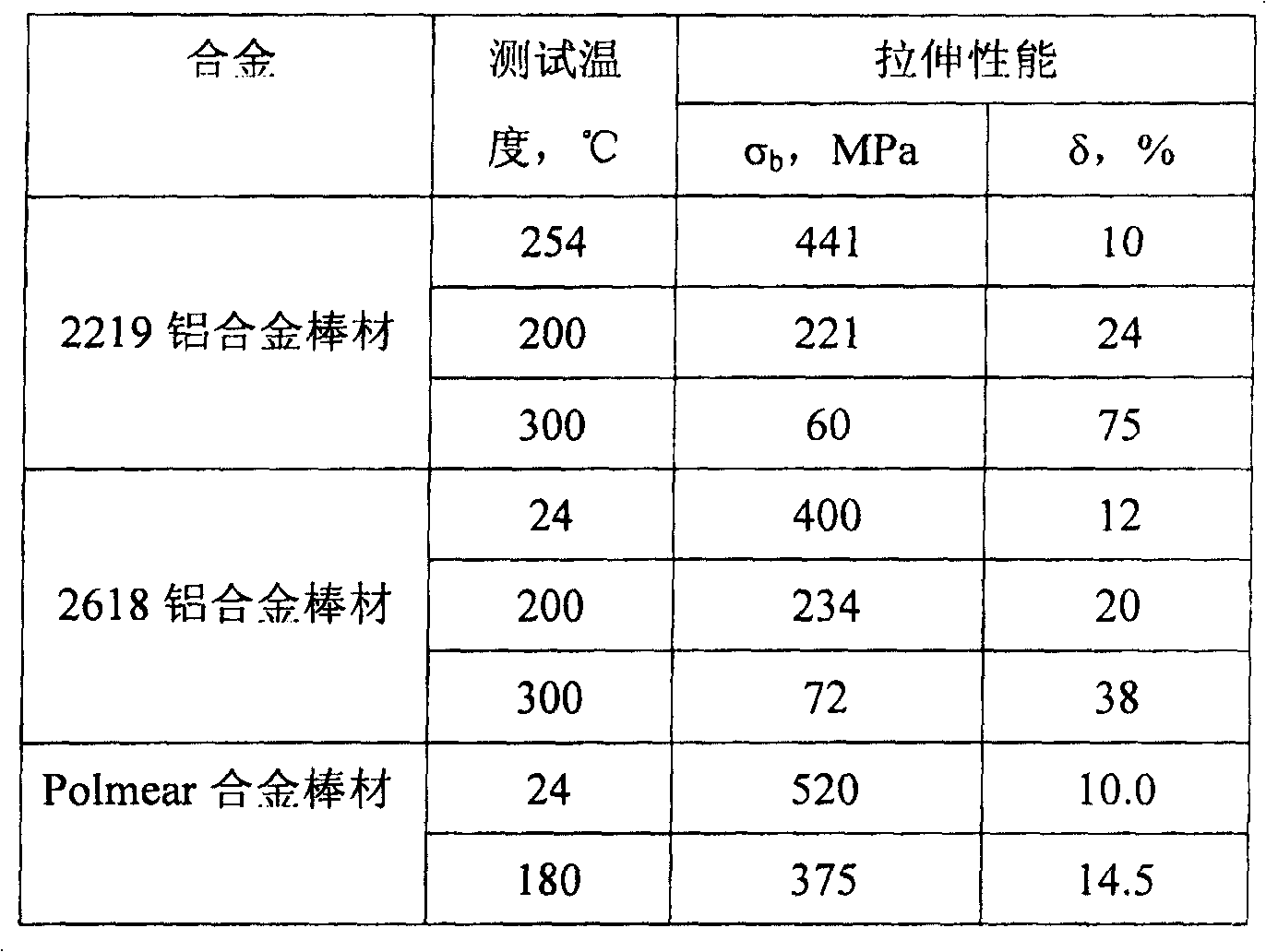

The invention relates to ytterbium-microalloyed aluminium copper madnesium silver manganese series aluminium alloy with high deforming and heat resisting, and a method for preparing it. The invention is used in the field of structural material with high performance. The specific composition of the invention and weight percentage are: Cu: 4-6.5%, Mg: 0.5-1.2%, Ag: 0.4-1.5%, Mn: 0.2-0.6%, Zr: 0.05-0.25%, Yb: 0.05-0.55%, the residuel of Al. Micro-ytterbium is added into the existing aluminium copper madnesium silver manganese series alloy and the formed alloy component is not changed, while the function of micro-ytterbium fines original cast structure of aluminium copper madnesium silver manganese series alloy. Integrated strength and heat resisting under high temperature of the alloy are improved in the invention, while the performances of the alloy exceed traditional 2618aluminium alloy, 2219 aluminium alloy and Polmear aluminium alloy.

Owner:CENT SOUTH UNIV

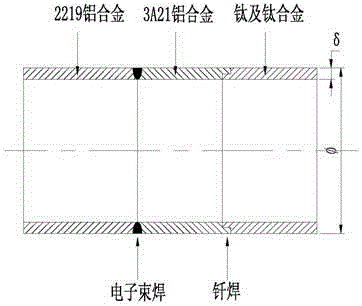

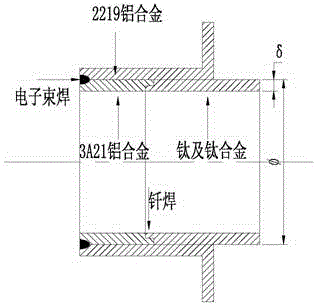

Method for welding titanium or titanium alloy with 2219 aluminum alloy

ActiveCN105033386AReliable weldingReduce corrosionSoldering apparatusWelding/soldering/cutting articlesBrazing2219 aluminium alloy

The invention relates to a method for welding titanium or titanium alloy with 2219 aluminum alloy and belongs to the field of metal connection. In order to achieve the purpose of the invention, first, a proper transition material needs to be found. The material needs to have great weldability (fusion welding, or high-energy beam welding or brazing) with titanium, titanium alloy and 2219 aluminum alloy, and the material self needs to have high strength and tenacity. Comprehensive performance comparison shows that the material has great brazing weldability with 3A21 aluminum alloy, the titanium and the titanium alloy and has great electron beam welding weldability with 2219 aluminum alloy, and a reliable welding joint can be formed in any case. The connecting technology is successfully used into an XX-1 or XX-2 level PMD management device structure and has a great application effect.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Aluminium alloy refiner and preparation method and application thereof

The present invention provides an aluminium alloy refiner. The aluminium alloy refiner is characterized by comprising 7 to 10 parts of Ti, 2 to 3 parts of B and the balance of Al by weight, for example, 8 parts of Ti, 3 parts of B and 89 parts of Al by weight. The aluminium alloy refiner is prepared by rapid solidification. After the refiner is added to A356.2 aluminium alloy, the grain size of the alloy is significantly reduced than that of the aluminium alloy treated by a conventional refiner. Moreover, the solubility of metals in liquid may be increased due to rapid solidification, such that the refiner is more easily absorbed by the aluminium alloy melt after being added to the aluminium alloy.

Owner:CITIC DICASTAL +1

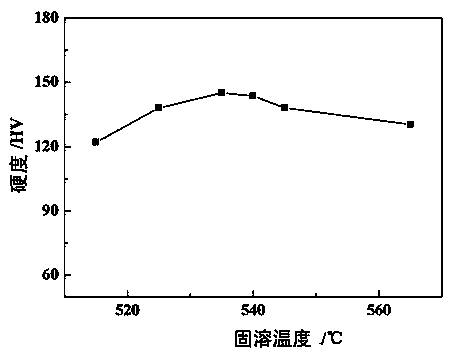

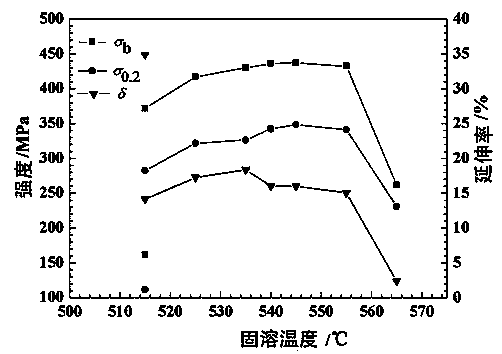

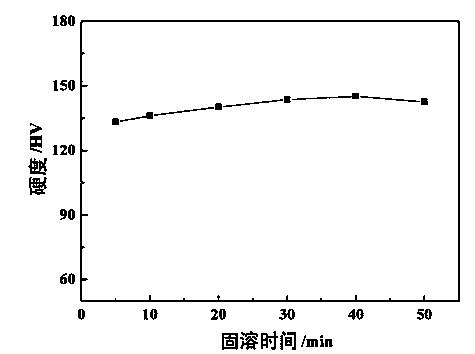

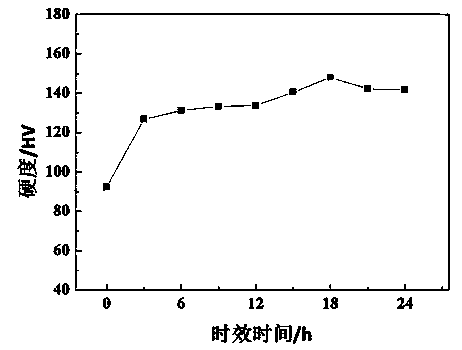

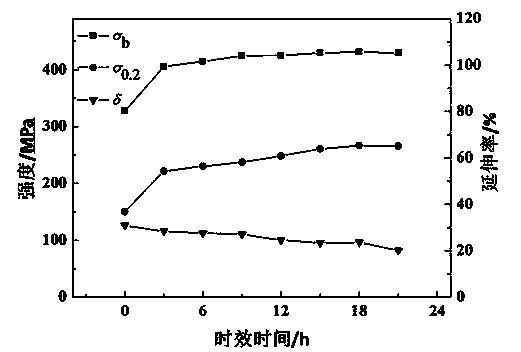

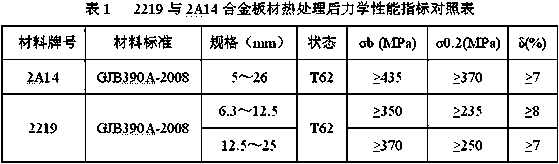

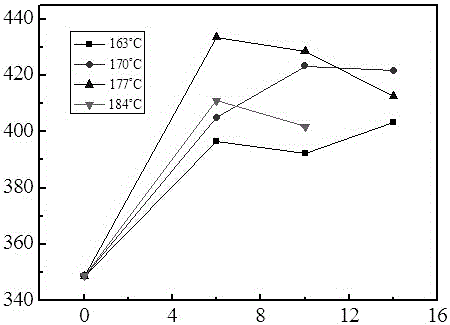

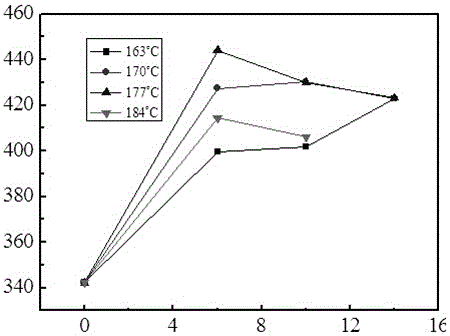

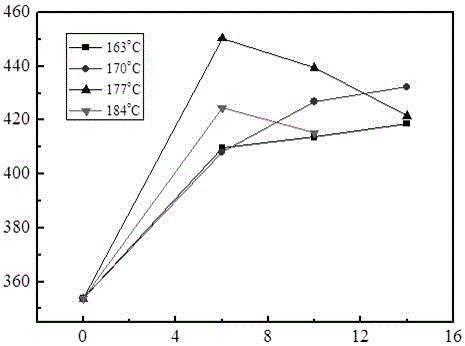

Aging heat treatment method of 2219 aluminum alloy

The invention discloses an aging heat treatment method of 2219 aluminum alloy, and belongs to the field of aluminum alloy heat treatment technology. The method comprises the following steps of: performing solid solution treatment to 2219 aluminum alloy for 5-40 minutes under the condition of 515 DEG C to 565 DEG C by adopting a T6 heat treatment method, then quenching in water for 5 minutes at room temperature, wherein the quenching transfer time is less than 10 seconds; finally, performing aging treatment for 1 to 21 hours at the temperature of 160 DEG C to 190 DEG C. The aging heat treatment method has the following advantages that the influence of heat treatment parameters on the mechanical performance of 2219 aluminum alloy is systematically researched by adopting a method of controlling variables, so that when the alloy is subjected to 40-minute solid solution at 535 DEG C and 12-hour aging at 175 DEG C, the mechanical performance of the alloy can be improved, and the application range of the aluminum alloy in the industrial field can be widened to a greater extent.

Owner:TIANJIN UNIV

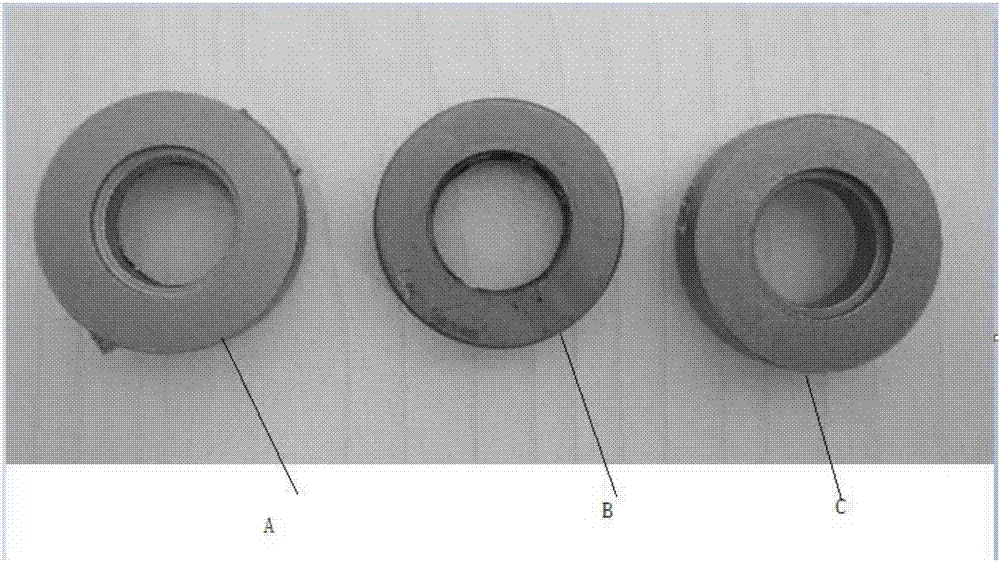

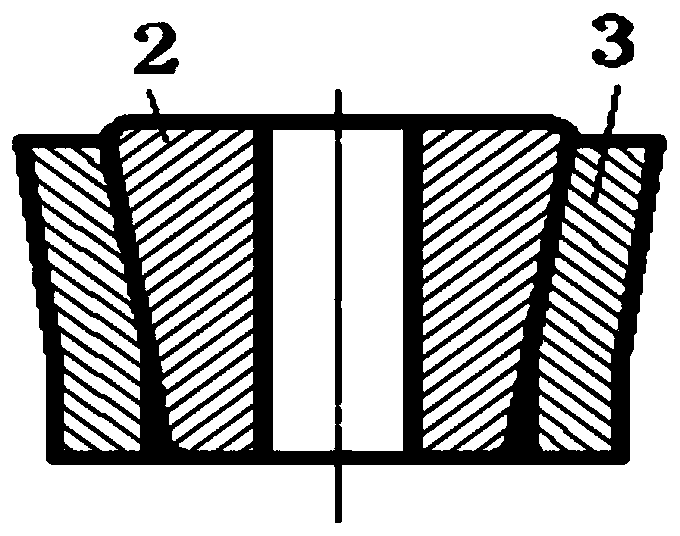

Manufacturing method for C-shaped section ring forging of 2219 aluminum alloy

InactiveCN108213843AIncrease profitResolving Tissue Differences in Crimp WeldsRoom temperatureHardness

The invention provides a manufacturing method for C-shaped section ring forging of a 2219 aluminum alloy. The manufacturing method for C-shaped section ring forging of the 2219 aluminum alloy comprises sawing; quenching treatment, upsetting, punching, carrying out mandrel support reaming hole to obtain a rectangular ring blank; and manufacturing a profile ring blank and manufacturing a forge piece. According to the manufacturing method, the 2219 aluminum alloy profile ring piece is produced, due to the appearance of the forge piece is closer to the part, a flow line of the forge piece can be kept even more complete, and the subsequent machining allowance is small, so that the machining period is short, and the material utilization rate is high, moreover, the ring part is a complete circular ring, internal tissues are uniform, so welding is not needed, and therefore the problem of tissue difference and deformation of plate curl welding is solved; and meanwhile, by adding the quenching and tempering treatment, the tensile strength in room temperature and the brinell hardness are increased.

Owner:GUIZHOU AVIATION TECHN DEV

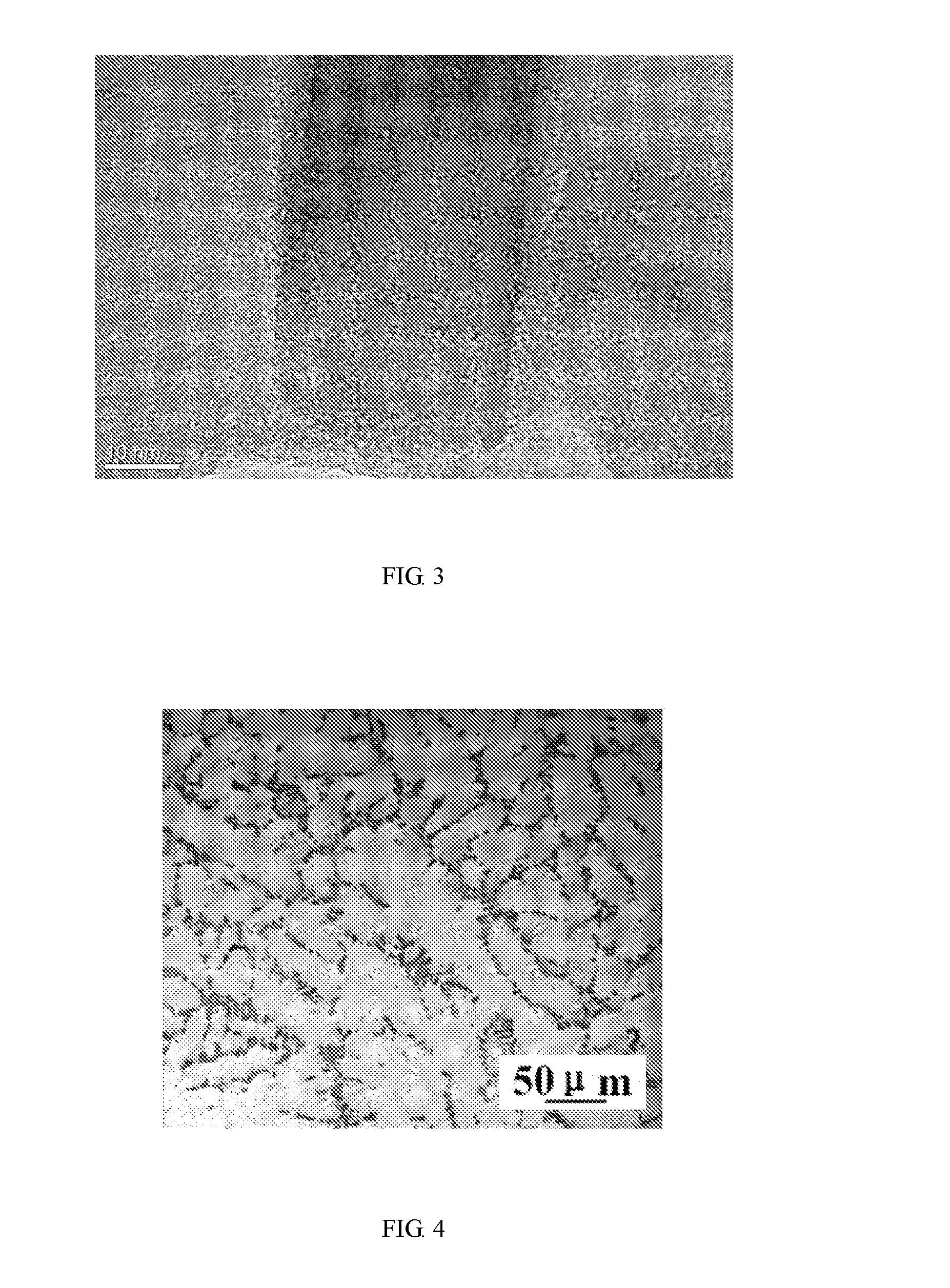

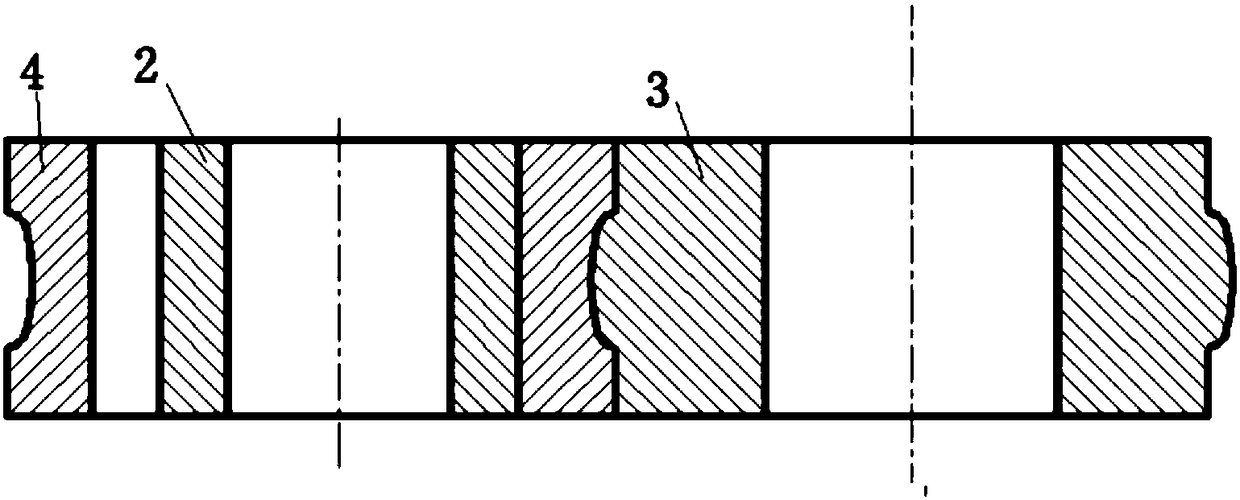

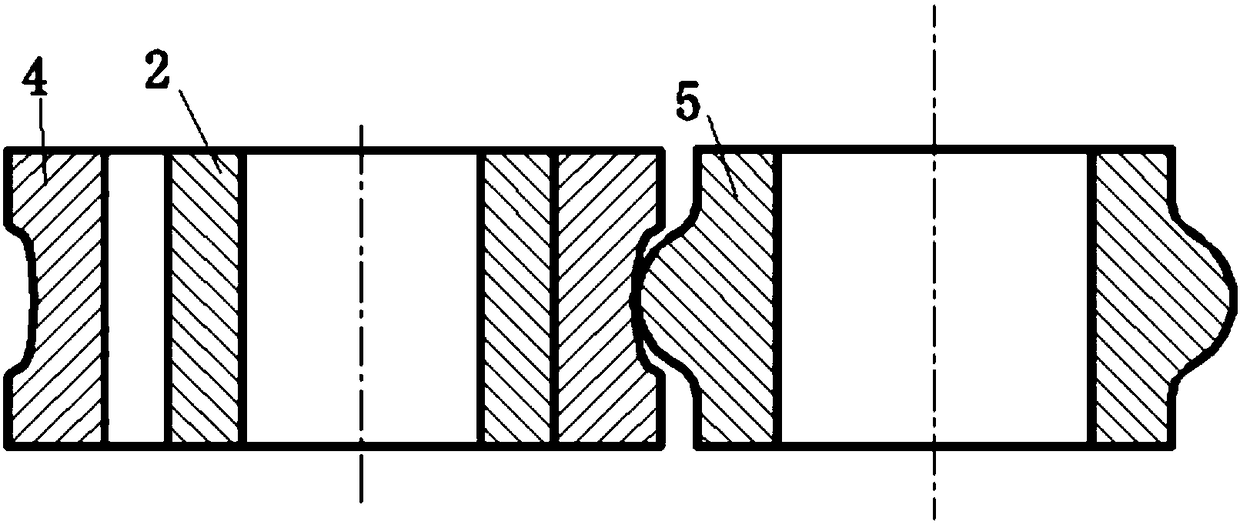

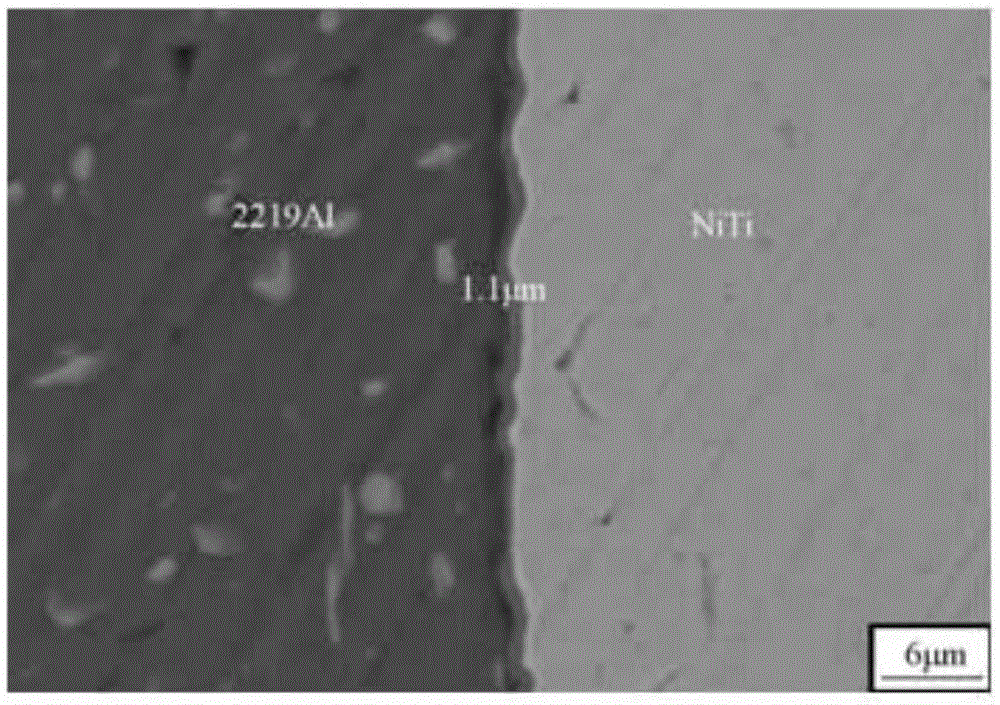

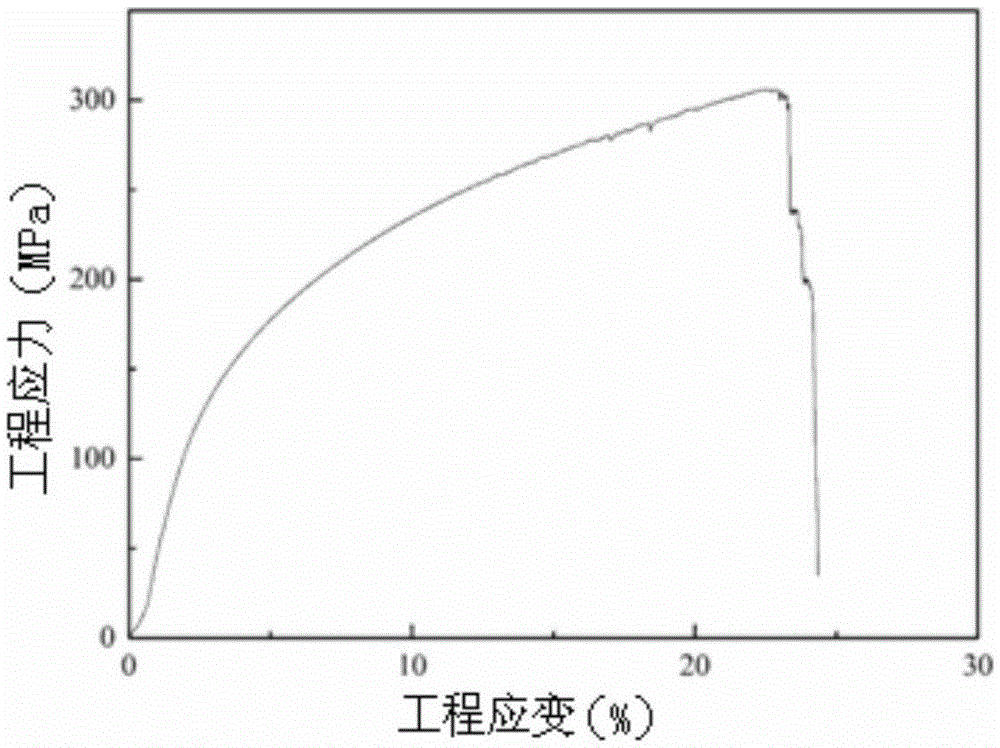

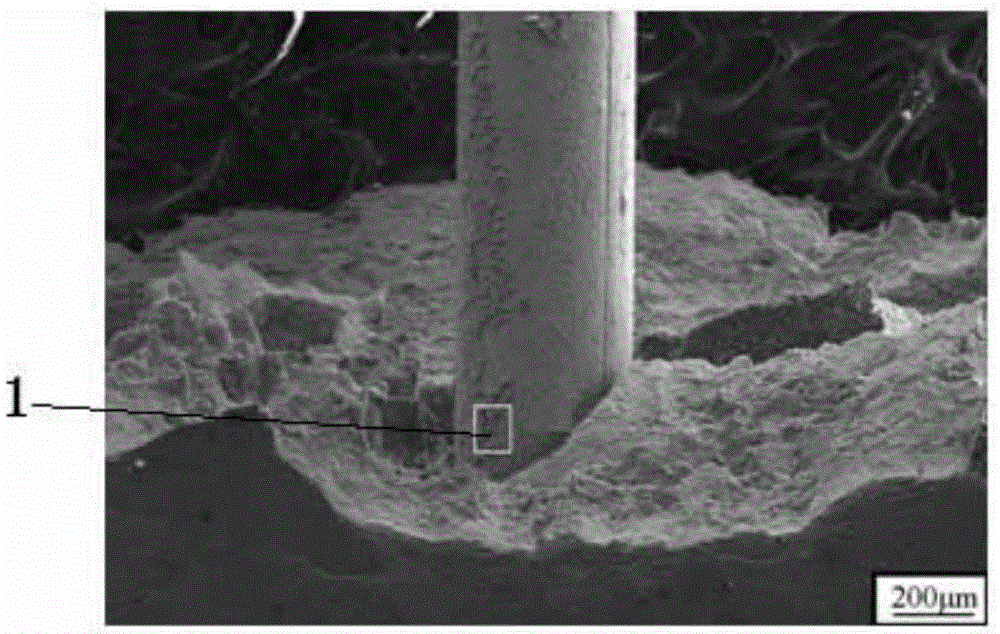

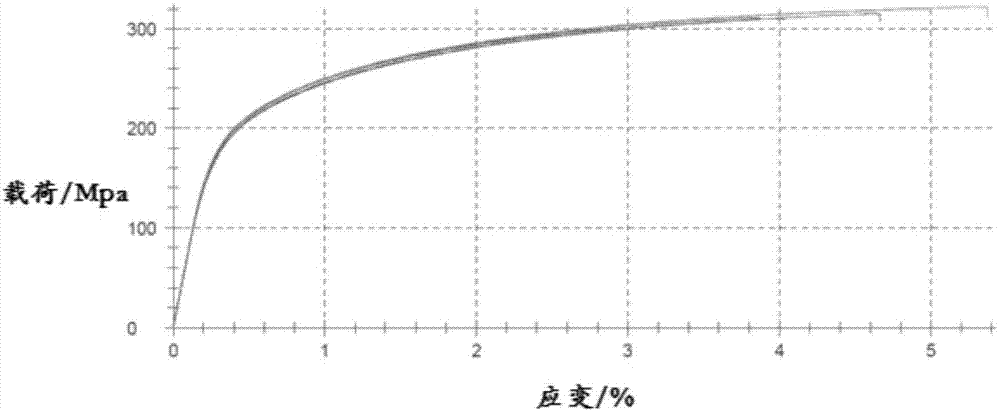

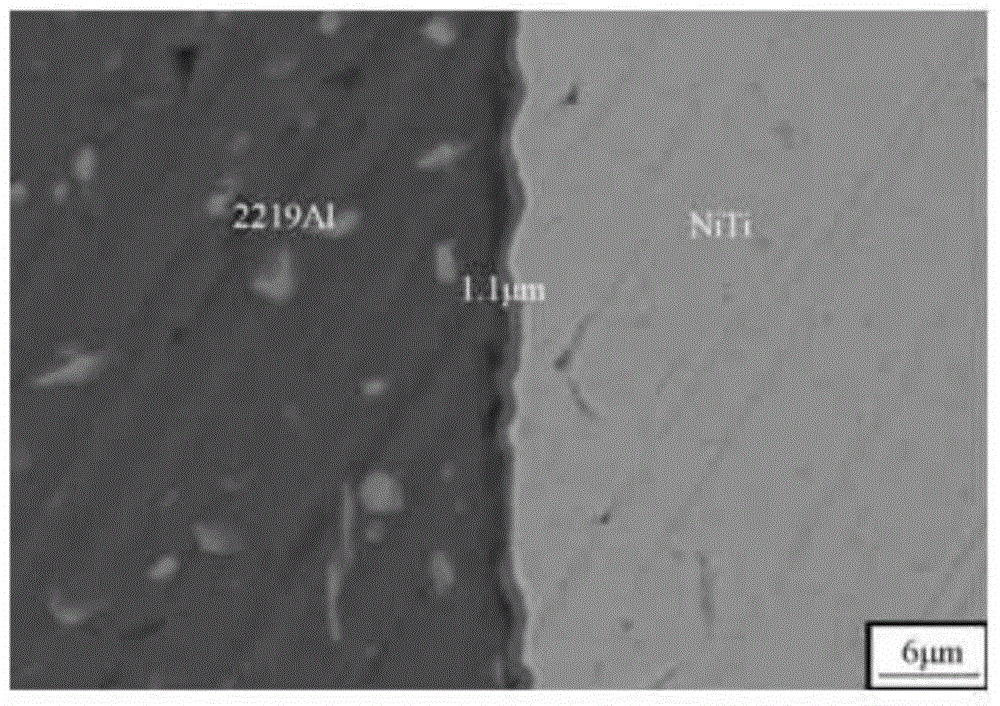

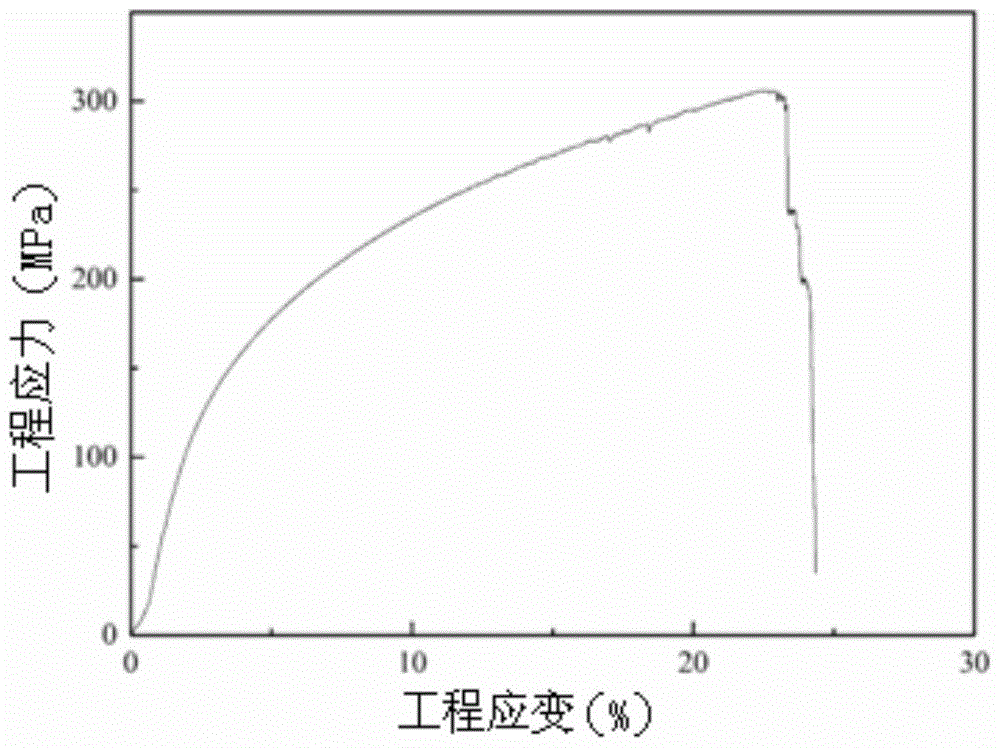

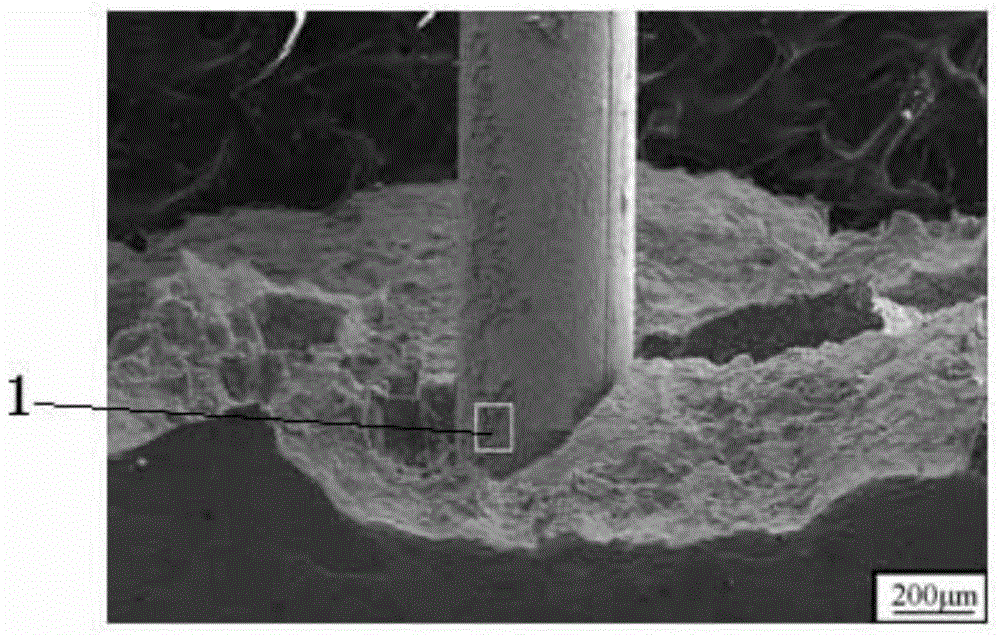

Method for preparing NiTi-fiber-enhanced 2219Al composite

ActiveCN105313426AAddressing densificationAddress reactivityLayered product treatmentLaminationFiberReaction layer

The invention relates to a method for preparing a NiTi-fiber-enhanced 2219Al composite. The method aims at solving the problem that an existing method for preparing a continuous nickel-titanium fiber enhanced 2219 aluminum alloy composite which is arranged in one direction needs to achieve the purposes of regulating and controlling the fiber arrangement mode, the fiber content control, the material compacting, the interface reactions and the interface combining degrees. The method includes the first step of raw material processing, the second step of short NiTi fiber arrangement, the third step of vacuum hot pressing and sintering, and the fourth step of composite thermal treatment. A reaction layer with the thickness of about 1 micrometer is arranged between NiTi fiber and 2219Al alloy in the NiTi-fiber-enhanced 2219Al composite. The tensile strength is 305 MPa, the elongation is 23%, the excellent strength and plasticity are shown, and the method can be used for the fields of aviation, aerospace, machines, traffic, electronics and the like.

Owner:HARBIN INST OF TECH

High-strength anodizing die-casting aluminium alloy and preparation method thereof

ActiveCN107447134ATo promote floatingImprove filtration efficiency5005 aluminium alloy6061 aluminium alloy

The invention belongs to the technical field of aluminium alloy and particularly relates to high-strength anodizing die-casting aluminium alloy and a preparation method thereof. Mg, Mn, Fe, Zn, Mo, Zr, Cr and Al constitute die-casting alloy elements, and the high-strength anodizing die-casting aluminium alloy is prepared by a smelting procedure and a die-casting procedure. The types, the contents and the adding modes of all the alloy elements are strictly controlled, so that lots of the elements mainly exist in a matrix in a solid solution format under the die-casting (fast cooling) condition; Zr and Mo ensure more uniform alloy tissue and refined crystal grains, so that the alloy has high strength and favorable die-casing performance and excellent anodizing performance; on a die-casting machine, die-casting molding can be performed by a die to directly obtain the required product without heat treatment or deformation, so that the production cost is greatly lowered; and the high-strength anodizing die-casting aluminium alloy is suitable for thin-walled shell members demanding much on the strength, the die-casting performance and the anodizing demand of the aluminium alloy.

Owner:苏州慧驰轻合金精密成型科技有限公司

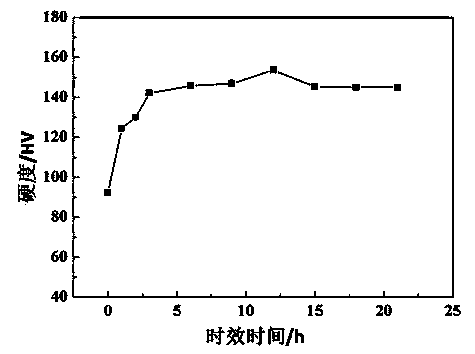

Method for determining deformation heat treatment conditions for improving 2219 aluminium alloy performance

The invention discloses a method for determining deformation heat treatment conditions for improving 2219 aluminium alloy performance. The method comprises the followings: an aging temperature is determined by adopting T6 heat treatment, solid dissolving, quenching and aging treatment are performed on the sample of 2219 aluminium alloy, and the aging temperature of optimal deformation heat treatment, corresponding to intensity and hardness, is determined; T8 heat treatment is adopted for determining aging time, solid dissolving, quenching and rolling are performed on the sample of the 2219 aluminium alloy, aging treatment is performed at the temperature determined by T6 heat treatment, and the aging time of the optimal deformation heat treatment, corresponding to intensity and hardness, is determined. The method provided by the invention has the advantages as follows: the heat treatment method is simple, the optimal aging time and aging temperature of the T8 heat treatment of 2219 aluminium alloy are determined, the problem of insufficient databases is solved, and the application scope of the aluminium alloy in the industrial field can be expanded.

Owner:TIANJIN UNIV

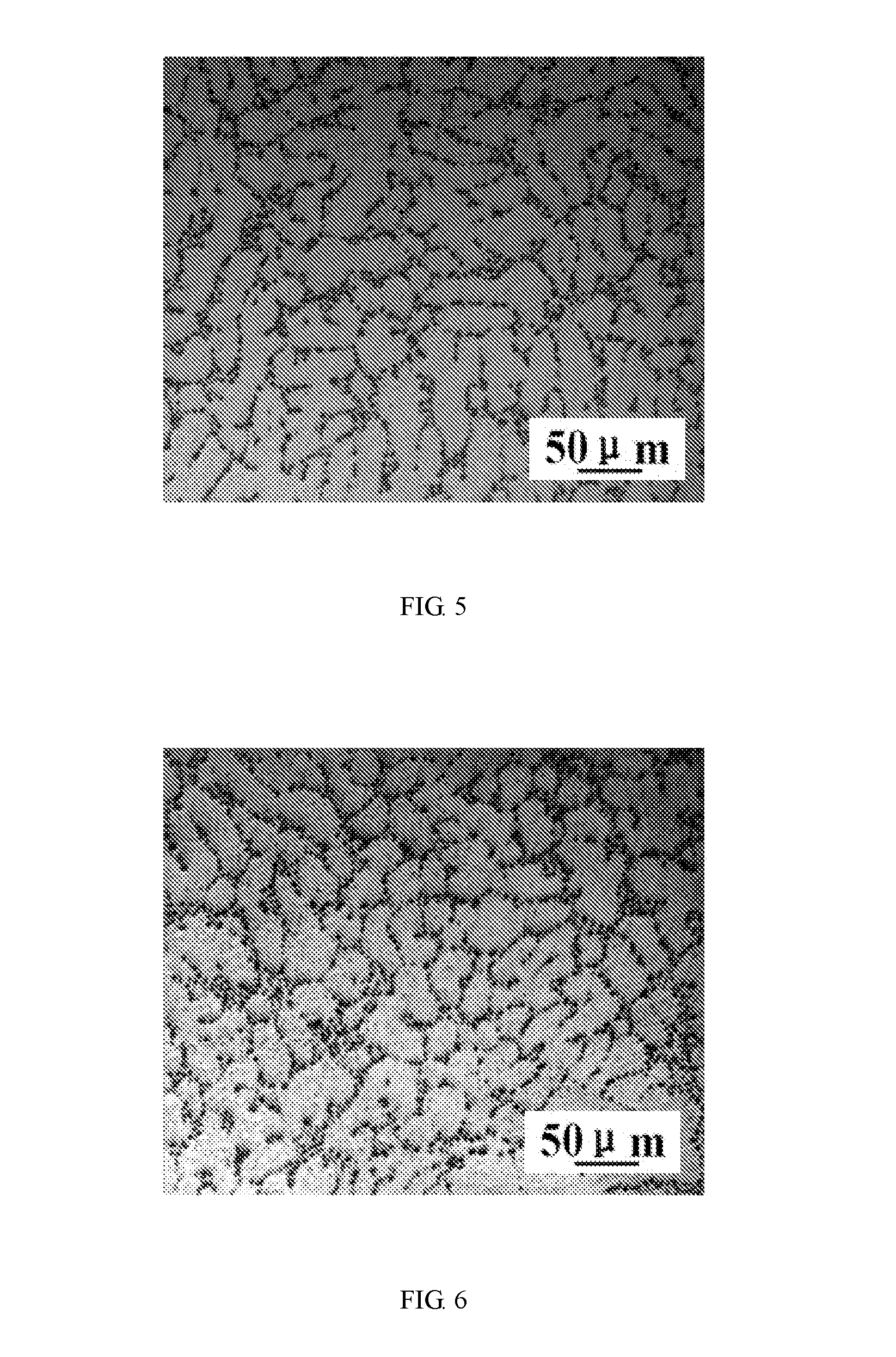

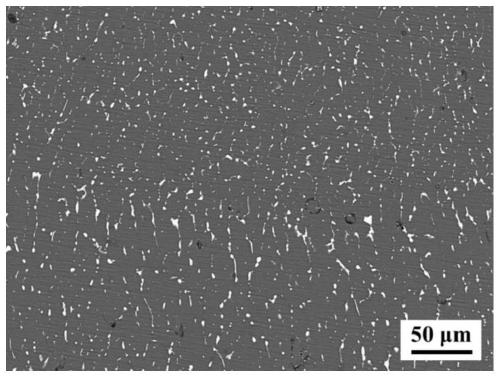

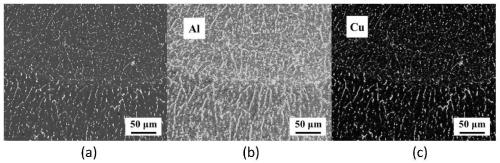

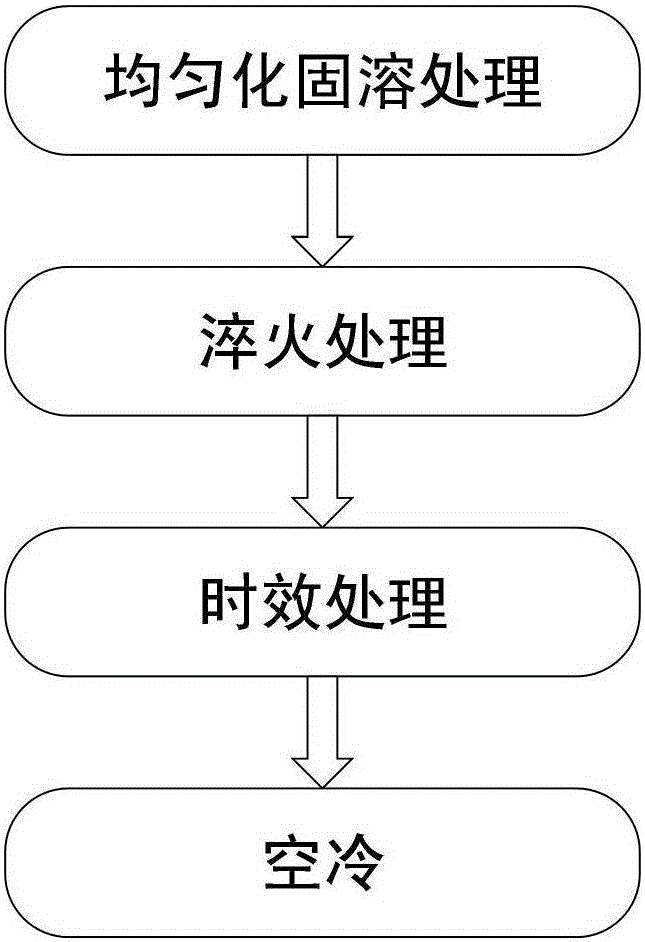

Heat treatment method for additive manufacturing of 2219 Al alloy

ActiveCN110438422AFast preparationHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencySolution treatmentCu element

The invention discloses a heat treatment method for additive manufacturing of a 2219 Al alloy and belongs to the field of heat treatment for metal additive manufacturing. The heat treatment method comprises the following steps: putting a 2219 Al alloy formed component into a heat treatment furnace of 500-550 DEG C for 1-5 hours' heat preservation, so as to obtain an Al alloy component subjected tosolution treatment; next, putting the Al alloy component subjected to solution treatment into water of 10-30 DEG C for quenching treatment, wherein the quenching transfer time lasts 5-20 seconds; then, putting the Al alloy component subjected to quenching treatment into the heat treatment furnace, heating the Al alloy component along with the heat treatment furnace to 150-250 DEG C, and carryingout heat preservation for 4-10 hours; and finally, carrying out air cooling till the room temperature is reached. According to the heat treatment method disclosed by the invention, the heat treatmentprocess is simple and convenient to operate as well as relatively high in efficiency; meanwhile, the segregation of Cu element of the 2219 Al alloy component subjected to heat treatment can be improved, the quantity of coarse eutectic structures can be greatly reduced, and the strength and the toughness can be well improved; and the requirements of aerospace products for the high-strength and high-toughness 2219 Al alloy component can be met.

Owner:DALIAN UNIV OF TECH

Method for improving heat treatment performance of 2219 aluminium alloy thin-walled curved part

The invention discloses a method for improving the heat treatment performance of a 2219 aluminium alloy thin-walled curved part, and belongs to the field of heat treatment of workpieces. The method comprises the following steps: after being fed and cleaned, an annealed plate is quenched, wherein the quenching temperature is 530-540 DEG C, and the quenching transferring time is less than or equal to 15 s; and within 2 h after quenching, the annealed plate is die-formed, and after being forming correcting is completed, the annealed plate is aged. In the method, heat treatment and pressure forming are combined, so that the pressure forming property, the tensile strength and the yield strength of the raw material, namely the annealed 2219 aluminium alloy thin-walled curved part are remarkably improved, the tensile strength sigma b of the annealed 2219 aluminium alloy thin-walled curved part is higher than or equal to 420 MPa, the yield strength sigma 0.2 of the annealed 2219 aluminium alloy thin-walled curved part is higher than or equal to 320 MPa, and the elongation delta of the annealed 2219 aluminium alloy thin-walled curved part is higher than or equal to 10.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

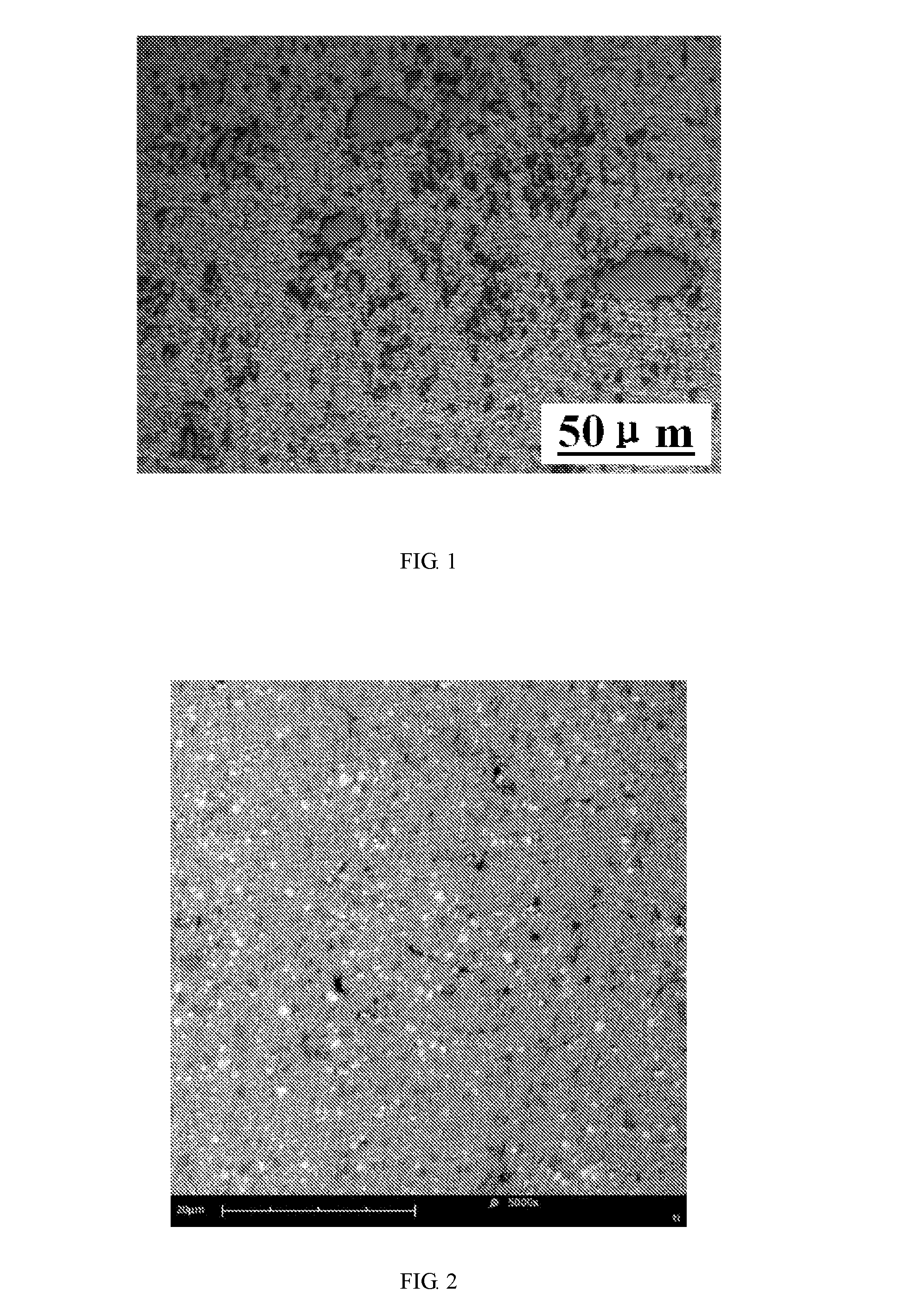

Thermal treatment method for as-deposited 2219 aluminum alloy

The invention discloses a thermal treatment method for an as-deposited 2219 aluminum alloy, and relates to the thermal treatment method for the as-deposited 2219 aluminum alloy. In order to solve the problems that a current as-deposited 2219 aluminum alloy has a coarse eutectic structure which is in net distribution along a grain boundary, has severe element segregation and very poor mechanical performance, the thermal treatment method comprises the following steps: carrying out uniform solid-solution treatment on the as-deposited 2219 aluminum alloy for 20 hours at a temperature of 530 DEG C; then, putting the as-deposited 2219 aluminum alloy into water at the room temperature for carrying out quenching treatment, and carrying out ageing treatment on the as-deposited 2219 aluminum alloy for 14-28 hours at a temperature of 160-190 DEG C; and finally, cooling the as-deposited 2219 aluminum alloy in air, thereby completing the thermal treatment for the as-deposited 2219 aluminum alloy. The thermal treatment method can effectively reduce the coarse eutectic structure in the as-deposited 2219 aluminum alloy and can improve segregation; and meanwhile, equipment needed by thermal treatment is simple, the operation is convenient and the production efficiency is high. The thermal treatment method belongs to the material additive manufacturing field.

Owner:HARBIN INST OF TECH

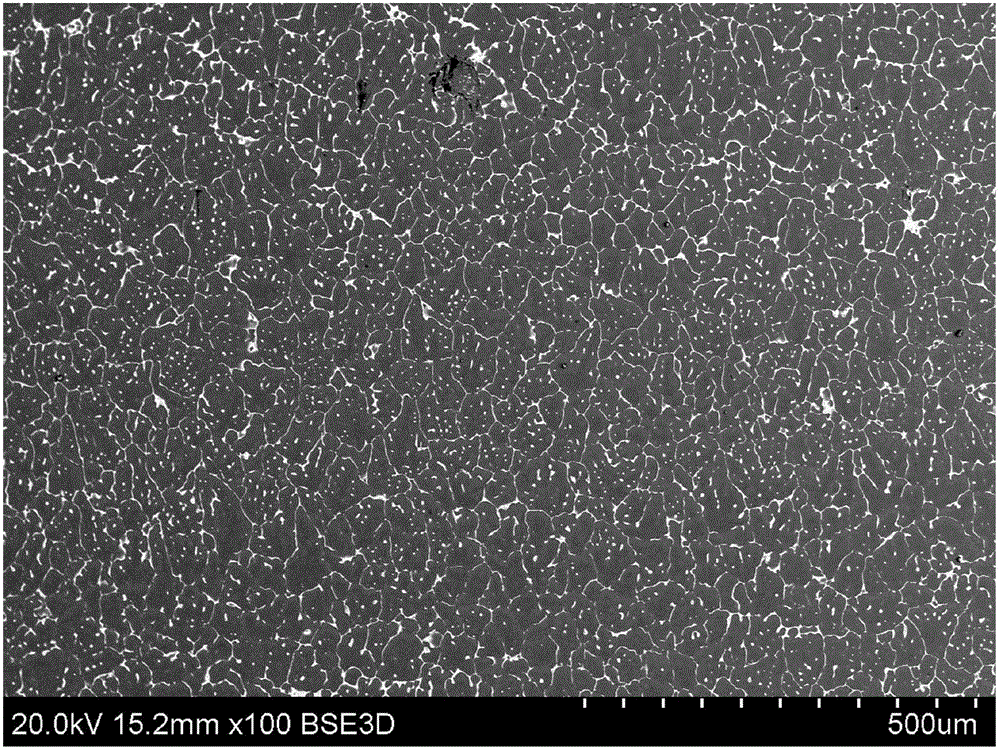

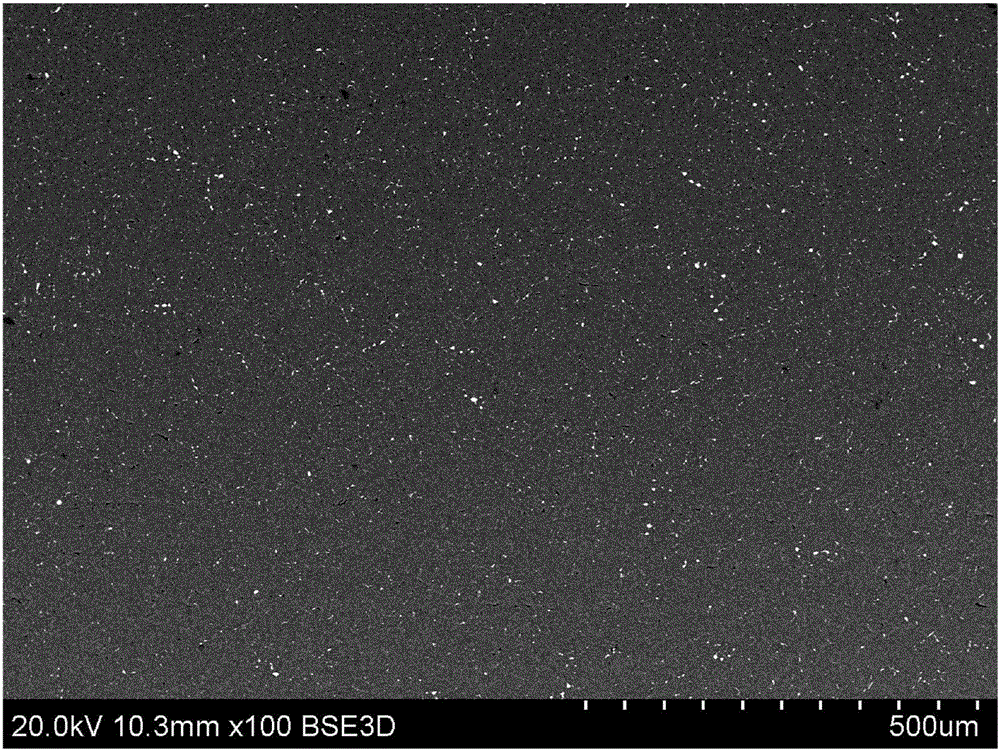

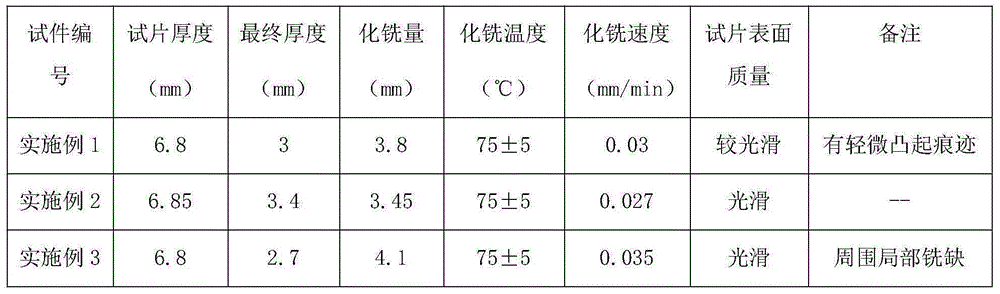

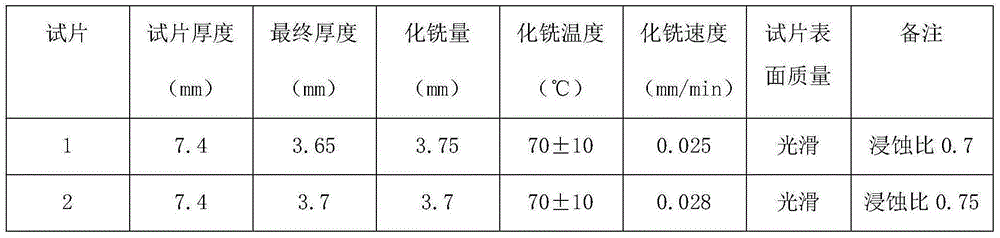

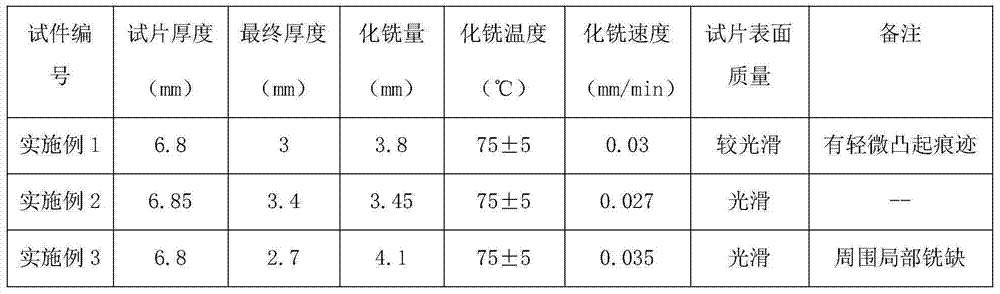

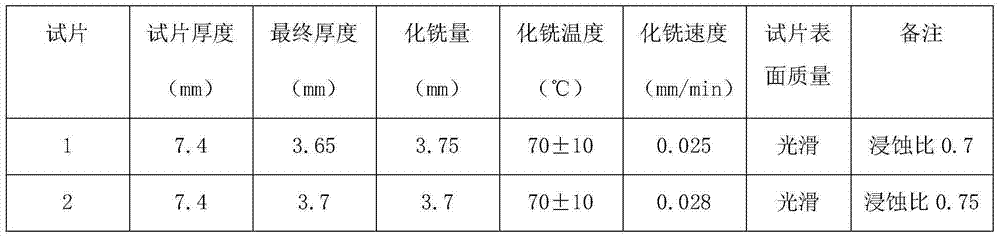

Chemical milling solution and chemical milling method thereof

The invention provides a chemical milling solution and a chemical milling method thereof. The chemical milling solution comprises the following ingredients, NaOH, Al3+, sodium sulphide, sodium thiosulfate, seignette salt and water which serves as a solvent, the solution is adopted to carry out chemical milling treatment on a workpiece, a high-copper-content aluminium alloy can be successfully reduced, particularly the problem that the surface of a 2219 aluminium alloy is rough is solved, after the workpiece is treated by the chemical milling solution, the surface of the workpiece is smooth, the orange peel is not generated, and the surface roughness can meet the requirement; in addition, the preparation of the solution is easy to operate, and the solution property is stable.

Owner:TIANJIN AEROSPACE CHANGZHENG ROCKET MFGCO +1

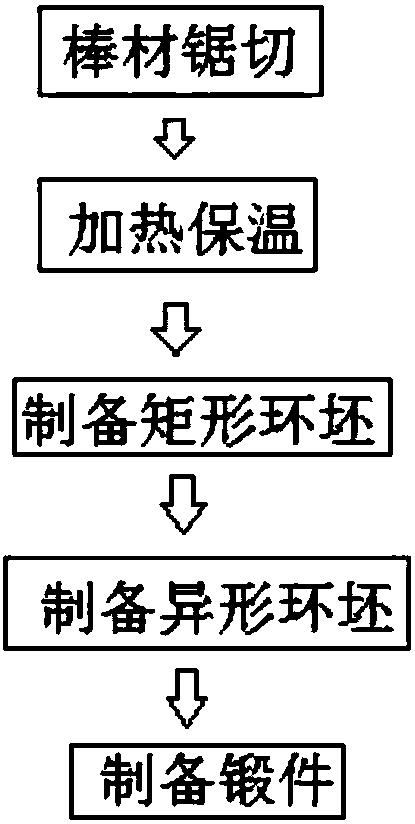

Manufacture method for 2219 aluminium alloy cone-shaped ring forging piece with large cone angle

ActiveCN108213316AEven heating inside and outsideIncrease profitEngine componentsManufacturing technologyAbnormal shaped

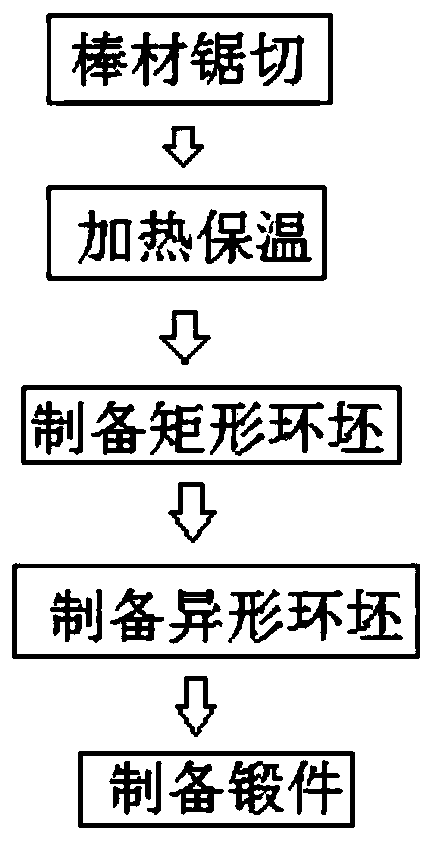

The invention relates to the technical field of forging manufacture and in particular to a manufacture method for a 2219 aluminium alloy cone-shaped ring forging piece with a large cone angle. By sawcutting a bar, heating and thermal insulating, preparing a rectangular ring blank, preparing a multiple special-shaped ring blank and forging the ring blank into a forging piece, the appearance of theobtained 2219 aluminium alloy cone-shaped ring forging piece with the large cone angle can be much closer to a part and a complete streamline of the forging piece can be kept; moreover, the subsequent machining allowance is small, the machining cycle is short and the material utilization rate is high; moreover, the obtained ring forging piece can be a complete circular ring and the interior structure is even without the need for welding, so that the problem of the structure difference and deformation of curl welding of a plate material can be solved.

Owner:GUIZHOU AVIATION TECHN DEV

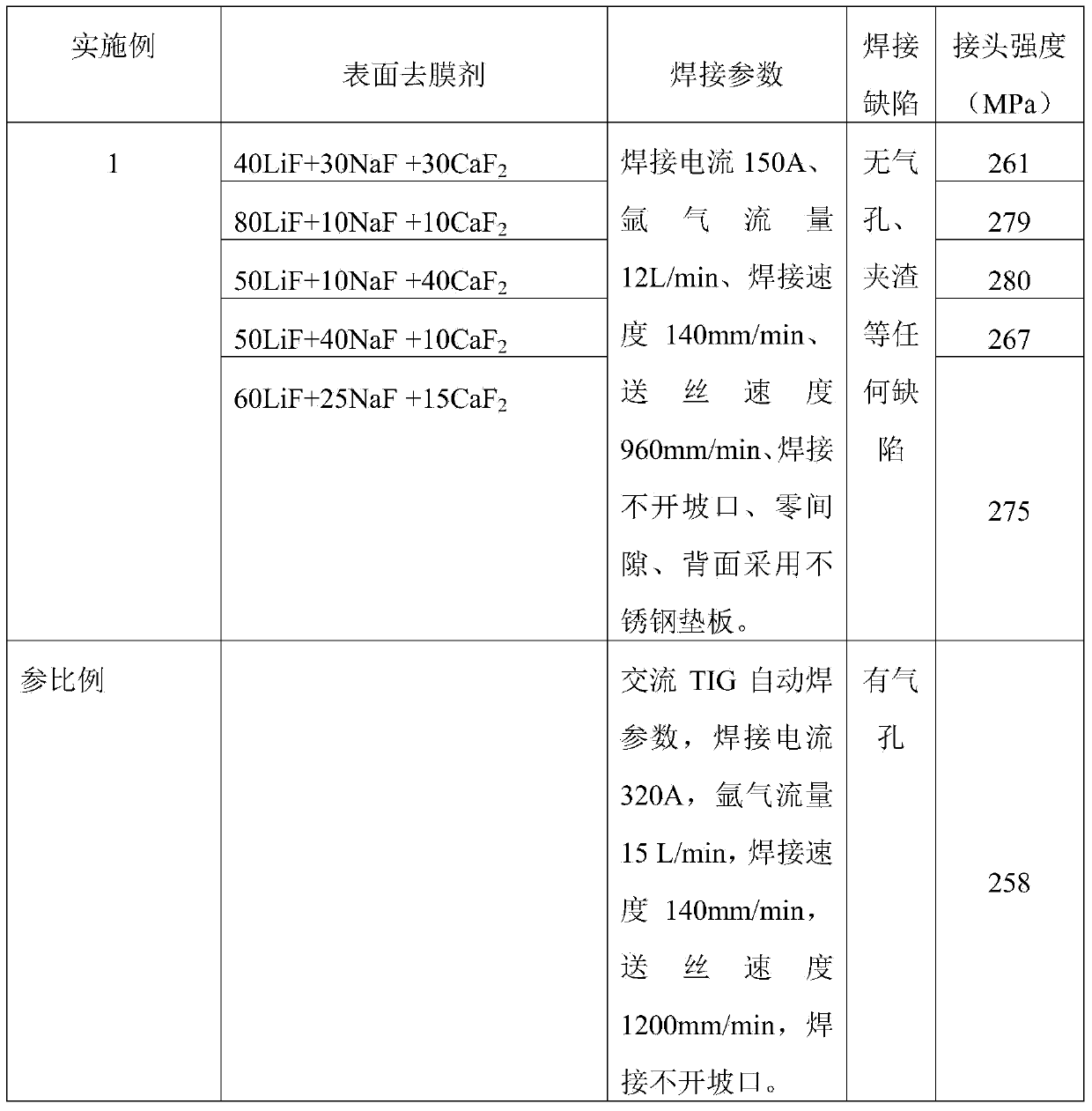

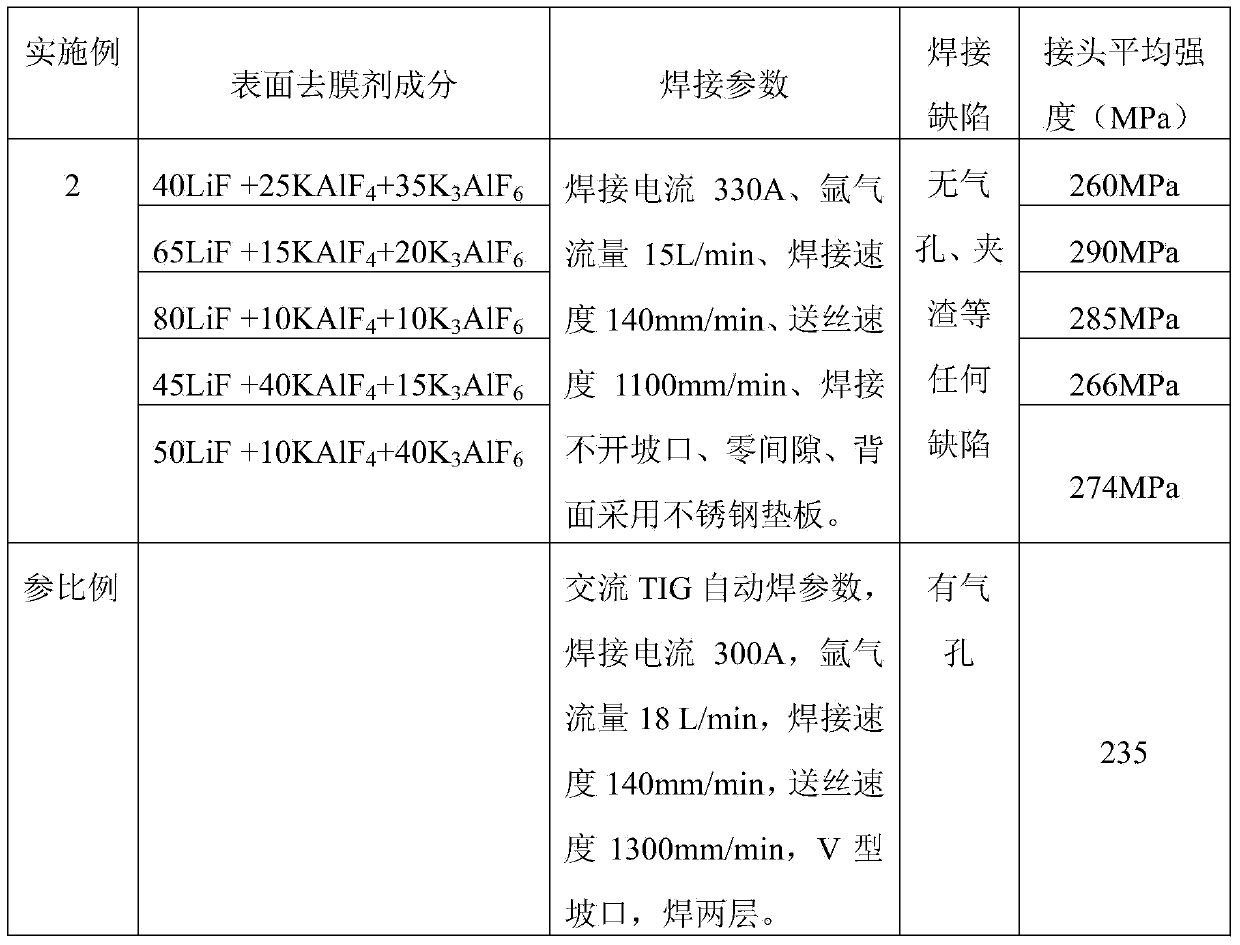

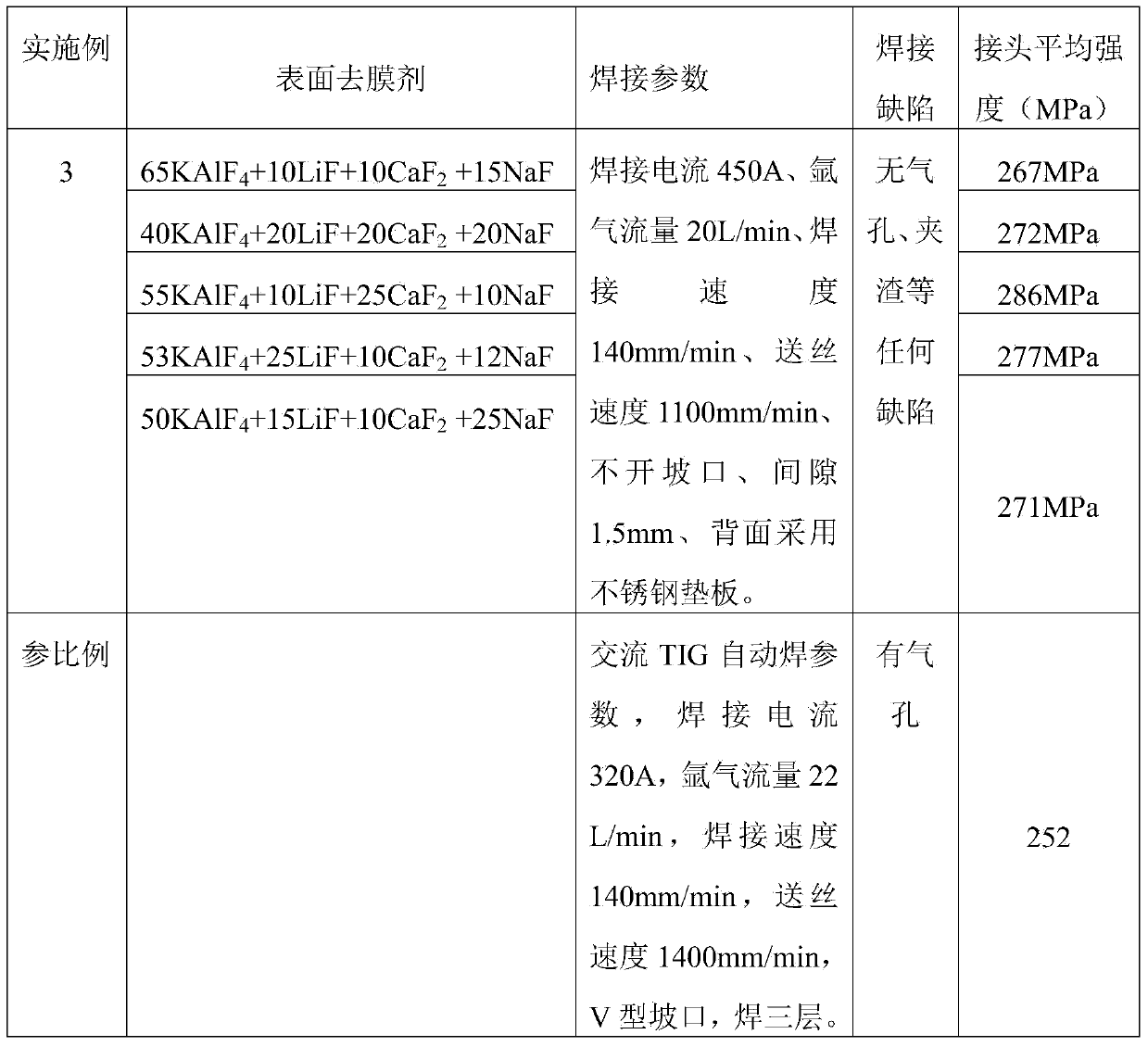

Method for welding non-defective low-energy-consumption 2219 aluminum alloy

InactiveCN103624381AHigh calorific valueIncrease weld penetrationArc welding apparatusWelding/cutting media/materialsPower flowAlternating current

The invention discloses a method for welding non-defective low-energy-consumption 2219 aluminum alloy. The method is characterized in that before welding, a to-be-welded part on the surface of 2219 aluminum alloy is sprayed with a layer of a surface film removing agent, and then the 2219 aluminum alloy is welded through a TIG welding processing method in a direct-current positive polarity mode. The surface film removing agent is composed of one or more kinds of fluoride in LiF, NaF, CaF2, KAlF4, K3AlF6 and the like. By means of the welding method, the 2219 aluminum alloy in the thickness range of 1mm-12mm can be formed through welding at a time without the need of grooving. The surface film removing agent has the functions of well removing oxidation films on the surface of the 2219 aluminum alloy and increasing the welding fusion depth, and welding currents are only 50% of currents in an alternating-current welding mode. Besides, no pore defects exist in welding seams of the welded 2219 aluminum alloy, and the tensile strength of a welding joint is 260-290MPa.

Owner:BEIHANG UNIV +1

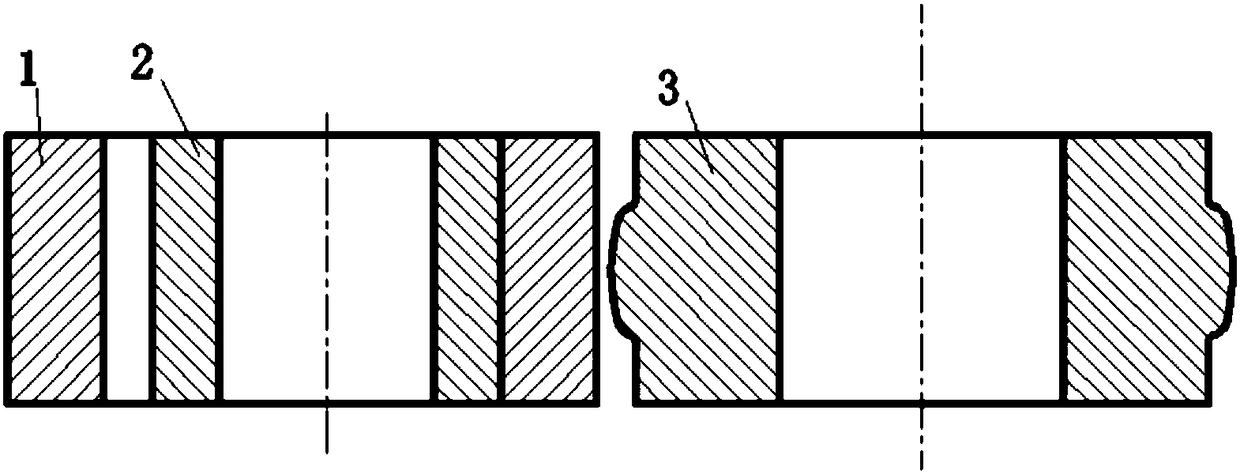

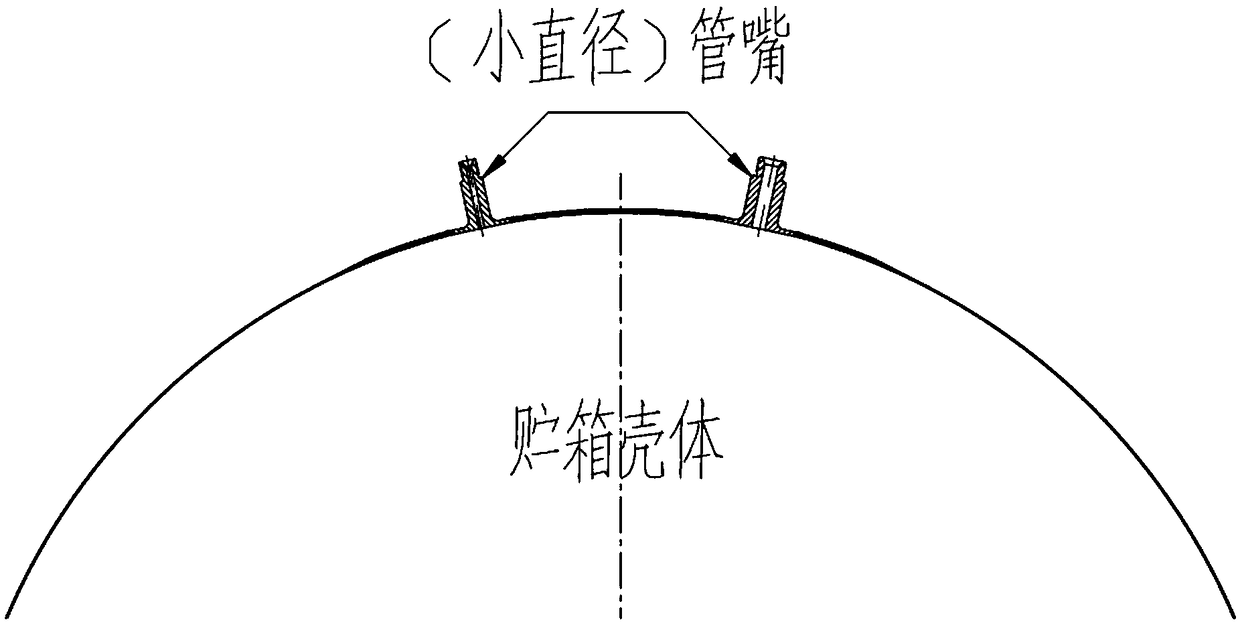

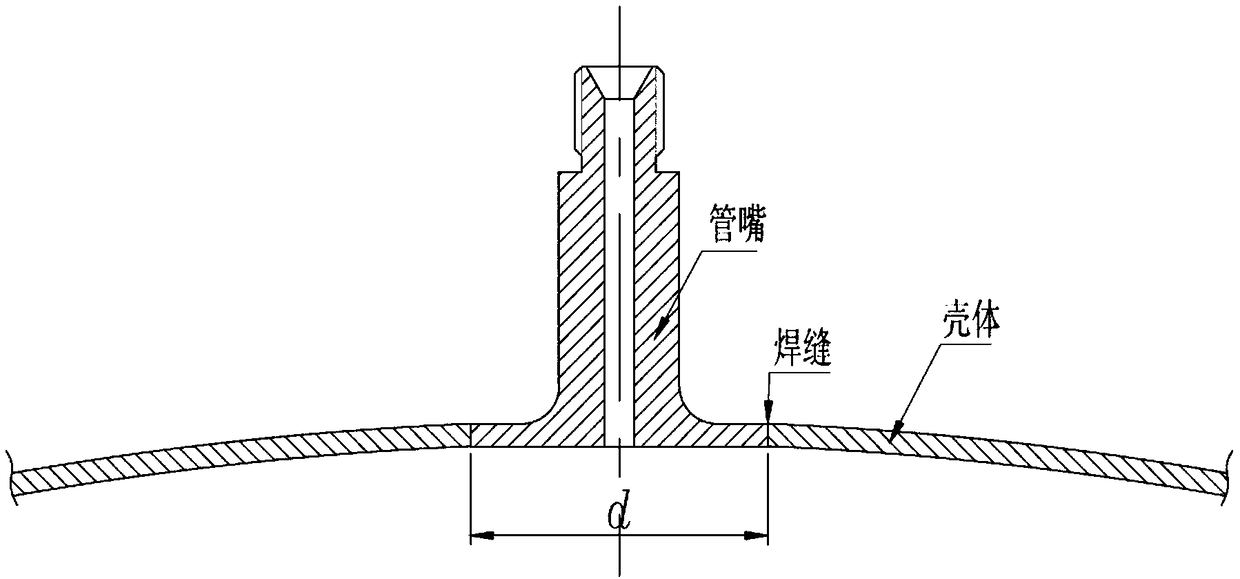

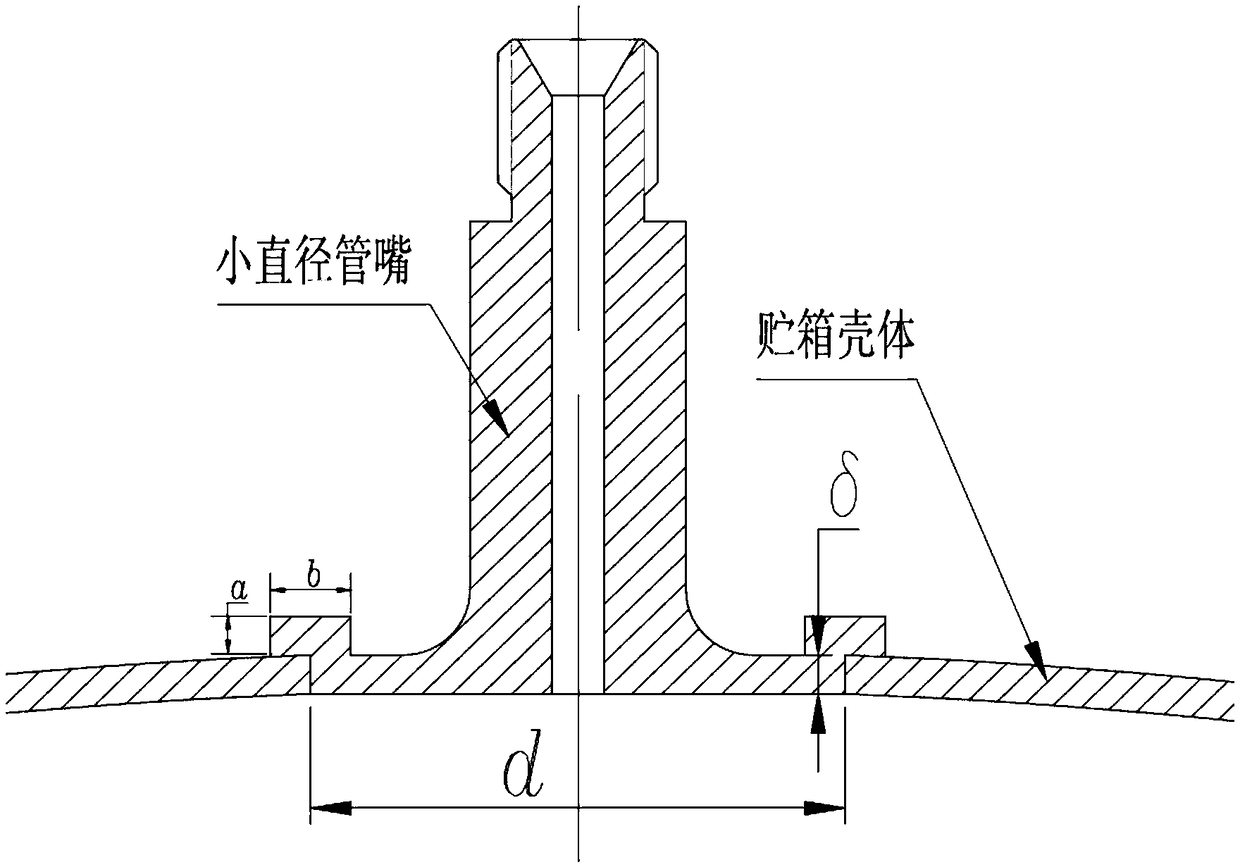

Welding method for aluminum alloy small-diameter pipe nozzle of storage tank

ActiveCN109317809AChange the state of stressAvoid processing difficultyElectron beam welding apparatusLaser beam welding apparatusMetallic materialsHigh energy beam

The invention relates to a welding method for an aluminum alloy small-diameter pipe nozzle of a storage tank, and belongs to the technical field of metal materials and technologies. The welding methodfor the aluminum alloy small-diameter pipe nozzle of the storage tank relates to welding structure form design and specific welding technological processes and is used for carrying out reliable connection between the 2219 aluminum alloy small-diameter pipe nozzle and a storage tank shell, an upper lock bottom annular boss of a special structure is designed in a welded junction of the small-diameter pipe nozzle, and the pipe nozzle of the structure is assembled to an opening of the storage tank shell to form an annular butt weld with the upper lock bottom structure. According to the method, the pipe nozzle and the storage tank shell are welded through high-energy beam welding to form a reliable welded joint. The method comprises the welding structure form design and a welding technologicalmethod.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

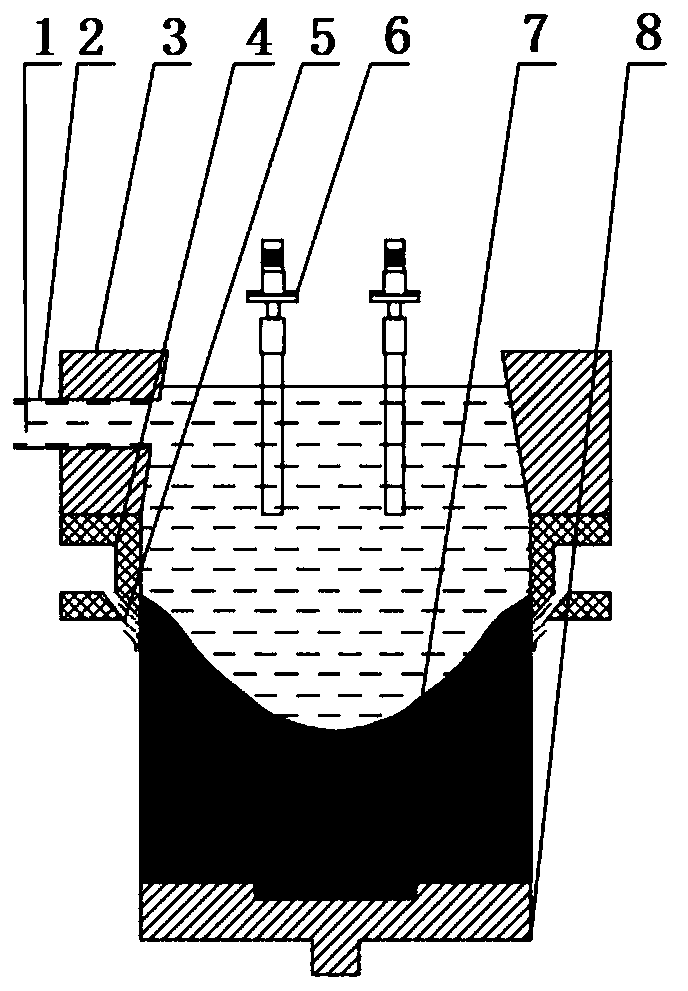

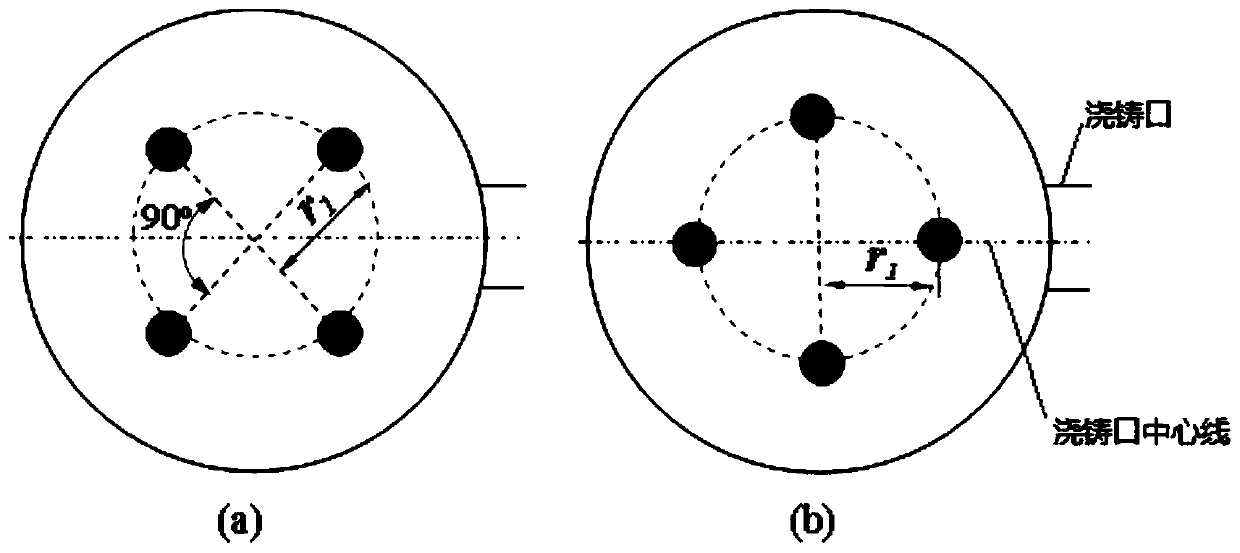

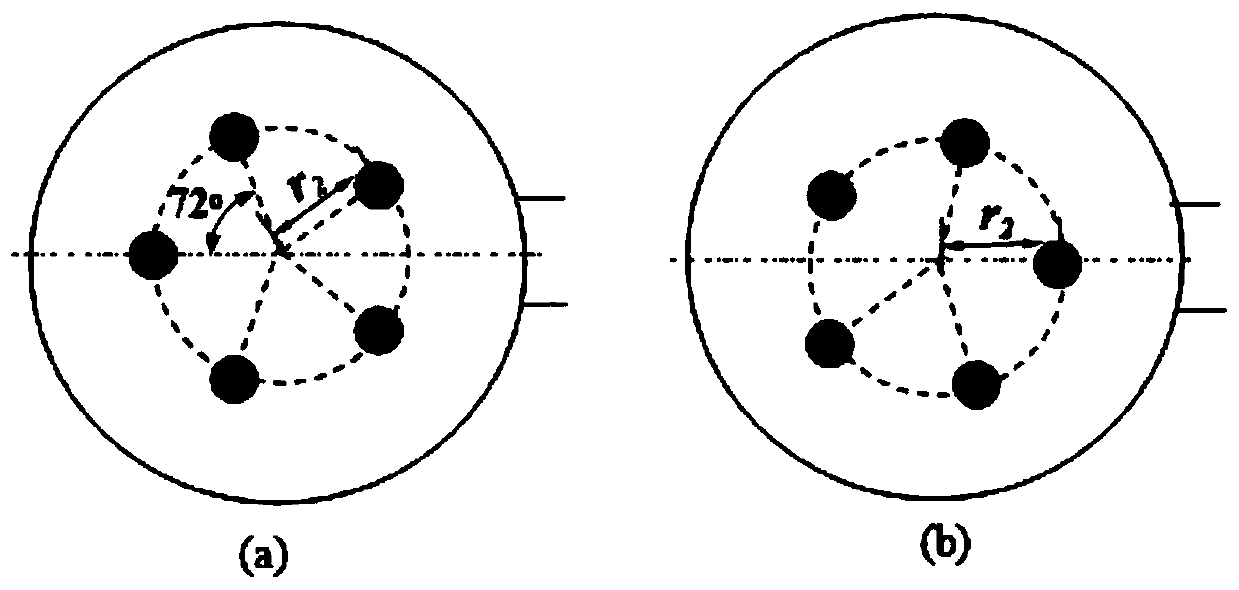

Multi-source ultrasonic distribution control method for controlling segregation of compositions of 2219 aluminum alloy round ingot with one-meter-level diameter

The invention relates to the technical field of metal smelting, and provides a multi-source ultrasonic distribution control method for controlling the segregation of compositions of a 2219 aluminum alloy round ingot withthe one-meter-level diameter. According to the multi-source ultrasonic distribution control method, a multi-source ultrasonic vibration system is applied in a crystallizer to assist in melt solidification; when the diameter of the cast ingot is larger than or equal to 1m and less than 1.2m, 4 sets of ultrasonic vibration systems are applied; and when the diameter of the cast ingot is larger than or equal to 1.2m and less than or equal to 1.4m, 4, 5 or 7 sets of ultrasonic vibration systems are applied. When the multi-source ultrasonic distribution control method is used for casting the 2219 aluminum alloy round ingot with the large diameter specification, a plurality of ultrasonic vibration sources are used for assisting in solidification of the cast ingot in a molten pool in the crystallizer through joint efforts, ultrasonic waves are applied to the interior of the molten pool in full-area and wide-coverage modes, the propagation range of the ultrasonic waves can be expanded as far as possible, and the balanced regulation and control effect of an external ultrasonic energy field on a melt solidification process energy field system can be enhanced, so that the uniformity of tissues and the compositions is improved, and especially, the segregation of the compositions of the 2219 alloy is greatly alleviated.

Owner:CENT SOUTH UNIV

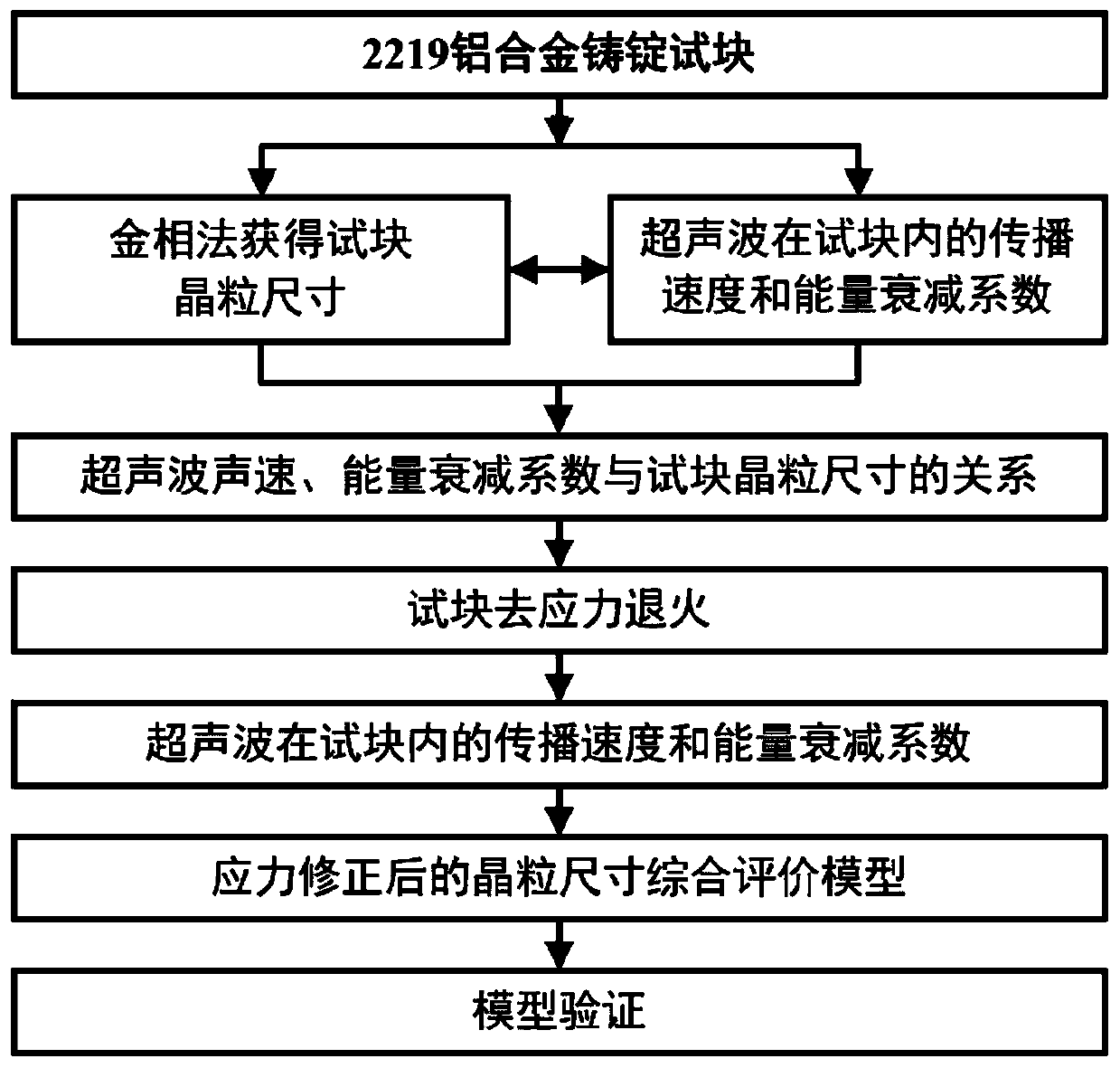

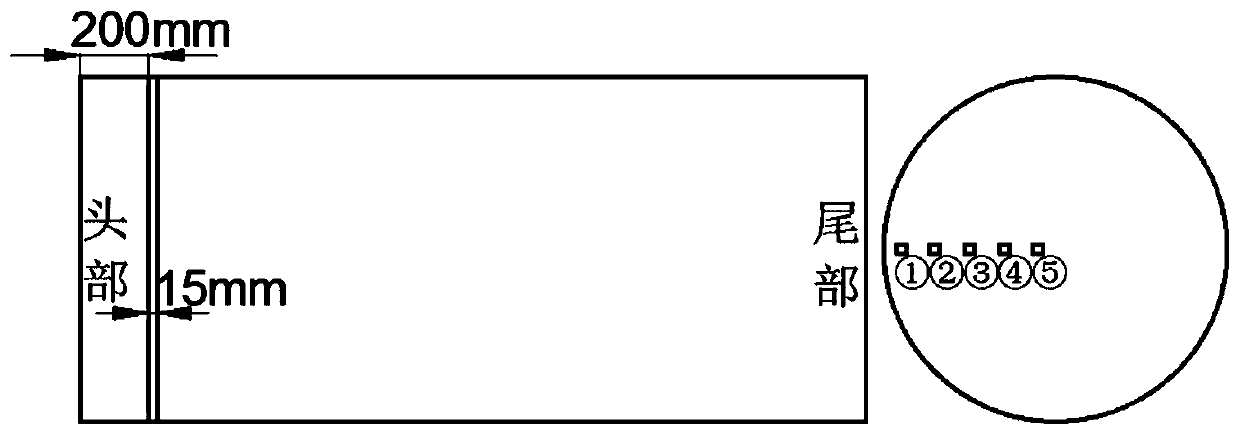

2219 aluminum alloy ingot casting average grain size ultrasonic assessment method

The invention discloses a 2219 aluminum alloy ingot casting average grain size ultrasonic assessment method, especially a method for establishing an average grain size ultrasonic evaluation model by analyzing the propagation sound velocity, attenuation coefficient and like parameters of the ultrasonic in the 2219 aluminum alloy ingot casting test block and considering the influence of the residualstress, and the ultrasonic evaluation model is used for high-precisely evaluating the 2219 aluminum alloy ingot casting average grain size. The model is scientific and simple in establishment process, the obtained data is precise, the obtained model is strong in applicability, a fitting result is precise, and the large-scale industrial application is convenient. And meanwhile, the model developedby the invention provides a necessary condition for the nondestructive detection.

Owner:CENT SOUTH UNIV

Aluminium alloy

The invention provides an aluminium alloy. The aluminium alloy is composed of, by weight, 0.1 to 0.5 part of manganese, 0.1 to 0.5 part of nickel, 2 to 2.5 parts of silicon, 1.5 to 2 parts of iron, 0.5 to 2 parts of copper, 0.1 to 0.2 part of zinc, 1 to 2.5 parts of chromium, the balance aluminium, and a small amount of inevitable impurities. Casting performance of the aluminium alloy is excellent; electrical conductivity, thermal conductivity, strength, and toughness are improved; corrosion resistance, welding performance, and machinability are excellent; and the aluminium alloy is suitable to be used for preparing housing parts.

Owner:余姚市朗霞镇大众铸件精工厂

A kind of method for preparing niti fiber reinforced 2219al composite material

ActiveCN105313426BImprove strong plasticityLayered product treatmentLaminationReaction layerAviation

The invention relates to a method for preparing a NiTi-fiber-enhanced 2219Al composite. The method aims at solving the problem that an existing method for preparing a continuous nickel-titanium fiber enhanced 2219 aluminum alloy composite which is arranged in one direction needs to achieve the purposes of regulating and controlling the fiber arrangement mode, the fiber content control, the material compacting, the interface reactions and the interface combining degrees. The method includes the first step of raw material processing, the second step of short NiTi fiber arrangement, the third step of vacuum hot pressing and sintering, and the fourth step of composite thermal treatment. A reaction layer with the thickness of about 1 micrometer is arranged between NiTi fiber and 2219Al alloy in the NiTi-fiber-enhanced 2219Al composite. The tensile strength is 305 MPa, the elongation is 23%, the excellent strength and plasticity are shown, and the method can be used for the fields of aviation, aerospace, machines, traffic, electronics and the like.

Owner:HARBIN INST OF TECH

A kind of chemical milling solution and its chemical milling method

The invention provides a chemical milling solution and a chemical milling method thereof. The chemical milling solution comprises the following ingredients, NaOH, Al3+, sodium sulphide, sodium thiosulfate, seignette salt and water which serves as a solvent, the solution is adopted to carry out chemical milling treatment on a workpiece, a high-copper-content aluminium alloy can be successfully reduced, particularly the problem that the surface of a 2219 aluminium alloy is rough is solved, after the workpiece is treated by the chemical milling solution, the surface of the workpiece is smooth, the orange peel is not generated, and the surface roughness can meet the requirement; in addition, the preparation of the solution is easy to operate, and the solution property is stable.

Owner:TIANJIN AEROSPACE CHANGZHENG ROCKET MFGCO +1

Manufacturing Method of 2219 Aluminum Alloy Large Conical Angle Conical Ring Forging

The invention relates to the technical field of forging manufacture and in particular to a manufacture method for a 2219 aluminium alloy cone-shaped ring forging piece with a large cone angle. By sawcutting a bar, heating and thermal insulating, preparing a rectangular ring blank, preparing a multiple special-shaped ring blank and forging the ring blank into a forging piece, the appearance of theobtained 2219 aluminium alloy cone-shaped ring forging piece with the large cone angle can be much closer to a part and a complete streamline of the forging piece can be kept; moreover, the subsequent machining allowance is small, the machining cycle is short and the material utilization rate is high; moreover, the obtained ring forging piece can be a complete circular ring and the interior structure is even without the need for welding, so that the problem of the structure difference and deformation of curl welding of a plate material can be solved.

Owner:GUIZHOU AVIATION TECHN DEV

Heat treatment method for enhancing deformation properties of 2219 aluminum alloy T81-T845

The invention discloses a heat treatment method for enhancing deformation properties of 2219 aluminum alloy T81-T845 and belongs to the field of alloy materials. The method comprises the following steps: solution treatment of test piece materials, preparation of various deformation quantity test pieces, aging treatment, mechanical property testing, and establishment of relation between various factors. According to the invention, correspondence between deformation quantity of 2219 aluminum alloy and aging technological parameters (such as aging temperature, aging time, etc.) is determined, a parameter model of the 2219 aluminum alloy thermomechanical treatment technological parameters can be determined rapidly and accurately, thus being convenient to choose corresponding heat treatment parameters according to actual deformation of a product (such as a melon petal part) in the production. The problem that there is no reference specification for product T8 heat treatment is solved. The relation graph obtained in the invention has strong relation graph adaptability. The method has a good application prospect. The application range of the 2219 aluminum alloy can be expanded.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

A kind of forging and blanking process method of super-large aluminum alloy ingot

ActiveCN106541064BGrain refinementImprove organizational structureMetal-working apparatusIngotMulti directional

The invention belongs to the technical field of forging forming, in particular to a forging and cogging technique for super-sized aluminum alloy ingots. The technical scheme provides the forging and cogging technique for super-sized aluminum alloy ingots and comprises following steps: utilizing multi-directional forging technology; controlling deformation of 2219 aluminum alloy ingots through controlling forging temperature, single-time forging ratio, cumulative forging ratio, deformation rate and ratios of width to height; refining grains of material and improving structure of material such that uniformity control over structure and performance of super-large diameter 2219 aluminum alloy rolled compact can be achieved, thereby improving uniformity among product quality and product qualification ratio; and the need for developing aerospace products is satisfied.

Owner:CAPITAL AEROSPACE MACHINERY +1

Active agent for 2219 aluminum alloy variable-polarity TIG welding and using method thereof

InactiveCN109732240AEasy to useEasy to implement in industrial applicationsArc welding apparatusWelding/cutting media/materialsActive agentWeld penetration

The invention discloses an active agent for 2219 aluminum alloy variable-polarity TIG welding and a using method thereof. The active agent comprises active agent powder, and the active agent powder iscomposed of the following components of, in percentage by mass, 50-78% of AlF3 powder, 10-25% of ZnF2 powder, 0.2-11% of LiF powder, 10-17% of NOCOLOK brazing flux powder and 0.3-8% of K2SiF6 powder.The using method of the active agent comprises the following steps of preparing the active agent powder, preparing a paste or cream active agent, carrying out surface treatment on a 2219 aluminum alloy workpiece, applying the active agent and welding. The active agent disclosed by the invention can remarkably reduce generation of weld pores when the 2219 aluminum alloy workpiece is subjected to variable-polarity TIG welding, so that weld penetration is increased by 1.6 times or above, formation of a welding line is good, and the tensile strength of joint of the welding line is obviously improved.

Owner:CHANGZHOU INST OF TECH

Ytterbium micro-alloyed aluminium-copper-magnesium-silver-manganese system high-strength deforming heat-stable aluminium alloy and preparation method thereof

The invention relates to ytterbium-microalloyed aluminium copper madnesium silver manganese series aluminium alloy with high deforming and heat resisting, and a method for preparing it. The invention is used in the field of structural material with high performance. The specific composition of the invention and weight percentage are: Cu: 4-6.5%, Mg: 0.5-1.2%, Ag: 0.4-1.5%, Mn: 0.2-0.6%, Zr: 0.05-0.25%, Yb: 0.05-0.55%, the residuel of Al. Micro-ytterbium is added into the existing aluminium copper madnesium silver manganese series alloy and the formed alloy component is not changed, while the function of micro-ytterbium fines original cast structure of aluminium copper madnesium silver manganese series alloy. Integrated strength and heat resisting under high temperature of the alloy are improved in the invention, while the performances of the alloy exceed traditional 2618aluminium alloy, 2219 aluminium alloy and Polmear aluminium alloy.

Owner:CENT SOUTH UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com