Manufacture method for 2219 aluminium alloy cone-shaped ring forging piece with large cone angle

A manufacturing method and aluminum alloy technology are applied in the field of forging manufacturing to achieve the effects of improving the qualification rate, reducing the scrap rate and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

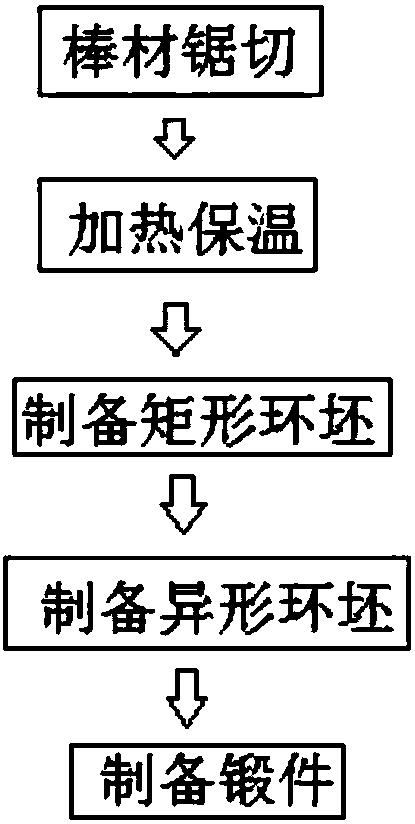

[0036] A method for manufacturing a 2219 aluminum alloy large cone angle conical ring forging, comprising the following steps:

[0037] 1) Saw the 2219 aluminum alloy bar, heat it to 460-480°C, and keep it warm for 20 minutes per 10mm effective thickness of the 2219 aluminum alloy bar;

[0038] 2) Upsetting, punching, and reaming the bar after heat preservation to obtain a rectangular ring blank 1;

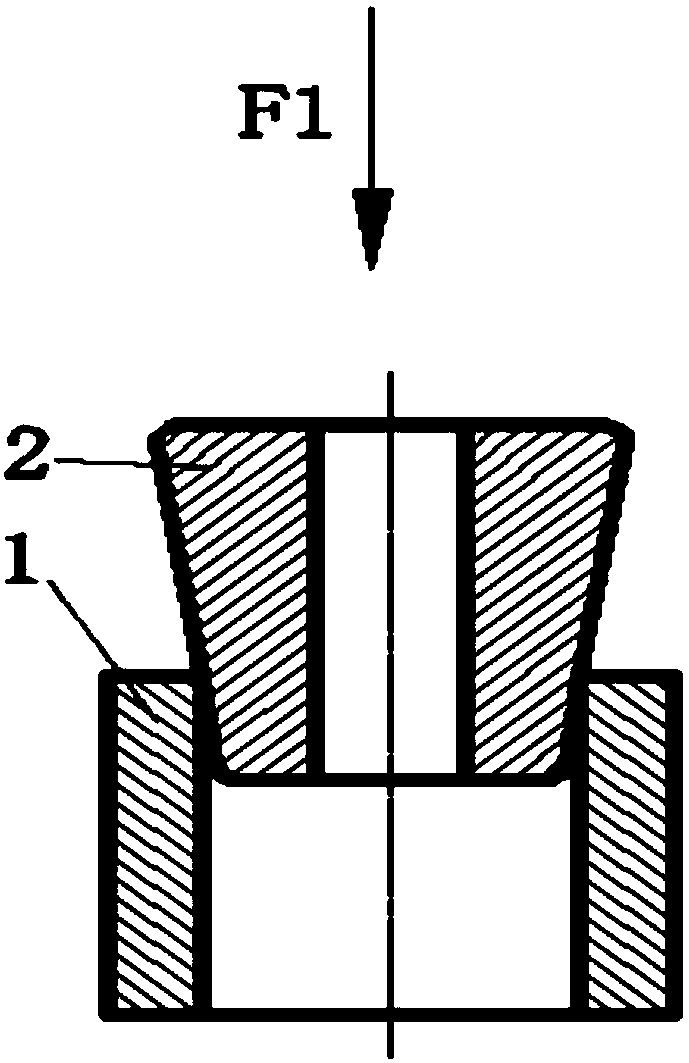

[0039] 3) Put the mold A2 into the upper end of the rectangular ring blank 1. Driven by the press, the cutting board exerts pressure F1 on the mold A2, so that the mold A2 is slowly pressed into the rectangular ring blank 1. After the mold 2 completely enters the rectangular ring blank 1, the cutting board Continue to apply pressure F1 to the mold A2, keep it for 10-15s, and then exit the mold A2 reversely to obtain the special-shaped ring blank A3;

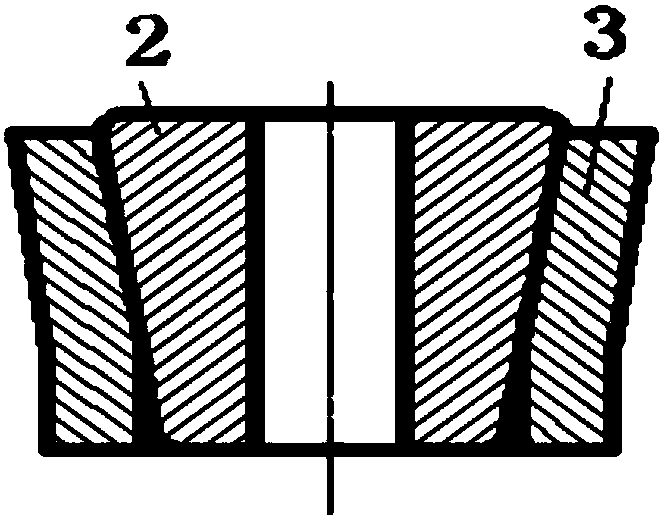

[0040] 4) Put the mold B4 into the upper end of the special-shaped ring blank A3. Driven by the press, the cutting board exerts pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com