Method for welding titanium or titanium alloy with 2219 aluminum alloy

A welding method and aluminum alloy technology, applied in welding equipment, welding/welding/cutting articles, metal processing equipment, etc., can solve the problems that welded joints do not have practical value, reliable welding cannot be performed, and direct brazing is not feasible, etc. Achieve the effect of reducing the possibility of joint corrosion, avoiding welding defects, and reliable welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

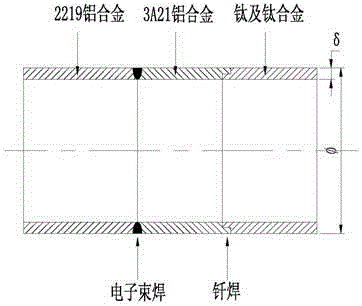

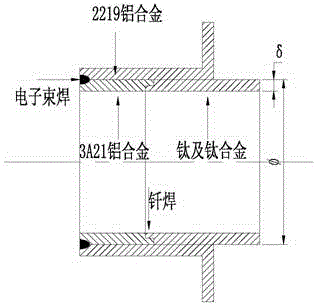

[0052] Step one, press figure 1 Process the parts, clean and dry the parts to be welded;

[0053] The second step is to assemble the 3A21 aluminum alloy pipe fittings and TC4 titanium alloy pipe fittings as required;

[0054] The third step is to select aluminum-based solder AlSiCuMg, the main components are Si: 10.0-13%, Cu: 4.0-6.0%, Mg: 1.2-2.0 and the balance is Al, and the solder is made into a suitable shape and put into the solder tank middle;

[0055] The fourth step is to put the workpiece to be welded with assembled solder into the vacuum brazing furnace. 8 to 20 minutes, then turn off the heating power and cool down with the furnace, the temperature of the furnace is cooled to below 100°C, and the vacuum pressure during the heating process is not greater than 5×10 -2 Pa;

[0056] The fifth step is to carry out air tightness and ultrasonic testing and tensile tests on the brazed joints; the brazing seam is continuous and dense, and there is no leakage at 3MPa for...

Embodiment 2

[0061] Step one, press figure 1 Process the parts, clean and dry the parts to be welded;

[0062] The second step is to assemble the 3A21 aluminum alloy pipe fittings and TC4 titanium alloy pipe fittings as required;

[0063] The third step is to select aluminum-based solder BAl88Si, the main components are Si: 10.0-13%, Cu: 4.0-6.0%, Mg: 1.2-2.0 and the balance is Al, and the solder is made into a suitable shape and put into the solder tank middle;

[0064] The fourth step is to put the workpiece to be welded with assembled solder into the vacuum brazing furnace. 8 to 20 minutes, then turn off the heating power and cool down with the furnace, the temperature of the furnace is cooled to below 100°C, and the vacuum pressure during the heating process is not greater than 5×10 -2 Pa;

[0065] The fifth step is to conduct air tightness, ultrasonic and tensile testing on the brazed joint;

[0066] The sixth step is to assemble the brazing parts and 2219 aluminum alloy pipe fit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com