Method for preparing NiTi-fiber-enhanced 2219Al composite

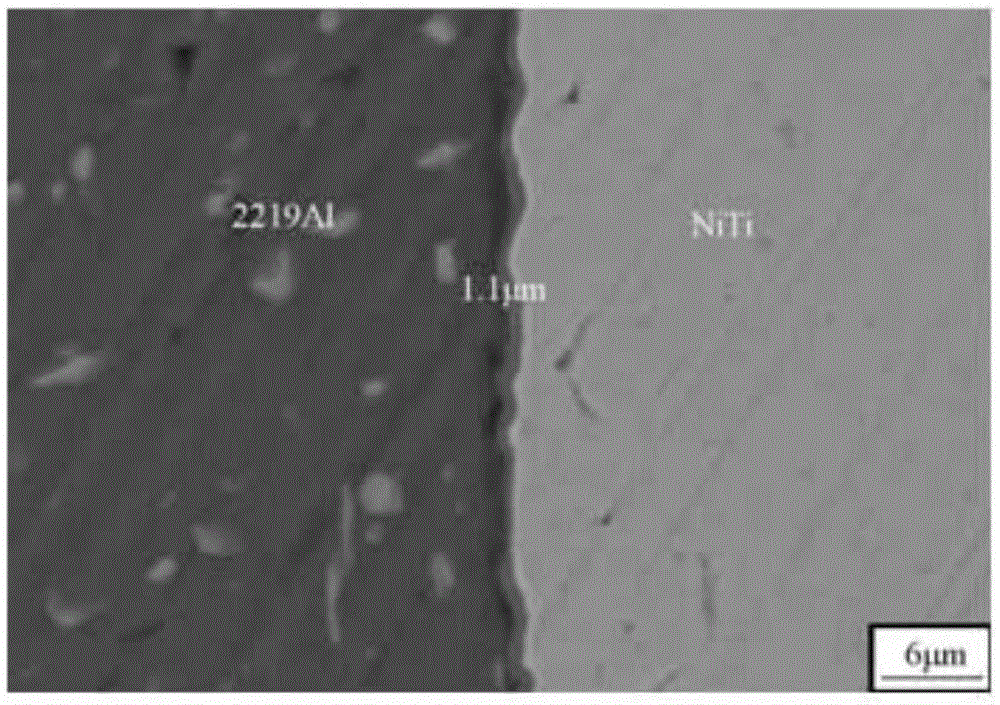

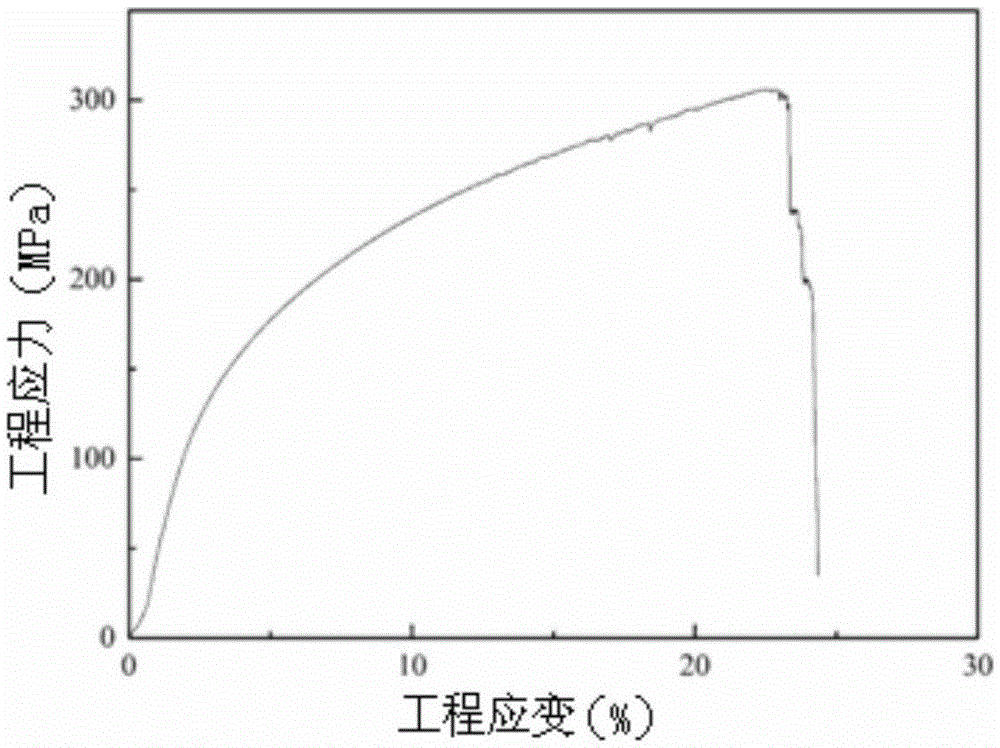

A composite material and fiber-reinforced technology, applied in the field of preparing 2219Al composite materials, to achieve the effect of excellent strong plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

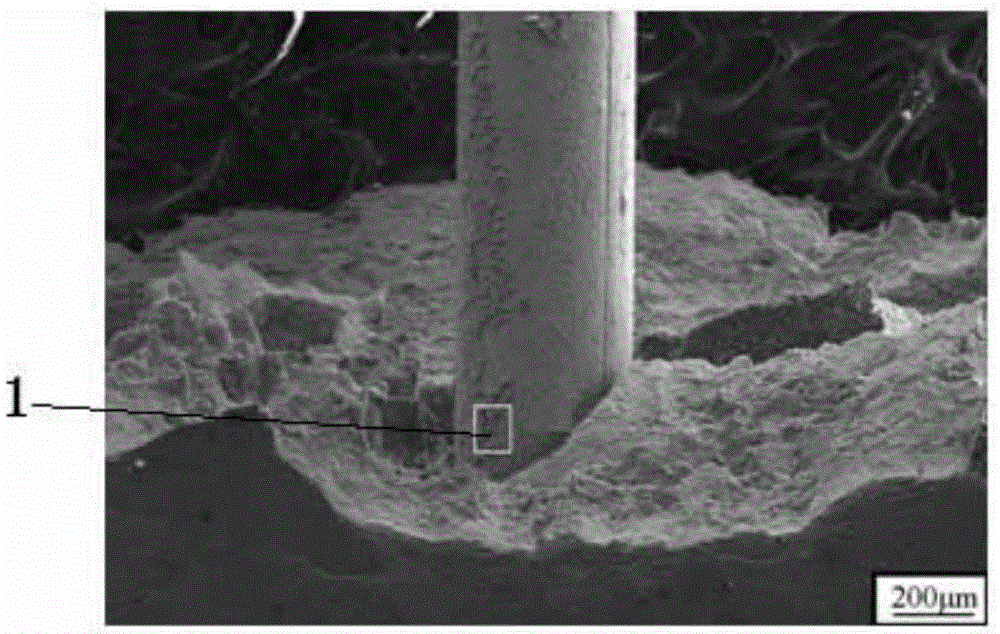

Examples

specific Embodiment approach 1

[0019] Embodiment 1: A method for preparing NiTi fiber-reinforced 2219Al composite material in this embodiment is carried out according to the following steps:

[0020] 1. Raw material treatment: ①Cut the 2219 aluminum sheet into a circle with a diameter of Φ by wire cutting method, and then use a NaOH solution with a concentration of 35g / L to 45g / L to alkali-wash the 2219 round aluminum sheet. The alkali-washing time is to remove 2219 Until the oil stain and oxide layer on the surface of the round aluminum sheet, take out the 2219 round aluminum sheet with a volume fraction of 5% HNO 3 Pickle the 2219 round aluminum sheet with the solution for 1min~3min, then ultrasonically clean the 2219 round aluminum sheet with absolute ethanol for 1min~3min, and finally take out the 2219 round aluminum sheet and place it in an oven with a temperature of 40~90℃ for 10min~20min, take it out Air-cooled to obtain the treated 2219 round aluminum sheet; ② Polish the surface of NiTi fiber with s...

specific Embodiment approach 2

[0028] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the 2219 aluminum sheet is cut into Φ59.5mm×1mm discs by wire cutting method. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the concentration of the NaOH solution described in step 1 is 40 g / L. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com