Welding method for aluminum alloy small-diameter pipe nozzle of storage tank

A technology of small-diameter pipes and welding methods, applied in welding equipment, laser welding equipment, electron beam welding equipment, etc., can solve problems such as weld surface depressions, avoid weld depressions, avoid opening processing difficulties, and improve The effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

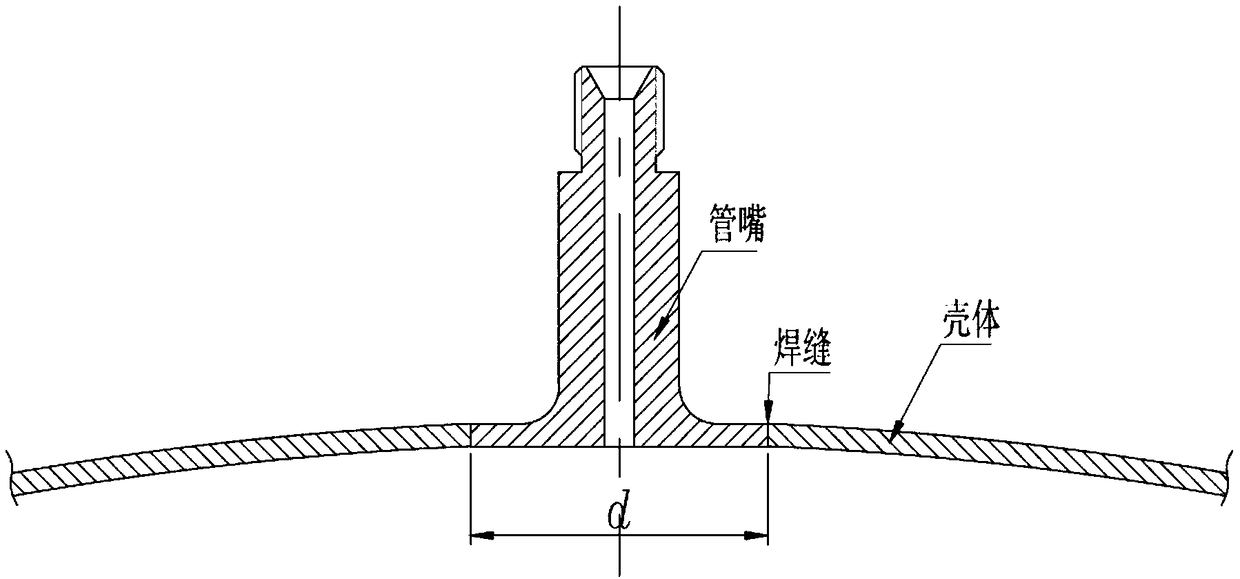

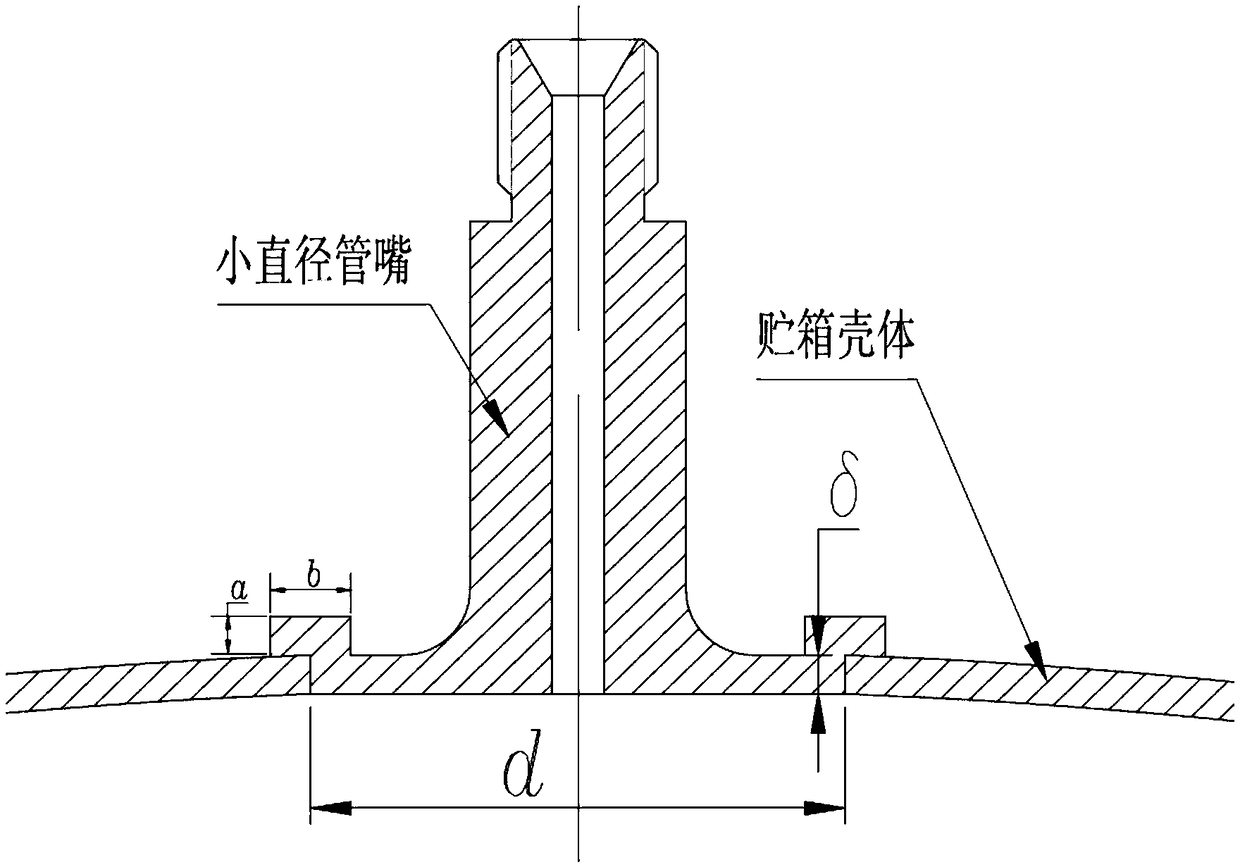

[0044] Such as Figure 1-Figure 3 shown;

[0045] 1. Process the nozzle made of 2219 aluminum alloy and open at the corresponding position of the tank shell. The diameter of the opening is 0.05-0.08mm larger than the diameter of the nozzle weld. 5, b=2~6mm, substrate thickness δ=3.0mm;

[0046] 2. Degrease, clean and dry the nozzle and tank shell;

[0047] 3. Assembly;

[0048] 4. Using laser welding, the parameters are as follows: spot diameter 0.3 ~ 0.5mm, defocus amount -5mm ~ 5mm,

[0049] Laser power 2200~3200W, welding speed 15~25mm / s;

[0050] 5. The quality of the weld seam has reached the GJB1718-2005 Class I standard through X-ray inspection, and the weld seam has no leakage after 0.8MPa and 15min hydraulic inspection.

Embodiment 2

[0052] Such as Figure 1-Figure 3 shown;

[0053] 1. Process the nozzle made of 2219 aluminum alloy and open at the corresponding position of the tank shell. The diameter of the opening is 0.05-0.08mm larger than the diameter of the nozzle weld. 5, b = 2 ~ 6mm;

[0054] 2. Degrease, clean and dry the nozzle and tank shell;

[0055] 3. Assemble the two;

[0056] 4. Using electron beam welding, the parameters are as follows: accelerating voltage 60-80KV, welding beam current 18-28mA, defocusing amount 0-2mm, welding speed 15-25mm / s;

[0057] 5. The quality of the weld seam has reached the GJB1718-2005 Class I standard through X-ray inspection, and the weld seam has no leakage after 0.8MPa and 15min hydraulic inspection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Radial thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com