A unit type curtain wall column side hanging connector

A unitary, connector technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of low installation efficiency and errors, and achieve the effects of high bearing capacity, improved force adjustment, and small space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

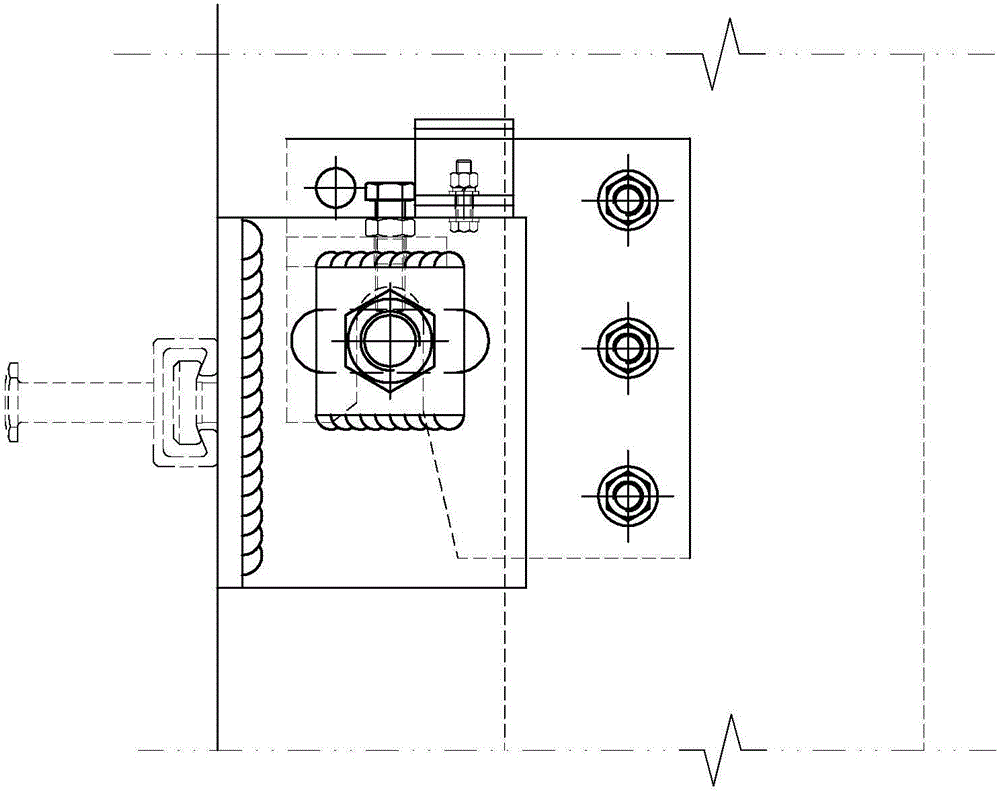

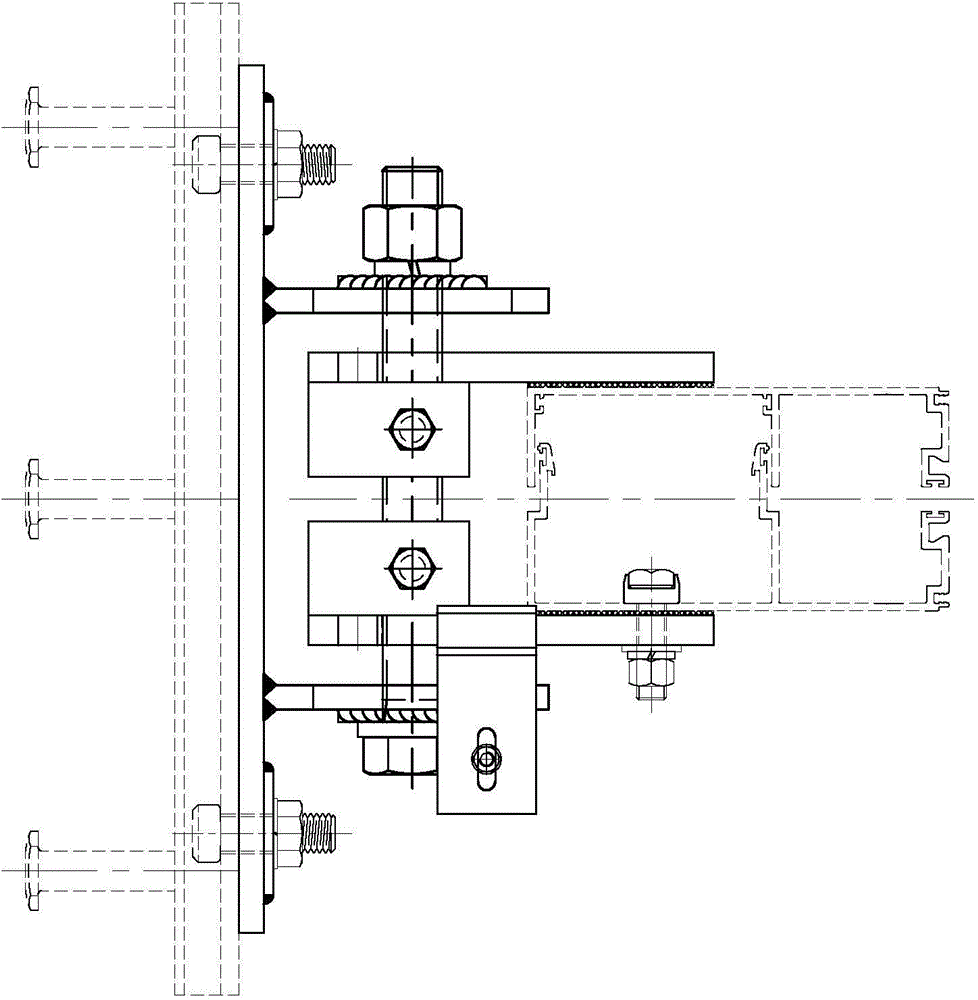

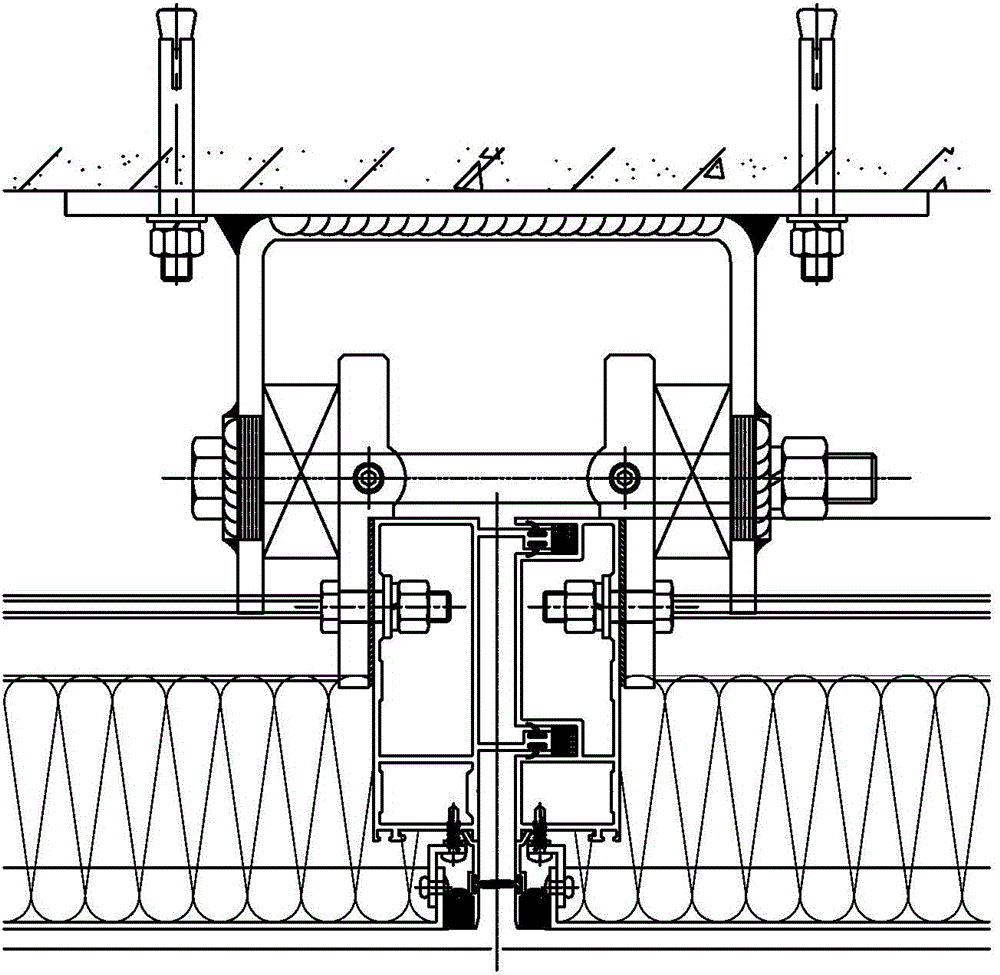

[0028] see Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 Shown: a unitized curtain wall column side hanging connector, which includes a back plate 1, two side plates 2, a bolt shaft 3, two hanging plates 4, a back plate 1 and two side plates 2 Connecting to form a bench shape, a horizontal long hole 5 is provided in the middle of the two side plates 2, a bolt shaft 3 is pierced on the horizontal long hole 5, and a gasket 6 is connected to the bolt shaft outside the two side plates and nuts 7, vertical holes 8 are arranged on the backboards outside the two sideboards, the backboard 1 and the two sideboards 2 are integrally formed by die-opening and extrusion of aluminum alloy materials, and the bolt shafts are pierced Aluminum alloy hanging scroll 9 is arranged. The hanging shaft 9 processed by the aluminum alloy profile is adopted to bear the load. Use a bolt shaft 3 to pass through the central bolt shaft hole 15 of the hanging shaft 9, and fix the hanging sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com