Frame type undercarriage brake hose connecting structure

A hose connection and landing gear technology, applied in the direction of the control mechanism, aircraft brake arrangement, etc., can solve the problems of the brake hose under severe stress and affect the service life, so as to improve the service life, prolong the service life, and change the service life of the brake hose. The effect of force status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

[0025] For the convenience of description, the relative positional relationship of each component, such as: the description of up, down, left, right, etc., is described according to the layout direction of the drawings in the specification, and does not limit the structure of this patent.

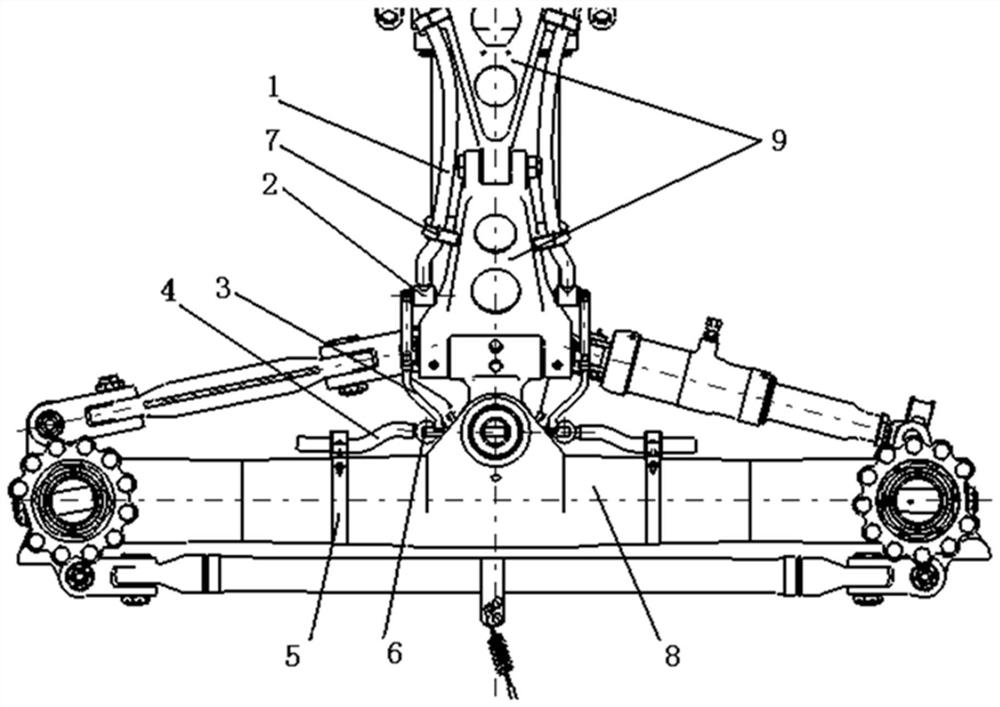

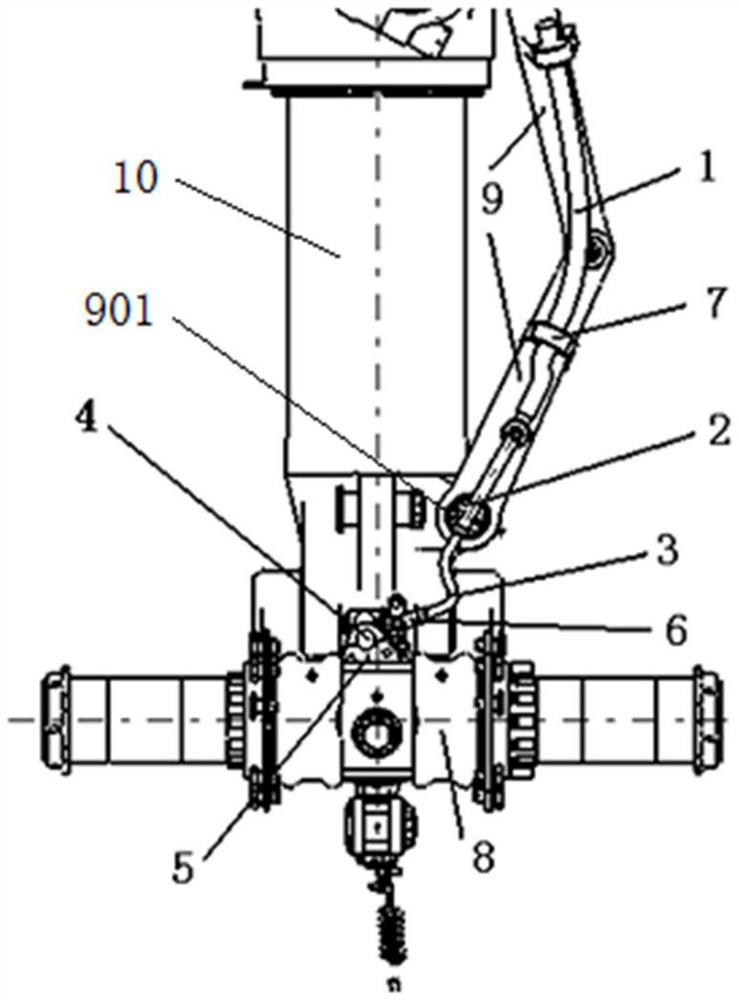

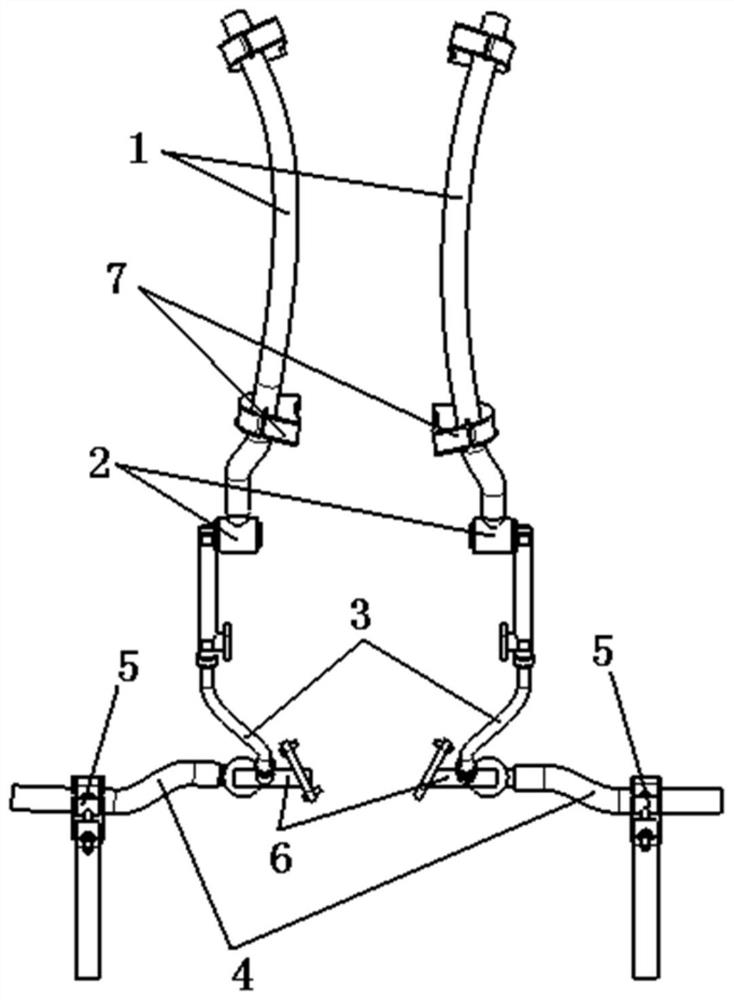

[0026] Such as figure 1 - Figure 5 As shown, an embodiment of the brake hose connection structure of the frame-type landing gear of the present invention includes a buffer pillar, a torsion arm 9 and a vehicle frame 8. The torsion arm 9 includes an upper section and a lower section that can be relatively bent, and the torsion arm 9 It is installed on the piston rod 10 of the buffer pillar through the first pin shaft 901 , and the bottom of the piston rod 10 is hinged to the middle part of the vehicle fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com