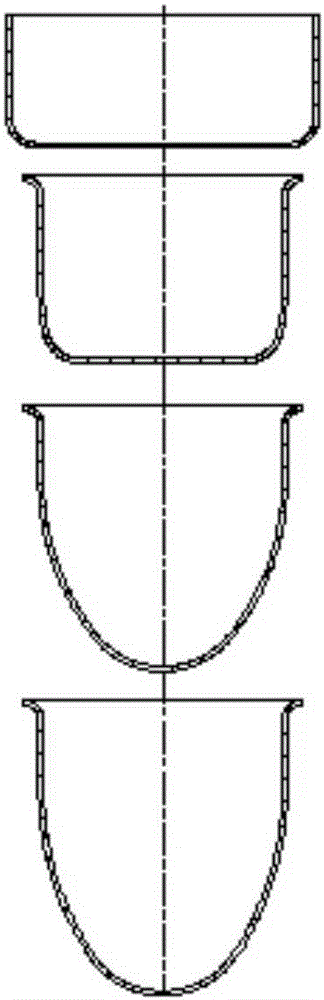

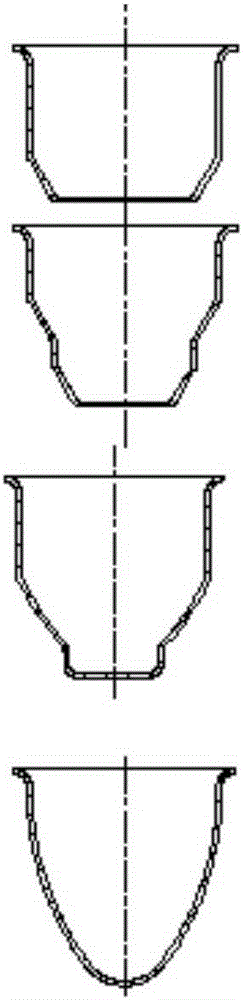

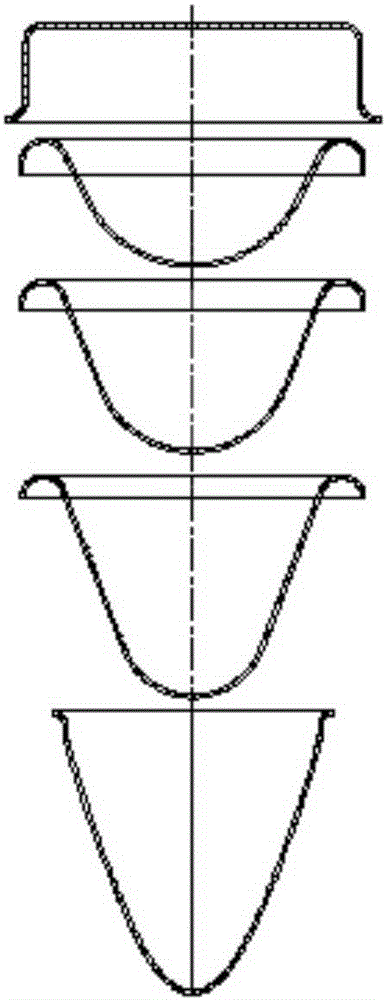

Single-die forming device and method of thin-wall deep parabolic drawing part

A parabolic, thin-walled technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of stretching failure, forming failure, forming joints, etc., to reduce the number of forming passes and improve forming performance, effect of good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0036] The invention provides a thin-walled deep parabola-shaped single-die forming device and method, see attached Figure 5 , including: upper template 1, pressure head 2, blank holder ring 3, forming medium 4, die 5 and lower template 6;

[0037] The indenter 2 includes a cylindrical section and an arc-shaped head section, and the arc-shaped head section and the cylindrical section have a smooth transition; the shape of the arc-shaped head section of the indenter 2 does not need to be consistent with the structure and size of the thin-walled deep parabolic stretching part, It is mainly used to transmit forming force, and has the function of non-uniformly transmitting pressure. Different shapes can be designed according to forming needs, the stress state of blank 7 can be changed, and the forming performance can be improved;

[0038] The blank holder 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com