Multi-source ultrasonic distribution control method for controlling segregation of compositions of 2219 aluminum alloy round ingot with one-meter-level diameter

A composition segregation and aluminum alloy technology, which is applied in the field of multi-source ultrasonic control to control the composition segregation of 1-meter-diameter 2219 aluminum alloy round ingots, can solve problems such as thick heart tissue, uneven heat transfer, and segregation, and achieve enhanced The effects of balanced regulation, solution to component segregation, and expansion of the scope of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

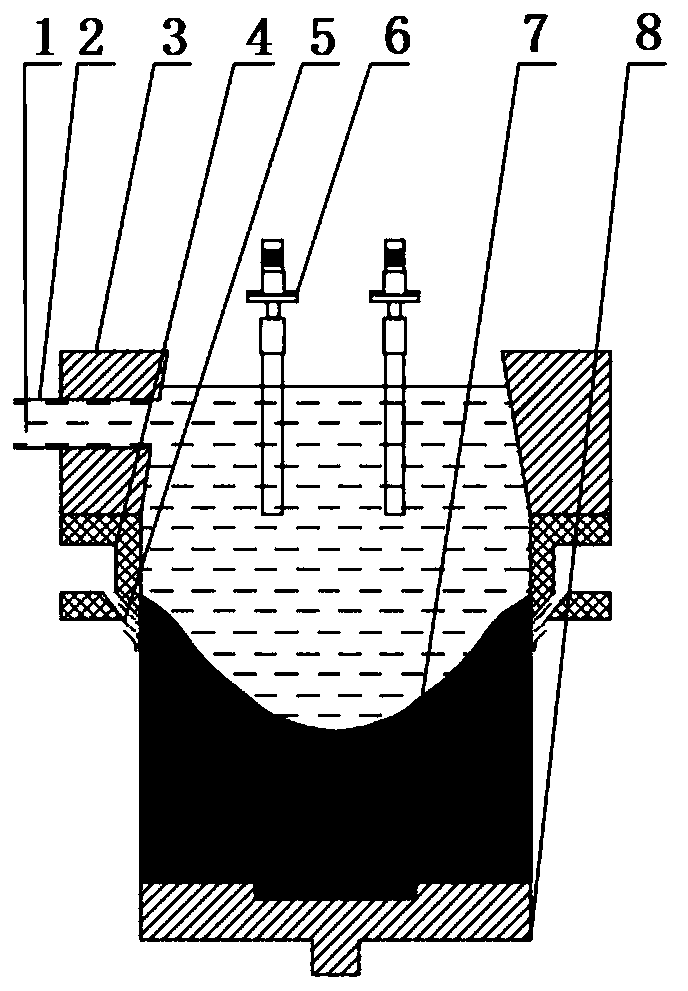

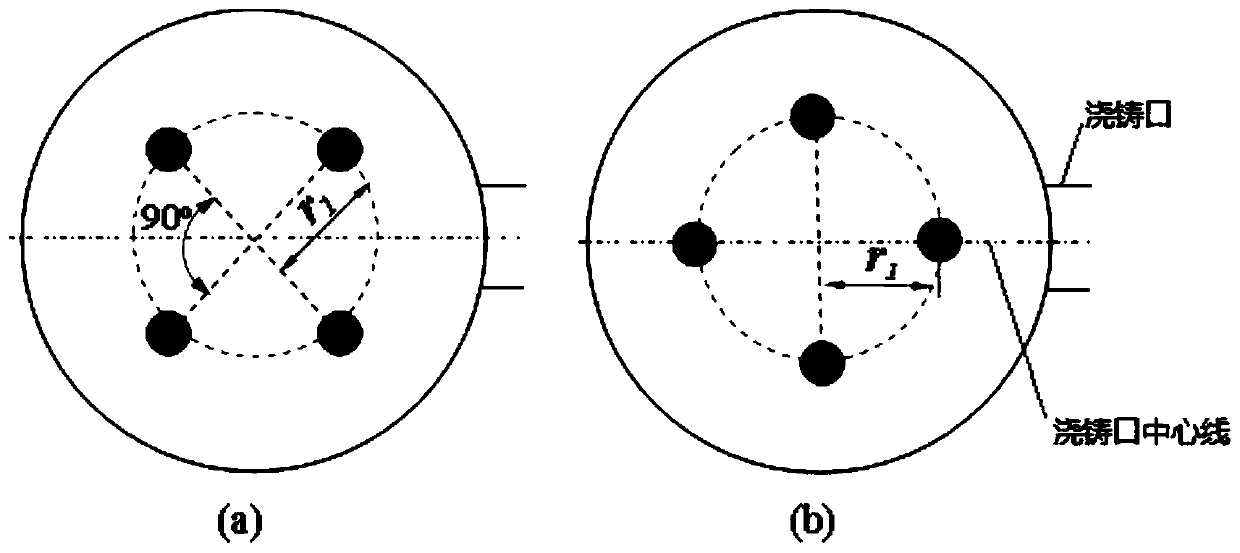

[0059] Φ1250mm 2219 aluminum alloy round ingot casting, 4 sets of ultrasonic vibration system applied

[0060] 1. Casting process:

[0061] 1) Debugging and preparation before casting

[0062] Inspect 20 tons of casting equipment to ensure that the furnace part ensures that the heating device, electromagnetic stirring device, and tilting power device are normal; ②The launder and the online degassing and impurity removal part mainly check whether the heating device is normal, whether the rotating nozzle is normally available, and the filter plate is worn out. Whether it is serious, whether the thinner wire feeder is operating normally, and ensure that the launder is cleaned without aluminum slag, etc.; ③Crystal part: Whether the hot top cap and graphite mold are seriously worn out and need to be replaced, and whether the starter device is normal, and ensure oil-air lubrication The system and cooling water system are normal.

[0063] 2) Alloy ratio and melting

[0064] The smelting proc...

Embodiment 2

[0097] Φ1380mm 2219 aluminum alloy, specification: Φ1380×3600mm, 4 sets of ultrasonic vibration system are applied, ultrasonic vibration system is applied during the whole casting process (that is, the ultrasonic vibration system is applied when the ingot length is 200mm, and the ultrasonic vibration system is removed before the end of casting), The proportion of high-purity aluminum is used, and the other conditions are the same as those in Example 1. The on-site picture after ultrasonic application is as follows Figure 8 Shown.

[0098] The component testing refers to the standard GB / T 3190, and the components are shown in Table 3:

[0099] Table 3 Φ1380mm2219 alloy ingot composition

[0100]

[0101]

[0102] The typical position of the obtained ultrasonic ingot was inspected at low power, the result is as follows Picture 9 As shown, the detection board is equally divided into 5 areas along the radial direction, and each area takes 2 low-power images, see Picture 9 B in 1 -1~B ...

Embodiment 3

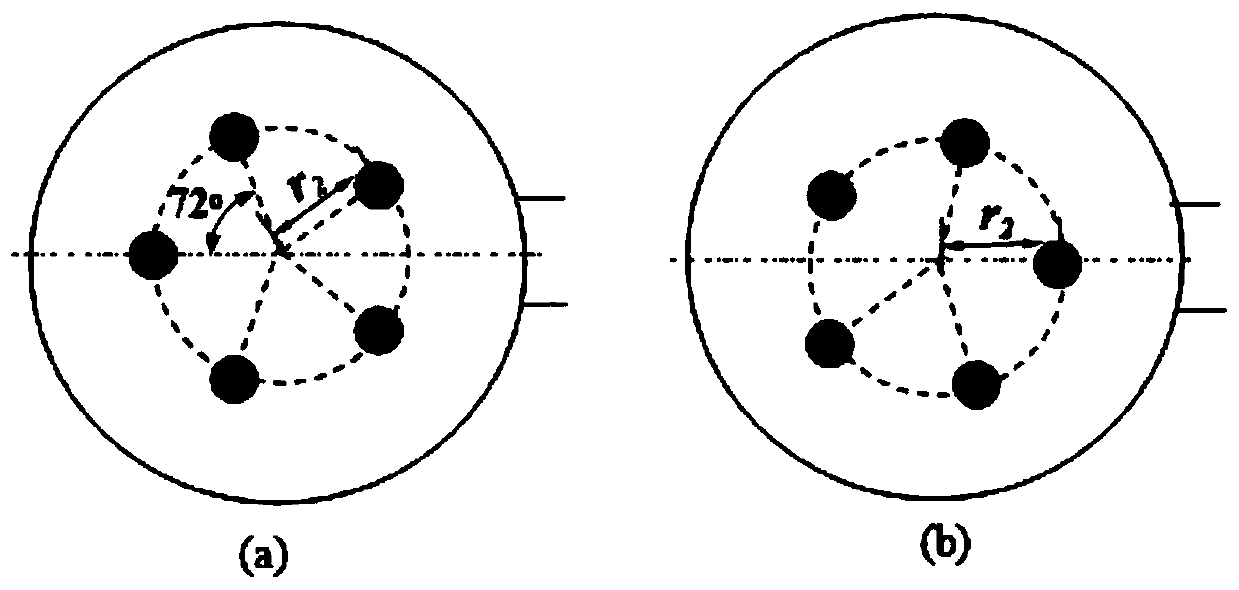

[0108] Φ1380mm 2219 aluminum alloy, specification: Φ1380×3600mm, 5 sets of ultrasonic vibration system are applied, the layout of the ultrasonic vibration system is as follows image 3 As shown in (a); ultrasound is applied throughout the casting process (that is, the ultrasonic vibration system is applied when the ingot length is 200mm, and the ultrasonic vibration system is removed before the end of the casting), high-purity aluminum ratio is used, other conditions and examples 1 Consistent, the scene picture after ultrasound application is as follows Picture 10 Shown.

[0109] The components are tested according to GB / T 3190, and the components are shown in Table 5:

[0110] Table 5 Φ1380mm2219 alloy ingot composition

[0111]

[0112]

[0113] The typical position of the obtained ultrasonic ingot was inspected at low power, the result is as follows Picture 11 As shown, Picture 11 E1~E5 in the middle represent 5 regions distributed equidistantly in the radial direction (each re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com