Chemical milling solution and chemical milling method thereof

A solution and chemical milling technology, which is applied in the aerospace field, can solve problems such as uneven corrosion, affecting product appearance processing, roughness and orange peel, etc., and achieves the effect of stable solution properties and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0022] The bath composition of each embodiment is shown in the following table:

[0023] bath composition

Embodiment 1 formula (g / L)

Embodiment 2 formula (g / L)

Embodiment 3 formula (g / L)

NaOH

120~150

120~150

120~150

Al 3+

30

30

30

0

10

10

10

10

10

15

20

30

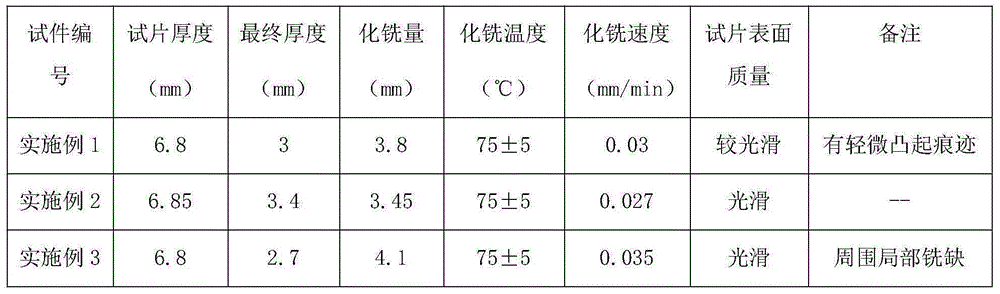

[0024] The experimental results are shown in the table below:

[0025]

Embodiment 4

[0027] Chemical milling solution formula: NaOH 120~150g / L, Al 3+ 30g / L, potassium sodium tartrate 10g / L, sodium thiosulfate 10g / L, sodium sulfide 30g / L.

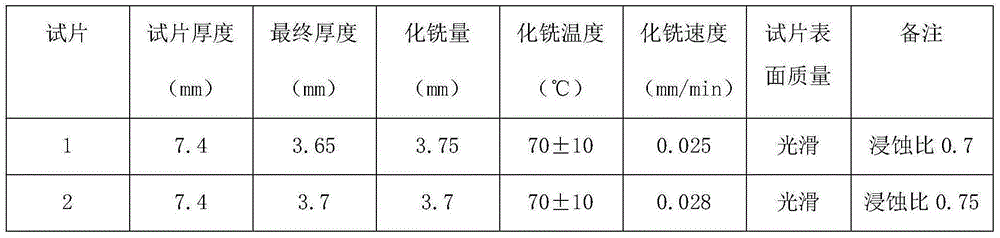

[0028] Adopt above-mentioned formula to carry out two groups of parallel tests, test result is shown in the following table:

[0029]

[0030] The melon petals have no roughness after chemical milling, and the surface is smooth without orange peel. The surface roughness has reached Ra6.3 after comparison.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com