Method for improving heat treatment performance of 2219 aluminium alloy thin-walled curved part

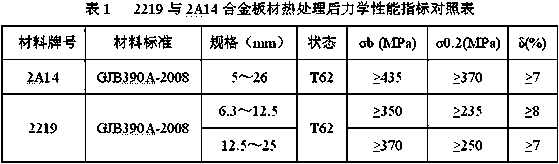

A technology of curved surface parts and aluminum alloys, which is applied in the field of improving the heat treatment performance of 2219 aluminum alloy thin-walled curved surface parts, can solve the problems that cannot meet the structural strength requirements of storage tanks, and achieve the effects of pressure forming, tensile strength and yield strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for improving the heat treatment performance of 2219 aluminum alloy thin-walled curved surface parts, comprising the following steps: the 2219 aluminum alloy annealed melon petal raw material plate is clamped on the quenching heat treatment fixture as a whole, put into the furnace at a temperature of 530 ° C in a salt bath furnace, and quenched The transfer time is not more than 15s. The plate is molded on a 2200T press within 2 hours after it is released from the furnace. After forming, the allowance is cut. After the cutting is completed, it enters the air circulation furnace for artificial aging. The performance parameters of the processed parts are as follows: tensile strength Strength σb≥421MPa, yield strength σ0.2≥323MPa, elongation δ≥10.6%.

Embodiment 2

[0019] A method for improving the heat treatment performance of 2219 aluminum alloy thin-walled curved surface parts, comprising the following steps: the 2219 aluminum alloy annealed melon petal raw material plate is clamped on the quenching heat treatment fixture as a whole, put into the furnace at a temperature of 535 ° C in a salt bath furnace, and quenched The transfer time is not more than 15s. The plate is molded on a 2200T press within 2 hours after it is released from the furnace. After forming, the allowance is cut. After the cutting is completed, it enters the air circulation furnace for artificial aging. The performance parameters of the processed parts are as follows: tensile strength Strength σb≥436MPa, yield strength σ0.2≥365MPa, elongation δ≥10.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com