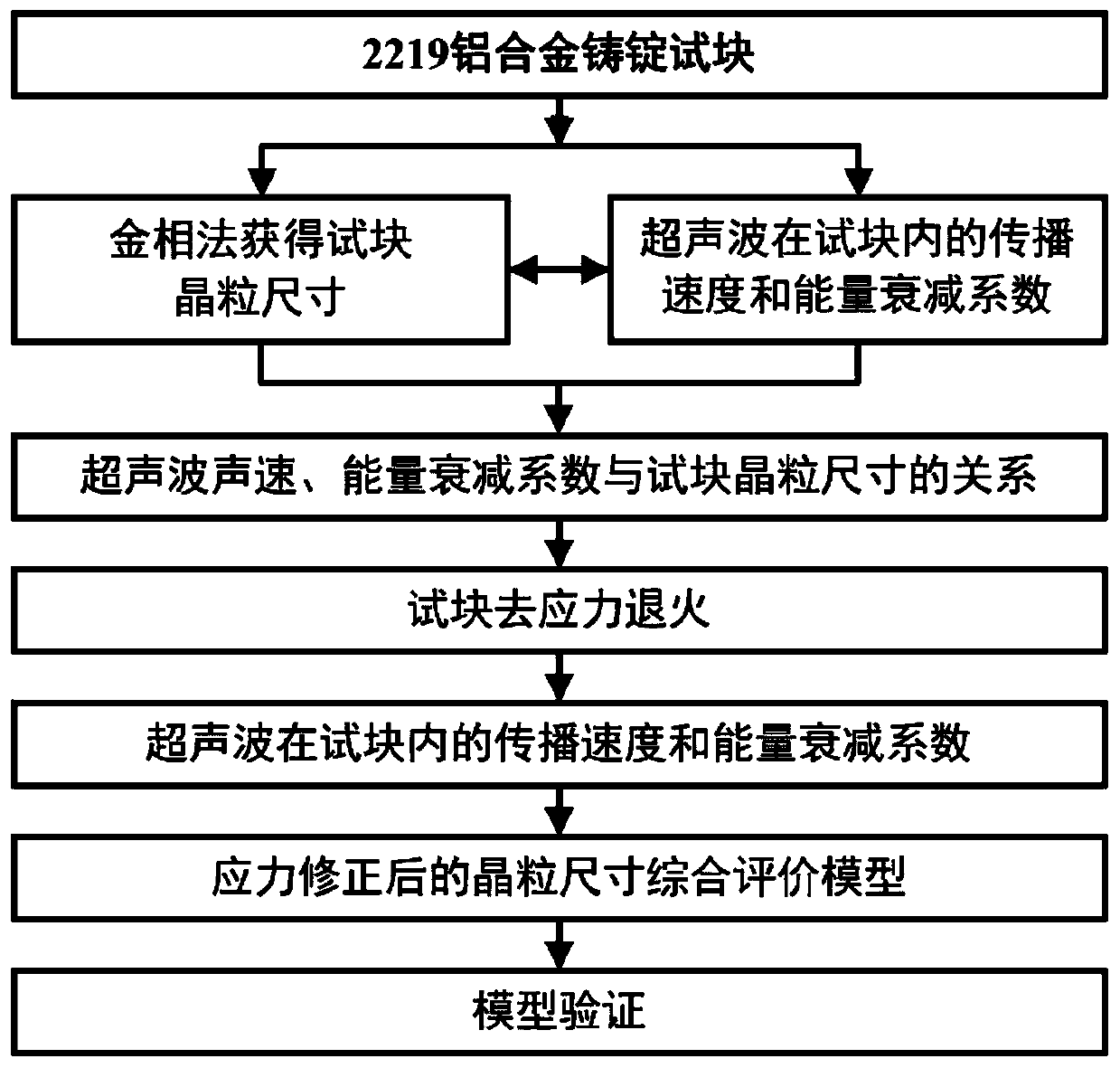

2219 aluminum alloy ingot casting average grain size ultrasonic assessment method

A technology of average grain size, aluminum alloy ingot, applied in particle size analysis, particle and sedimentation analysis, measuring device, etc., can solve the problems of test result influence, low precision, easy to be interfered, etc., and achieve accurate and efficient evaluation method , Improve the accuracy and avoid the effect of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples of implementation.

[0042] The specific implementation method is to conduct research on two 2219 aluminum alloy ingots of φ1380mm and one 2219 aluminum alloy ingot of φ800mm. Among the two φ1380mm ingots, one is a conventional casting ingot and the other is an ultrasonic-assisted casting ingot; the φ800mm ingot is a conventional casting ingot.

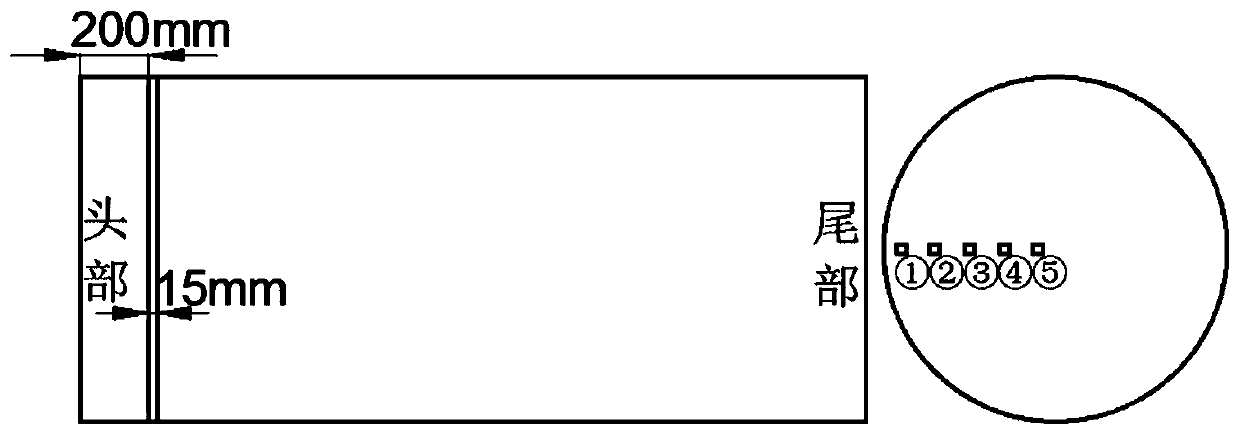

[0043] Cut out a circular cake with a thickness (in the axial direction of the cylindrical ingot) of 15mm from three circular ingots at a distance of 200mm from one end of the axial direction, and then cut out five samples of 40mm×40mm×15mm in the radial direction on the circular cake , the general location layout of five samples: the first one is located on the outer diameter, the second one is located at a radius of 3 / 4 from the center of the circle, the third one is located at a radius of 1 / 2 from the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com