Aluminum alloy blade forged piece and manufacturing method thereof

A technology for aluminum alloys and forgings, which is applied in the field of aluminum alloy blade forgings and its preparation, can solve the problems of not significantly improving the comprehensive mechanical properties of 2219 aluminum alloys, the comprehensive mechanical properties of 2219 aluminum alloys are not up to the standard, and the implementation steps are complicated and cumbersome. Industrial production application, saving manpower and material resources, and the effect of short process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

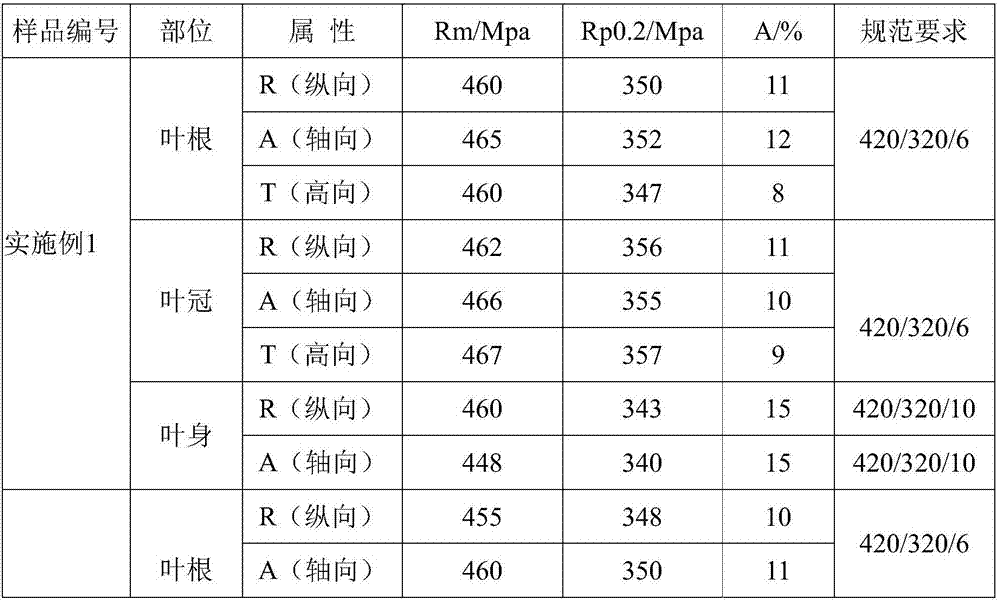

Embodiment 1

[0038] 1) Unloading;

[0039] 2) The roll forging die is used for roll forging, drawing and upsetting, the bar heating temperature is 400℃, the holding time is 2min / mm, the bar deformation is 60%, and the tooling preheating temperature is 200℃;

[0040] 3) Place the billet in a die for forging, select spiral pressure for die forging, and control the deformation of each part at 20-80%, the billet heating temperature is 400℃, the holding time is 2min / mm, and the tooling preheating temperature is 200℃;

[0041] 4) Solution heat treatment of the workpiece: holding temperature 300℃, holding time 100min, heating rate 100℃ / h, quenching transfer time≤60s, quenching water temperature≤30℃, temperature rise during quenching not exceeding 20℃, forging cooling time 30min;

[0042] 3) Cold forging: the deformation of the workpiece is controlled at 3%, and it needs to be completed 3h after solid solution;

[0043] 6) The workpiece is subjected to aging heat treatment: the holding temperature is 160℃, ...

Embodiment 2

[0045] 1) Unloading;

[0046] 2) The roll forging die is used for roll forging, drawing and upsetting, the bar heating temperature is 380℃, the holding time is 1min / mm, the bar deformation is 20%, and the tooling preheating temperature is 130℃;

[0047] 3) Place the billet in a die for forging, select spiral pressure for die forging, and control the deformation of each part at 20%, the billet heating temperature is 380°C, the holding time is 1 min / mm, and the tooling preheating temperature is 130°C;

[0048] 4) Solution heat treatment of the workpiece: holding temperature 490℃, holding time 60min, heating rate 30℃ / h, quenching transfer time≤60s, quenching water temperature≤30℃, temperature rise during quenching not exceeding 20℃, forging cooling time 30min;

[0049] 3) Cold forging: the deformation of the workpiece is controlled at 1%, and it needs to be completed 4 hours after solid solution;

[0050] 6) The workpiece is subjected to aging heat treatment: the holding temperature is 190...

Embodiment 3

[0052] 1) Unloading;

[0053] 2) The roll forging die is used for roll forging and drawing and the upsetting of the upsetting die. The bar heating temperature is 480℃, the holding time is 3min / mm, the bar deformation is 80%, and the tooling preheating temperature is 400℃;

[0054] 3) The blank is placed in a die for forging, and the screw pressure is selected for die forging. The deformation of each part is controlled at 80%, the blank heating temperature is 480℃, the holding time is 3min / mm, and the tooling preheating temperature is 400℃;

[0055] 4) The workpiece is subjected to solution heat treatment: holding temperature 340℃, holding time 120min, heating rate 130℃ / h, quenching transfer time≤60s, quenching water temperature≤30℃, temperature rise during quenching does not exceed 20℃, forging cooling time 100min;

[0056] 3) Cold forging: the deformation of the workpiece is controlled at 3%, and it needs to be completed within 8 hours after solid solution;

[0057] 6) The workpiece is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com