Yogurt stabilizer, fermented yogurt containing same and preparation method of the fermented yogurt

A technology of stabilizer and yogurt, applied in the field of yogurt stabilizer and fermented yogurt, can solve the problems of whey precipitation, low viscosity and poor taste of coagulated yogurt products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

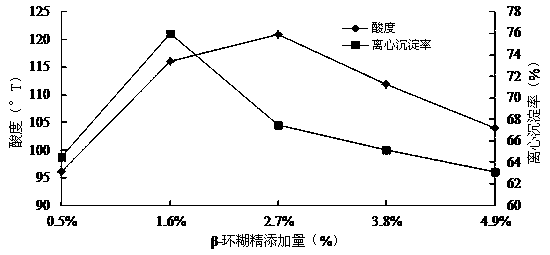

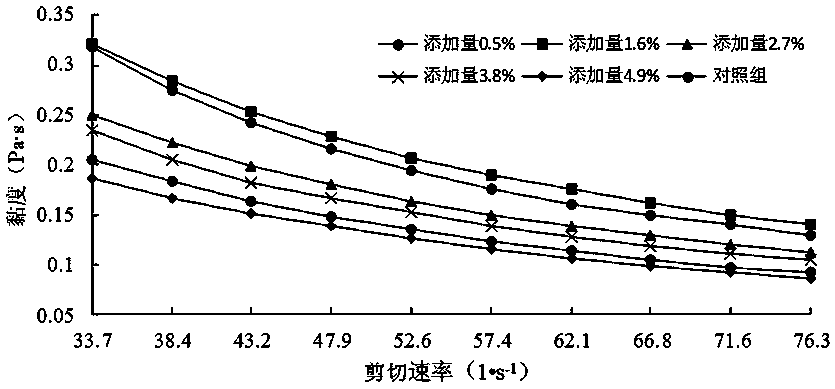

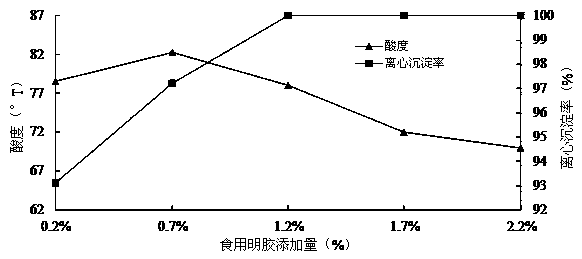

[0035] A yogurt stabilizer is composed of the following raw materials in parts by weight: 0.5-4.9 parts of beta-cyclodextrin, 0.2-2.2 parts of edible gelatin, and 0.02-0.14 parts of agar.

[0036] It consists of the following raw materials in parts by weight: 1.6 parts of β-cyclodextrin, 0.7 parts of edible gelatin, and 0.065 parts of agar.

[0037] The method for preparing fermented yoghurt by utilizing the above-mentioned yoghurt stabilizer comprises the following steps:

[0038] ① After conventional pretreatment of the pure milk, add 8-10% white sugar to the pure milk, stir until the white sugar melts to obtain sweet milk, then add the compounded yogurt stabilizer to the sweet milk, the yogurt is stable The amount of additives accounted for 0.72-7.24% of the mass percentage of the added pure milk, and the amount of white granulated sugar accounted for the mass percentage of the added pure milk;

[0039] 2. Homogenize the mixed solution obtained in step 1. The homogenizatio...

Embodiment 2

[0046] A yogurt stabilizer is composed of the following raw materials in parts by weight: 0.5 g of β-cyclodextrin, 0.2 g of edible gelatin, and 0.02 g of agar.

[0047] The method for preparing fermented yoghurt by utilizing the above-mentioned yoghurt stabilizer comprises the following steps:

[0048] ① After conventional pretreatment of 500g pure milk, add 8% white sugar to the pure milk, stir until the white sugar melts to obtain sweet milk, then add the compounded yogurt stabilizer to the sweet milk, yogurt stabilizer The added amount of the added amount accounts for 0.72% of the mass percentage of the added pure milk, and the added amount of white granulated sugar accounts for the mass percentage of the added pure milk;

[0049] 2. Homogenize the mixed solution obtained in step 1. The homogenization pressure is 15MPa;

[0050] ③ Sterilize the homogenized liquid at a temperature of 110°C for 8 minutes;

[0051] ④ Cool the liquid in step ③, and inoculate the starter for f...

Embodiment 3

[0055] A yogurt stabilizer is composed of the following raw materials in parts by weight: 1 g of β-cyclodextrin, 0.5 g of edible gelatin, and 0.04 g of agar.

[0056] The method for preparing fermented yoghurt by utilizing the above-mentioned yoghurt stabilizer comprises the following steps:

[0057] ① After conventional pretreatment of 500g of pure milk, add 8.2% white sugar to the pure milk, stir until the white sugar melts to obtain sweet milk, then add the compounded yogurt stabilizer to the sweet milk, yogurt stabilizer The added amount of granulated sugar accounts for 1% of the mass percentage of the added pure milk, and the added amount of white granulated sugar accounts for the mass percentage of the added pure milk;

[0058] 2. Homogenize the mixed solution obtained in step 1. The homogenization pressure is 15.4MPa;

[0059] ③ Sterilize the homogenized liquid at a temperature of 111°C for 8.4 minutes;

[0060] ④ Cool the liquid in step ③, and inoculate the starter for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com