The preparation method of flat apricot jam using soybean seed coat pectin as gelling agent

A technology of gelling agent and apricot, which is applied in the field of preparation of apricot jam, can solve the problems of environmental pollution and solvent residue, and achieve the effect of high gel strength, low cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

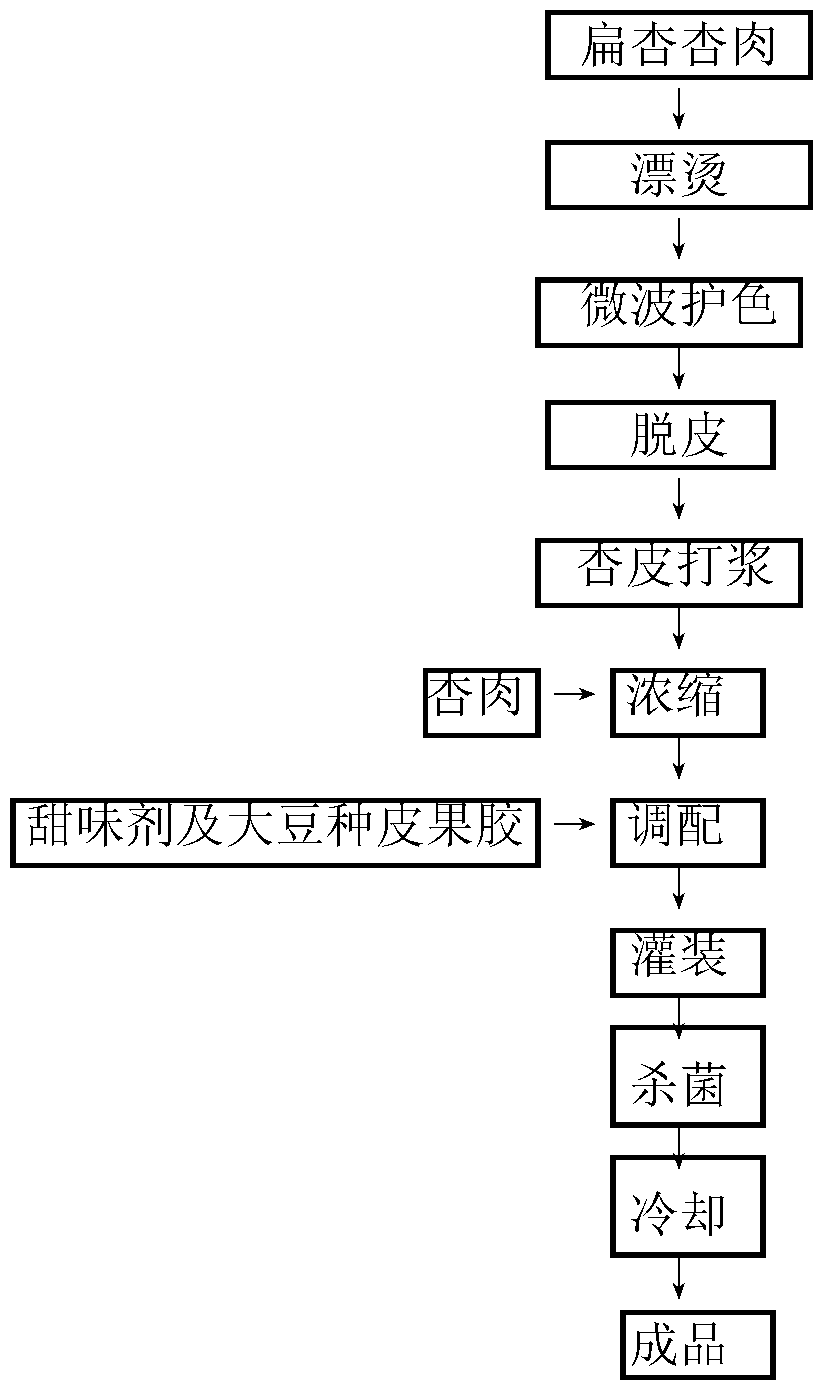

Method used

Image

Examples

Embodiment 1

[0028] 1.1, flat apricot pretreatment

[0029] According to the number of parts by weight, 500 parts of apricot pulp were blanched in 90°C water for 10 minutes, then microwaved for 120 s, with a microwave power of 300W and a microwave frequency of 800MHz; the sensory evaluation criteria for apricot jam are shown in Table 1, with 10 participants Professionals formed a sensory evaluation team to conduct a comprehensive evaluation of the color, smell, taste, and organizational state of the jam. The impact of microwave treatment on the sensory score of the jam is shown in Table 2. The sensory score of the untreated jam was 68.44, while that of the microwave-treated The sensory score of jam is 80.73, indicating that microwave treatment can retain the color and flavor of raw materials to the greatest extent;

[0030] 1.2. Beating

[0031] Dehulling the pretreated flat apricot apricot meat in step 1.1, injecting the apricot skin into a refiner for beating, and retaining the apricot ...

Embodiment 2

[0039] 1.1, flat apricot pretreatment

[0040] In terms of parts by weight, 600 parts of flat apricot meat were blanched in water at 93°C for 7 minutes, then microwaved for 90 seconds, with a microwave power of 600W and a microwave frequency of 915MHz; as can be seen from Table 2, the sensory scores of jams without microwave treatment was 68.44, while the sensory score of microwave-treated jam was 80.97, indicating that microwave treatment can retain the color and flavor of raw materials to the greatest extent;

[0041] 1.2. Beating

[0042] Dehulling the pretreated flat apricot apricot meat in step 1.1, injecting the apricot skin into a refiner for beating, and retaining the apricot meat and apricot skin slurry;

[0043] 1.3. Concentration

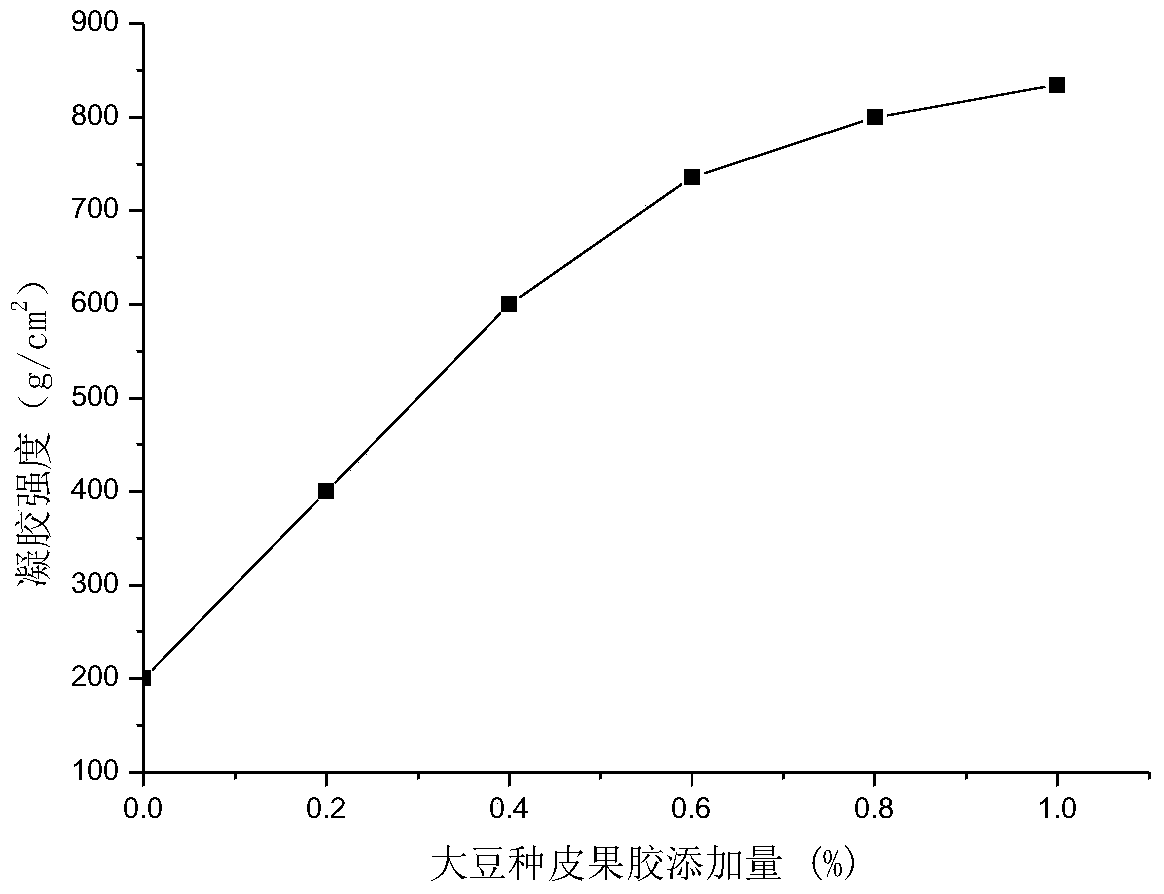

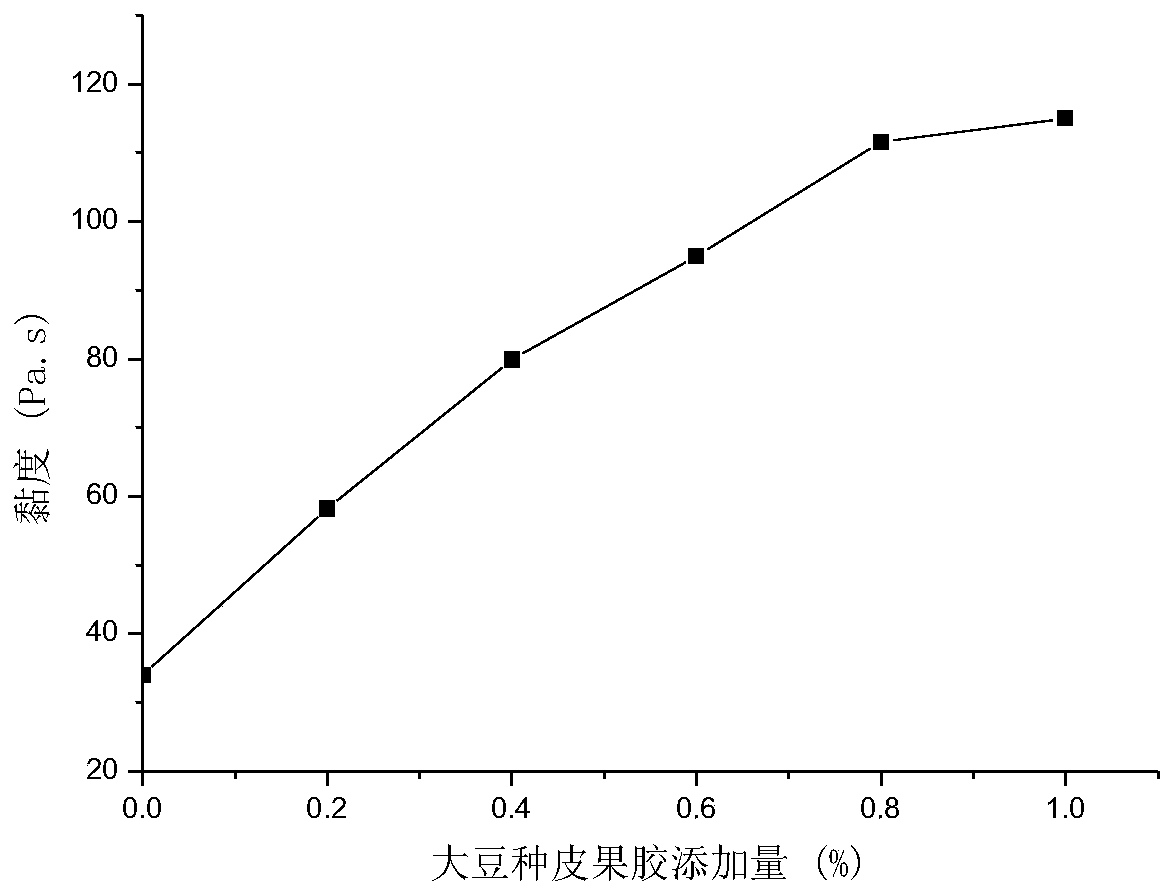

[0044] The apricot flesh and apricot skin slurry are heated to 70°C for concentration, 150 parts of sorbitol and 2.4 parts of soybean seed coat pectin are put into the mixture and stirred slowly and uniformly, and the concentration is s...

Embodiment 3

[0050] 1.1, flat apricot pretreatment

[0051] In terms of parts by weight, 800 parts of flat apricot meat were blanched in water at 95°C for 8 minutes, then microwaved for 60 seconds, with a microwave power of 500W and a microwave frequency of 1350MHz; as can be seen from Table 2, the sensory scores of jams without microwave treatment was 68.44, while the sensory score of microwave-treated jam was 83.10, indicating that microwave treatment can retain the color and flavor of raw materials to the greatest extent;

[0052] 1.2. Beating

[0053] Dehulling the pretreated flat apricot apricot meat in step 1.1, injecting the apricot skin into a refiner for beating, and retaining the apricot meat and apricot skin slurry;

[0054] 1.3. Concentration

[0055] The apricot meat and apricot skin slurry are heated to 75°C for concentration, put into 200 parts of erythritol and 4.8 parts of soybean seed coat pectin and stir slowly and evenly, and stop concentration when the concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com