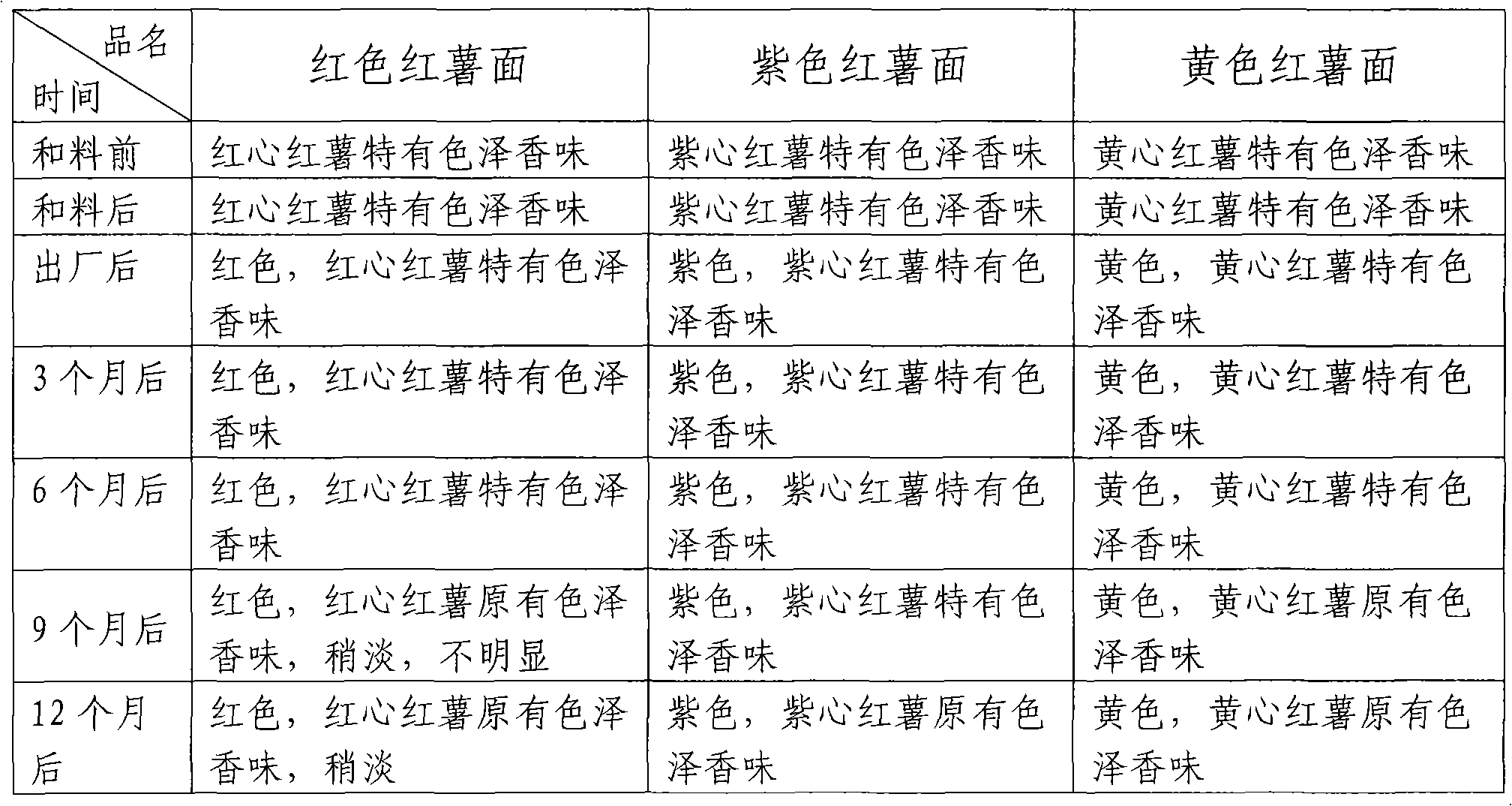

Production process of colored sweet potato noodles

A production process, sweet potato noodle technology, applied in dough processing, baking, food preparation, etc., can solve the problems of not having the color and fragrance of fresh sweet potatoes, not having the color of fresh sweet potatoes, waste of nutrients, etc., to achieve good elasticity, Delicate taste and quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

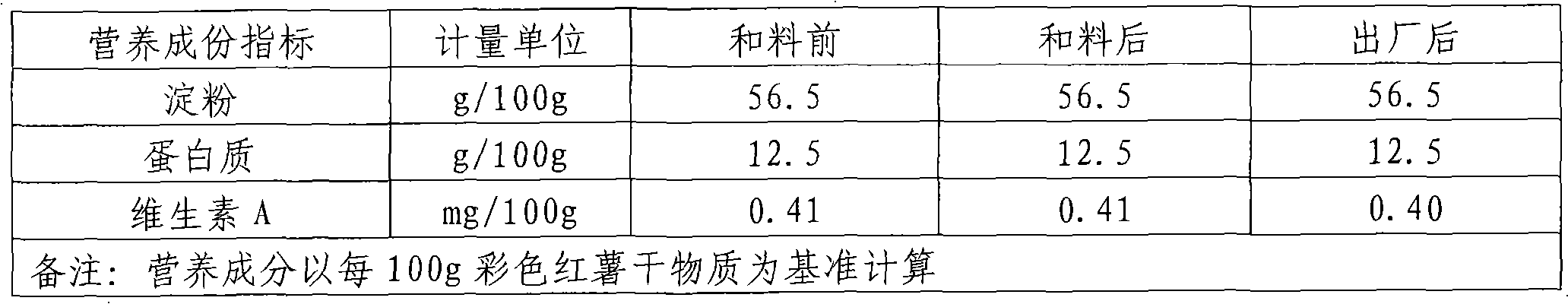

[0039] A method for blending red sweet potato noodles and a production process thereof, comprising the following steps:

[0040] 1. After steaming and cooling the sweet potatoes with red hearts, add edible salt water with a weight ratio of 3% of sweet potatoes to grind mature sweet potato puree in a refiner; wherein, the concentration of salt in the edible salt water is 2% by weight;

[0041] ②Mix the cooked sweet potato mash, gluten and high-gluten wheat flour in the dough mixer and stir evenly, among which:

[0042] Sweet potato puree weight percentage is: 40.5%;

[0043] The weight percentage of gluten powder is: 1.5%;

[0044] The weight percent of high-gluten wheat flour is: 58%;

[0045] ③ ripening

[0046] Let the ingredients reconciled in step 2 stand and mature at room temperature for 30 minutes, so that the flour can further absorb water and swell the flour grains and grain dough, so as to form a gluten network structure with uniform texture and good viscoelastici...

Embodiment 2

[0054] A method for blending red sweet potato noodles and a production process thereof, comprising the following steps:

[0055] 1. After steaming and cooling the sweet potatoes with red hearts, add edible salt water with a weight ratio of 6% of sweet potatoes to grind mature sweet potato puree in a refiner; wherein, the concentration of salt in the edible salt water is 2% by weight;

[0056] ②Mix the cooked sweet potato mash, gluten and high-gluten wheat flour in the dough mixer and stir evenly, among which:

[0057] The weight percentage of mashed sweet potato is: 30%;

[0058] The weight percentage of gluten powder is: 2%;

[0059] The weight percent of high-gluten wheat flour is: 68%;

[0060] ③ ripening

[0061] Let the ingredients reconciled in step ② stand and mature at room temperature for 25 minutes, so that the flour can further absorb water and swell the flour grains and grain dough, so as to form a gluten network structure with uniform texture and good viscoelasti...

Embodiment 3

[0069] A method for mixing ingredients of purple sweet potato noodles and a production process thereof, comprising the following steps:

[0070] 1. After steaming and cooling purple sweet potatoes, add edible salt water with a weight ratio of 6% of sweet potatoes to grind mature sweet potato puree in a refiner; wherein, the concentration of salt in edible salt water is 2% by weight;

[0071] ②Mix the cooked sweet potato mash, gluten and high-gluten wheat flour in the dough mixer and stir evenly, among which:

[0072] Sweet potato puree weight percentage is: 9%;

[0073] The weight percentage of gluten powder is: 2%;

[0074] The weight percent of high-gluten wheat flour is: 89%;

[0075] ③ ripening

[0076] Let the ingredients reconciled in step ② stand and mature at room temperature for 10 minutes, so that the flour can further absorb water and swell the flour grains and grain dough, so as to form a gluten network structure with uniform texture and good viscoelasticity;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com