Instant fresh noodles, instant fresh vermicelli and instant fresh rice noodles as well as manufacturing method thereof

A production method and fresh noodle technology, applied in the field of instant noodles, instant noodles, instant rice noodles and their production, can solve the problems that have not been seen in media reports and literature records, etc., to enrich product varieties, suppress heat generation and oxidation , The effect of warm and soft or smooth taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0037] 1. Ingredients: 80 kg flour, 5 kg corn starch, 5 kg modified starch, 2.8 kg gluten, 500 g salt, 800 g edible oil, 420 g sodium alginate, 1.3 kg lactic acid;

[0038] 2. Put the prepared ingredients into the vacuum mixer, add 36 kg of water, and mix the dough for 15 minutes under vacuum;

[0039] 3. Cut the dough into small pieces of about 2 kilograms and add them to special twin-screw equipment for extrusion. In a high temperature and high pressure environment of 120℃-150℃, the dough will be cured and sterilized for 2-3 minutes, and the noodle diameter is 1.2mm. After the first 2 kg is emptied, the official product will be released.

[0040] 4. Cut to 300mm after cooling in a high clean environment;

[0041] 5. In a high-clean environment, use vacuum packaging bags at 100 grams per bag;

[0042] 6. Put it in a vacuum packaging machine in a highly clean environment and vacuum package;

Embodiment approach 2

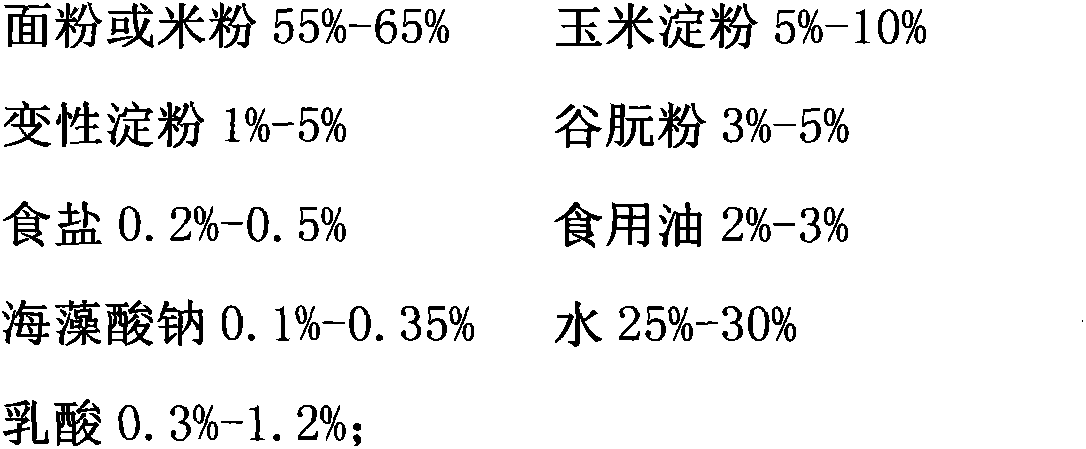

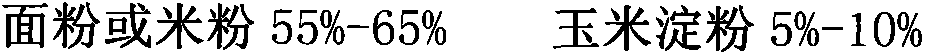

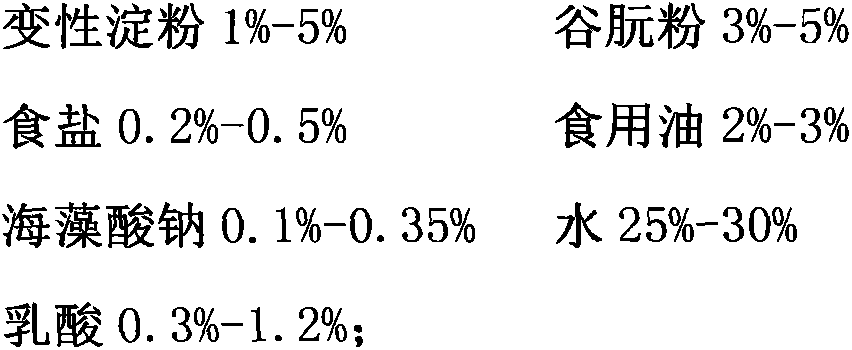

[0044] 1) Mix and add flour 57%, corn starch 6%, modified starch 2%, gluten 3.5%, salt 0.3%, edible oil 3%, sodium alginate 0.2%, water 27%, and lactic acid 1% according to the above ratio. Vacuum dough mixer, mix for 15 minutes to make dough.

[0045] 2) Add the dough to the special twin-screw noodle-making equipment and extrude it, ripen it in a high temperature and high pressure environment of 140°C for 2.5 minutes, and sterilize it and form it.

[0046] 3) Cool the formed noodles and cut them to a length of 20 cm.

[0047] 4) Vacuum bag packaging, vacuum and packaging.

[0048] 5) Put the bag, vegetable bag, and oil bag into the outer packaging bag for packaging.

[0049] 6) The finished product is stored at -10°C, and the shelf life is 12 months.

[0050] The above steps 4 and 5 are all performed in a highly clean environment.

[0051] The edible method of instant noodles, instant noodles and instant noodles of the present invention:

[0052] 1. The noodle soup (powder) method (the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com