Ultra-high temperature and ultra-high pressure instant sterilization method of foods

A technology of instantaneous sterilization and sterilization method, applied in the field of ultra-high temperature and ultra-high pressure instantaneous sterilization of food and food sterilization, it can solve the problems of poor heat preservation effect, uneven temperature distribution, uneven food sterilization, etc. Short time, low temperature, the effect of retaining color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

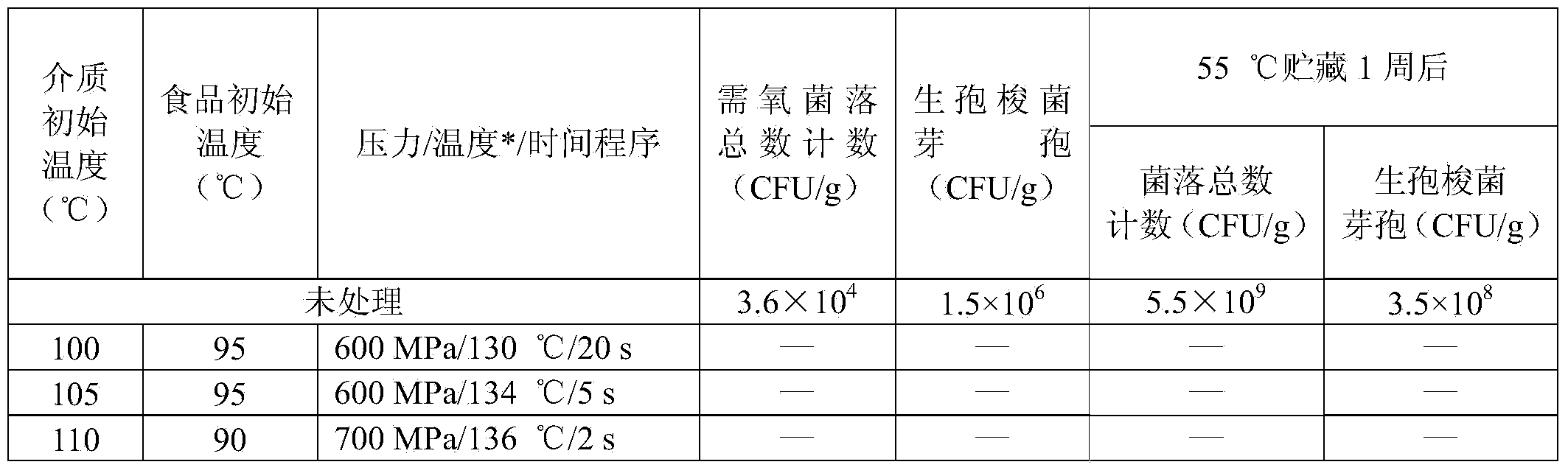

[0023] Embodiment 1, ultra-high temperature and ultra-high pressure instantaneous sterilization stewed tenderloin

[0024] Cut the braised tenderloin (with a one-week refrigerated shelf life at 4°C) purchased in the mall into slices (5cm×5cm×0.5cm), put them in high-temperature-resistant aluminum foil bags, 100g per bag, and inoculate Clostridium sporogenes (Clostridium sporogenes P.A. 3679) spores to a final concentration of spores of about 1.0 x 10 6 CFU / g, vacuum-packed, placed in an ice-water bath before ultra-high pressure treatment, and heated to the preheating temperature in a boiling water bath for about 5 minutes before pressurization.

[0025] The pressure transmission medium is soybean oil, which is added into the autoclave, and the autoclave is filled, and the soybean oil and the wall of the autoclave are heated to the set temperature. After pressure treatment, they are cooled rapidly with ice water. The processing parameters are shown in Table 1, and the time for...

Embodiment 2

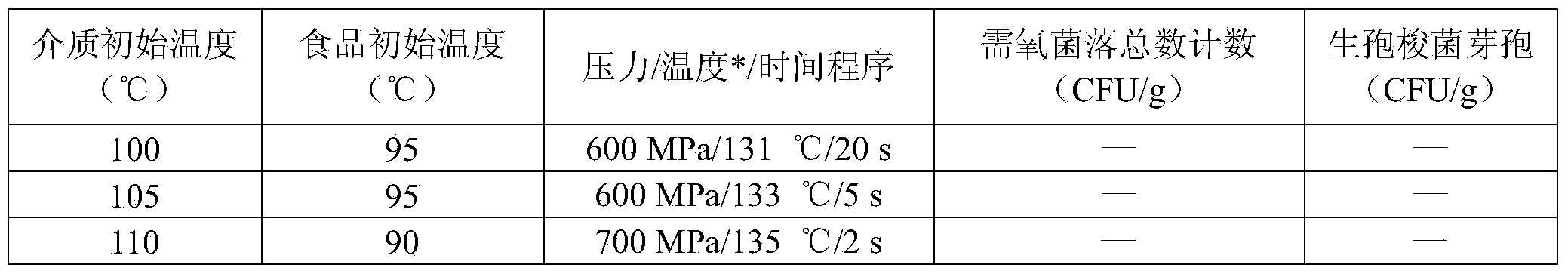

[0034] Embodiment 2, ultra-high temperature and ultra-high pressure instant sterilization braised beef in brown sauce

[0035] In this embodiment, beef tenderloin is taken as an example, braised beef is prepared by a conventional cooking method, and the product segmentation, Clostridium sporogenes inoculation and preheating are the same as those in Example 1.

[0036] The pressure transmission medium is olive oil, which is added into the autoclave and filled with the autoclave. Both the olive oil and the wall of the autoclave are heated to the set temperature, and after pressure treatment, they are rapidly cooled with ice water. Three bags were processed in parallel for each parameter and repeated three times. The processing parameters are shown in Table 2.

[0037] According to the provisions of GB13100-2005 "Hygienic Standards for Canned Meat", the analysis methods of sensory, physical and chemical and microbial indicators of braised beef in brown sauce are the same as those...

Embodiment 3

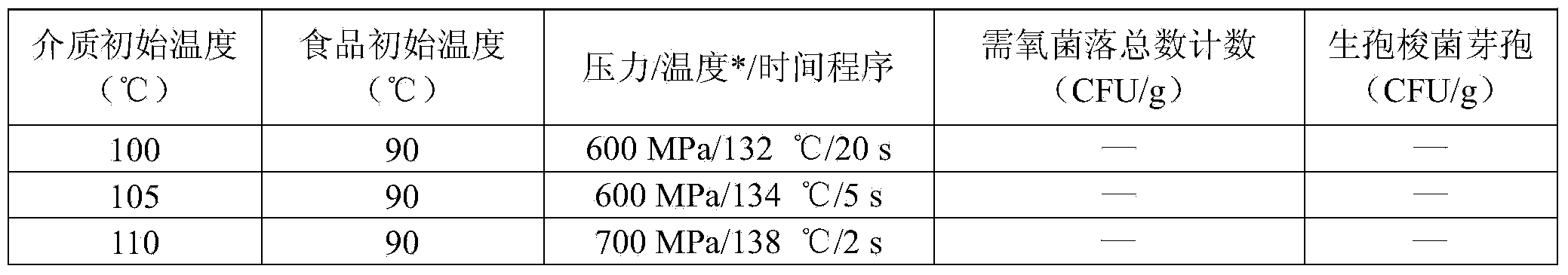

[0043] Embodiment 3, ultra-high temperature and ultra-high pressure instant sterilized green beans

[0044] In this embodiment, peas are taken as an example. The peas purchased in the market are peeled, cleaned, sorted, bagged, 100 g per bag, inoculated with Clostridium sporogenes and preheated as in Example 1.

[0045] The pressure transmission medium is a mixture of linseed oil and castor oil (1:1, v / v), which is added to the autoclave and filled with the autoclave. The mixed oil medium and the wall of the autoclave are heated to the set temperature. After pressure treatment, Cool quickly with ice water. Three bags were processed in parallel for each parameter and repeated three times. The processing parameters were shown in Table 3, and the time for instantaneous pressure relief was 3 s.

[0046] The samples subjected to high-pressure treatment and stored at 55°C for 1 week were analyzed according to the relevant index analysis methods of GB11671-2003 "Hygienic Standards f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com