Heat treatment method for enhancing deformation properties of 2219 aluminum alloy T81-T845

A technology of T81-T845 and heat treatment method, which is applied in the field of heat treatment to improve the deformation performance of 2219 aluminum alloy T81‑T845, and can solve the problems that the deformation of melon parts cannot be satisfied, and the mechanical properties of melon parts have a large gap. , to achieve good application prospects, strong adaptability, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

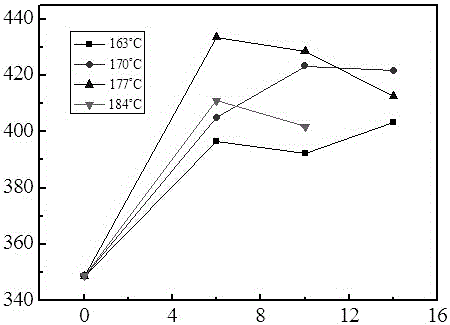

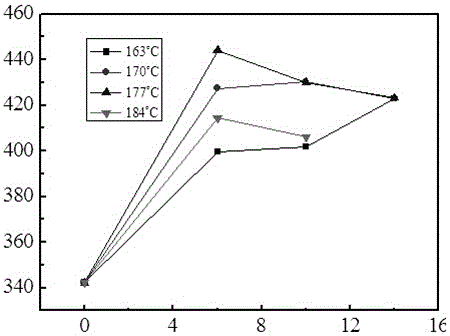

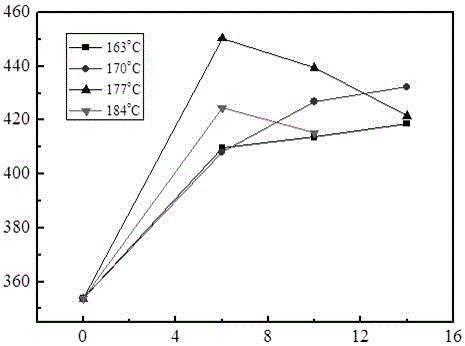

[0019] A heat treatment method for improving the deformation performance of 2219 aluminum alloy T81-T845, comprising the following steps: solid solution treatment of test piece material, preparation of test pieces with various deformation amounts, aging treatment, mechanical performance test, establishment of the relationship between various factors, and the results See Figure 1(a)-(d), Figure 2(a)-(d), Figure 3(a)-(d);

[0020] Wherein, the deformation amount is 1%, 4%, 6%, 8%, 12%, 15%, 20%, 25%, 30%, 45%.

[0021] The aging treatment temperatures are 163°C, 170°C, 177°C, 184°C.

[0022] The aging treatment time is 0-32h.

[0023] The focus of the present invention lies in the relationship between the deformation amounts of the 2219 aluminum alloy material and the aging treatment parameters, and other processes belong to conventional processes.

[0024] After obtaining the relationship between various factors, the steps used to guide the deformation heat treatment of 2219 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com