Manufacturing method for C-shaped section ring forging of 2219 aluminum alloy

A manufacturing method and aluminum alloy technology, applied in the field of forgings, can solve the problems of reducing specific strength, room temperature tensile strength and Brinell hardness, low material utilization rate, long processing cycle, etc., to increase room temperature tensile strength and Brinell hardness Hardness, resolution of structure differences and deformation, and short processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a method for manufacturing a 2219 aluminum alloy C-shaped cross-section ring forging, including the following steps:

[0029] 1) sawing; sawing the 2219 aluminum alloy bar according to the specification;

[0030] 2) Quenching treatment, heat the sawed 2219 aluminum alloy bar to 440-460°C and keep it warm. Cool at a rate of min to below 200°C; in this embodiment, the preferred heating temperature is 450°C, the processing time is the holding time: the effective thickness of the rod × 2.5min / mm, and then cooled to below 200°C at a rate of 3°C / min ;

[0031] 3) Upsetting, punching, and reaming the quenched 2219 aluminum alloy bar to obtain a rectangular ring blank 1, the temperature of the whole process is 400-430°C; the preferred temperature in this embodiment is 420°C;

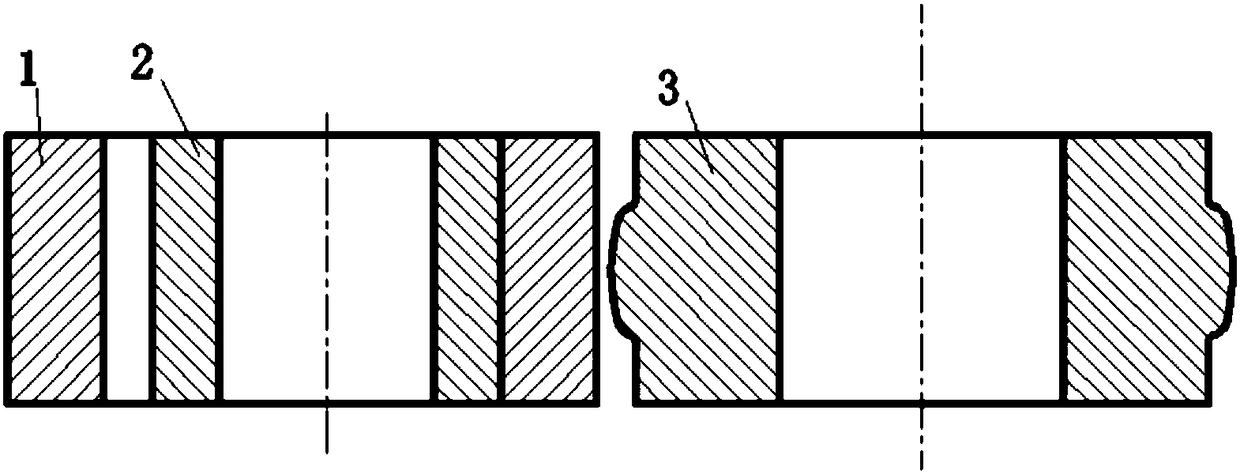

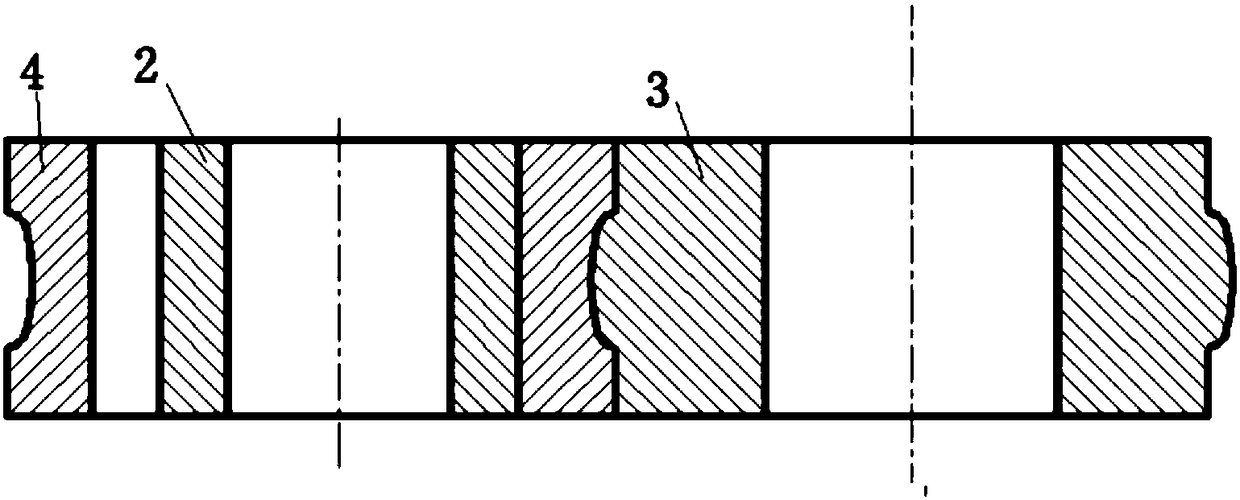

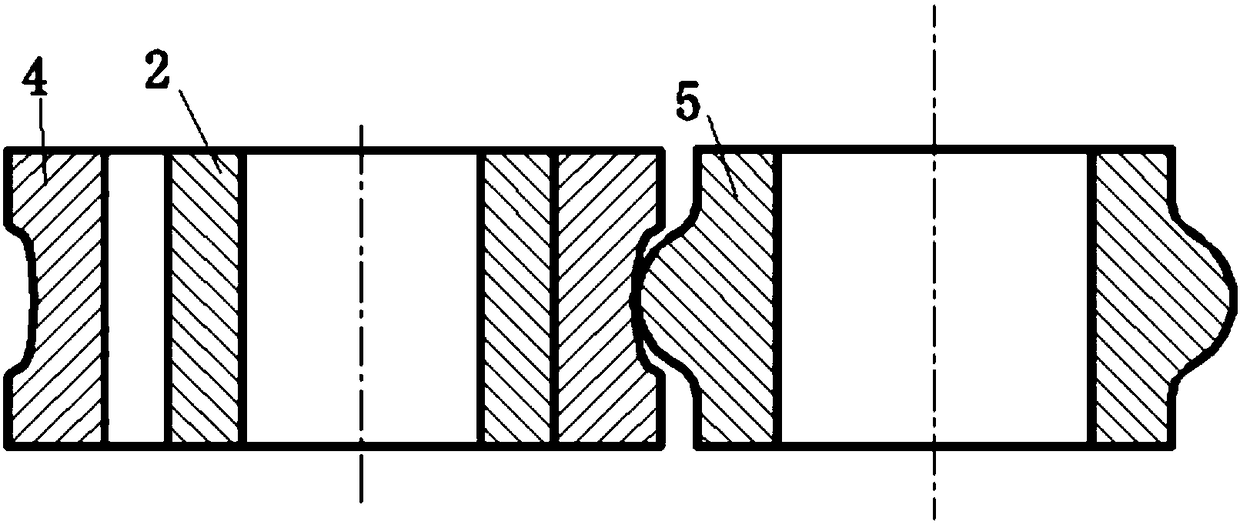

[0032] 4) Production of special-shaped ring blanks, such as figure 1 with figure 2 As shown, the rectangular ring billet is placed on the ring rolling mill, the rotation spee...

Embodiment 2

[0035] This embodiment provides a method for manufacturing a 2219 aluminum alloy C-shaped cross-section ring forging, including the following steps:

[0036] 1) sawing; sawing the 2219 aluminum alloy bar according to the specification;

[0037] 2) Quenching treatment, heat the sawed 2219 aluminum alloy bar to 440-460°C and keep it warm. Cool at a rate of min to below 200°C; in this embodiment, the preferred heating temperature is 450°C, the processing time is the holding time: the effective thickness of the rod × 2.5min / mm, and then cooled to below 200°C at a rate of 3°C / min ;

[0038] 3) Upsetting, punching, and reaming the quenched 2219 aluminum alloy bar to obtain a rectangular ring blank 1, the temperature of the whole process is 400-430°C; the preferred temperature in this embodiment is 420°C;

[0039] 4) Production of special-shaped ring blanks, such as figure 1 with figure 2 As shown, the rectangular ring billet is placed on the ring rolling mill, the rotation spee...

Embodiment 3

[0043] This embodiment provides a method for manufacturing a 2219 aluminum alloy C-shaped cross-section ring forging, including the following steps:

[0044] 1) sawing; sawing the 2219 aluminum alloy bar according to the specification;

[0045] 2) Quenching treatment, heat the sawed 2219 aluminum alloy bar to 440-460°C and keep it warm. Cool at a rate of min to below 200°C; in this embodiment, the preferred heating temperature is 450°C, the processing time is the holding time: the effective thickness of the rod × 2.5min / mm, and then cooled to below 200°C at a rate of 3°C / min ;

[0046] 3) Upsetting, punching, and reaming the quenched 2219 aluminum alloy bar to obtain a rectangular ring blank 1, the temperature of the whole process is 400-430°C; the preferred temperature in this embodiment is 420°C;

[0047] 4) Production of special-shaped ring blanks, such as figure 1 with figure 2 As shown, the rectangular ring billet is placed on the ring rolling mill, the rotation spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com