Thermal treatment method for as-deposited 2219 aluminum alloy

A heat treatment method and technology of aluminum alloy, applied in the field of heat treatment of deposited 2219 aluminum alloy, can solve problems such as poor mechanical properties and element segregation, and achieve the effects of high production efficiency, accelerated diffusion, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

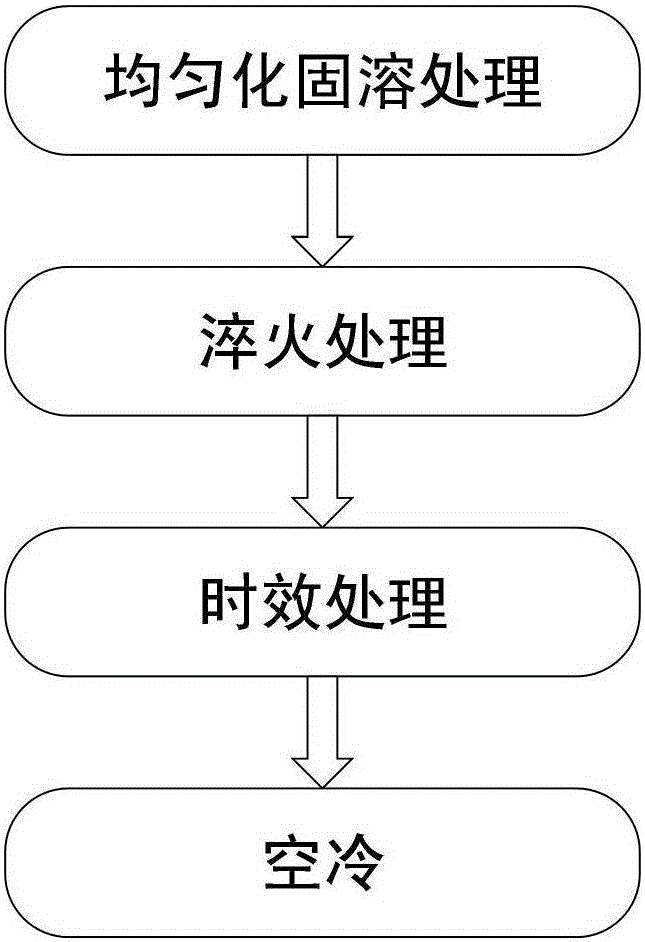

[0016] Specific Embodiment 1: In this embodiment, a heat treatment method for deposited 2219 aluminum alloy is carried out according to the following steps:

[0017] 1. The as-deposited 2219 aluminum alloy was homogenized and solution treated at 530°C for 20 hours to obtain an aluminum alloy after homogenization and solution treatment;

[0018] 2. Place the aluminum alloy after the homogenization and solid solution treatment in step 1 in water at room temperature for quenching treatment to obtain the aluminum alloy after the quenching treatment;

[0019] 3. aging the aluminum alloy after the quenching treatment in step 2 for 14-28 hours at 160-190° C. to obtain the aluminum alloy after the aging treatment;

[0020] 4. Cool the aluminum alloy after the aging treatment in step 3 in the air, and the process is completed.

[0021] This embodiment improves the conventional solution treatment process, keeps the material at a higher temperature for a long time, accelerates the diffu...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment differs from Embodiment 1 in that: the deposited 2219 aluminum alloy is obtained after additive manufacturing of 2219 aluminum alloy. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in step 3, the aluminum alloy after the step 2 quenching treatment is aged at 160°C for 20-28 hours, and the aging treatment is obtained. aluminum alloy. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com