Process method for improving comprehensive mechanical property of 2219 aluminum alloy ring piece

A technology of comprehensive mechanics and process methods, applied in the field of improving the comprehensive mechanical properties of 2219 aluminum alloy rings, can solve the problems of inability to adapt to size specifications, deformation and cracking of rings, and reduced mechanical properties of materials, etc., to achieve full crushing and uniform distribution, Improve strength and plasticity, the effect of strength and plasticity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

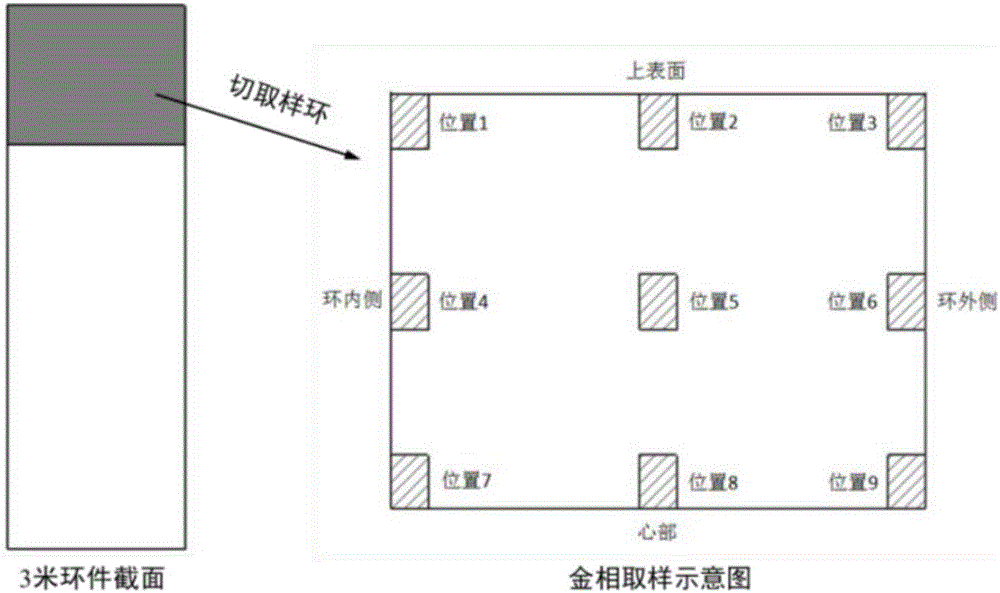

Examples

Embodiment 1

[0036] Example 1 (high temperature blanking at 510°C + segmental medium and low temperature ring rolling)

[0037] Step 1: High-temperature multi-directional forging blanking.

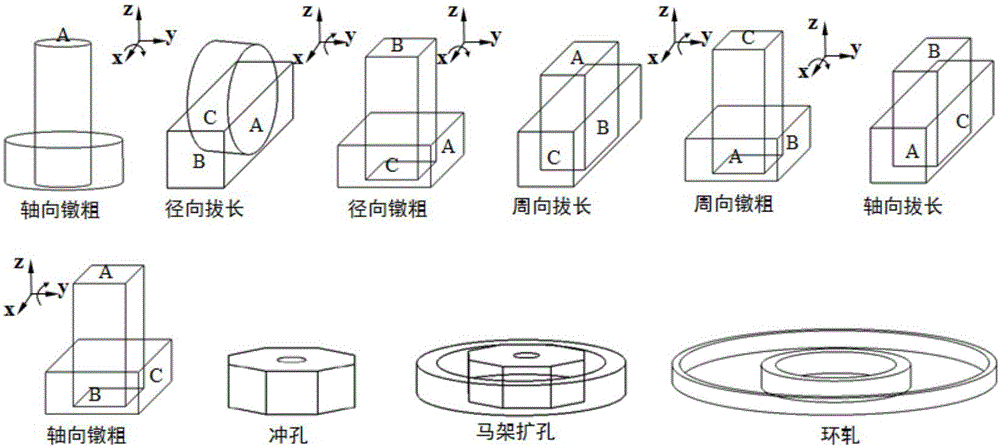

[0038] Take a homogenized ingot Press on the 3600 ton hydraulic press figure 1 Multi-directional forging is carried out in the process flow chart shown in the figure. Before forging, the billet is fully preheated to 510°C±10°C, the mold is preheated to 350-450°C, and the billet is opened by four-upsetting and three-drawing multi-directional forging. Upsetting is carried out in three directions, axial and circumferential, and the single deformation of upsetting is 45% to 55%.

[0039] Step 2: Punch.

[0040] After multi-directional forging, punch directly on the press, and fully preheat the punch to 350-450°C. After punching, air-cool to room temperature, clean the surface burrs, scale, folds and other defects, and fully clean the strain defects caused by punching.

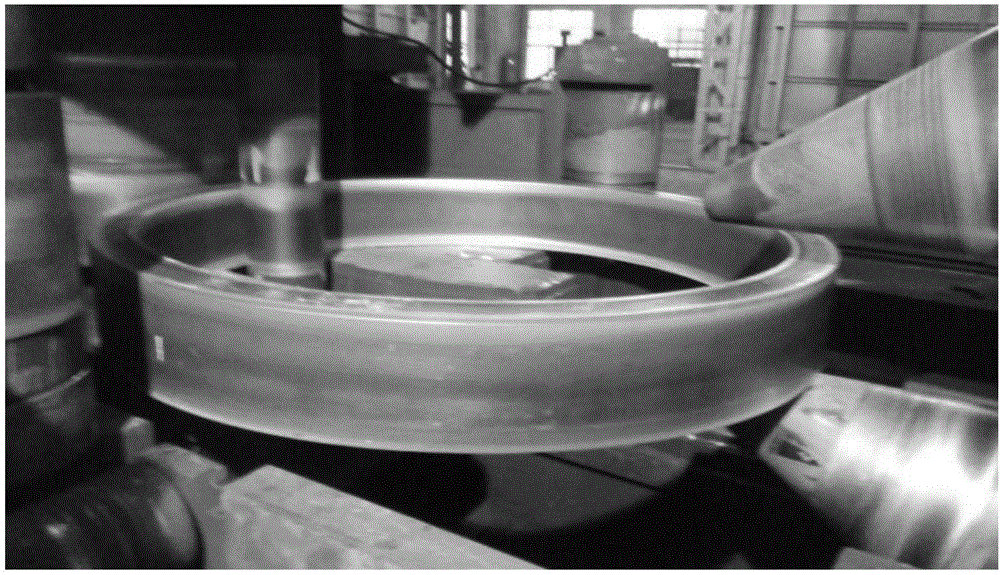

[0041] Step 3: Reaming the hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com