Patents

Literature

132 results about "6061 aluminium alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

6061 is a precipitation-hardened aluminum alloy, containing magnesium and silicon as its major alloying elements. Originally called "Alloy 61S", it was developed in 1935. It has good mechanical properties, exhibits good weldability, and is very commonly extruded (second in popularity only to 6063). It is one of the most common alloys of aluminum for general-purpose use.

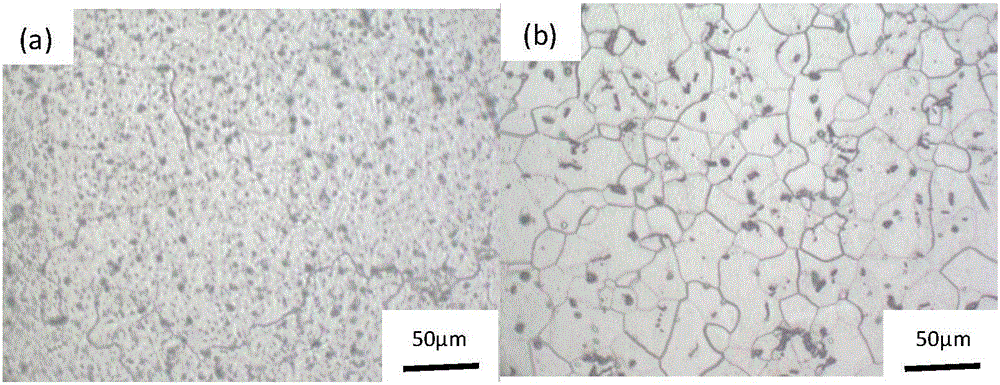

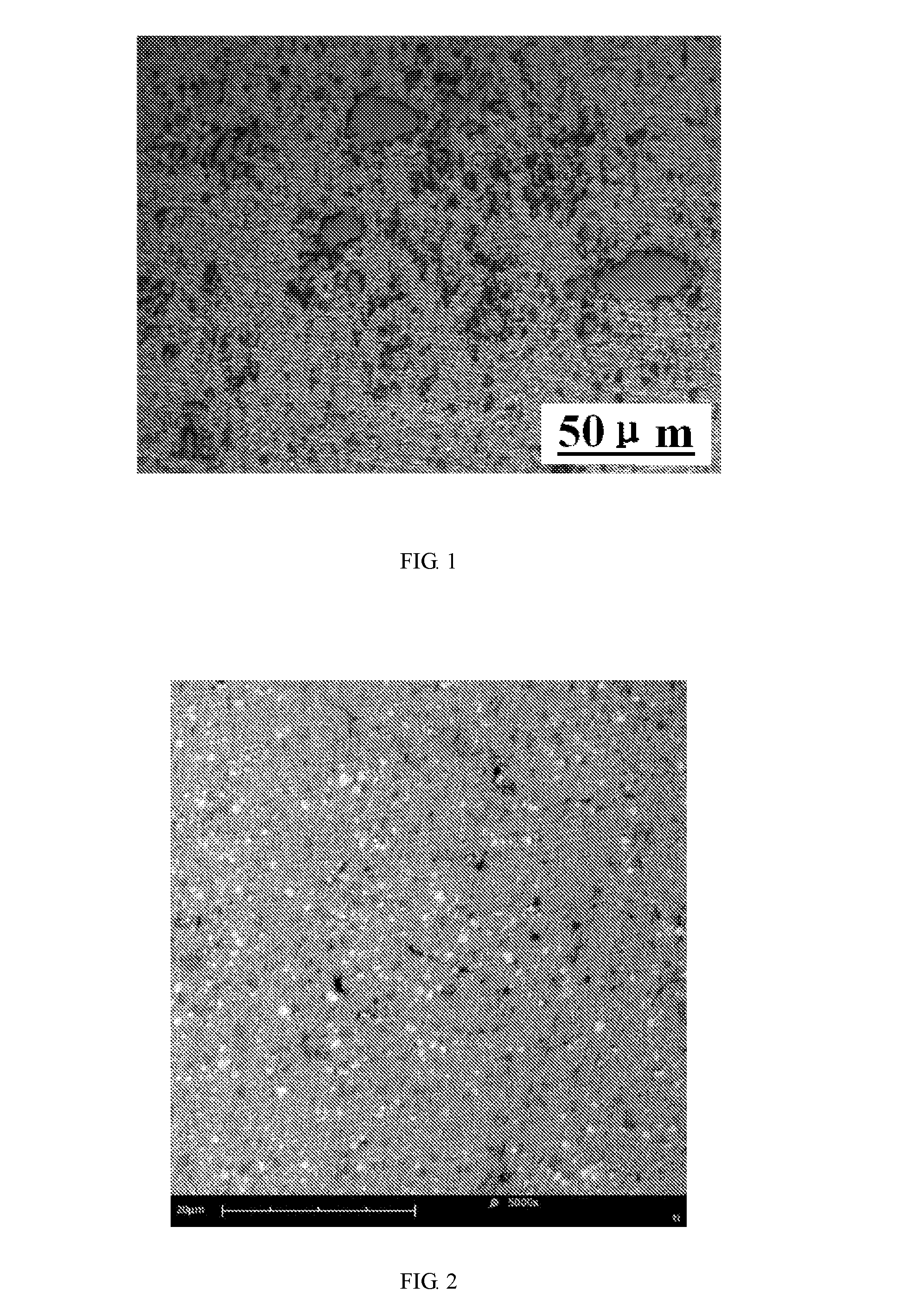

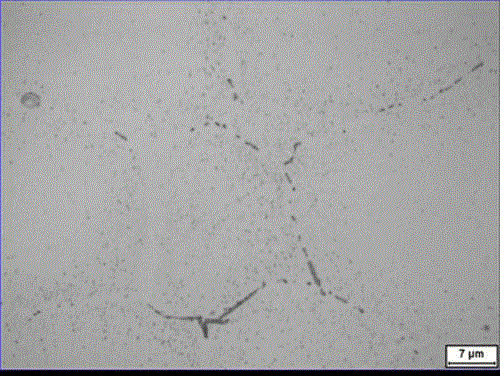

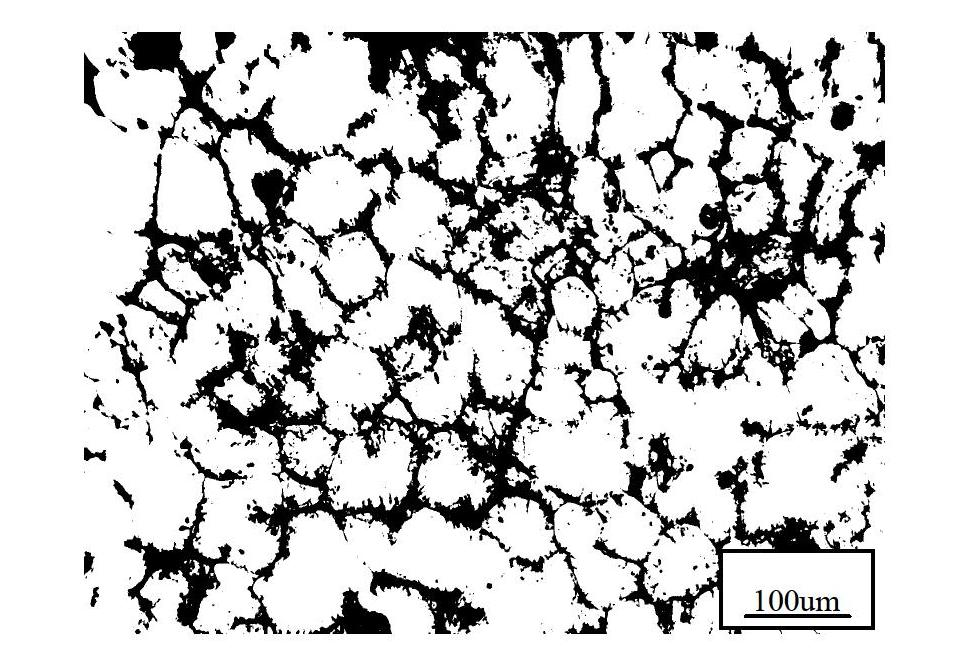

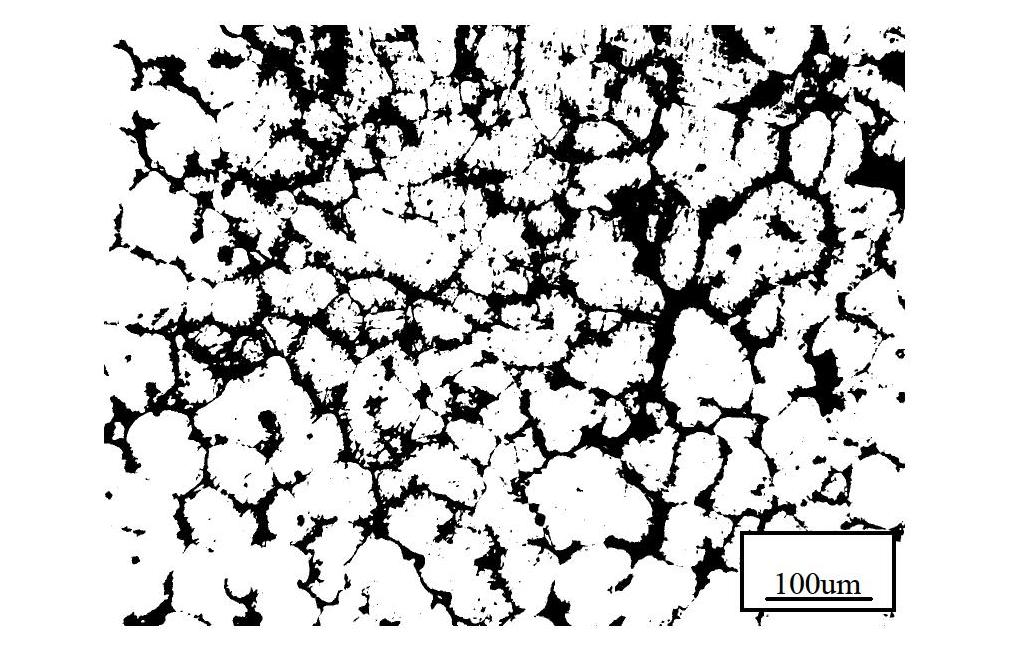

Process for homogenizing aluminum alloy

The invention relates to a process for homogenizing aluminum alloy, in particular to a process for homogenizing high-quality 6061 aluminum alloy for a reaction chamber liner of a plasma etcher, belonging to the technical field of non-ferrous metal heat treatment technique. The 6061 aluminum alloy comprises 0.4-0.6 wt% of Si, 0.8-1.2 wt% of Mg, 0.15-0.4 wt% of Cu, 0.01-0.35 wt% of Cr, less than 0.15 wt% of Fe, less than 0.15 wt% of Mn, less than 0.15 wt% of Ti and the balance of Al. The process provided by the invention comprises the following steps: carrying out furnace-heating on 6061 aluminum alloy cast ingots, keeping the temperature at 560+ / -5 DEG C for 9 hours, discharging, and carrying out water quenching at room temperature. The homogenizing treatment can enhance the structural homogenity of the aluminum alloy matrix, redissolve the Mg2Si phase, and nodulize the iron-containing phase, thereby enhancing the effect of anodic oxidation and the corrosion resistance of aluminum alloy after anodic oxidation.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

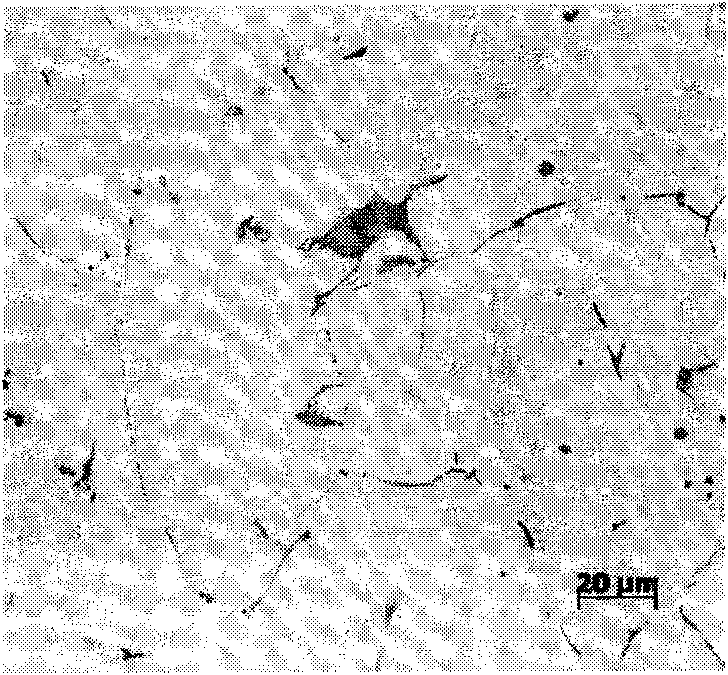

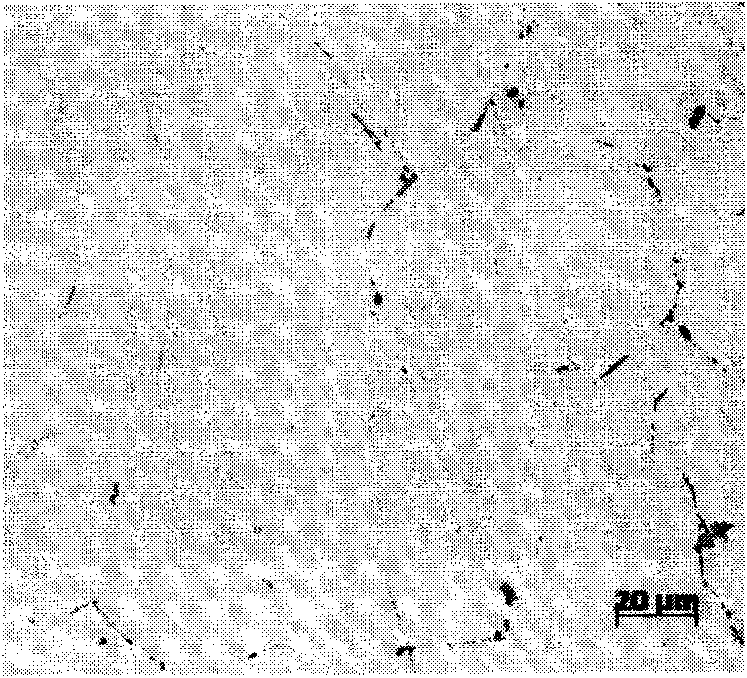

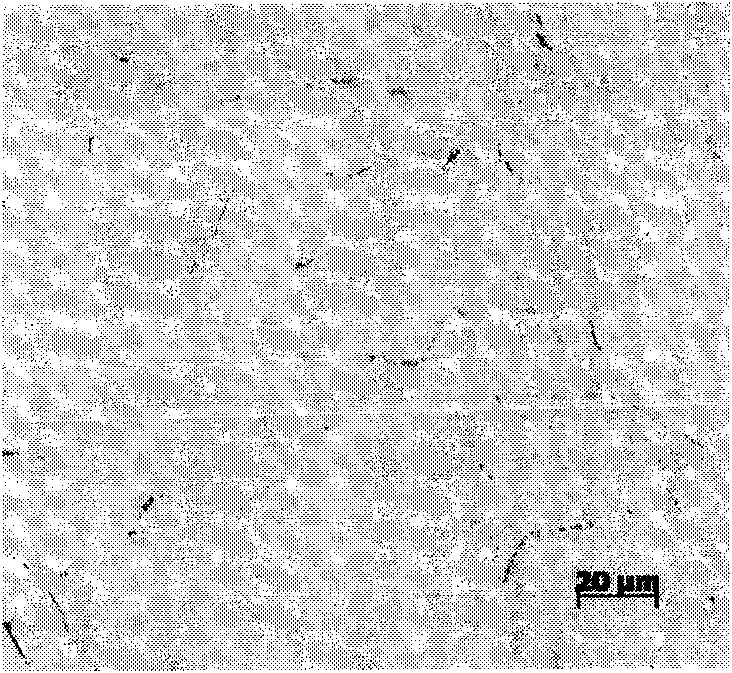

Preparation method of high-quality 6061 aluminium alloy forging for semiconductor equipment

ActiveCN102644039AImprove qualityEasy to operateMetal-working apparatus5005 aluminium alloyHeat treated

A preparation method of a high-quality 6061 aluminium alloy forging for semiconductor equipment comprises the following steps of: (1) blank making by a common semicontinuous casting method; (2) homogenization heat treatment of 6061 aluminium alloy by two-stage homogenization technology, wherein a first-stage temperature range is 540-570 DEG C, heat preservation time is selected to be 12-24 hours, a second-stage temperature range is 570-620 DEG C, and heat preservation time is selected to be 18-24 hours; (3) forging technology, wherein a preheating temperature of a press chopping block is 300-350 DEG C, the maximal forging heating time is not more than 3 when multi-heating forging is employed, an upsetting forging ratio for each heating is controlled to be 4-6 when forging with 2-3 heating times is employed, the forging ratio is controlled to be 7-9 when forging with one heating time is employed, and the final forging temperature is controlled to be 320-360 DEG C; (4) solid solution aging technology, wherein a solid solution temperature is 520-540 DEG C, heat preservation time is on a basis of 45 min, the heat preservation time increases by 1 min when the thickness of the forging increases by 1 mm, an aging temperature is 160-180 DEG C, and heat preservation time is between 16-25 hours. The invention provides the preparation method of a high-quality 6061 aluminium alloy forging for semiconductor equipment, and the method has the advantages of strong operability, high yield, stable product performance, high product added value, and the like, is applicable to production for small-lot supply, and has significant economic benefits.

Owner:GRIMAT ENG INST CO LTD

Process for avoiding coarse-grain rings of 6061 aluminum alloy bars and rods

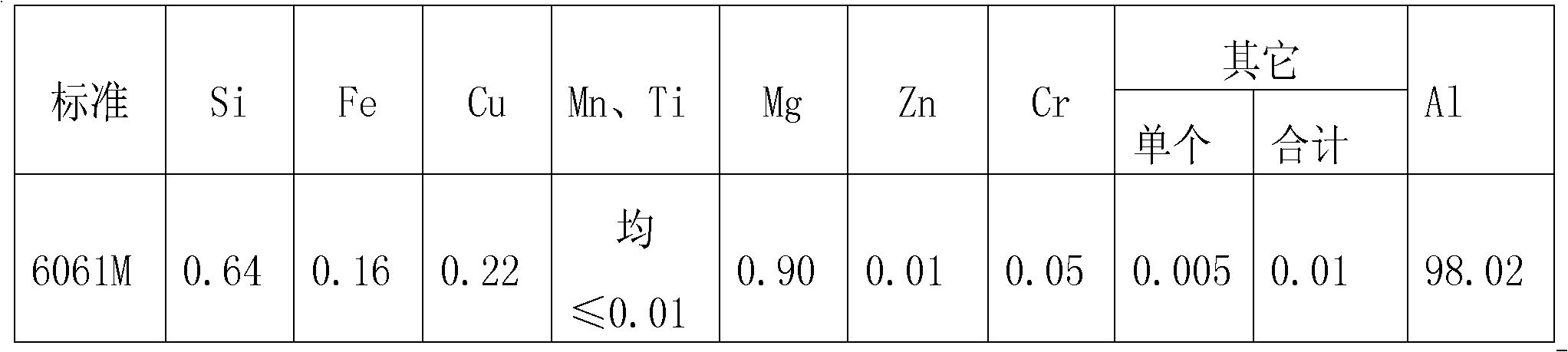

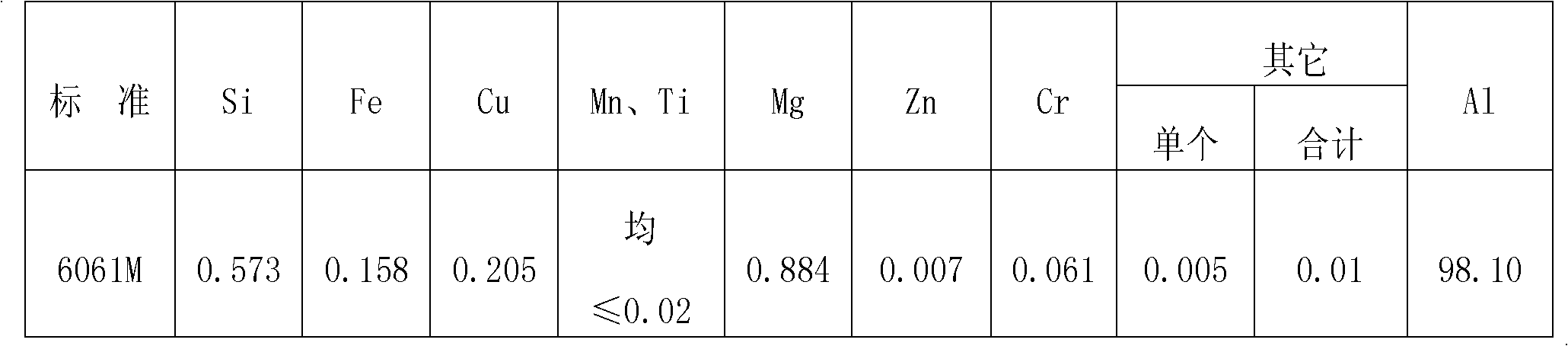

The invention discloses a process for avoiding coarse-grain rings of 6061 aluminum alloy bars and rods, and belongs to the technical field of aluminum alloy machining. The process includes the steps of alloy component optimization, cast bar heating, the extrusion process, online quenching, stretch flattening and artificial aging. Chemical components of optimized alloy components include 0.60-0.65% of Si, 0.20% of Fe, 0.19-0.24% of Cu, 0.05-0.10% of Mn, 0.90-0.95% of Mg, 0.25-0.30% of Cr, 0.15% of Zn, 0.10% of Ti, 0.15% of other substances, and the balance Al. Double-hole die extrusion is adopted for the extrusion process. By means of the process, extruded aluminum alloy products can be free of coarse-grain ring tissue defects, the mechanics, fatigue and other physical performance of materials are greatly improved, the bearing capacity and use safety of materials are improved, the service life of materials is prolonged, and use risks of materials are reduced.

Owner:CHINA ZHONGWANG

6061 deforming aluminum alloy and production process thereof

InactiveCN103205615AImprove plastic processing performanceEasy to processRare-earth elementMaterials science

The present invention discloses a 6061 deforming aluminum alloy and production process thereof. Adding Aluminum-rare earth master alloy while 6061 aluminum alloy is melting. 6061 deforming aluminum alloy comprises, based on the weight percentage, 0.5%- 0.52% of Si, 0.19%- 0.21% of Fe, 0.8% - 0.9% of Mg, 0.28% -0.3% of Cu, 0.15% - 0.18% of Cr, 0.24% - 0.26% of Zn, 0.14% - 0.16% of Ti, 0.1% - 0.05% rare earth elements, 0-0.1% of the remaining impurities and the balance of Al. The sum percentage of the components is 100 %. The production process includes smelting, proportioning, melting, casting, extrusion molding and aging treatment. The invention improves the plasticity and formability of alloy in aluminum alloy by adding Aluminum-rare earth master alloy, thus reducing the amount of alloy elements and production cost.

Owner:CHENGDU SUNSHINE ALUMINUM

Method for producing ultrahigh-precision hard disk driving arm sections

The invention provides a method for producing ultrahigh-precision hard disk driving arm sections, relating to a production method by using 6061 aluminum alloy round ingot casting. A main technology of hot extrusion in the method comprises the following steps of: casting the aluminum alloy round ingot casting, homogenizing and carrying out induction preheating, designing, manufacturing and preheating a divergent die, carrying out hot extruding and shaping, carrying out online quenching by spraying water mist, dragging synchronously, interrupting, cooling a cooling bed, stretching and straightening, cutting to length, carrying out manual ageing treatment, checking finished products, packaging and dispatching and the like. The sections finally obtained by the production method meet various requirement of the hard disk driving arm sections, such as hardness, strength, yield strength and the like.

Owner:钱政

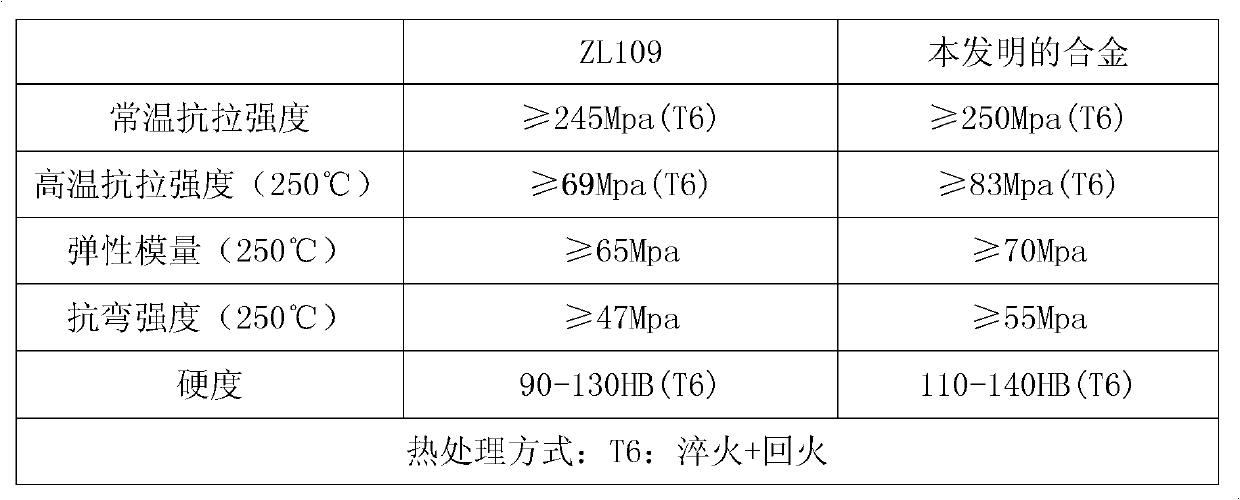

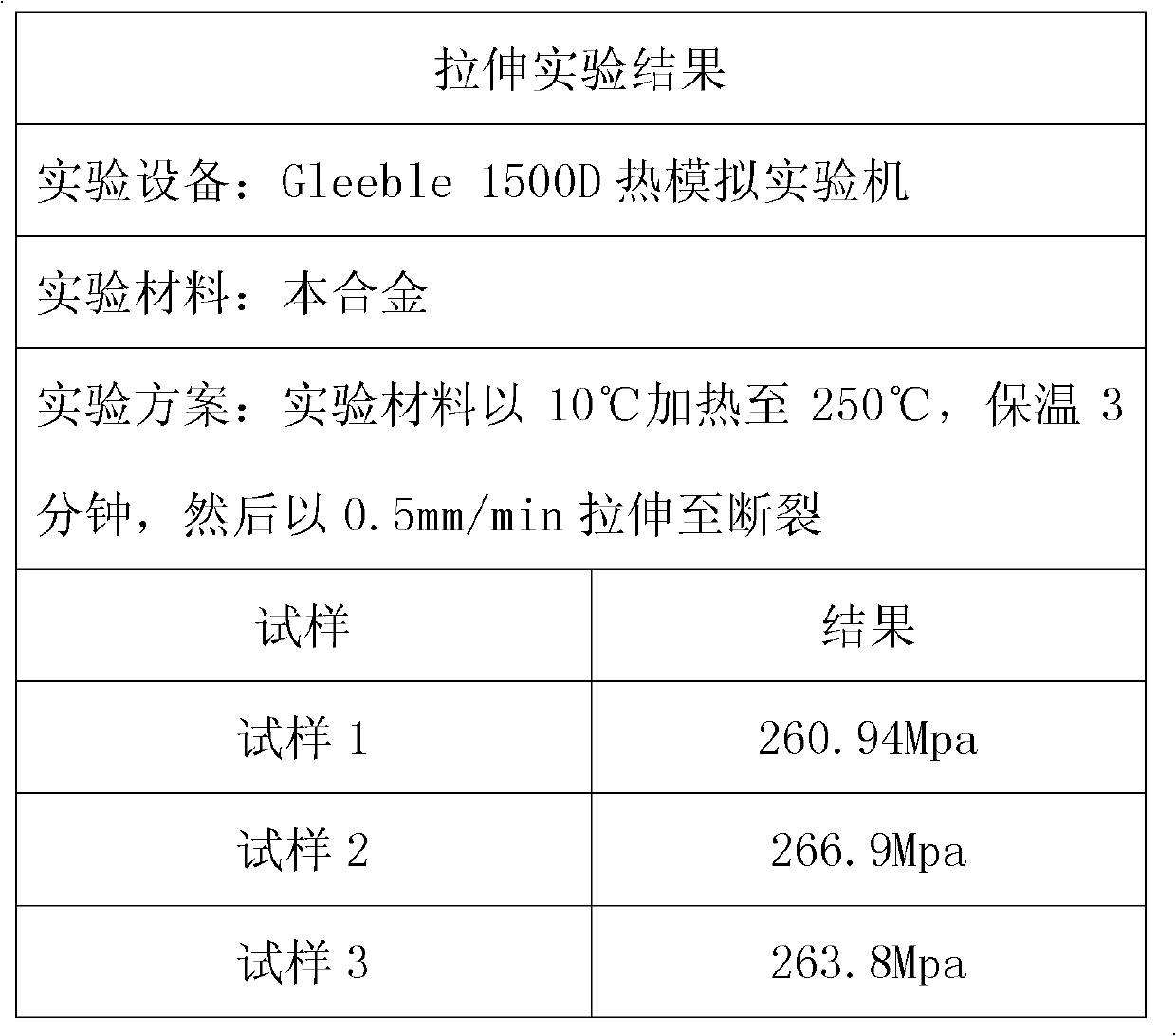

Novel casting aluminium alloy and preparation method thereof

The invention discloses a casting aluminium alloy and a preparation method thereof. The casting aluminium alloy comprises the following components in percentage by weight: 11-13wt% of Si, 2-4wt% of Cu, 0.5-1.2wt% of Mg, 2-3.5wt% of Ni, 0.08-0.18wt% of Ti, 0.1-0.2wt% of V and the balance of aluminium ingot, wherein the mark of the aluminium ingot is Al99.50. Compared with the existing casting aluminium alloy ZL109, the casting aluminium alloy has the advantages that comprehensive mechanical property is greatly improved, and high-temperature thermal fatigue strength is improved by 10%. Each index of the obtained aluminium alloy is far beyond the national criterion of acceptability after the aluminium alloy is tested by the aluminium alloy tensile property experiment of the environment experiment center of the China Academy of Engineering Physics. The casting aluminium alloy is used for manufacturing engine pistons, the working performance of the engine piston can be greatly improved, and the service life of the piston can be greatly prolonged.

Owner:四川渝邻汽车零部件有限公司

Aluminium alloy material, aluminium alloy shaped part, and preparation method of aluminium alloy shaped part

ActiveCN105695809AHigh thermal conductivityGood molding effectTelephone set constructions5005 aluminium alloyMechanical property

The invention provides an aluminium alloy material. The aluminium alloy material is composed of, by mass, 5.5 to 8.5% of silicon, 0.1 to 0.4% of magnesium, 0.01 to 0.2% of boron, chromium<0.05%, 0.05 to 0.5% of iron, strontium<0.1%, and aluminium and inevitable impurities, wherein the content of each impurity element is less than 0.05%. The aluminium alloy possesses high heat-conducting properties, and excellent forming properties, and mechanical properties; thermal conductivity is higher than 140W / m.k under common pressure casting conditions; thermal conductivity is even higher than 150W / m.k under gravity casting or extrusion casting conditions; the aluminium alloy can be applied to the field of mobile phone product and communication product, can be used for solving problems in the prior art that thermal conductivity properties of materials used in mobile phone products and communication products are poor, product heat dissipation performance is poor, and severe heating phenomenon is caused. The invention also provides an aluminium alloy shaped part prepared from the aluminium alloy, and a preparation method of the aluminium alloy shaped part.

Owner:HUAWEI TECH CO LTD +1

Al-Fe-Au-RE aluminium alloy, preparation method thereof and power cable

ActiveCN103103395AEvenly heatedEliminate damagePower cablesMetal/alloy conductorsPower cableMetallurgy

The invention provides an Al-Fe-Au-RE aluminium alloy and a preparation method thereof. The preparation method comprises the following steps of: a) casting an aluminium alloy cast ingot; b) homogenizing the aluminium alloy cast ingot and rolling the homogenized aluminium alloy cast ingot to obtain an aluminium alloy rod material; c) intermittently annealing the aluminium alloy rod material obtained in the step b); and d) aging the aluminium alloy rod material obtained in the step c), thus obtaining the aluminium alloy. The invention also provides a power cable. The aluminium alloy has better overall performances by selecting and controlling the added elements and adopting a reasonable preparation process.

Owner:ANHUI JOY SENSE CABLE

6061 aluminum alloy for 3C product appearance piece and processing method of 6061 aluminum alloy

ActiveCN106868357AGood anodizing effectSurface reaction electrolytic coatingSolution treatmentSand blasting

The invention relates to a 6061 aluminum alloy for a 3C product appearance piece and a processing method of the 6061 aluminum alloy. The micro elements in the aluminum alloy comprise, by mass percentage, smaller than or equal to 0.05wt% of Mn, 0.05-0.10wt% of Cr and smaller than or equal to 0.10wt% of Fe. The processing method includes that a cast ingot is heated to 360-420 DEG C at the speed of 20-50 DEG C / h, heat preservation is performed for 8-12 h, then the cast ingot is heated to 540-570 DEG C at the speed of 20-50 DEG C / h, and heat preservation is performed for 10-20 h; then hot rolling and cold rolling are performed; a cold rolled plate is subjected to solution treatment; and finally, aging treatment is performed, and heat preservation is performed for 1-24 h at 150-220 DEG C. By means of the technical scheme, a 6061 aluminum alloy plate material can be subjected to sand blasting treatment by using number 203-205 zircon sand in the anode oxidization manufacturing procedure, the anode oxidizing effect is extremely good, and the anode oxidization material stripe defect can be avoided.

Owner:苏州中色研达金属技术有限公司 +1

Medium-temperature high-strength aluminum alloy powder solder and preparation method thereof

ActiveCN102773630ASmall tissueUniform compositionWelding/cutting media/materialsSoldering mediaSolution treatmentChemical composition

The invention discloses medium-temperature high-strength aluminum alloy powder solder, comprising the following components by weight: 6.0-8.5% of Si, 10.0-12.0% of Cu, 3.0-4.0% of Ge, 3.0-4.0% of Ni, 0.5-0.8% of La and the balance of A1. The invention also discloses a method for preparing the medium-temperature high-strength aluminum alloy powder solder by adopting a melt rapid cooling technology. The melting temperature range of the solder disclosed by the invention is 515-539 DEG C, and the brazing temperature is 545-560 DEG C. The solder is suitable for the brazing the aluminum alloy of which a solidus is higher than 560 DEG C, especially suitable for the heat-treatable strengthening aluminium alloy which is subjected to a solution treatment after being brazed and is of the solution temperature no more than 545 DEG C. The solder is also suitable for furnace brazing, vacuum brazing, induction brazing, torch brazing, and the like. The solder disclosed by the invention is adopted to be matched with QJ201 brazing flux for brazing the 6061 aluminum alloy in a furnace; after being brazed, the 6061 aluminum alloy is subjected to a T6 heat treatment; and the shear strength of a brazing joint is more than 94MPa.

Owner:ZHEJIANG UNIV

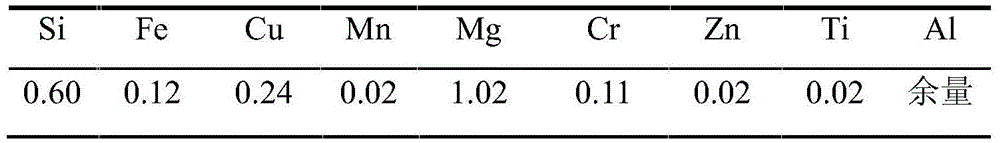

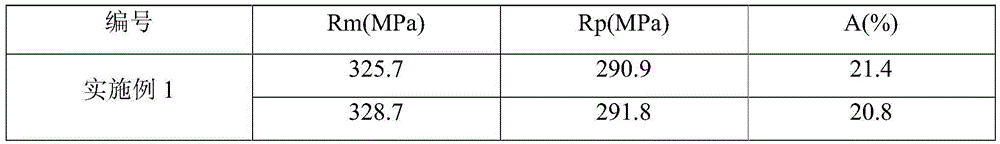

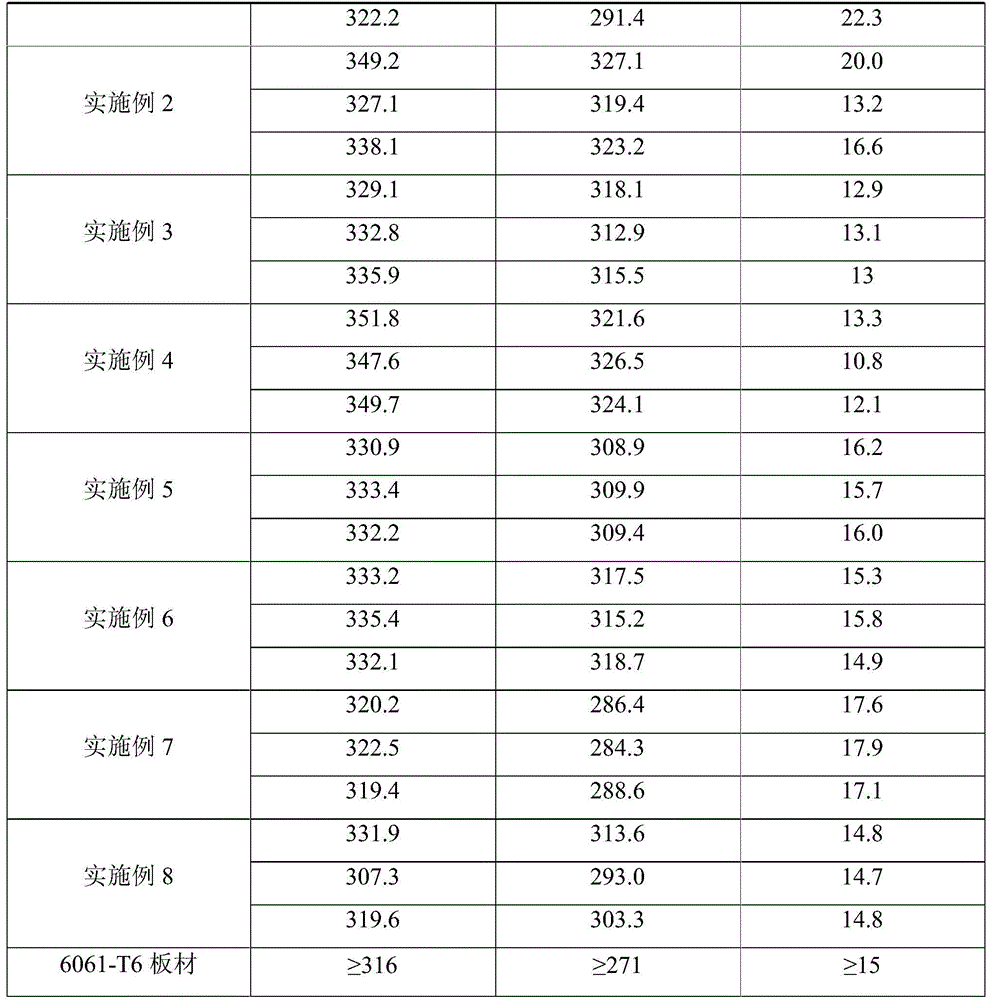

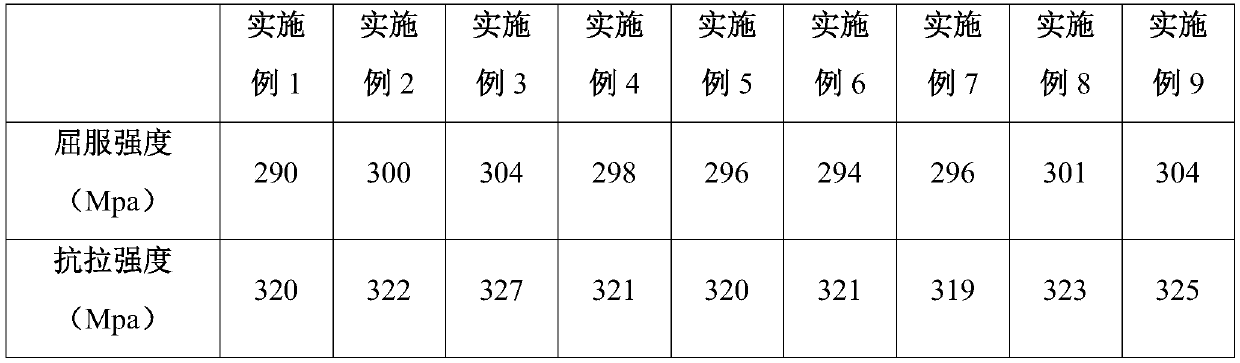

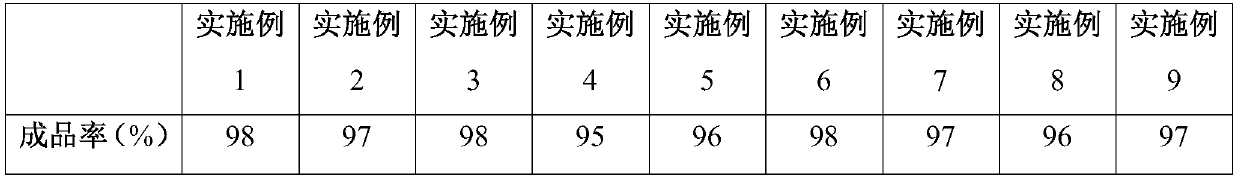

Rolling technology for 6061 aluminium alloy medium-thickness plate

InactiveCN111254329AGuaranteed remelting effectUniform generalized complete recrystallization behaviorGrain structureUltimate tensile strength

The invention belongs to the technical field of aluminium alloy manufacture and relates to a rolling technology for a 6061 aluminium alloy medium-thickness plate. An aluminium alloy raw material is prepared from, by weight, 0.4-0.8% of Si, smaller than or equal to 0.7% of Fe, 0.15-0.4% of Cu, smaller than or equal to 0.15% of Mn, 0.8-1.2% of Mg, 0.04-0.35% of Cr, smaller than or equal to 0.25% ofZn, smaller than or equal to 0.15% of Ti, smaller than or equal to 0.05% of single impurity, smaller than or equal to 0.15% of alloy, and the balance Al. After hot rolling is performed, a cold rollingprocess is added, a solid solution process is adjusted, so that the aluminium alloy plate obtains fine grain organization of a uniform grain structure, the uniformity of all the performance of alloyis improved, and the strength and plasticity are cooperatively improved.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

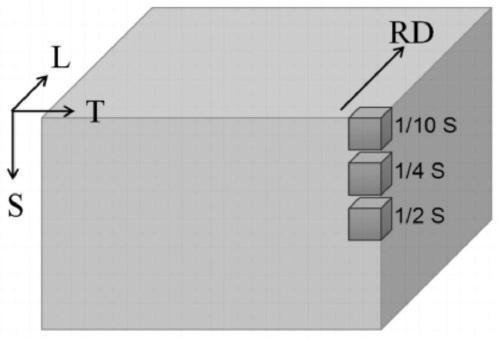

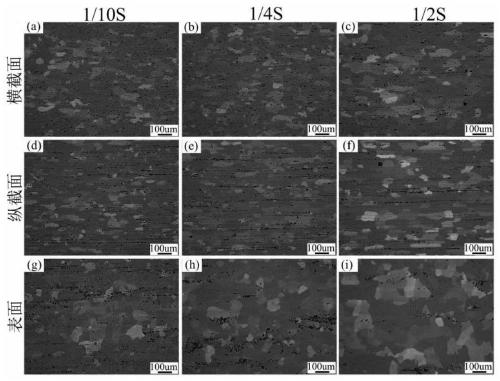

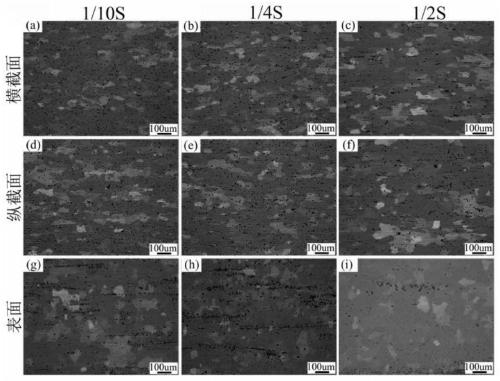

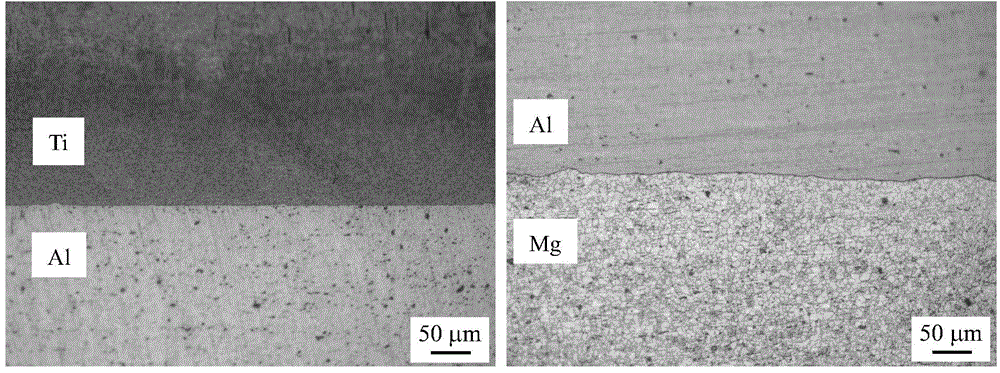

Three-layer titanium/aluminum/magnesium composite board and manufacturing method thereof

The invention discloses a three-layer titanium / aluminum / magnesium composite board. The three-layer composite board is formed by rolling a titanium alloy hot rolled steel plate, an aluminum alloy hot rolled steel plate and a magnesium alloy hot rolled steel plate together in a stacked mode. The manufacturing method of the composite board mainly comprises the steps that the TC4 titanium alloy plate, the 6061 aluminum alloy plate and the AZ31B magnesium alloy plate are selected and used, and the TC4 titanium alloy plate, the 6061 aluminum alloy plate and the AZ31B magnesium alloy plate are polished mechanically; the titanium alloy plate, the aluminum alloy plate and the magnesium alloy plate are placed in a stacked mode in sequence, and the titanium alloy plate, the aluminum alloy plate and the magnesium alloy plate are placed in a resistance furnace to be preheated for 6 min-10 min at the temperature ranging from 300 DEGC to 450 DEG C after one end of the titanium alloy plate, one end of the aluminum alloy plate and one end of the magnesium alloy plate are riveted; then the titanium alloy plate, the aluminum alloy plate and the magnesium alloy plate are conveyed onto a rolling mill immediately to be rolled, wherein the rolling speed ranges from 0.3m / s to 1.2m / s, and the hot milling deformation ranges from 25% to 50%. According to the three-layer titanium / aluminum / magnesium composite board and the manufacturing method of the three-layer titanium / aluminum / magnesium composite board, the technology is simple, cost is low, the production efficiency is high, and large-scale industrial production can be achieved easily; the interfaces of the manufactured three-layer titanium / aluminum / magnesium composite board are bonded tightly, and obvious micro-cavities and brittle intermetallic compounds are avoided; compared with an aluminum alloy plate with the same weight, the high-speed impact damage resistance of the composite board is improved by 50%.

Owner:YANSHAN UNIV

Six-series high-surface mobile phone aluminum alloy shell and production method of aluminum alloy thin plate

The invention provides a six-series high-surface mobile phone aluminum alloy shell. The six-series high-surface mobile phone aluminum alloy shell is obtained by carrying out stamping, machining and oxidization on an aluminum alloy plate, and the aluminum alloy is an aluminum alloy 6061. Starting from the raw material of the aluminum alloy plate of the mobile phone aluminum alloy shell, by combining the strength requirement of the mobile phone aluminum alloy shell and the appearance requirement of the high surface, special selection is carried out on the type of the aluminum alloy, the components of the aluminum alloy are creatively selected and combined and supplemented by specific proportion contents, the specific aluminum alloy 6061 is selected as the aluminum alloy plate, and thereforethe material line defect and the black line defect are eliminated from the basic aluminum alloy plate, the rejection rate caused by the material line defect and the black line defect is greatly reduced, the working procedures are simple and suitable for application and popularization of industrial mass production, and important actual significance and market prospects are achieved.

Owner:SOUTHWEST ALUMINUM GRP

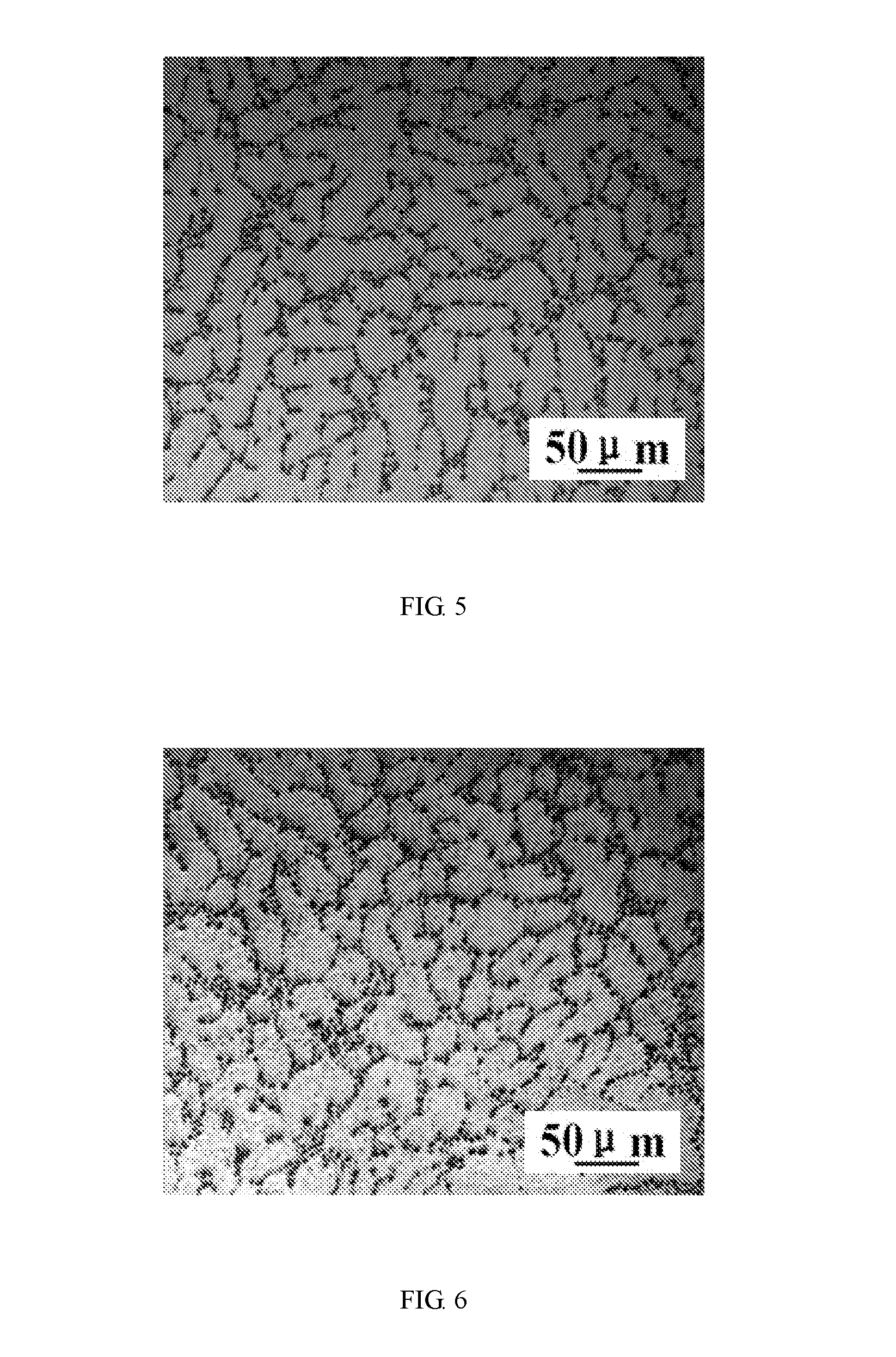

6061 aluminum alloy doped with rare earth element yttrium and preparation method of 6061 aluminum alloy

The invention belongs to the technical field of aluminum alloy, and relates to 6061 aluminum alloy doped with rare earth element yttrium and a preparation method of the 6061 aluminum alloy. The preparation method particularly comprises the following steps of 1 aluminum-yttrium alloy ingot preparation, 2 homogenization treatment, 3 extrusion forming and 4 heat treatment. By adding rare earth element yttrium (0.1%-0.4%) into the 6061 aluminum alloy, the microstructure of the alloy is improved. Meanwhile, by means of the reasonable extrusion and heat treatment technologies, the mechanical property of the alloy is improved, the tensile strength of the aluminum-yttrium alloy reaches 355 MPa or above, and the application requirement of the alloy in the textile industry field is met.

Owner:常熟市恒泰精密金属制品有限公司 +1

Crystal and non-crystal ultrasonic welding method

InactiveCN102407402AAchieve weldingExpand application spaceNon-electric welding apparatusUltrasonic weldingUltimate tensile strength

The invention relates to a crystal and non-crystal ultrasonic welding method. The method comprises the following steps of: (1) cutting out a 6061 aluminum alloy foil; (2) cutting out a non-crystal alloy Zr44Cu40Ag8Al8 sheet; (3) carrying out welding pre-machining on non-crystal and aluminum alloy surfaces;(4) regulating parameters and welding planes of an ultrasonic metal welding device; and (5) ultrasonically welding the 6061 aluminum alloy foil and the non-crystal alloy Zr44Cu40Ag8Al8 sheet. The invention has the advantages that: (1) the welding of crystals and non-crystals is realized, thus an application space of non-crystals is largely expanded; and (2) the ultrasonic welding of the crystals and the non-crystals is a solid joining technology, is not restrained by metallurgy weldability and does not have the characteristics of air and liquid phase pollution and the like, and a welding joint has high strength and good stability.

Owner:NANCHANG UNIV

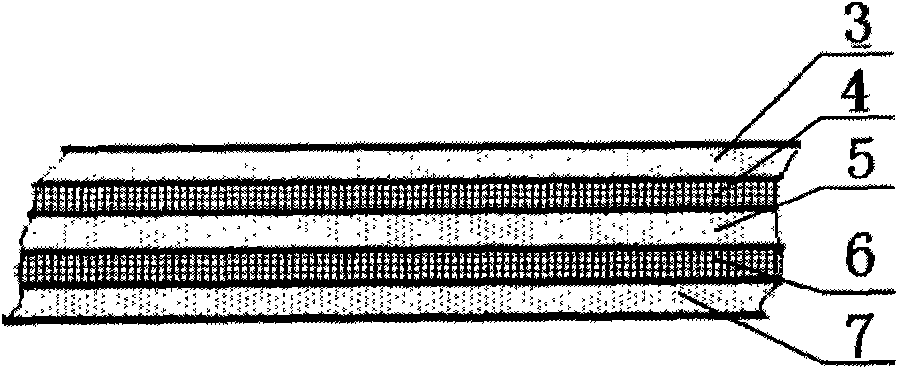

Composite automobile bumper

InactiveCN101767556AImprove impact resistanceExtended service lifeSynthetic resin layered productsEpoxy resin adhesivesEpoxyAlloy

The invention relates to a composite automobile bumper which consists of a gel coat layer, a structure layer, an adhesive layer, a primer layer, a foam aluminum layer and a collision bumper, wherein the gel coat layer adopts neopentyl glycol phenylene resin; the structure layer comprises a plurality of resin layers and a fiber layer; the adhesive layer and the primer layer both adopt epoxy resin as main material; the foam aluminum layer adopts 6061 aluminum alloy foam aluminum; and the collision bumper is a gas-liquid bumper. The composite automobile bumper has the advantages of good impact resistance, long service life, easy repair, high strength, high corrosion resistance, good processing performance (capable of being sawn, planed and drilled) and good mechanical performance, as well as light weight and low cost, thereby being widely popular with users. Therefore, the composite automobile bumper integrates the characteristics of safety, high efficiency, light weight, corrosion resistance and beautiful appearance.

Owner:SHENYANG LIGONG UNIV

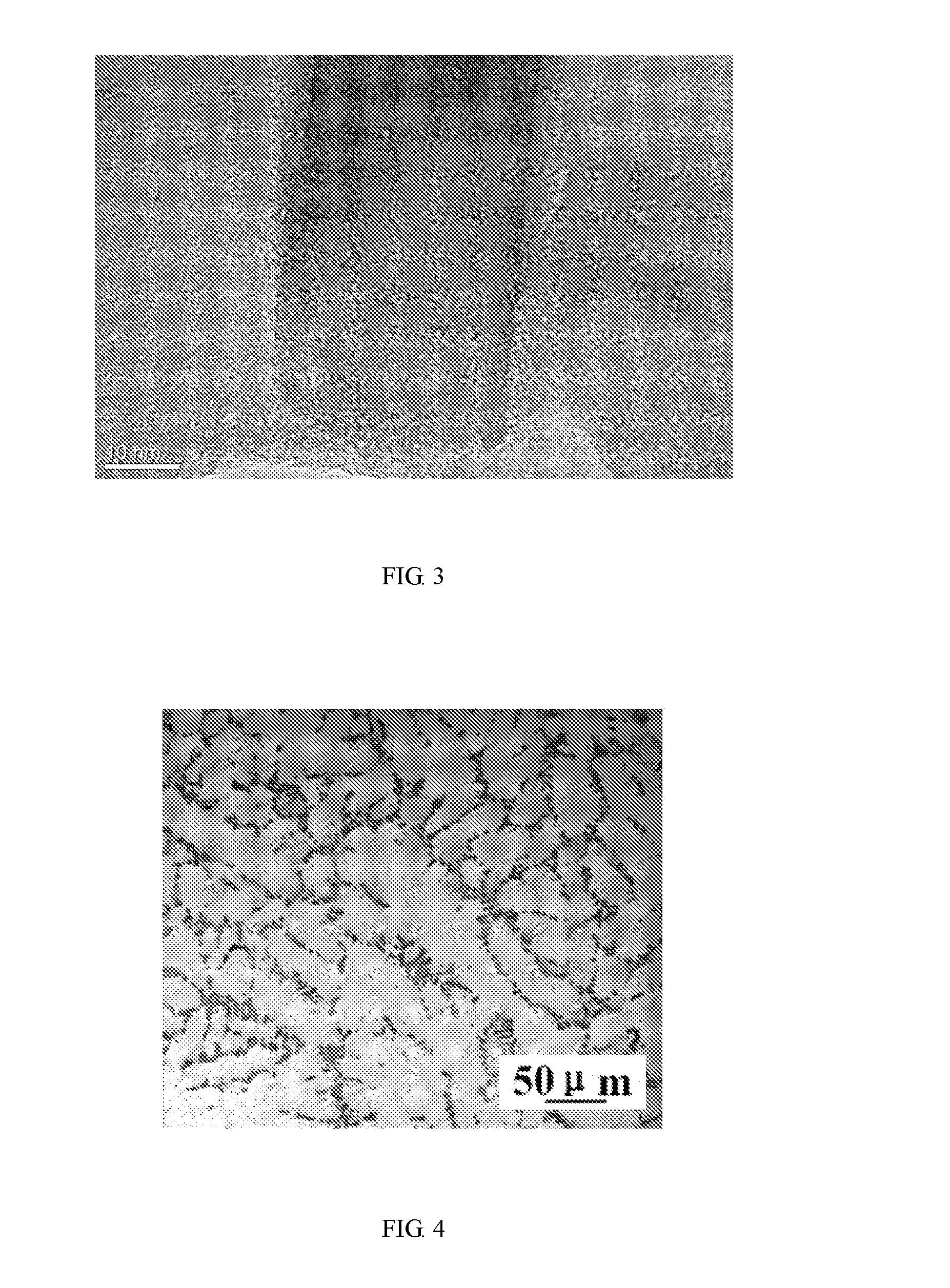

Aluminium alloy refiner and preparation method and application thereof

The present invention provides an aluminium alloy refiner. The aluminium alloy refiner is characterized by comprising 7 to 10 parts of Ti, 2 to 3 parts of B and the balance of Al by weight, for example, 8 parts of Ti, 3 parts of B and 89 parts of Al by weight. The aluminium alloy refiner is prepared by rapid solidification. After the refiner is added to A356.2 aluminium alloy, the grain size of the alloy is significantly reduced than that of the aluminium alloy treated by a conventional refiner. Moreover, the solubility of metals in liquid may be increased due to rapid solidification, such that the refiner is more easily absorbed by the aluminium alloy melt after being added to the aluminium alloy.

Owner:CITIC DICASTAL +1

Aluminium alloy plate for cartridge case, and production method thereof

ActiveCN109022944AImprove performanceEasy to controlAmmunition projectilesCasting cleaning apparatus2014 aluminium alloyChemical element

The invention discloses an aluminium alloy plate for a cartridge case, and a production method thereof. The aluminium alloy plate comprises the chemical elements: Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti and the balance Al; and the aluminium alloy plate containing the above elements is prepared through the procedures of smelting, casting, soaking treatment, face milling, hot rolling, annealing and the like.According to the aluminium alloy plate and the production method, the characteristics of low strength and high plasticity of aluminium alloy before solid solution heat treatment are utilized effectively; through high precision equipment and the rational processing technology of the aluminium alloy plate, the composition segregation of an aluminium alloy ingot is eliminated effectively, and the internal stress of the ingot is reduced; the chemical components are uniform; the produced aluminium alloy plate for an aluminium cartridge case is high in plasticity, strength and hardness, and the adverse effects of hydrogen and residues in metal materials are reduced and eliminated; and the high performance requirements for the cartridge case are met completely.

Owner:HENAN MINGTAI AL INDUSTRIAL CO LTD

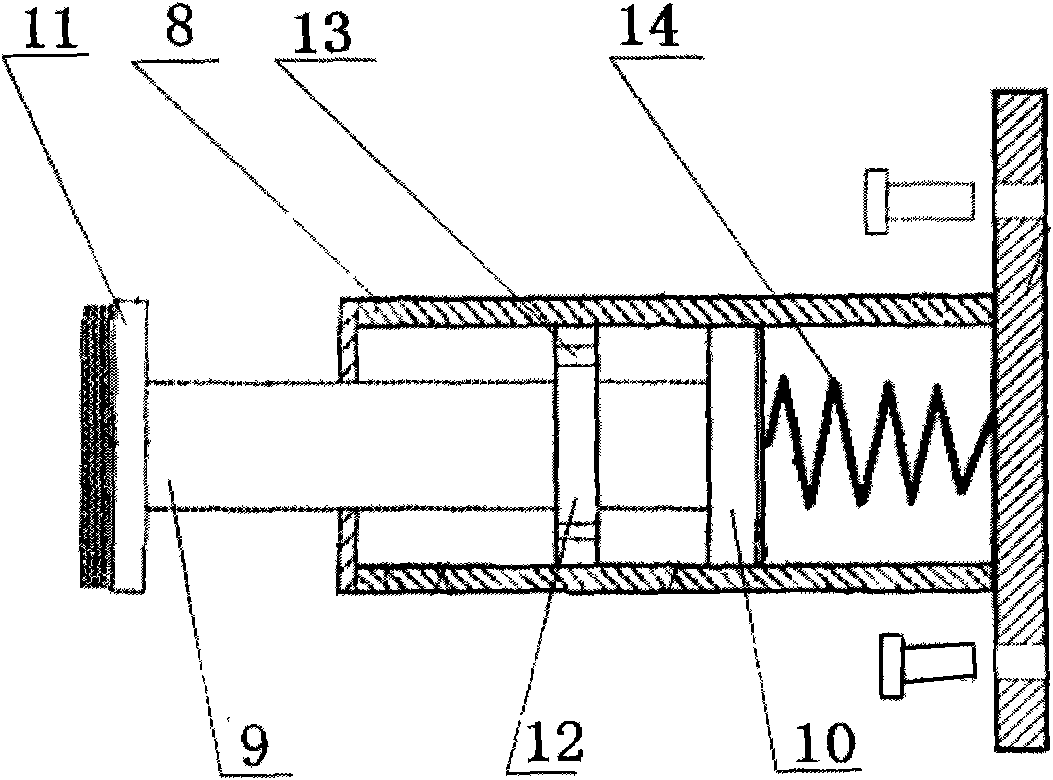

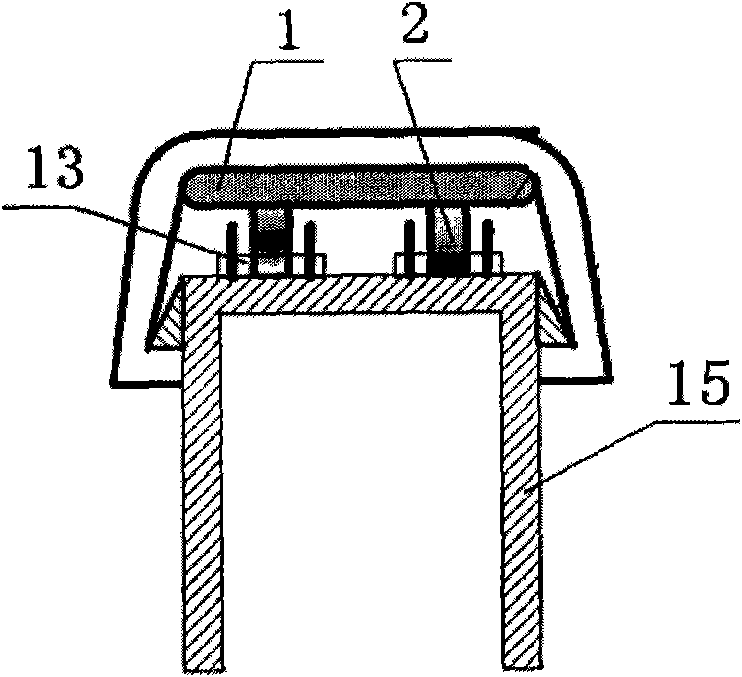

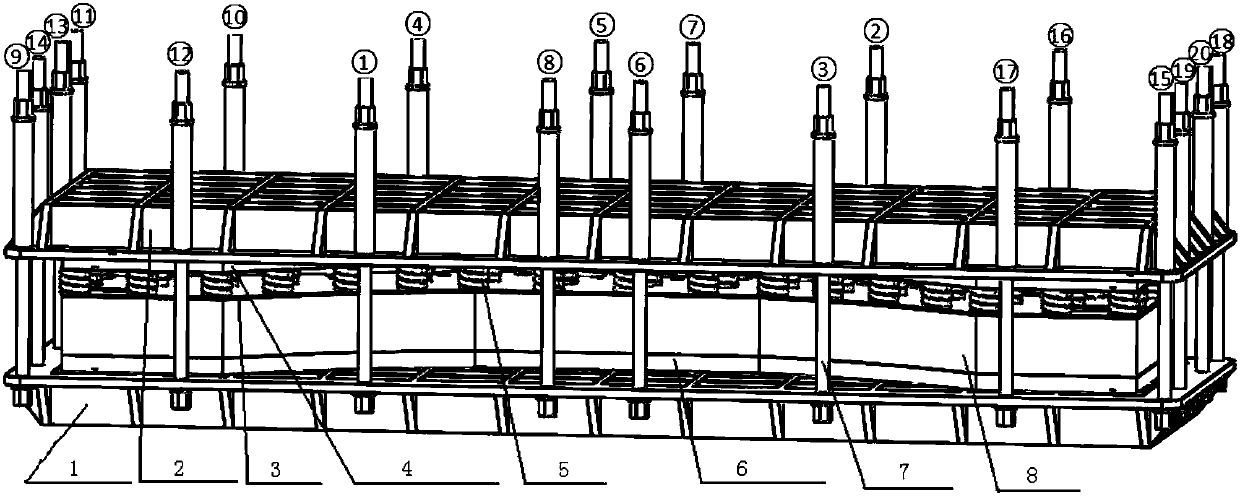

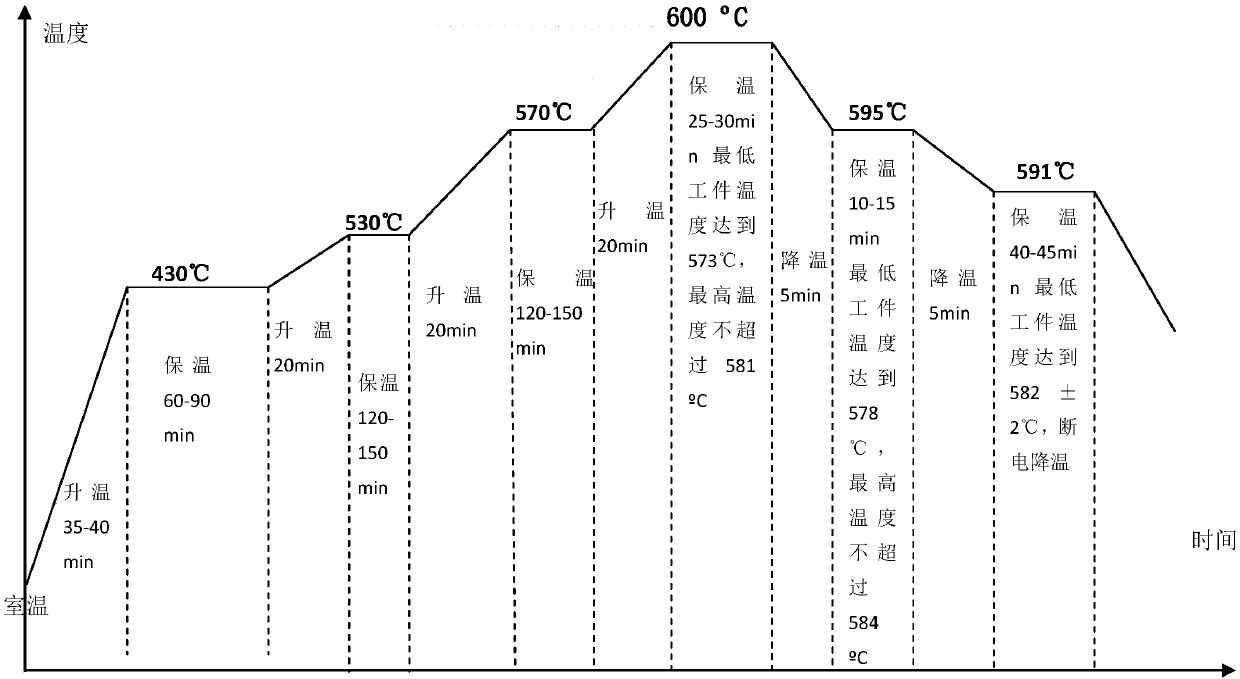

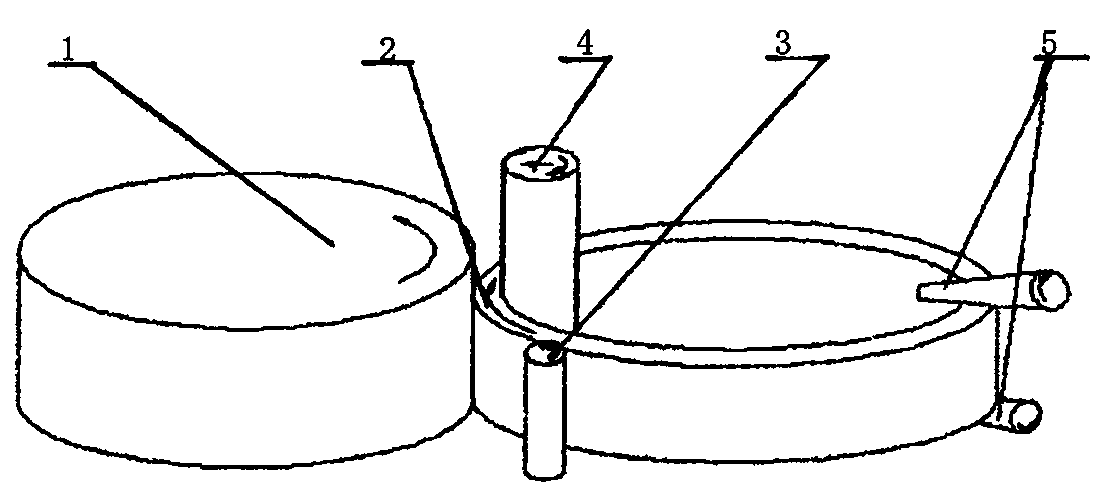

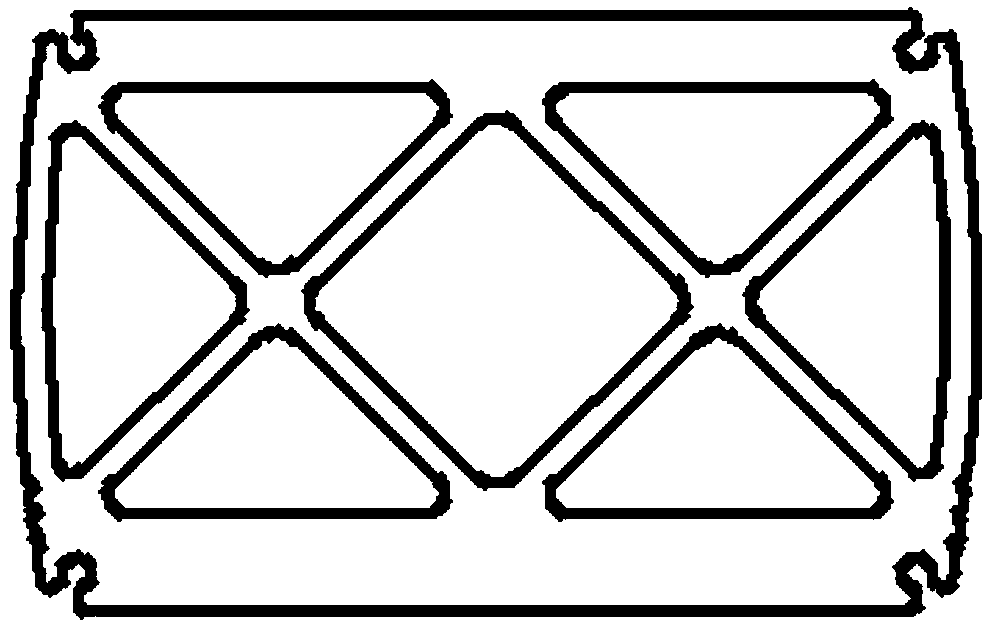

Process method for reducing vacuum brazing defects of 6061 aluminum alloy and clamp

ActiveCN107598318ALarge boardPrevent thinningWelding/cutting auxillary devicesAuxillary welding devices6061 aluminium alloySteel plates

The invention discloses a process method for reducing vacuum brazing defects of a 6061 aluminum alloy and a clamp. The clamp comprises an upper cover plate (2) and a lower cover plate (1) connected through a vertical rod (7); an upper stainless steel plate (4), a spring (5) and a gasket (3) are successively arranged below the upper cover plate (2); and a lower stainless steel plate (6) is arrangedabove the lower cover plate (1). According to the process method and clamp disclosed by the invention, curves of temperature-raising, insulating and cooling processes are adjusted during brazing. Thecold plates can be domesticated by adopting the processing method and the clamp, the vacuum brazing defects of the 6061 aluminum alloy are reduced greatly, the product quality is improved, and meanwhile the international image of an enterprise is enhanced.

Owner:贵州永红换热冷却技术有限公司

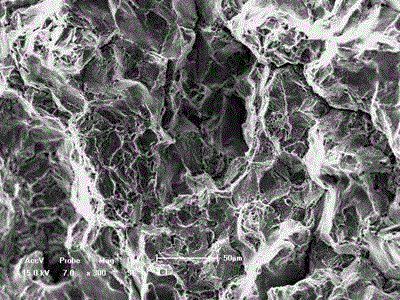

Method of preparing aluminum alloy wheel hub with high structural strength

InactiveCN104674032AImprove structural strengthHigh hardnessElectromagnetic castingMetallic materials

The invention relates to a method of preparing an aluminum alloy wheel hub with high structural strength and belongs to the technical field of metal material processing. The method comprises the steps of smelting a 6061 aluminum alloy, preparing a semisolid 6061 aluminum alloy blank with equiaxed grains by using an electromagnetic casting technique, then carrying out thixotropic die forging on the semisolid 6061 aluminum alloy blank, and carrying out T6 heat treatment on a formed part at last. The whole technical process is simple to implement; small damage is caused to a die; the aluminum alloy wheel hub with the high structural strength can be prepared; and the hardness, tensile strength and elongation of the prepared 15-21in aluminum alloy wheel hub are higher than those of an aluminum alloy wheel hub prepared by the conventional casting method by 50-60Hv, 160-170MPa and 2-3% respectively.

Owner:NORTHEASTERN UNIV

Technological method for carrying out solid solution and aging thermal treatment on 6061 aluminum alloy

ActiveCN105568187AGood mechanical propertiesReduce heat treatment energy consumption6061 aluminium alloyMetal

The invention discloses a technological method for carrying out solid solution and ageing treatment on a 6061 aluminum alloy, and belongs to the technical field of metal material thermal treatment. The technological method specifically comprises the following steps: (1) homogenizing treatment: carrying out homogenizing treatment and carrying out air-cooling to the room temperature while providing current to a 6061 aluminum alloy cast ingot; (2) thermal extrusion; (3) solid solution treatment: carrying out solid solution treatment and carrying out water-cooling at the room temperature while providing current to square billet; and (4) ageing treatment: carrying out the ageing treatment while providing current to the square billet. According to the technological method, the current intensity, the heating temperature and the heat preservation time of the homogenizing treatment, the solid solution treatment and the ageing treatment are reasonably controlled, so that a workpiece with excellent mechanical properties is finally obtained on the premise of remarkably reducing energy consumption of the thermal treatment, and therefore, the technological method is an aluminum alloy continuous solid solution and ageing treatment technological method which is suitable for quickly heating and reducing energy consumption, and is applied to industrial production.

Owner:NORTHEASTERN UNIV

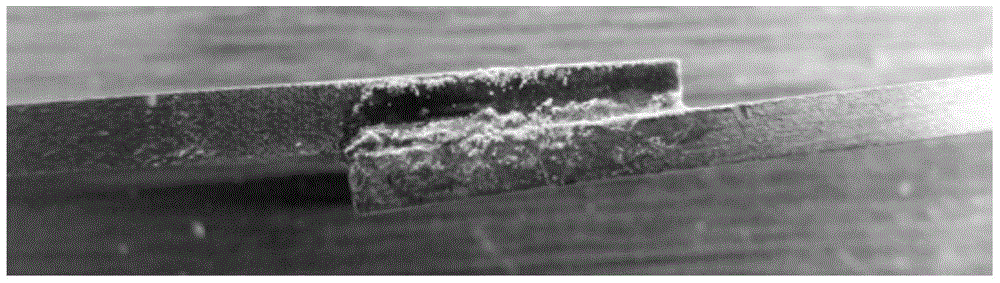

Brazing technique for 6061 aluminum alloy and AZ31B magnesium alloy

ActiveCN104439590AGood mechanical propertiesReduce weightSoldering apparatusWelding/soldering/cutting articlesFiller metal6061 aluminium alloy

The invention relates to a brazing technique for 6061 aluminum alloy and AZ31B magnesium alloy and belongs to the brazing techniques of aluminum and magnesium alloy. The brazing technique comprises the steps that aluminum alloy passing raw material inspection, magnesium alloy passing raw material inspection and Zn-12Cd flake brazing filler metal passing raw material inspection are prepared, an oxidation layer on the surface of the 6061 aluminum alloy, an oxidation layer on the surface of the AZ31B magnesium alloy and an oxidation layer on the surface of the brazing filler metal are removed through abrasive paper, then the two faces of the brazing filler metal, the face, sanded by the abrasive paper, of the aluminum alloy and the surface, sanded by the abrasive payer, of the magnesium alloy are cleaned with alcohol, the brazing filler metal is arranged between the aluminum alloy and the magnesium alloy, the brazing filler metal, the aluminum alloy and the magnesium alloy are fixed through a clamp and put in a KTF series pipe type vacuum atmosphere resistance furnace, the heating speed is set as 6 DEG C-10 DEG C / min, heating is conducted until the temperature reaches 310 DEG C-335 DEG C, then the heating speed is set as 2 DEG C-8 DEG C / min, heating is conducted until the temperature reaches 365 DEG C-390 DEG C, heat preservation is conducted for 40 min-70 min, the temperature is reduced to 260 degrees, heat preservation is conducted for 30 min, and the razing filler metal, the aluminum alloy and the magnesium alloy are cooled to the room temperature along with the furnace, and a brazed part is obtained. The brazing technique for the 6061 aluminum alloy and the AZ31B magnesium alloy is low in operation cost and easy to achieve, the obtained brazed connector is excellent in performance, and the application field of the magnetism alloy and the aluminum alloy is enlarged.

Owner:CHINA UNIV OF MINING & TECH

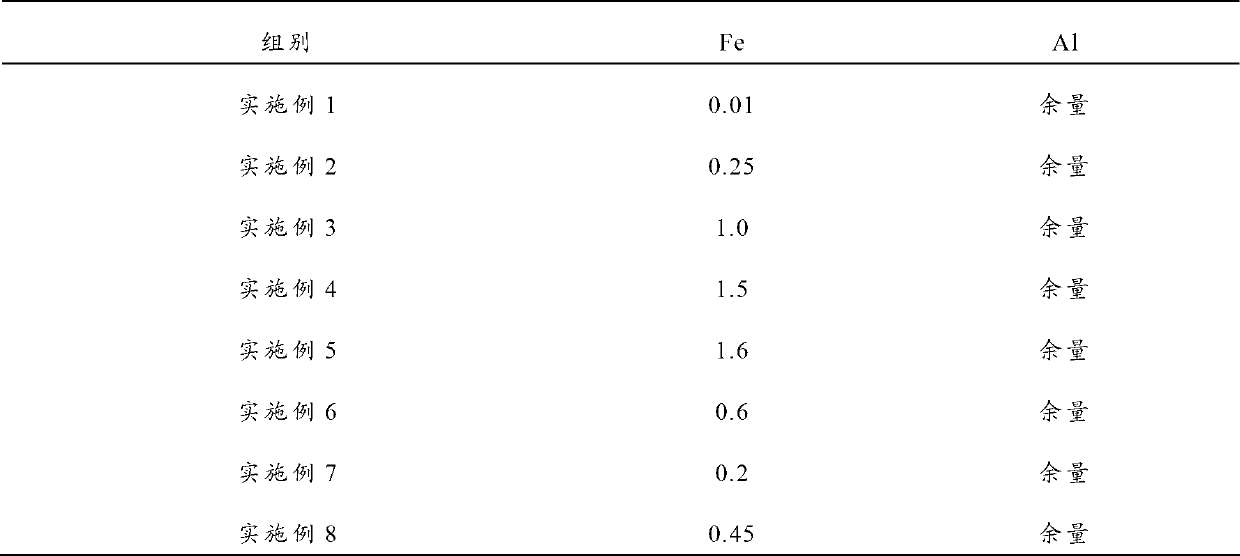

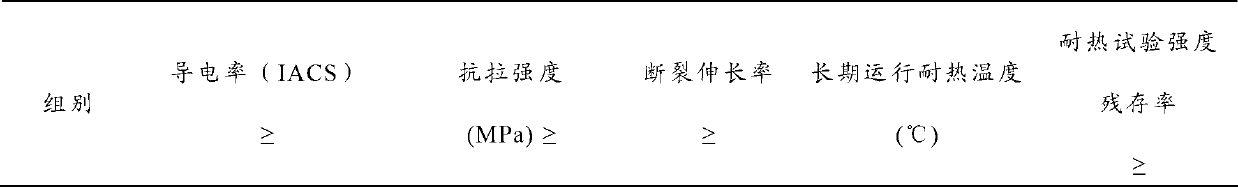

Al-Fe aluminium alloy, preparation method thereof and power cable

InactiveCN103103390AEvenly heatedEliminate damagePower cablesMetal/alloy conductorsPower cable5005 aluminium alloy

The invention provides an Al-Fe aluminium alloy. The aluminium alloy comprises 0.01-1.6wt% of Fe and the balance of aluminium. The invention also provides a preparation method of the Al-Fe aluminium alloy. The preparation method comprises the following steps of: a) casting an aluminium alloy cast ingot comprising 0.01-1.6wt% of Fe and the balance of aluminium; b) homogenizing the aluminium alloy cast ingot and rolling the homogenized aluminium alloy cast ingot to obtain an aluminium alloy rod material; c) intermittently annealing the aluminium alloy rod material obtained in the step b); and d) aging the aluminium alloy rod material obtained in the step c), thus obtaining the aluminium alloy. The invention also provides a power cable. The aluminium alloy has better overall performances by selecting and controlling the added elements and adopting a reasonable preparation process.

Owner:ANHUI JOY SENSE CABLE

Preparation method of boron carbide reinforced 6061 aluminum alloy hub

The invention discloses a preparation method of a boron carbide reinforced 6061 aluminum alloy hub. The aluminum alloy hub is prepared from the following alloy elements in percentage by mass: 0.2-0.4% of Cu, 0-0.7% of Fe, 0.5-1% of Mg, 0.4-0.8% of Si, 0.06-0.24% of Cr, 0-0.15% of Mn, 0.06-0.12% of Cr, 0-0.15% of Zn, 0.1-0.15% of Ti, 0.02-0.24% of Be, 0.015-0.3% of Ge, 0.01-0.02% of Sc and the balance of Al. The aluminum alloy hub is excellent in mechanical properties, has relatively high tensile strength, yield strength and elongation at break, and also has excellent wear resistance, high-temperature stability, chemical stability and fatigue resistance; the service life of the hub can be greatly prolonged.

Owner:安徽省斯特嘉汽车零部件有限公司

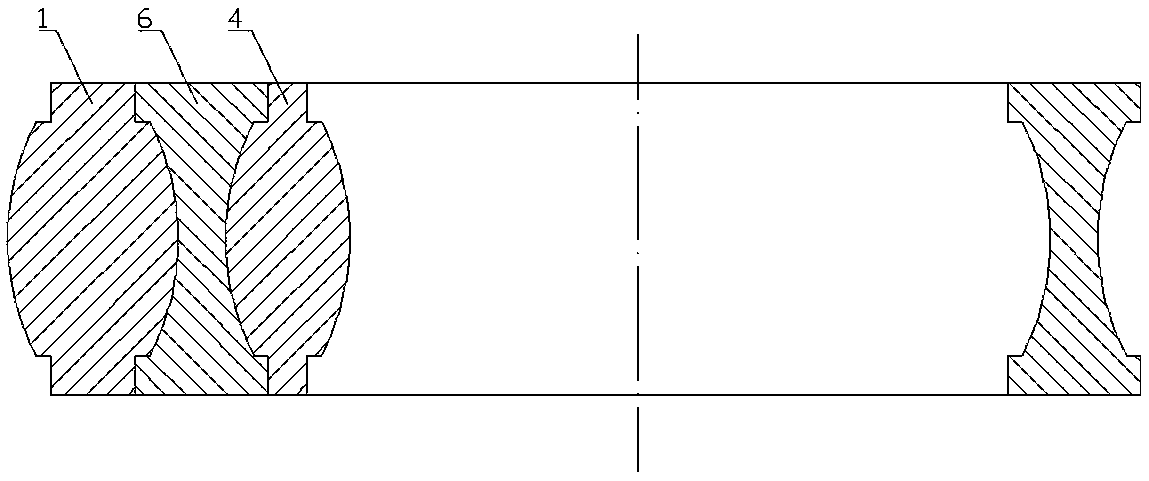

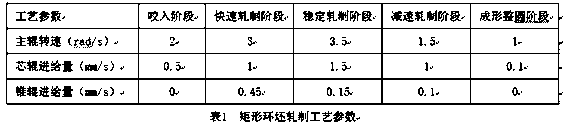

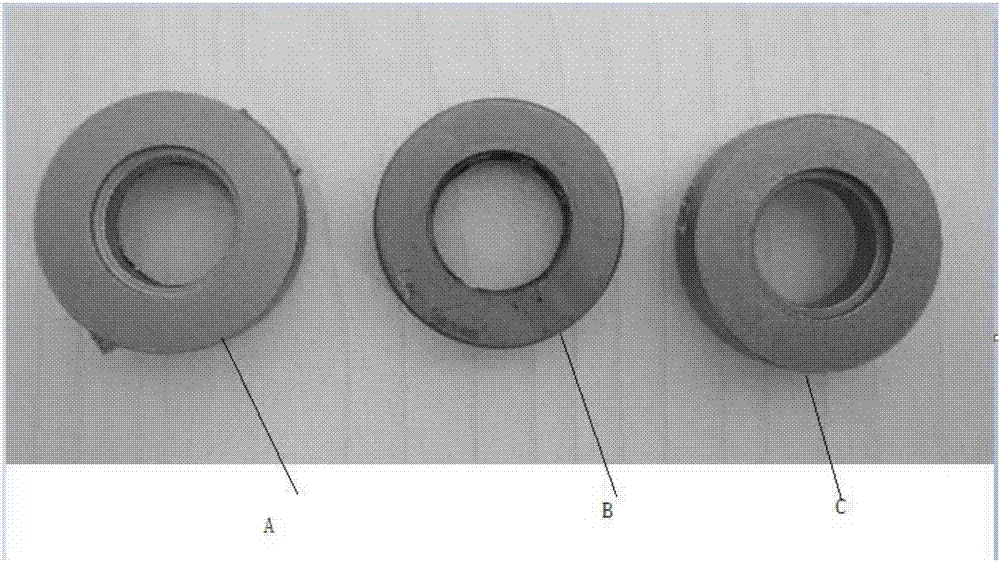

Rolling method of 6061 aluminum alloy ring part with ultra-large diameter and special-shaped section

The invention relates to the field of rolling methods for ring parts, in particular to a rolling method of a 6061 aluminum alloy ring part with an ultra-large diameter and a special-shaped section. The rolling method comprises the following steps of blanking, heating and heat preservation of a cast ingot, free forging, manufacturing of a rectangular ring blank, manufacturing of the ring part withthe special-shaped section, cooling of the ring part, solid solution, aging treatment, and dimension detection. The rolling method has the advantages that the streamline of a forged part can be kept complete, the internal tissue is uniform, welding is not needed, the machining cycle is short, the material utilization rate is high, and the subsequent machining allowance is small.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

High-strength anodizing die-casting aluminium alloy and preparation method thereof

ActiveCN107447134ATo promote floatingImprove filtration efficiency5005 aluminium alloy6061 aluminium alloy

The invention belongs to the technical field of aluminium alloy and particularly relates to high-strength anodizing die-casting aluminium alloy and a preparation method thereof. Mg, Mn, Fe, Zn, Mo, Zr, Cr and Al constitute die-casting alloy elements, and the high-strength anodizing die-casting aluminium alloy is prepared by a smelting procedure and a die-casting procedure. The types, the contents and the adding modes of all the alloy elements are strictly controlled, so that lots of the elements mainly exist in a matrix in a solid solution format under the die-casting (fast cooling) condition; Zr and Mo ensure more uniform alloy tissue and refined crystal grains, so that the alloy has high strength and favorable die-casing performance and excellent anodizing performance; on a die-casting machine, die-casting molding can be performed by a die to directly obtain the required product without heat treatment or deformation, so that the production cost is greatly lowered; and the high-strength anodizing die-casting aluminium alloy is suitable for thin-walled shell members demanding much on the strength, the die-casting performance and the anodizing demand of the aluminium alloy.

Owner:苏州慧驰轻合金精密成型科技有限公司

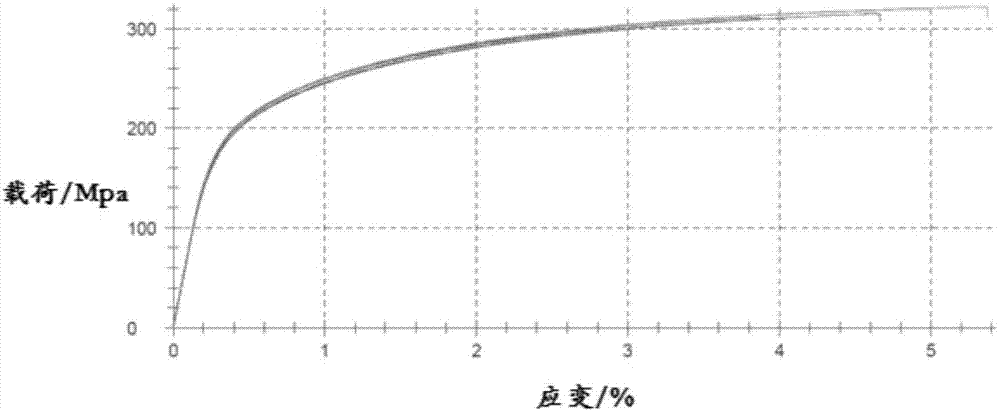

Production process of high-performance 6061 aluminum alloy for cell phone card slot and key materials

InactiveCN109536792AImprove metallographic structureImprove the ratio of ingredientsSolution treatmentMetal machining

The invention belongs to the technical field of aluminum alloy metal machining and discloses a production process of a high-performance 6061 aluminum alloy for cell phone card slot and key materials.According to the production process, a high-performance 6061 aluminum alloy plate is obtained through the steps of smelting and casting, homogenization treatment, machining face-milling, hot rolling,cold rolling to the finished product thickness, solution treatment and quenching at a continuous quenching line, manual aging treatment and the like, the tensile strength Rm of the high-performance 6061 aluminum alloy plate reaches 300 MPa or above, the hardness HV of the high-performance 6061 aluminum alloy plate reaches 90 or above, and on the one hand, the high-performance 6061 aluminum alloy plate has good machining performance and can be suitable for early CNC machining of the cell phone card slot and key materials; and on the other hand, the high-performance 6061 aluminum alloy plate hasgood anodic oxidation performance, can be oxidized into various bright colors and thus is quite attractive, a layer of uniform and luster-consistent protecting film is formed on the surfaces of the materials after oxidation, the hardness and abrasion resistance of a cell phone card slot and keys are greatly improved, and the service life of a product is prolonged.

Owner:郑州明泰实业有限公司

Aluminium alloy semi-solid preform body and preparation method thereof

InactiveCN102644011ADoes not cause rheologyRatio accuracy requirements are low2024 aluminium alloy5005 aluminium alloy

The invention discloses an aluminium alloy semi-solid preform body and a preparation method thereof, and is characterized in that: the preform body is deformed aluminium alloy and comprises components as following: Mg, Zn, Cu, Al and component A, the component A is selected from at least two ingredients of Cr, Si, Fe or Mn. By the adoption of the deformed aluminium alloy according to the aluminium alloy semi-solid preform body, the corrosion resistance is good, and the requirement on proportioning precision between components is lower, i.e. an obvious fluctuation on rheological, thixotropy and mechanical behavior of aluminium is not caused by a tiny fluctuation of the component. The alloy semi-solid preform body is prepared by the method of ultrasonic vibration according to the invention, the tensile strength is as high as 480MPa, the crystalline particles are small, with average diameters smaller than 40mum, the forming property is good, the requirement on process condition is lower, and the method is convenient to control and operate.

Owner:CSIC NO 12 RES INST

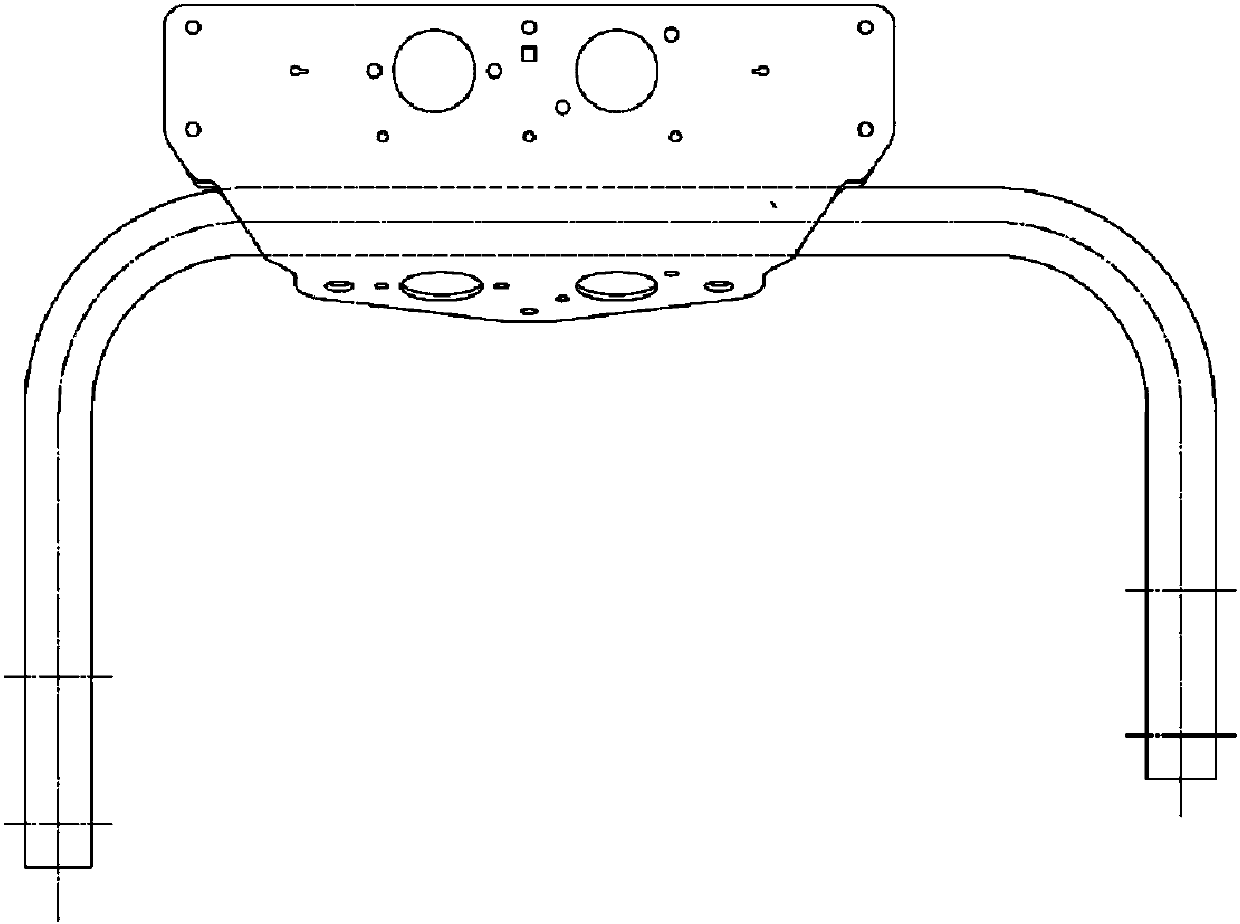

Production technology for aluminum alloy wire harness installing support for trailer

The invention belongs to the technical field of aluminum alloy machining, and relates to a production technology for an aluminum alloy wire harness installing support for a trailer. A 6061 aluminum alloy cast ingot comprises, by mass percent, 0.4%-0.8% of Si, smaller than or equal to 0.7% of Fe, 0.15%-0.4% of Cu, smaller than or equal to 0.15% of Mn, 0.08%-0.12% of Mg, 0.04%-0.35% of Cr, smaller than or equal to 0.25% of Zn, smaller than or equal to 0.15% of Ti, smaller than or equal to 0.05% of single impurities, smaller than or equal to 0.15% of all impurities, and the balance Al. The aluminum alloy cast ingot with the formula is cast, homogenizing treatment is conducted, a 1250 T extruder is used for extrusion, the extrusion temperature ranges from 500 DEG C to 520 DEG C, the extrusionspeed ranges from 7 m / min to 9 m / min, the temperature of an aluminum alloy sectional material before quenching is larger than or equal to 510 DEG C, and the quenching manner is water cooling; the temperature of the aluminum alloy sectional material after quenching is smaller than or equal to 50 DEG C, the stretch rate is controlled to range from 0.5% to 1.0%, the extruded sectional material is cutto the required size, aging is conducted within 12H, the aging system is 175 DEG C x (7-9) H, stretch bending forming is conducted after aging, the produced wire harness installing support is high instrength, the structure is simplified, space is saved, stability is good, and safety performance is high; and the wire harness installing support does not need to be welded, the integral structure ismore light and attractive, and rapid mounting and dismounting of the installing support are achieved.

Owner:CHINA ZHONGWANG

6061 aluminum alloy and processing method thereof

The invention relates to a 6061 aluminum alloy and a processing method thereof, and belongs to the field of metal materials. The processing method comprises the following steps of smelting and refining raw materials of the 6061 aluminum alloy, casting, homogenizing and extruding. The 6061 aluminum alloy is prepared from the raw materials in percentage by weight 0.65 to 0.7 percent of Si, 0.25 to 0.35 percent of Fe, 0.18 to 0.23 percent of Cu, 0.1 to 0.15 percent of Mn, 0.85 to 0.9 percent of Mg, 0.15 to 0.25 percent of Cr, 0.08 to 0.12 percent of Ti, 0.15 to 0.2 percent of rare earth cerium tin, and the balance Al. The processing method is simple and easy to operate, and extrusion cracks of the 6061 aluminum alloy can be effectively reduced. The obtained 6061 aluminum alloy is good in quality and cannot produce cracks at the extrusion speed of 6m / min.

Owner:SHANDONG NANSHAN ALUMINUM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com