Patents

Literature

47 results about "Plasma etcher" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A plasma etcher, or etching tool, is a tool used in the production of semiconductor devices. A plasma etcher produces a plasma from a process gas, typically oxygen or a fluorine-bearing gas, using a high frequency electric field, typically 13.56 MHz. A silicon wafer is placed in the plasma etcher, and the air is evacuated from the process chamber using a system of vacuum pumps. Then a process gas is introduced at low pressure, and is excited into a plasma through dielectric breakdown.

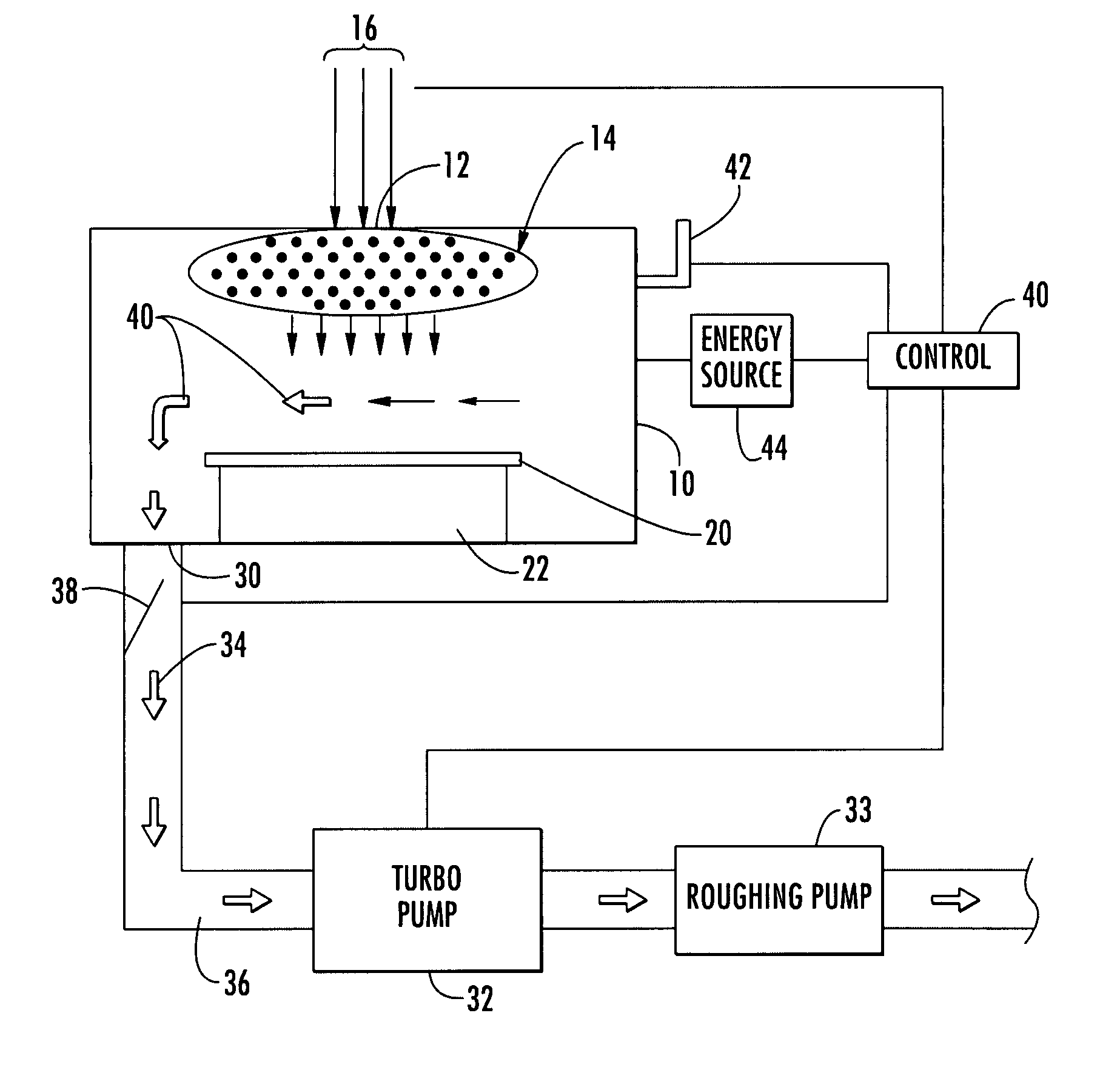

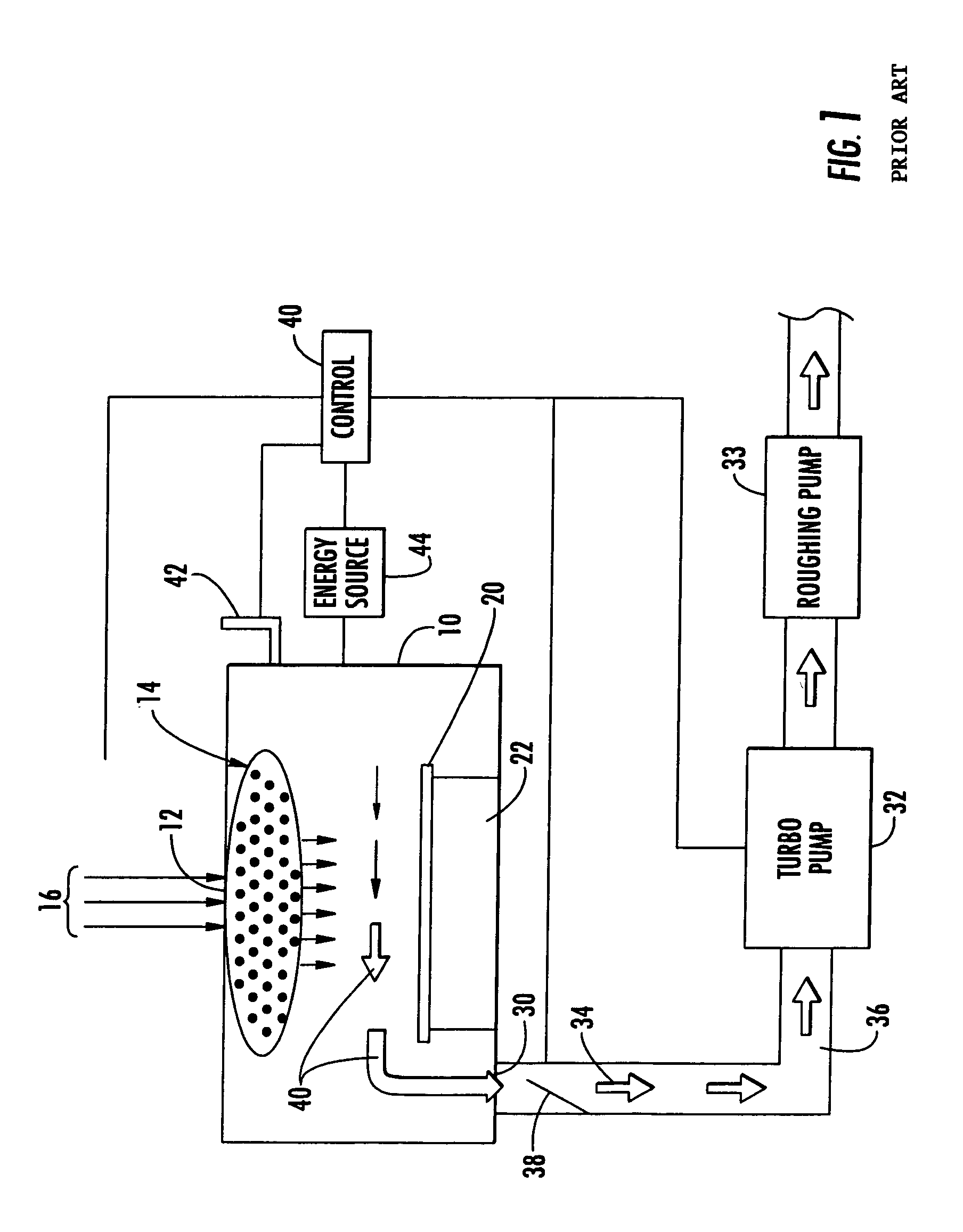

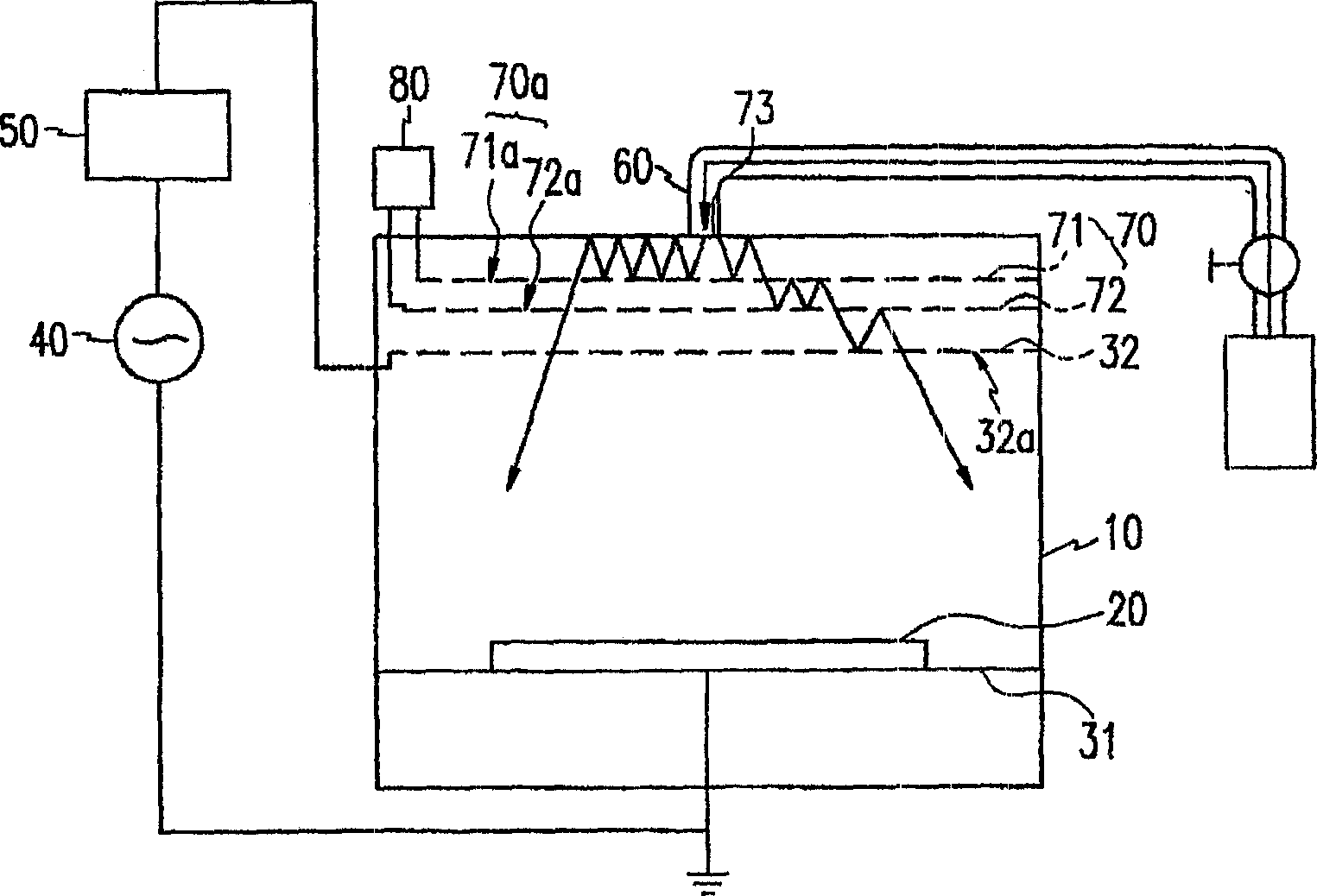

Low-temperature compatible wide-pressure-range plasma flow device

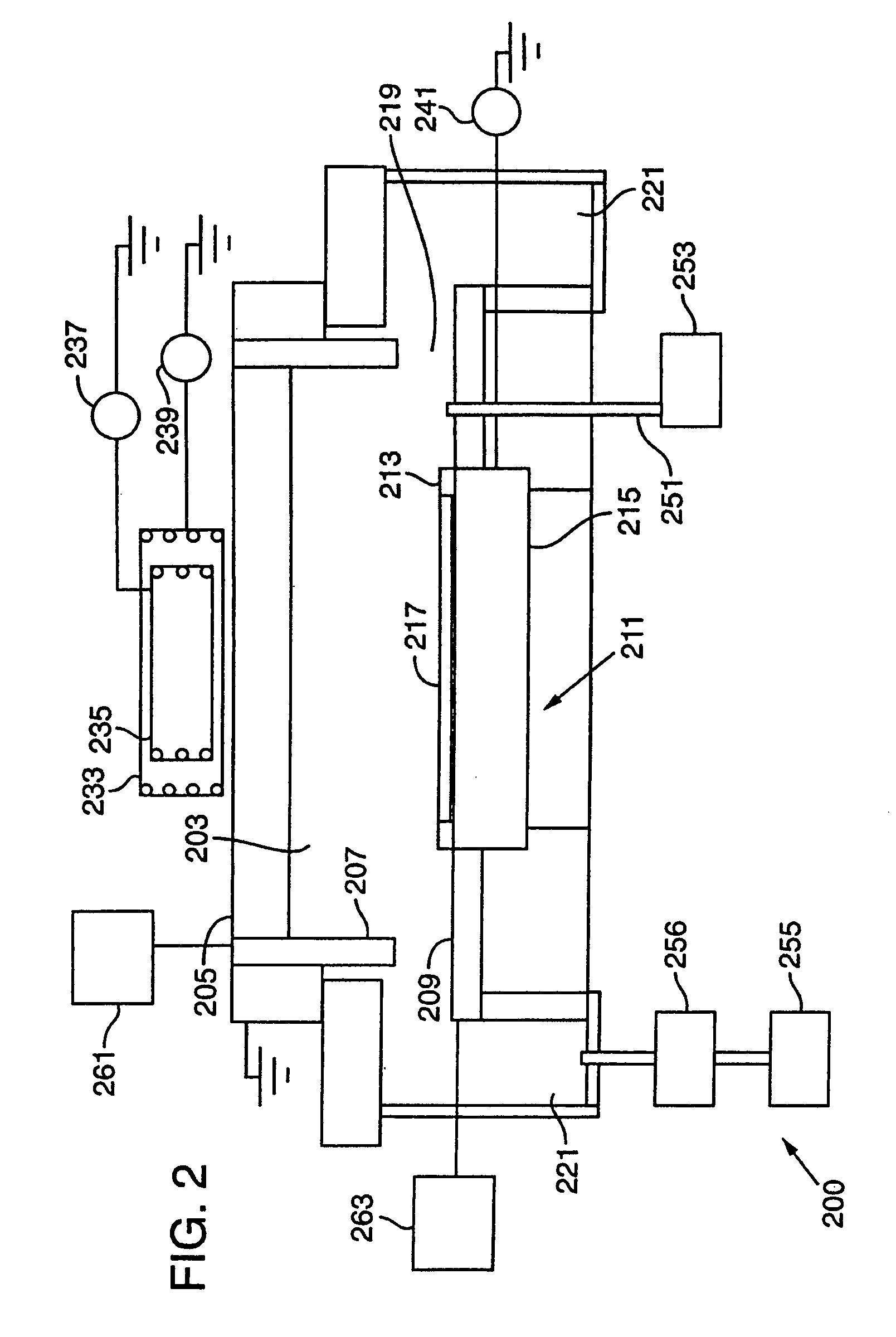

InactiveUS20020129902A1Electric discharge tubesSemiconductor/solid-state device manufacturingGas phaseReactive gas

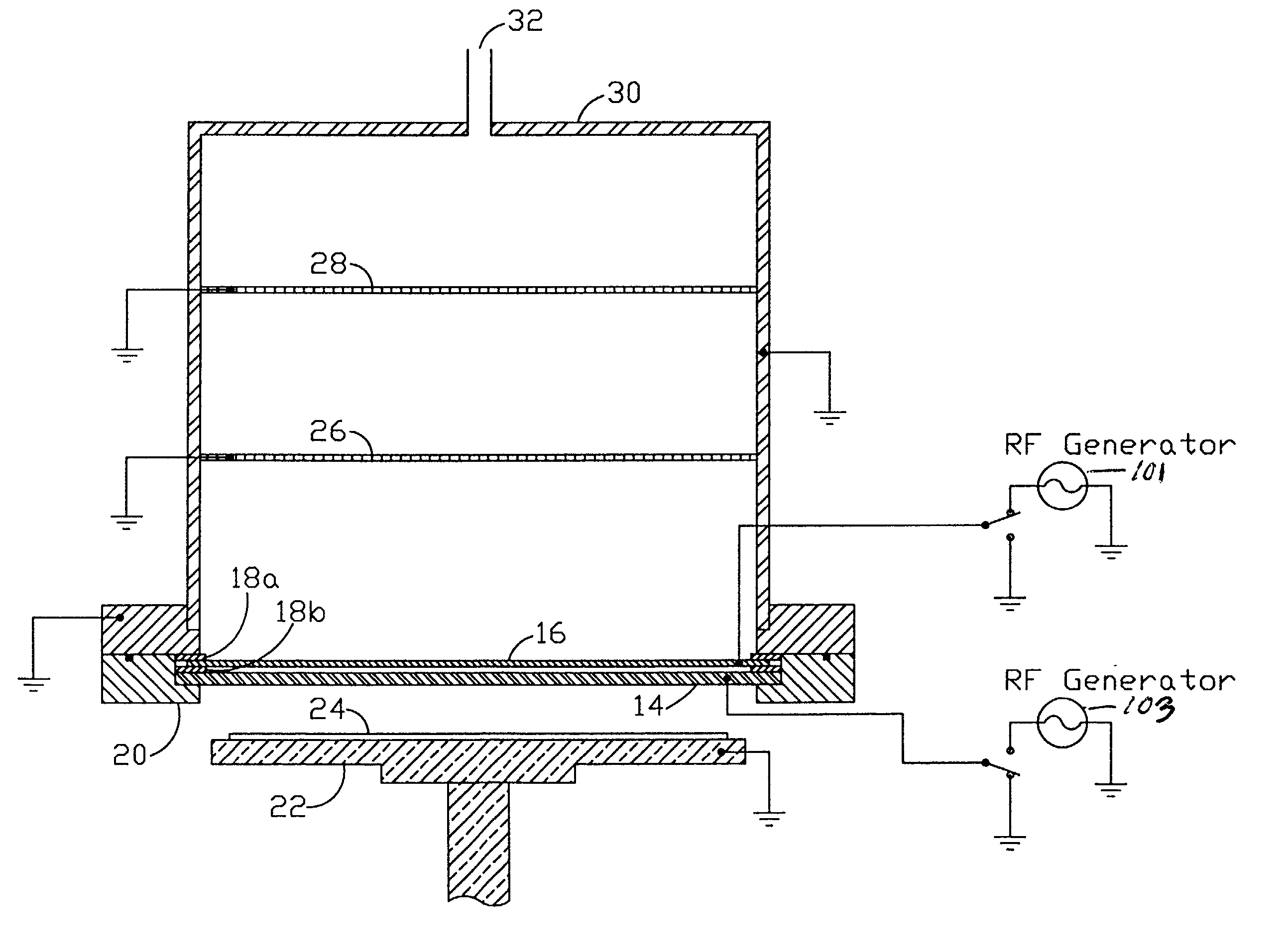

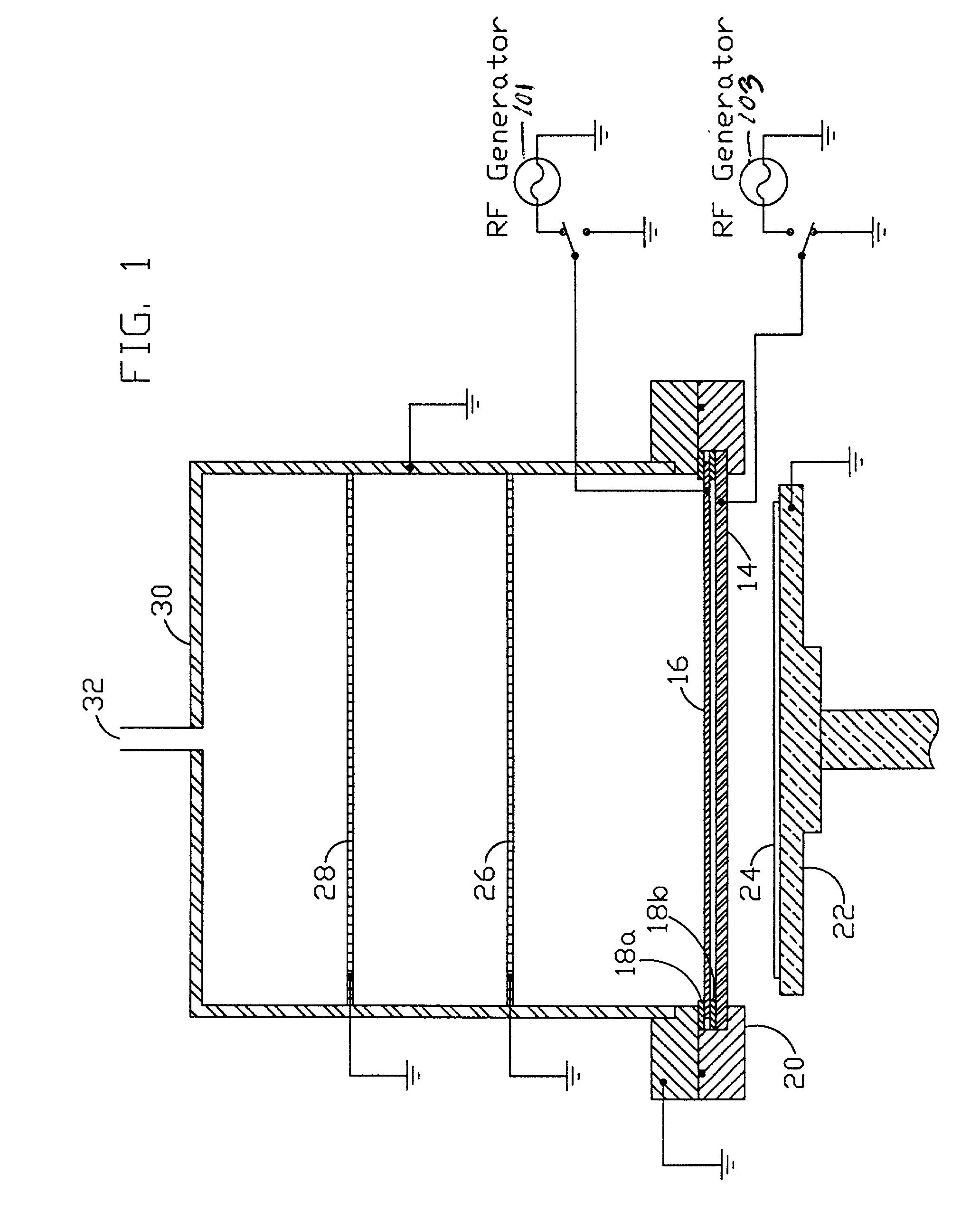

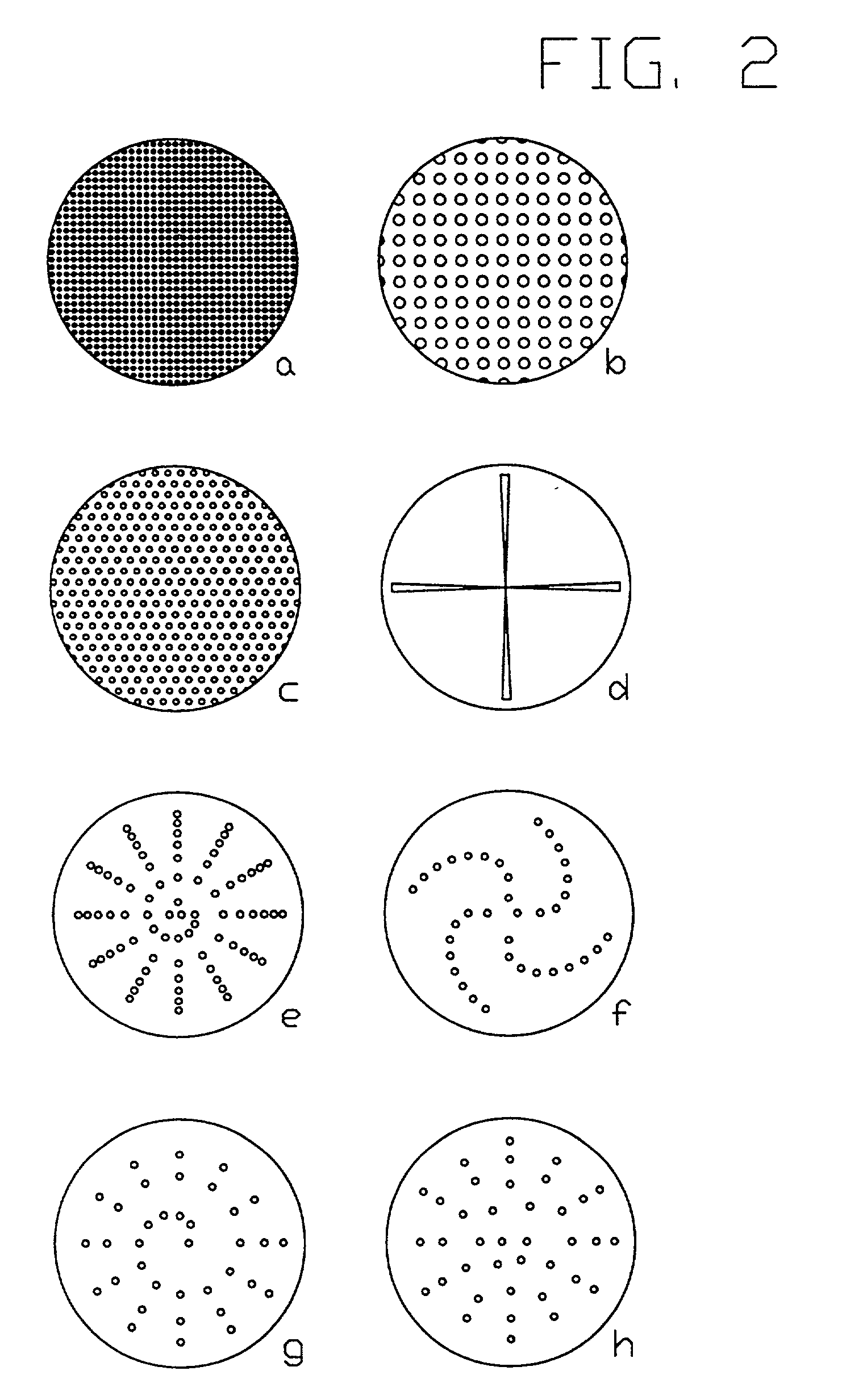

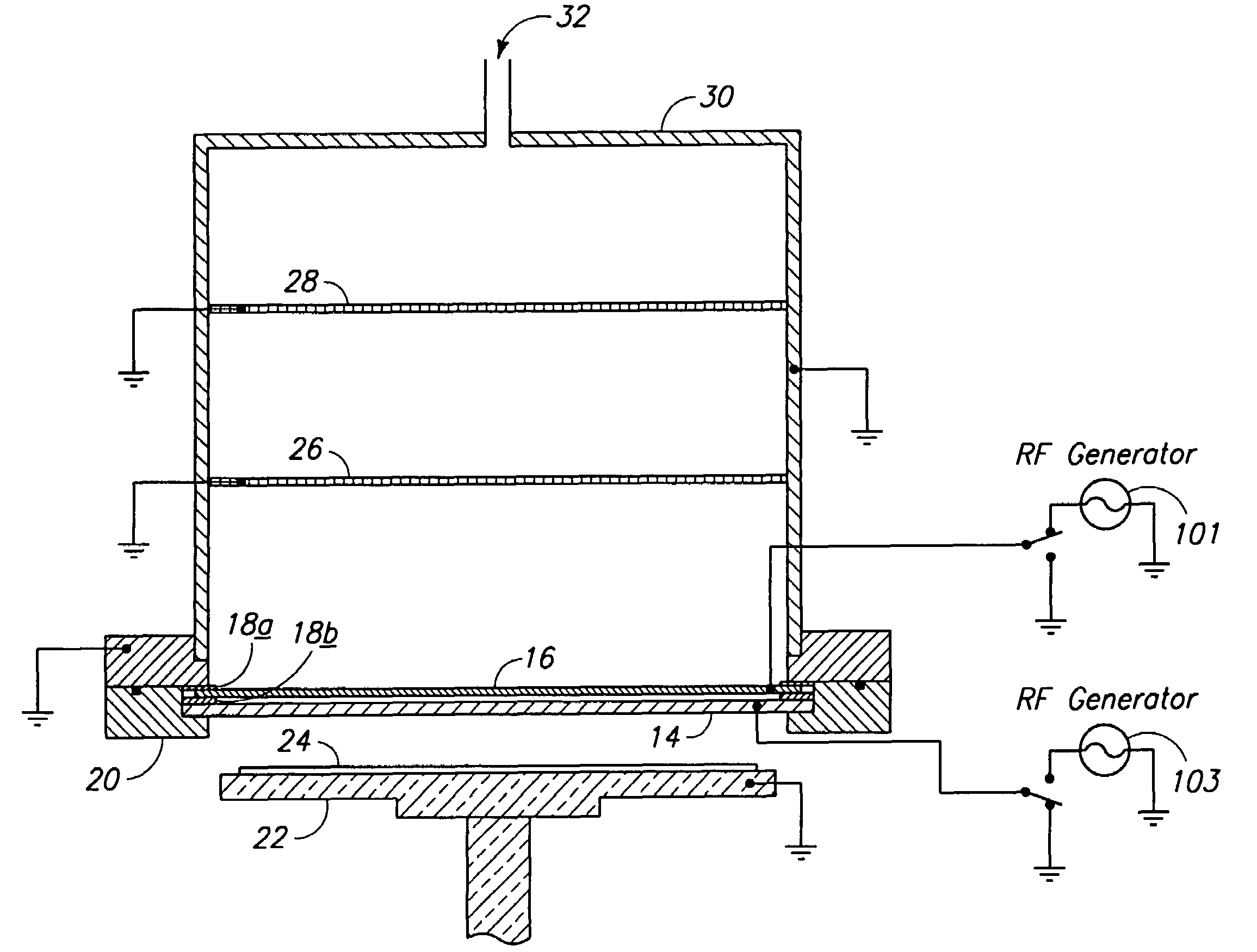

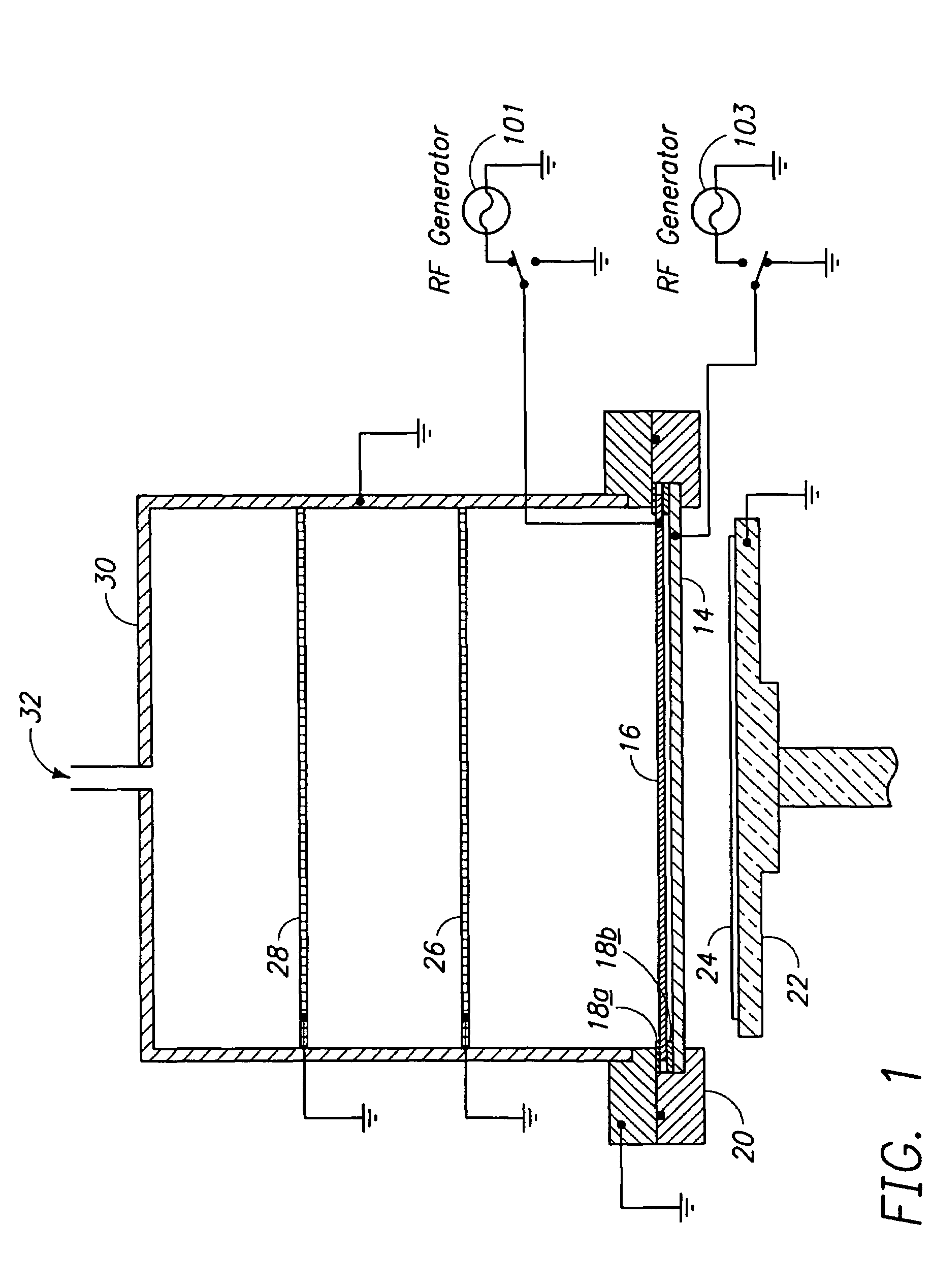

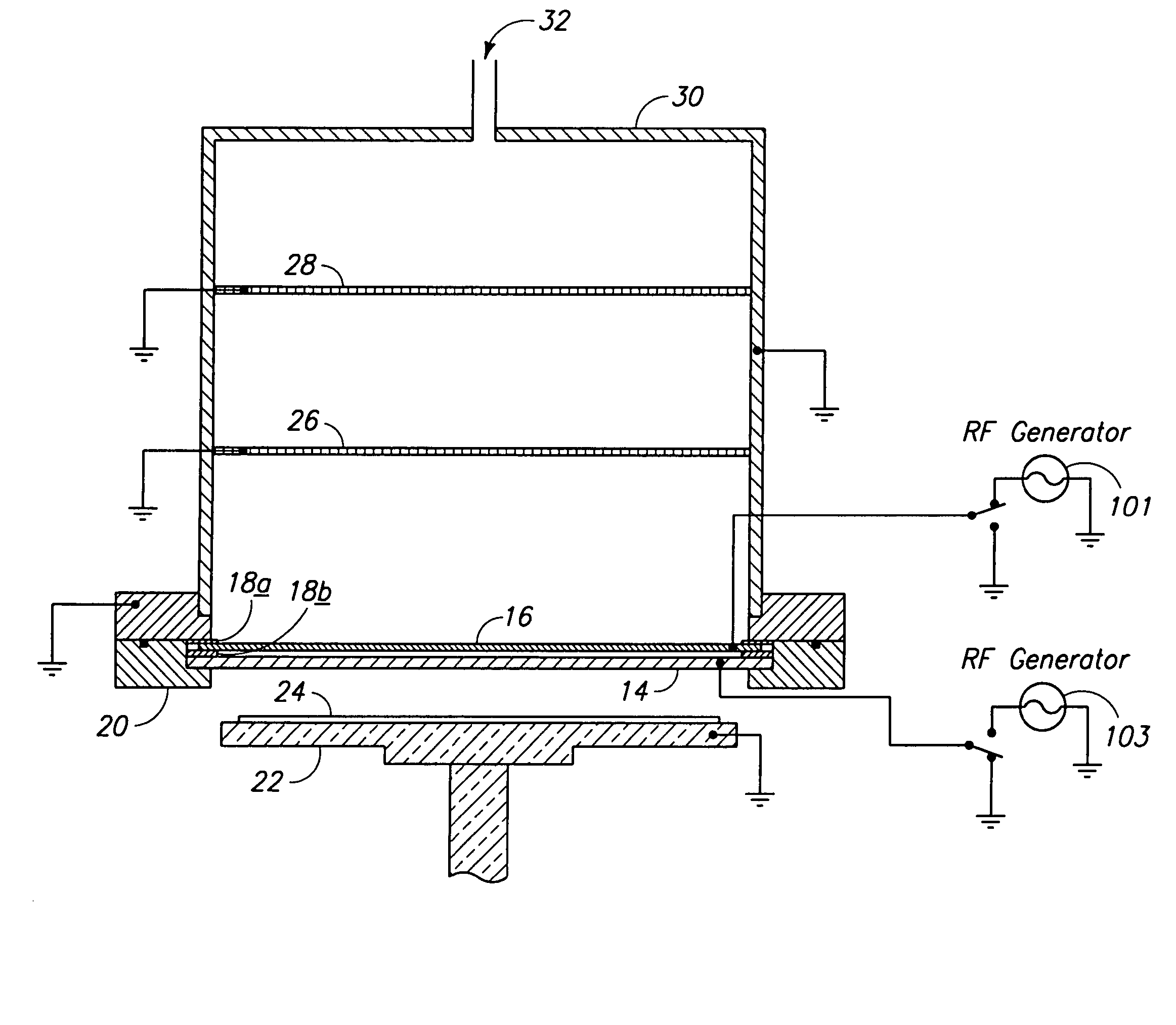

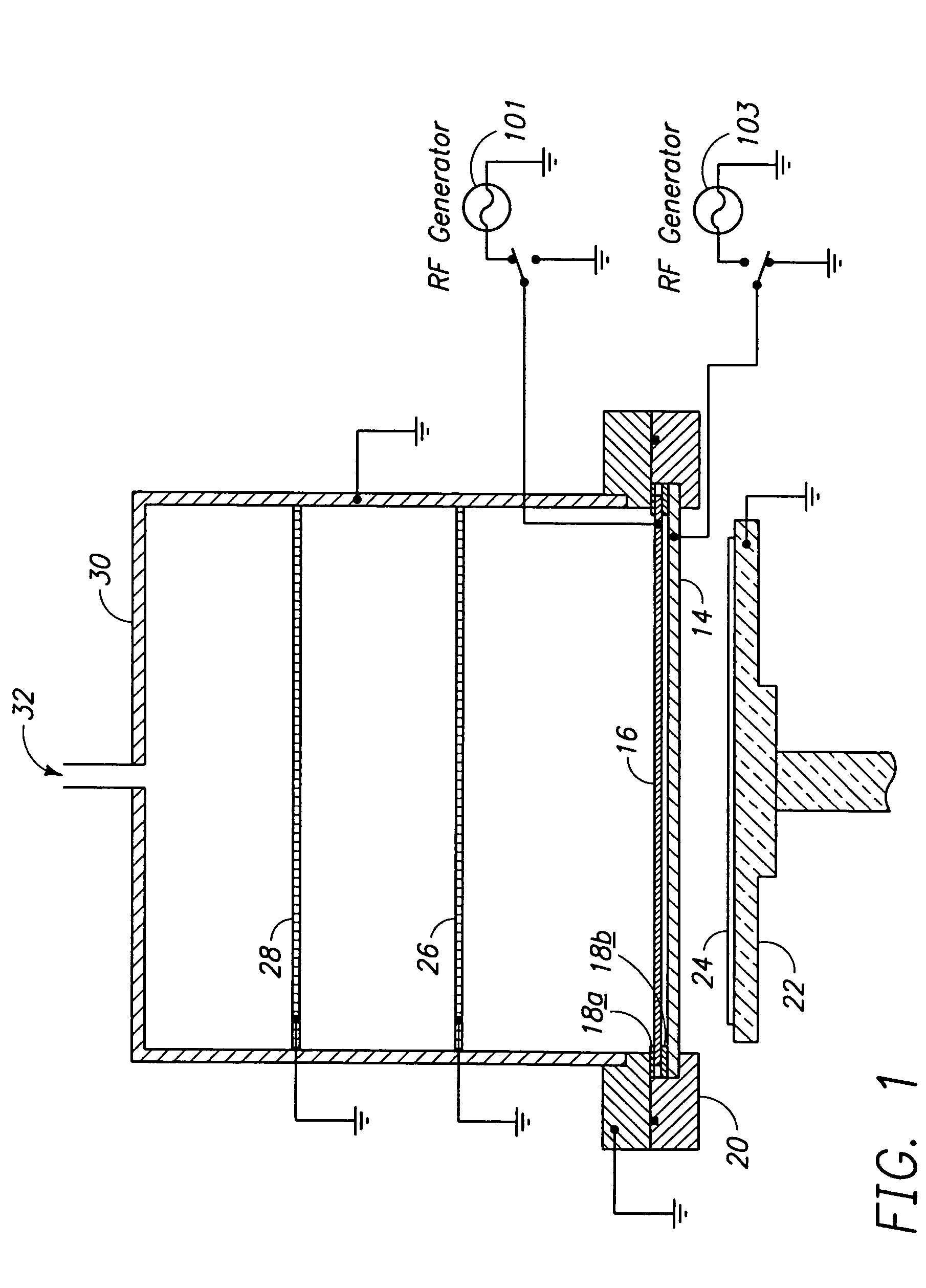

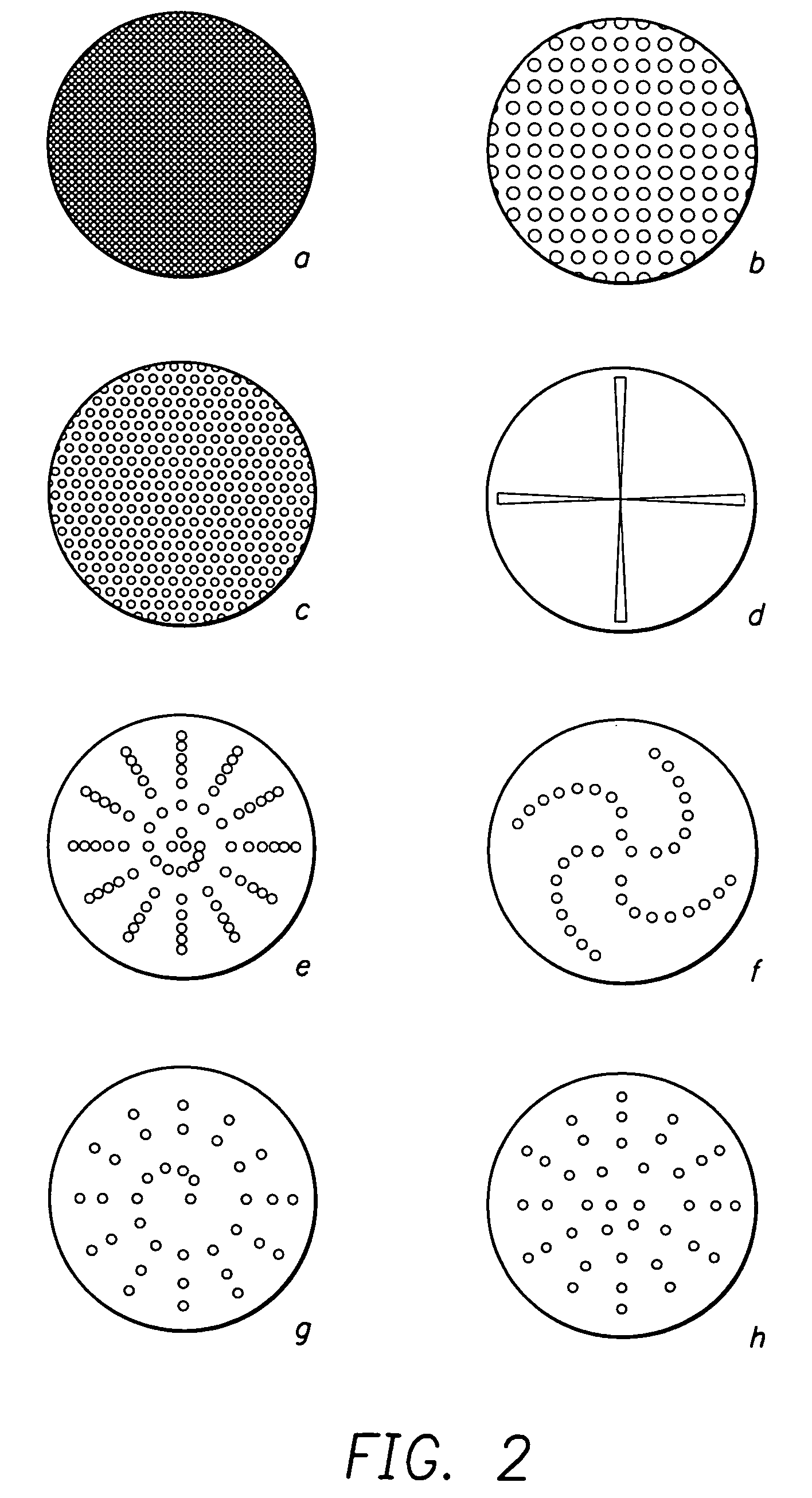

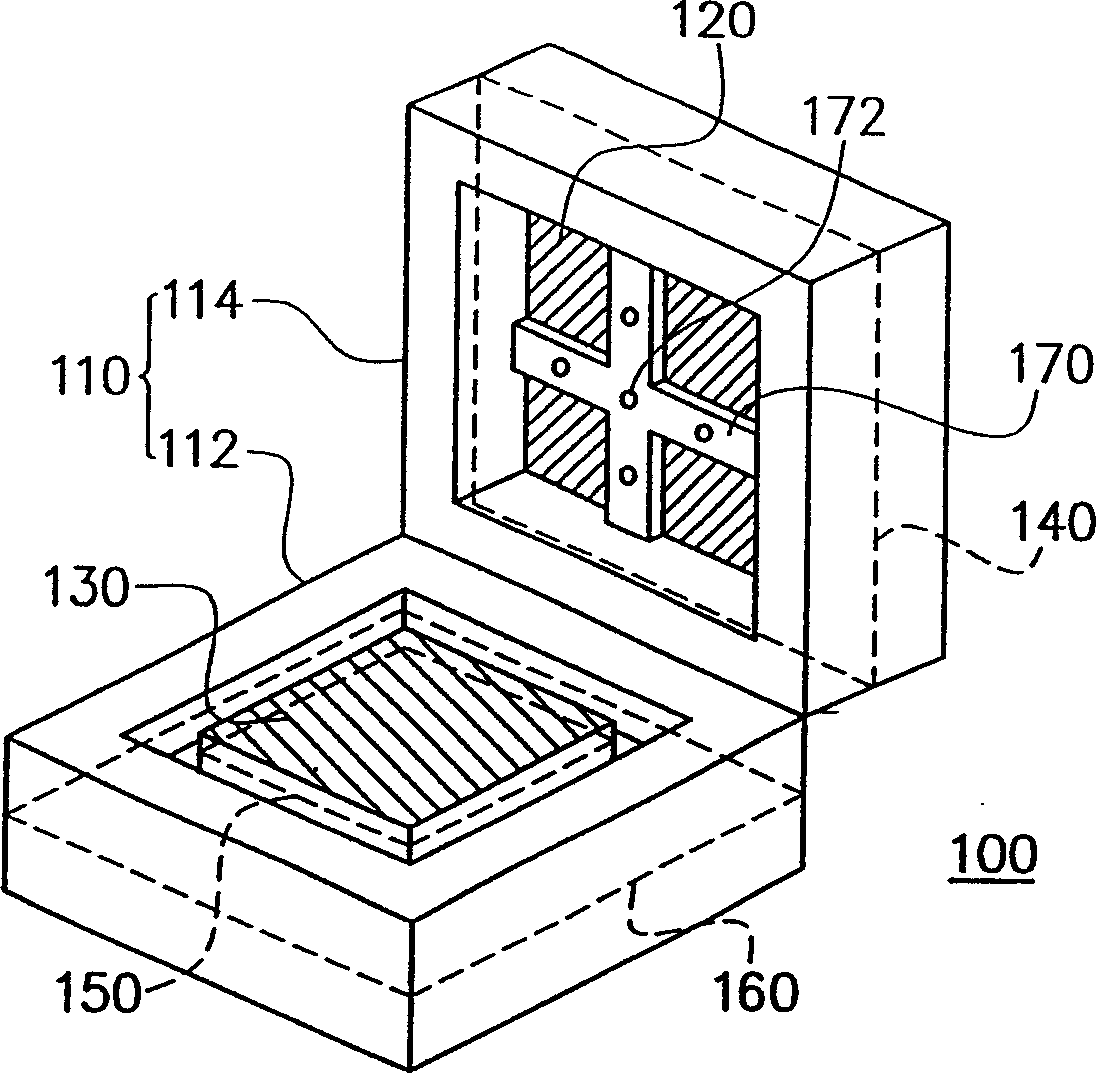

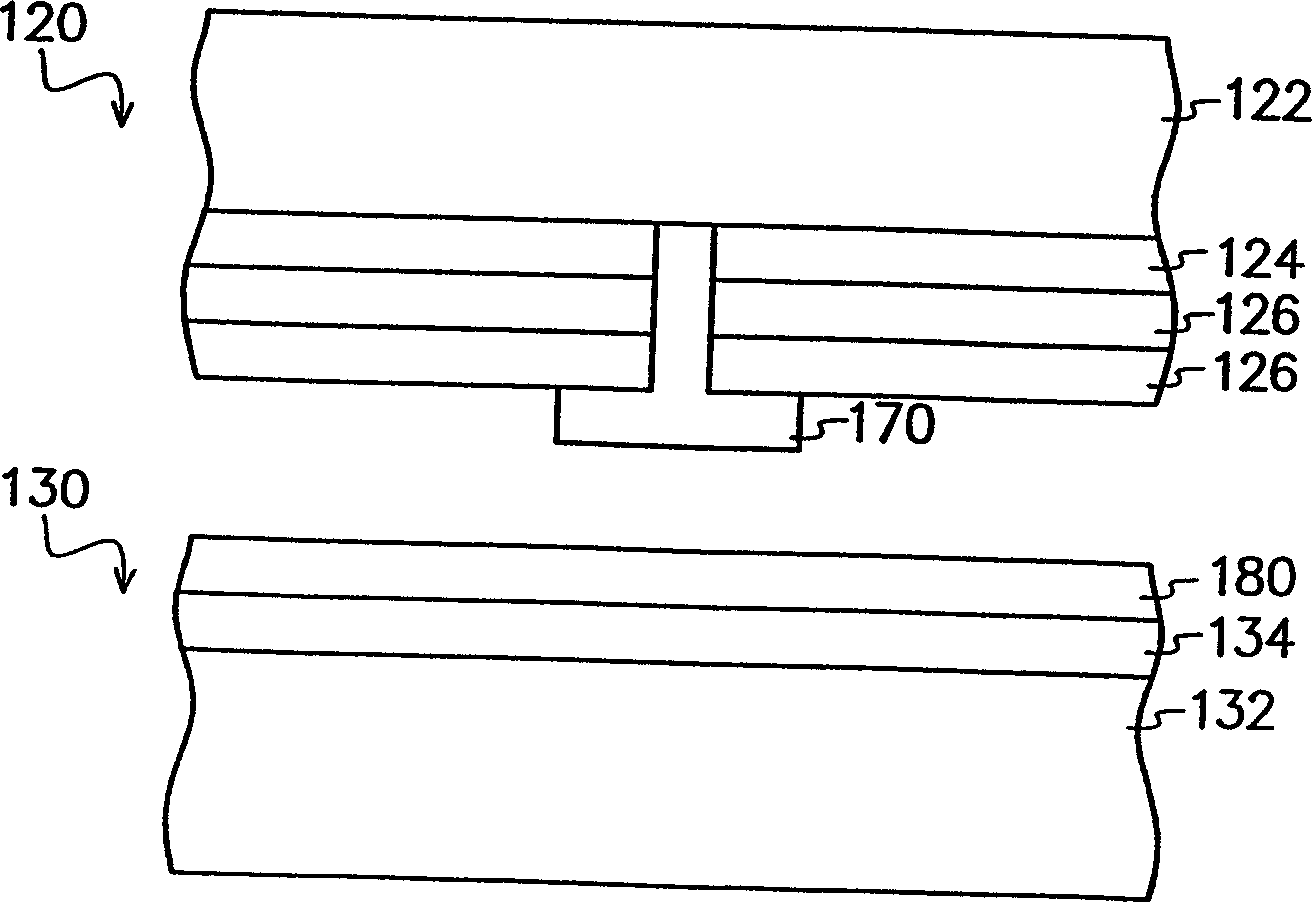

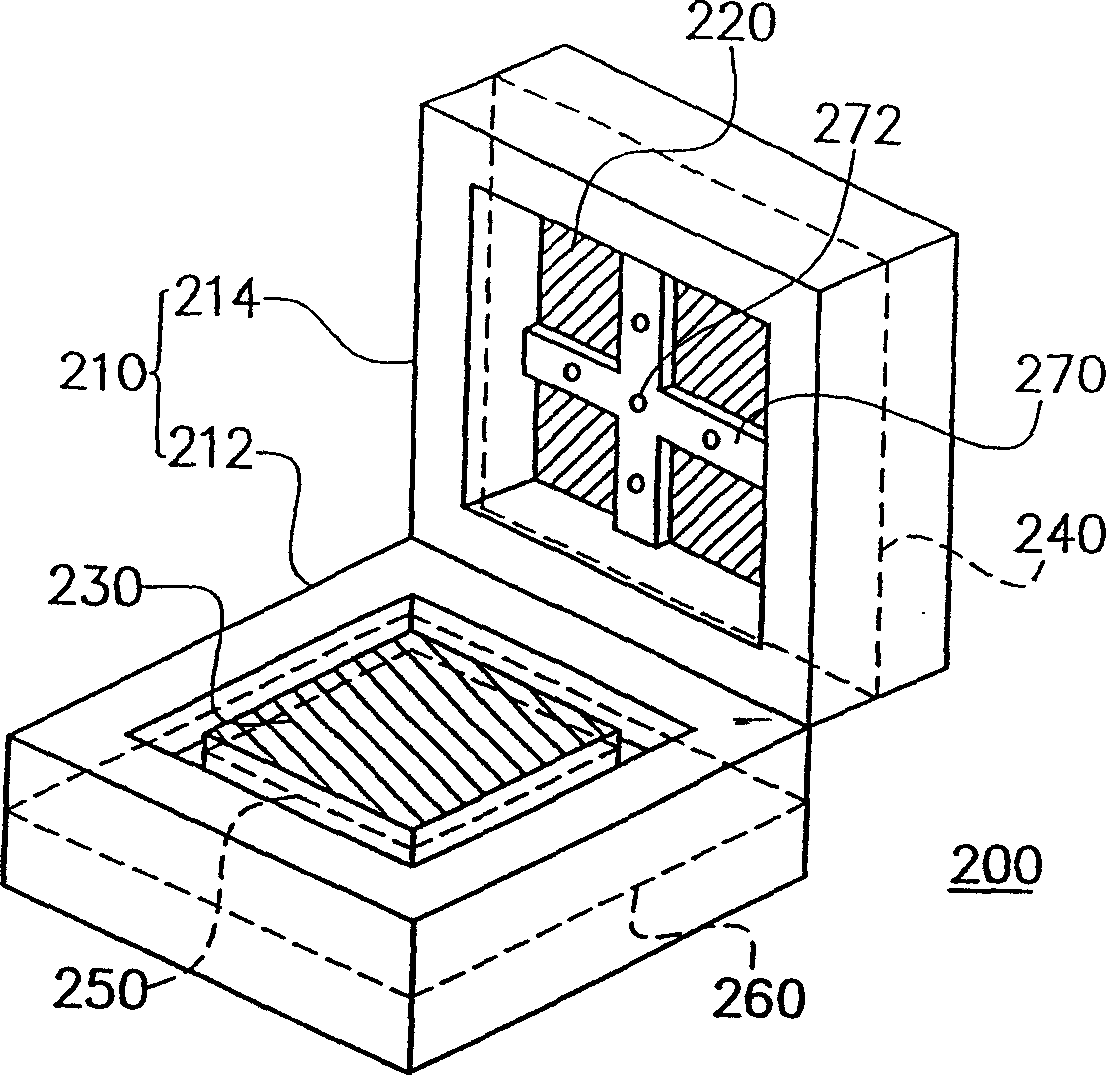

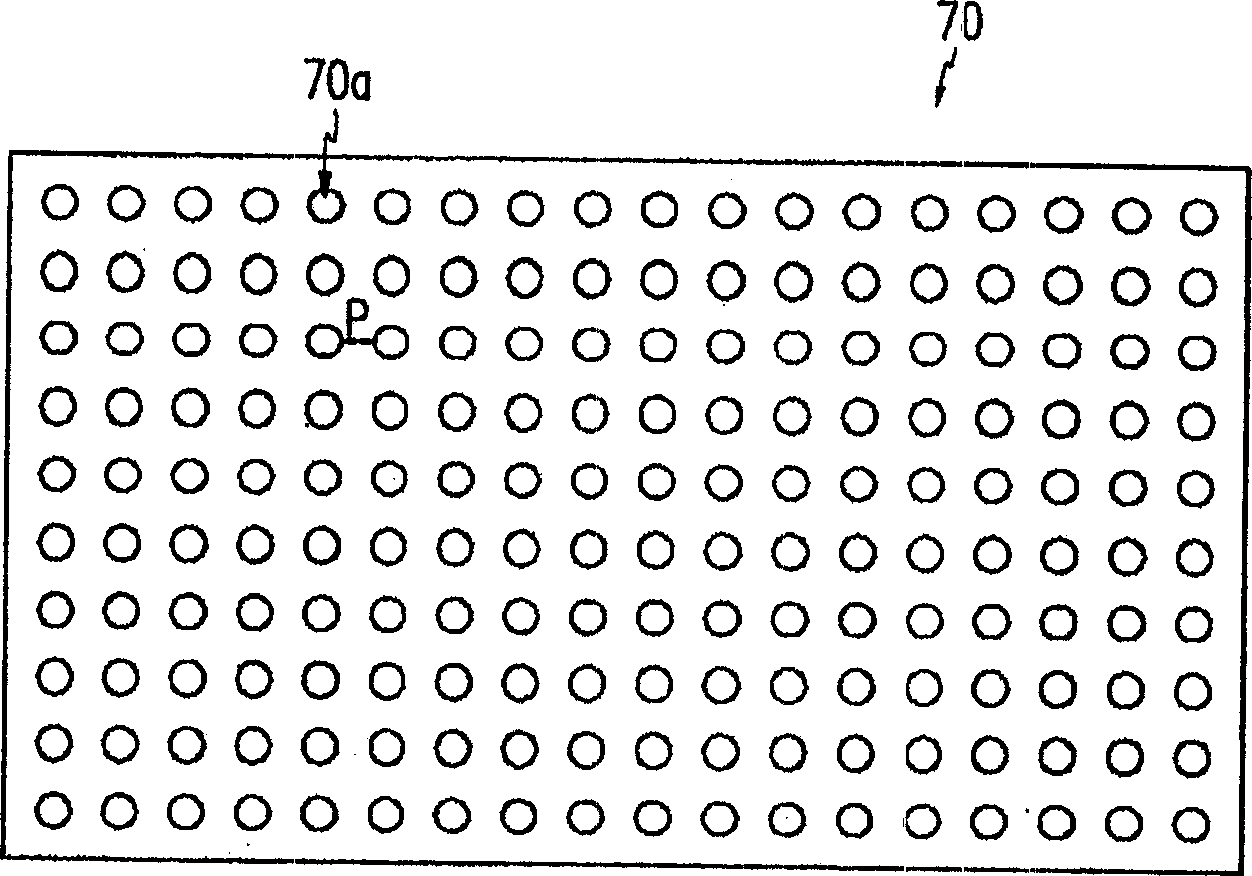

The invention is embodied in a plasma flow device or reactor having a housing that contains conductive electrodes with openings to allow gas to flow through or around them, where one or more of the electrodes are powered by an RF source and one or more are grounded, and a substrate or work piece is placed in the gas flow downstream of the electrodes, such that said substrate or work piece is substantially uniformly contacted across a large surface area with the reactive gases emanating therefrom. The invention is also embodied in a plasma flow device or reactor having a housing that contains conductive electrodes with openings to allow gas to flow through or around them, where one or more of the electrodes are powered by an RF source and one or more are grounded, and one of the grounded electrodes contains a means of mixing in other chemical precursors to combine with the plasma stream, and a substrate or work piece placed in the gas flow downstream of the electrodes, such that said substrate or work piece is contacted by the reactive gases emanating therefrom. In one embodiment, the plasma flow device removes organic materials from a substrate or work piece, and is a stripping or cleaning device. In another embodiment, the plasma flow device kills biological microorganisms on a substrate or work piece, and is a sterilization device. In another embodiment, the plasma flow device activates the surface of a substrate or work piece, and is a surface activation device. In another embodiment, the plasma flow device etches materials from a substrate or work piece, and is a plasma etcher. In another embodiment, the plasma flow device deposits thin films onto a substrate or work piece, and is a plasma-enhanced chemical vapor deposition device or reactor.

Owner:RGT UNIV OF CALIFORNIA

Method of processing a substrate

InactiveUS7329608B2Semiconductor/solid-state device detailsDispersed particle separationReactive gasGas phase

Owner:RGT UNIV OF CALIFORNIA

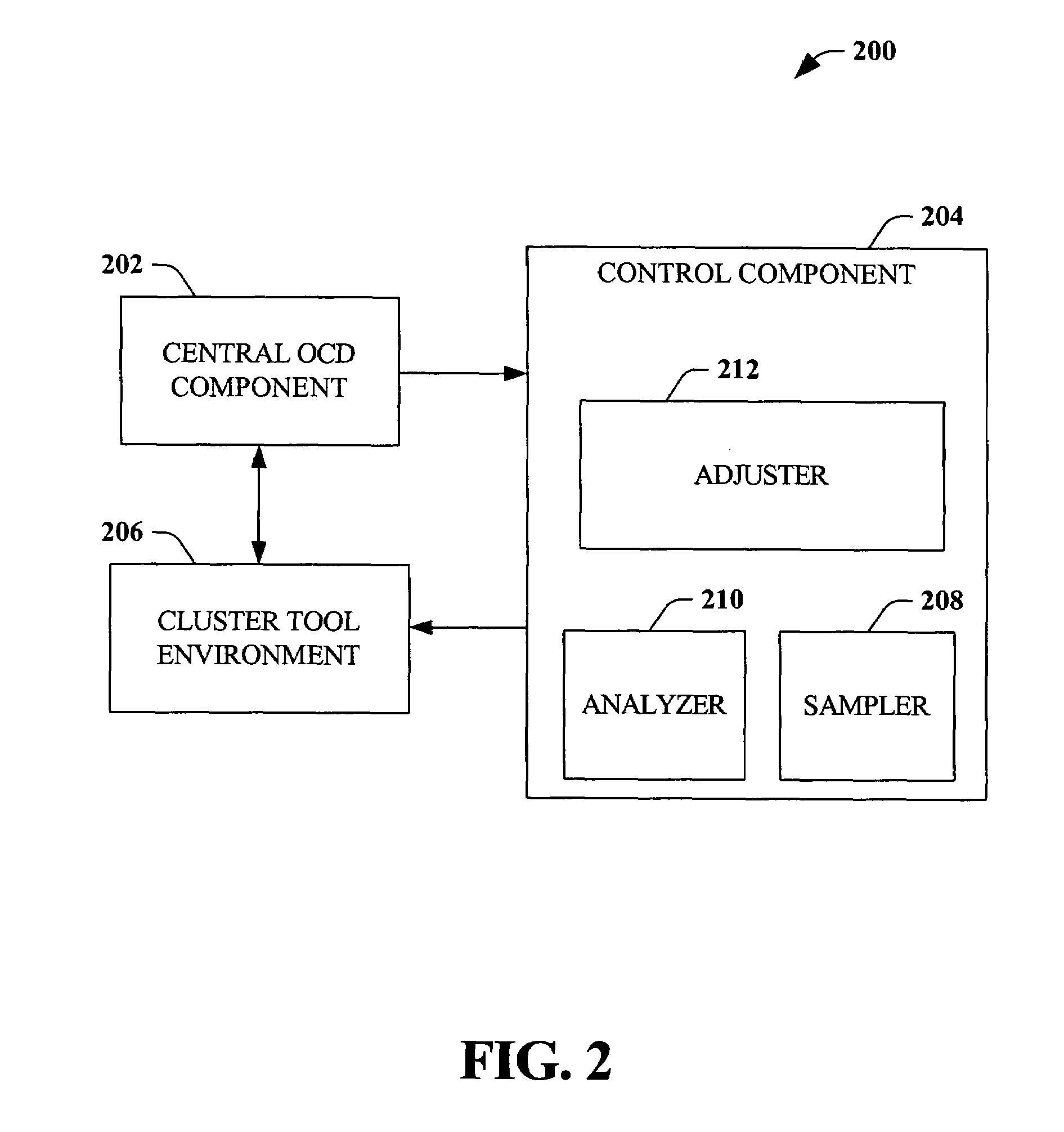

Scatterometry monitor in cluster process tool environment for advanced process control (APC)

ActiveUS7076320B1Strengthen process controlIncrease productivityFeeler-pin gaugesPhotomechanical apparatusControl limitsPlasma etcher

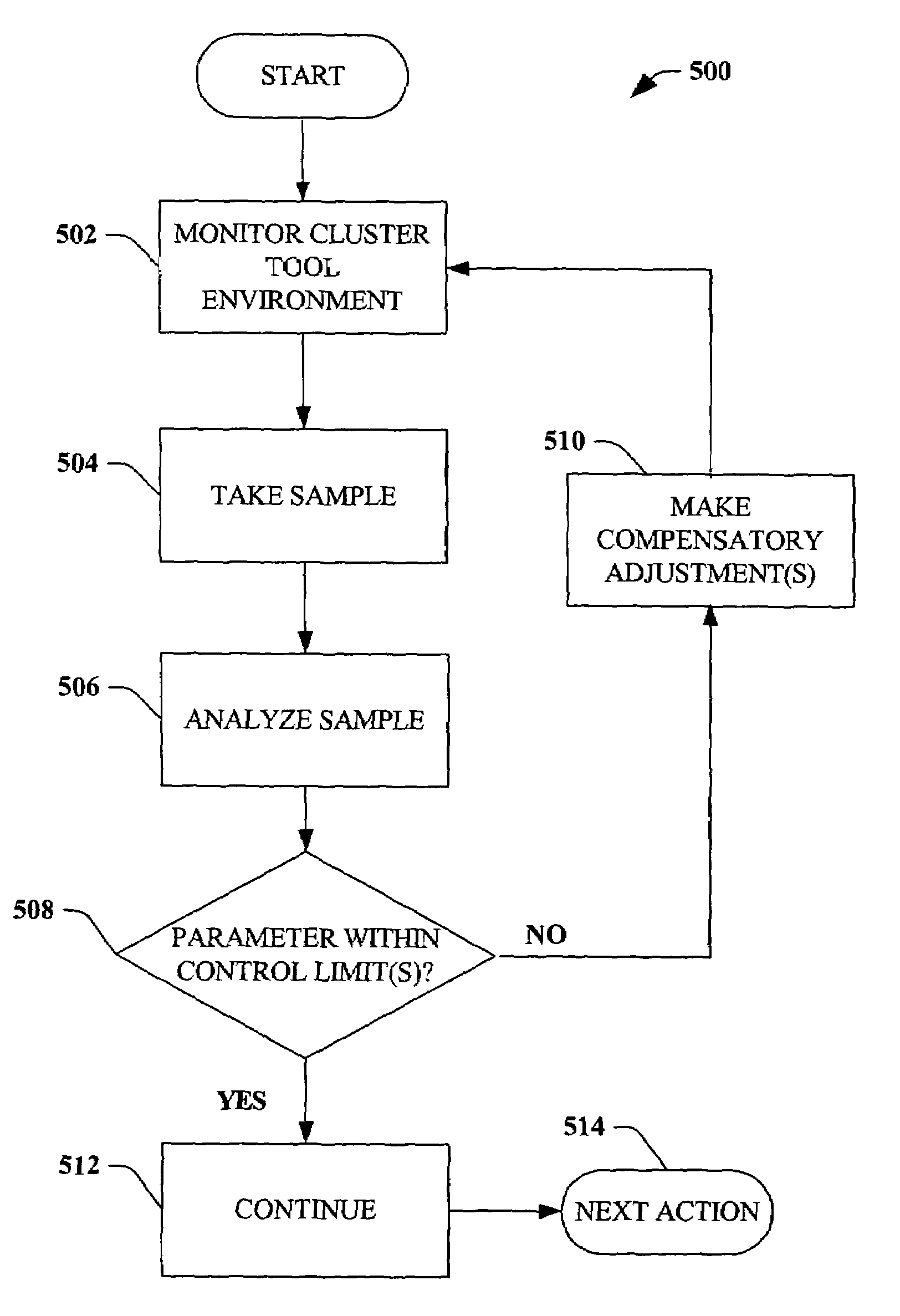

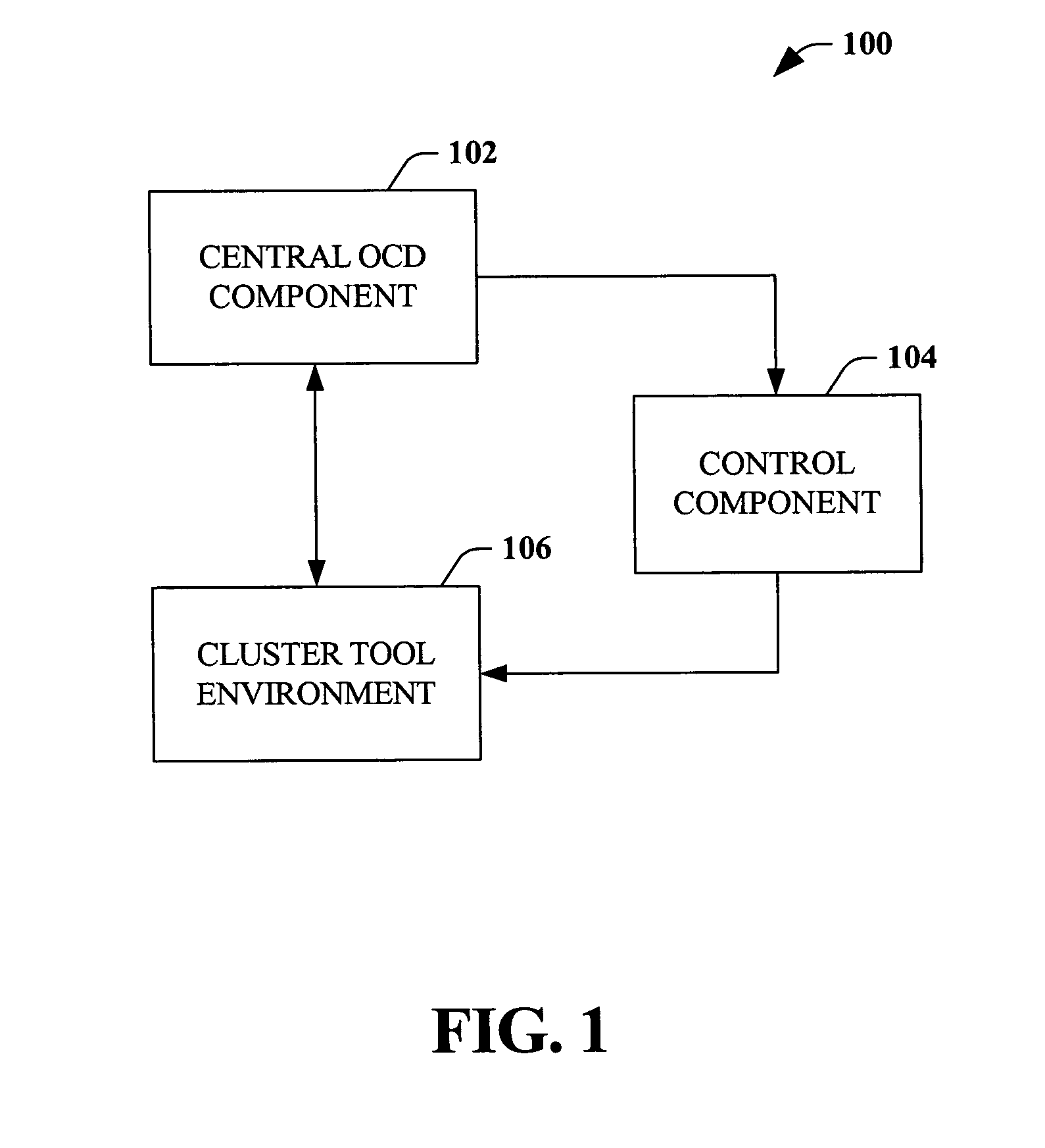

Systems and methods that improve process control in semiconductor manufacturing are disclosed. According to an aspect of the invention, conditions in a cluster tool environment and / or a wafer therein can be monitored in-situ via, for example, a scatterometry system, to determine whether parameters associated with wafer production are within control limits. A cluster tool environment can include, for example, a lithography track, a stepper, a plasma etcher, a cleaning tool, a chemical bath, etc. If an out-of-control condition is detected, either associated with a tool in the cluster tool environment or with the wafer itself, compensatory measures can be taken to correct the out-of-control condition. The invention can further employ feedback / feed-forward loop(s) to facilitate compensatory action in order to improve process control.

Owner:ADVANCED MICRO DEVICES INC

Method of processing a substrate

InactiveUS20050093458A1Electric discharge tubesSemiconductor/solid-state device detailsReactive gasGas phase

The invention is embodied in a plasma flow device or reactor having a housing that contains conductive electrodes with openings to allow gas to flow through or around them, where one or more of the electrodes are powered by an RF source and one or more are grounded, and a substrate or work piece is placed in the gas flow downstream of the electrodes, such that said substrate or work piece is substantially uniformly contacted across a large surface area with the reactive gases emanating therefrom The invention is also embodied in a plasma flow device or reactor having a housing that contains conductive electrodes with openings to allow gas to flow through or around them, where one or more of the electrodes are powered by an RF source and one or more are grounded, and one of the grounded electrodes contains a means of mixing in other chemical precursors to combine with the plasma stream, and a substrate or work piece placed in the gas flow downstream of the electrodes, such that said substrate or work piece is contacted by the reactive gases emanating therefrom. In one embodiment, the plasma flow device removes organic materials from a substrate or work piece, and is a stripping or cleaning device. In another embodiment, the plasma flow device kills biological microorganisms on a substrate or work piece, and is a sterilization device. In another embodiment, the plasma flow device activates the surface of a substrate or work piece, and is a surface activation device. In another embodiment, the plasma flow device etches materials from a substrate or work piece, and is a plasma etcher. In another embodiment, the plasma flow device deposits thin films onto a substrate or work piece, and is a plasma-enhanced chemical vapor deposition device or reactor.

Owner:RGT UNIV OF CALIFORNIA

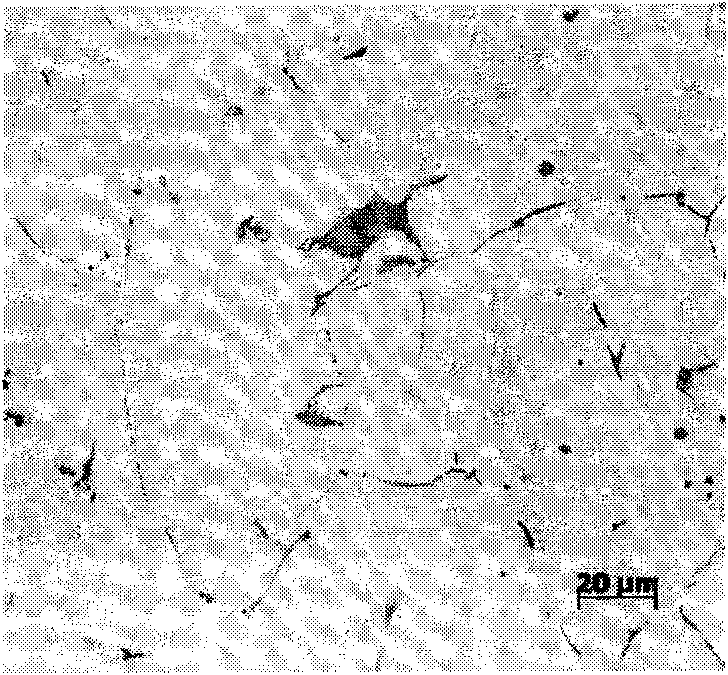

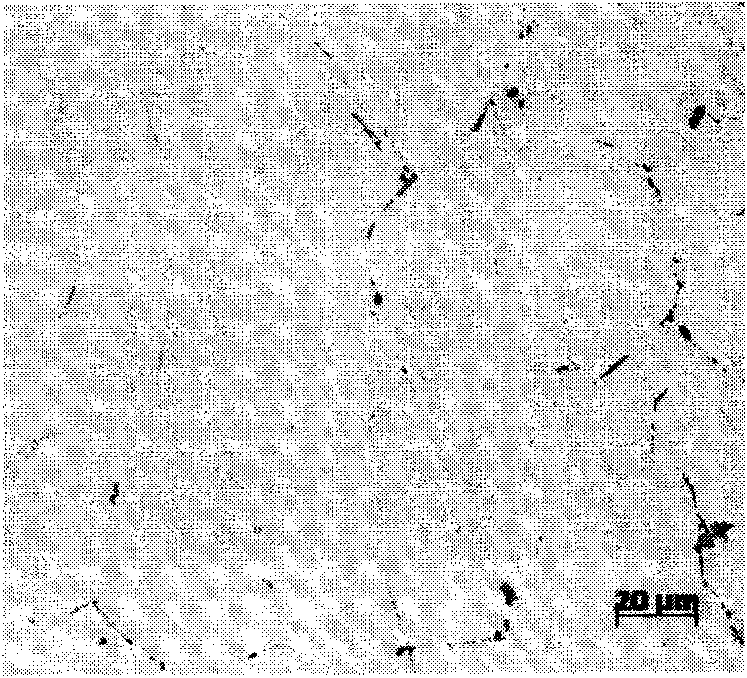

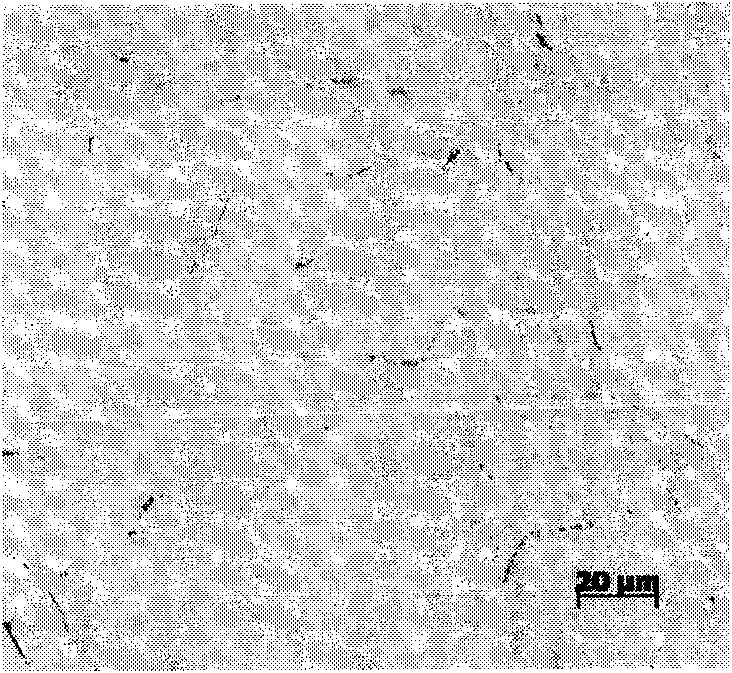

Process for homogenizing aluminum alloy

The invention relates to a process for homogenizing aluminum alloy, in particular to a process for homogenizing high-quality 6061 aluminum alloy for a reaction chamber liner of a plasma etcher, belonging to the technical field of non-ferrous metal heat treatment technique. The 6061 aluminum alloy comprises 0.4-0.6 wt% of Si, 0.8-1.2 wt% of Mg, 0.15-0.4 wt% of Cu, 0.01-0.35 wt% of Cr, less than 0.15 wt% of Fe, less than 0.15 wt% of Mn, less than 0.15 wt% of Ti and the balance of Al. The process provided by the invention comprises the following steps: carrying out furnace-heating on 6061 aluminum alloy cast ingots, keeping the temperature at 560+ / -5 DEG C for 9 hours, discharging, and carrying out water quenching at room temperature. The homogenizing treatment can enhance the structural homogenity of the aluminum alloy matrix, redissolve the Mg2Si phase, and nodulize the iron-containing phase, thereby enhancing the effect of anodic oxidation and the corrosion resistance of aluminum alloy after anodic oxidation.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

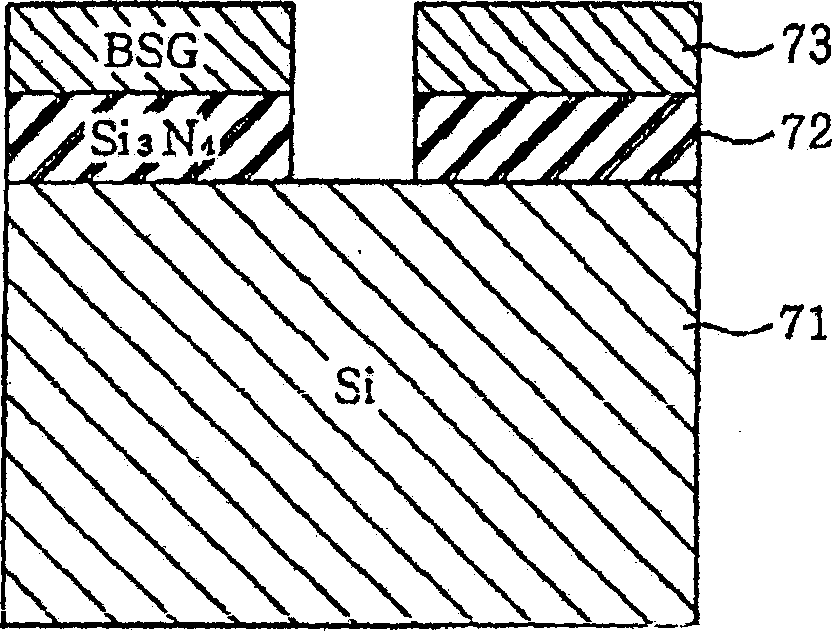

Method of plasma etching the tungsten silicide layer in the gate conductor stack formation

InactiveUS6207580B1Improves device quality factorImprove equipment qualitySemiconductor/solid-state device manufacturingSuccessful completionElectrical conductor

A method of plasma etching a Si3N4 masked tungsten silicide layer down to an underlying doped polysilicon layer in the gate conductor stack formation process is disclosed. The method is performed in a plasma etcher and the etching mixture contains C12, HCl and O2 wherein the C12 / HCl ratio is approximately equal to 4.7 and the oxygen flow varies between 20 and 30 sccm, 25 sccm being the optimal value. A slight overetching of the underlying doped polysilicon layer with this mixture is recommended. The etching method of the present invention preserves the thickness and integrity of the top Si3N4 masking layer that are essential elements for the successful completion of the remaining steps of the gate conductor stack formation process.

Owner:IBM CORP

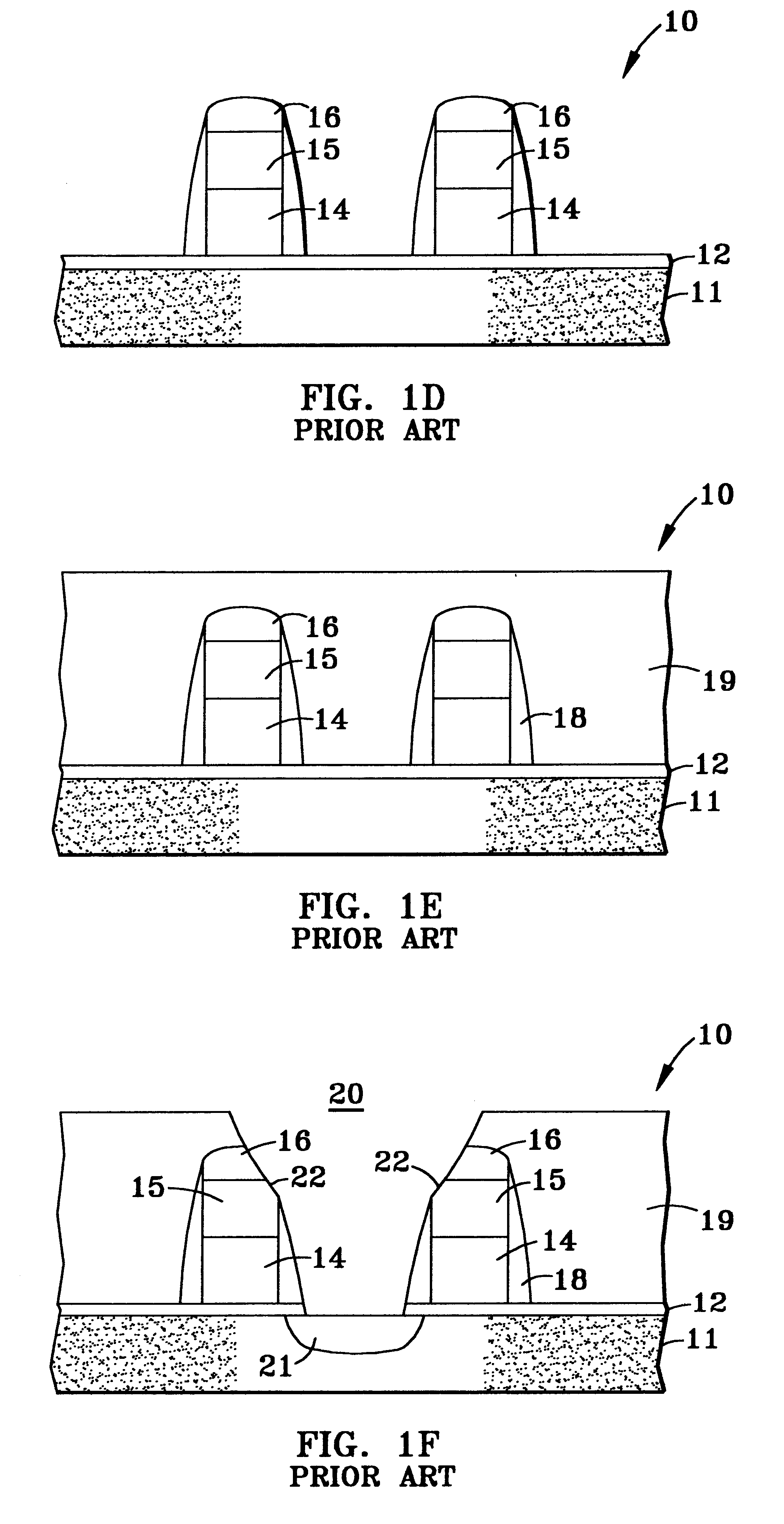

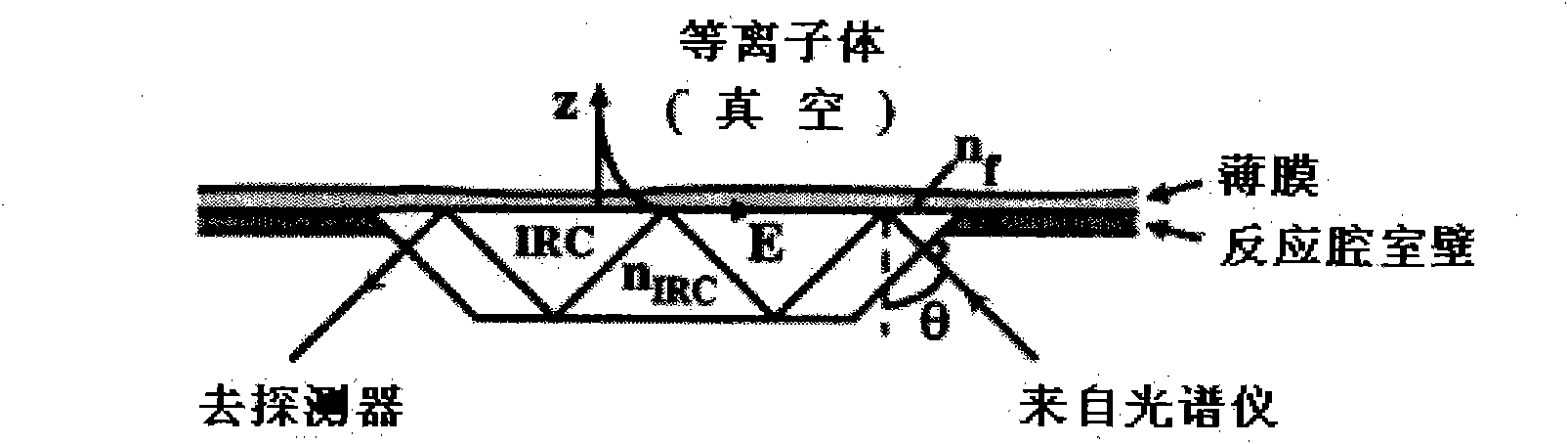

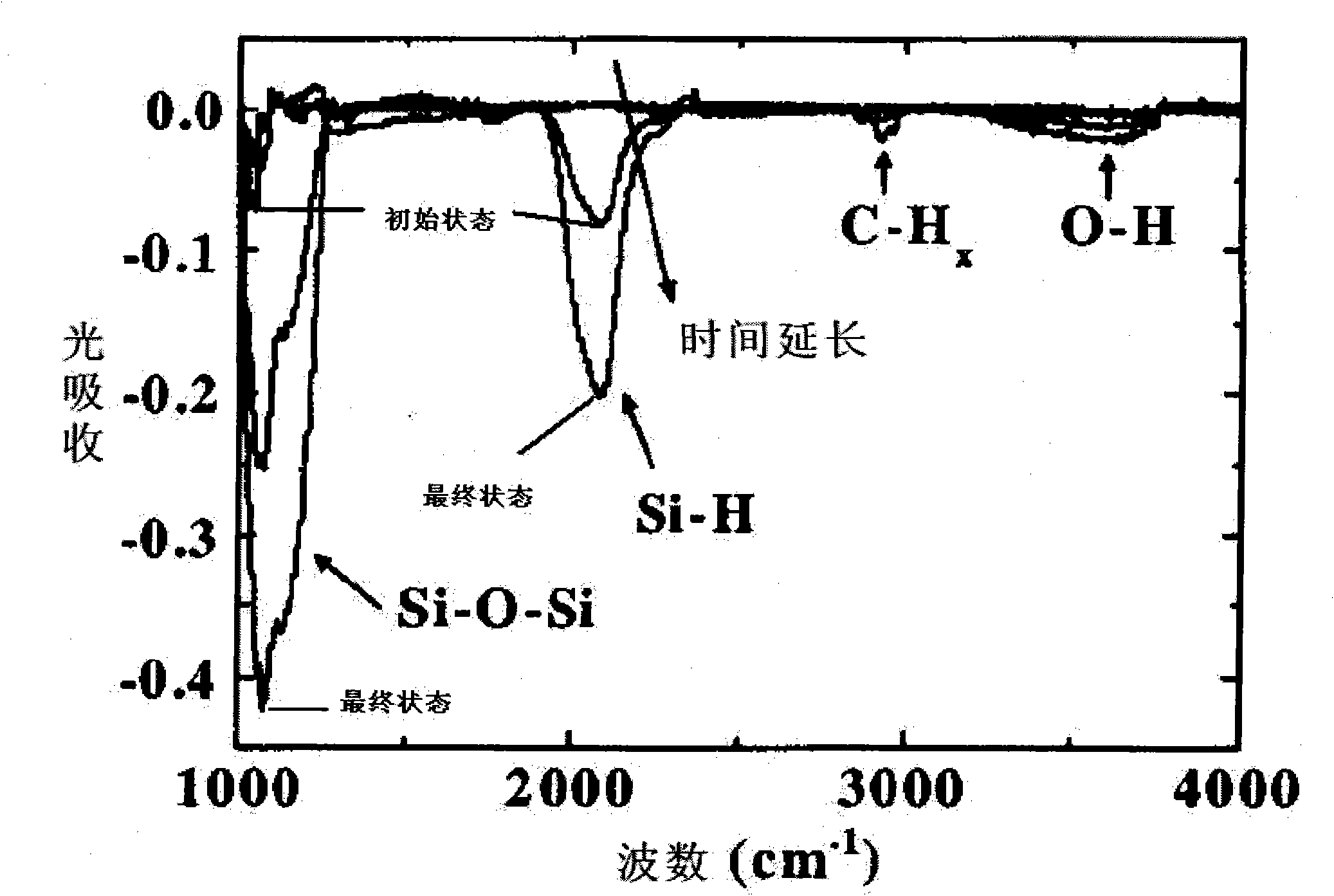

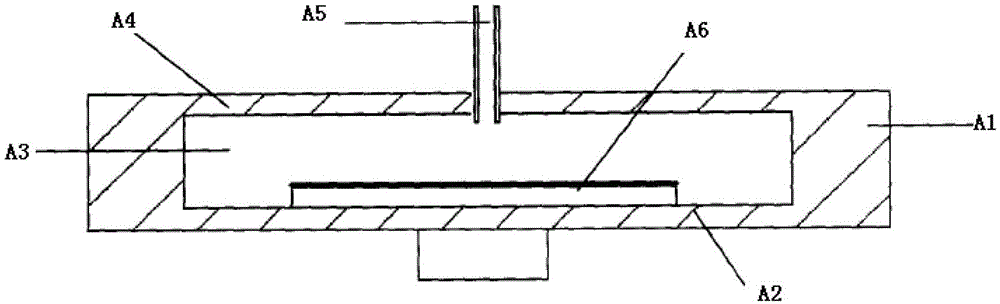

FTIR spectrum monitoring based internal state maintenance method of plasma etcher

ActiveCN101958232ATimely maintenancePrecise maintenanceSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingFast Fourier transformPlasma etcher

The invention provides an FTIR spectrum monitoring based internal state maintenance method of a plasma etcher. The outer wall of a reaction chamber of a plasma etcher is provided with a window for installing an internal reflection crystal. An ATR-FTIR spectrum probe is installed at one end of the window, and an infrared detector is installed at the other end of the window. After light rays emitted by the Fourier transform infrared spectrum probe are reflected many times in the internal reflection crystal, the light rays are emitted from the other end of the internal reflection crystal, and are focused on the infrared detector. An HgCdTe detector is connected with a spectrum processing system so as to obtain the Fourier transform infrared spectrum graph of the inner wall of the reaction chamber of the plasma etcher regularly or at real time. The Fourier transform infrared spectrum graph is used for measuring the components of attached polymers, and is compared with a standard Fourier transform infrared spectrum graph to determine whether the reaction chamber needs cleaning. If so, the reaction chamber of the plasma etcher is cleaned.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

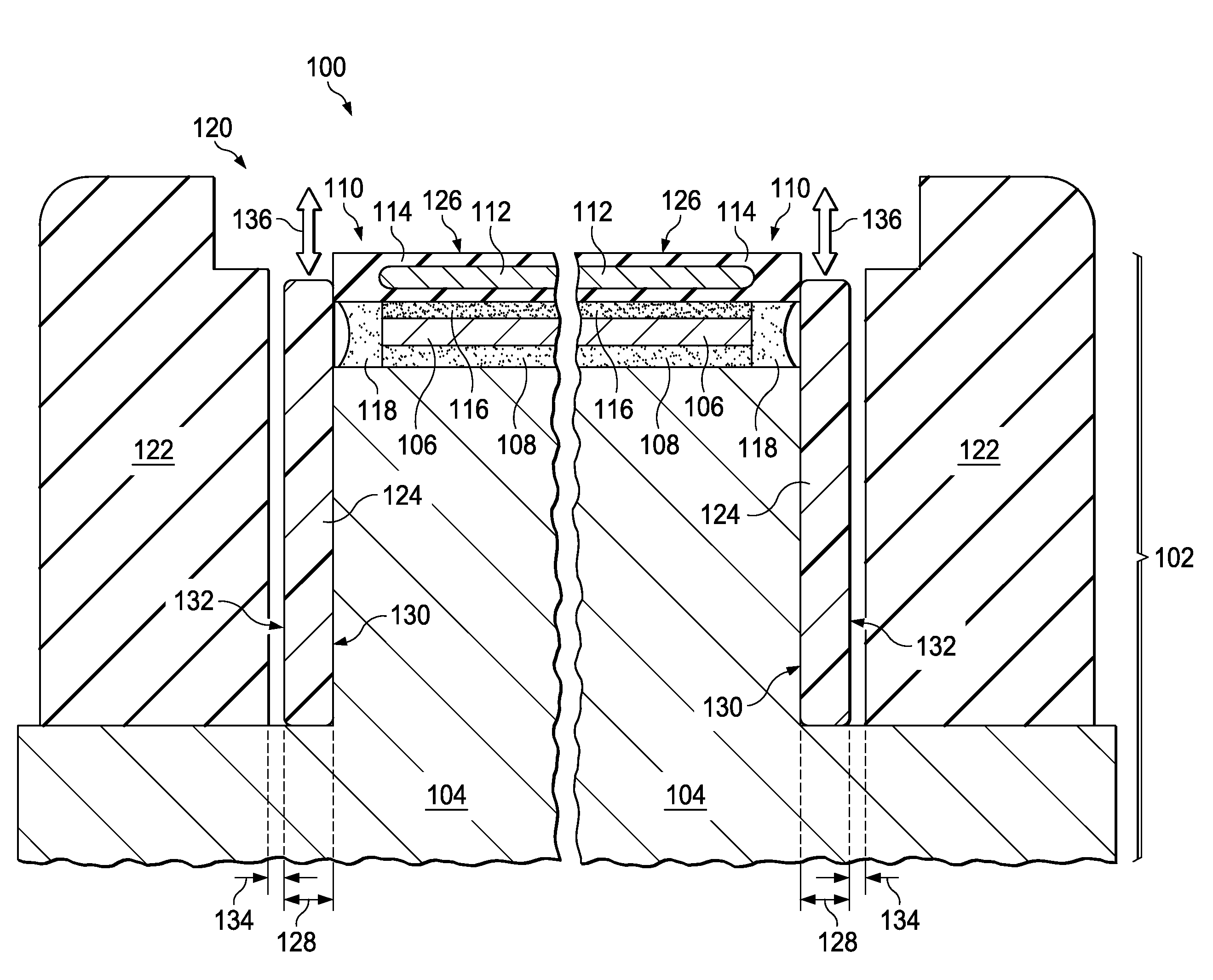

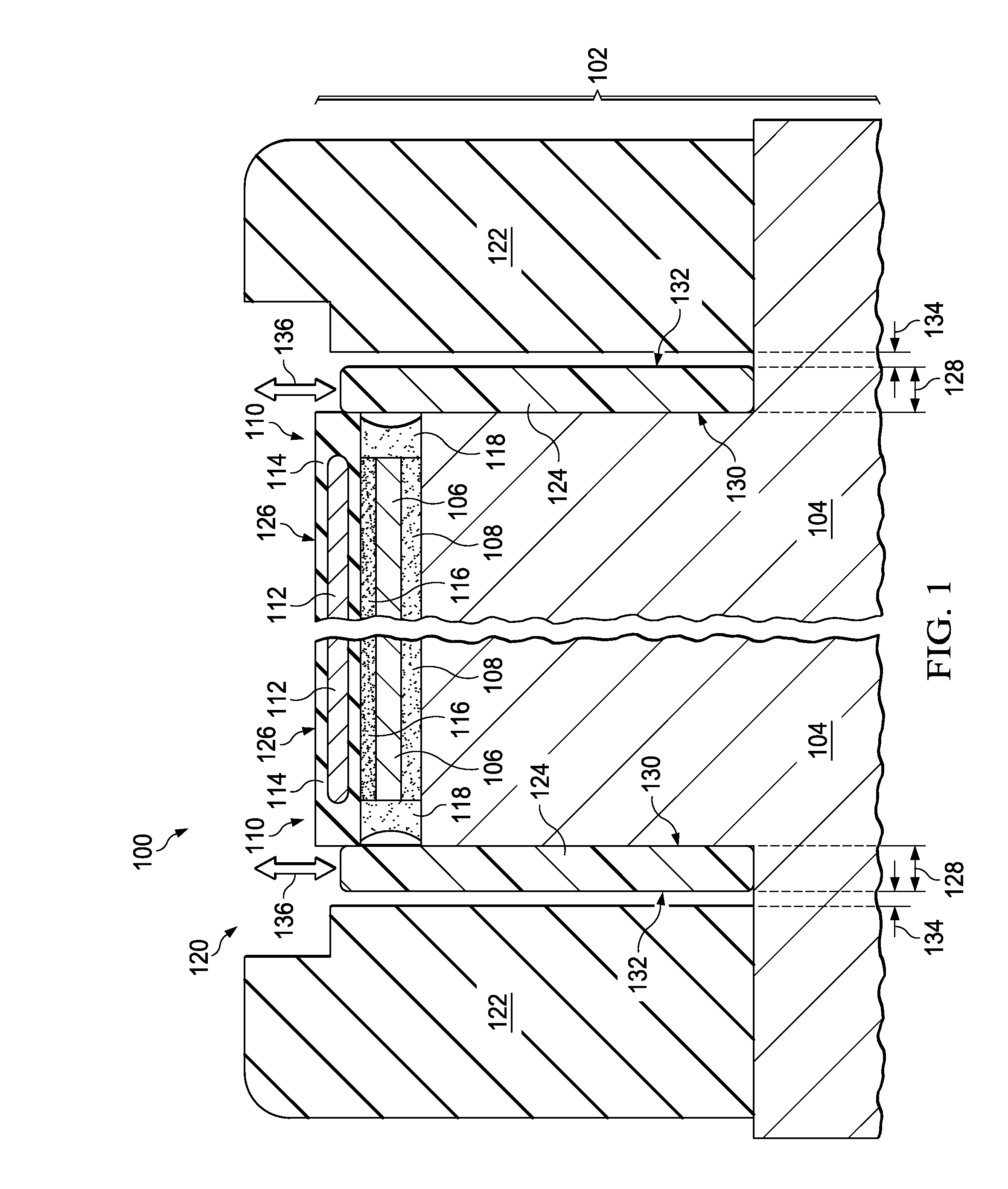

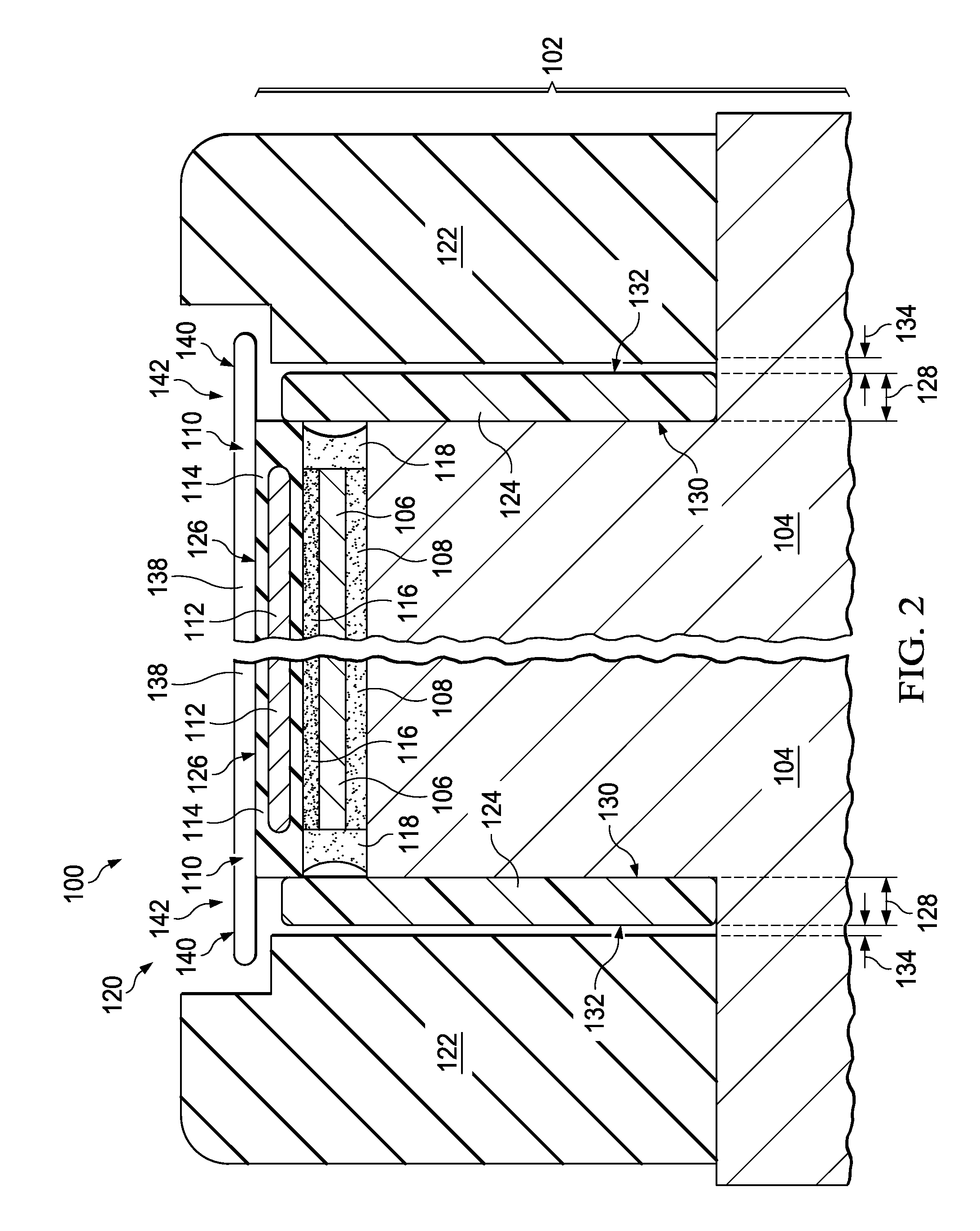

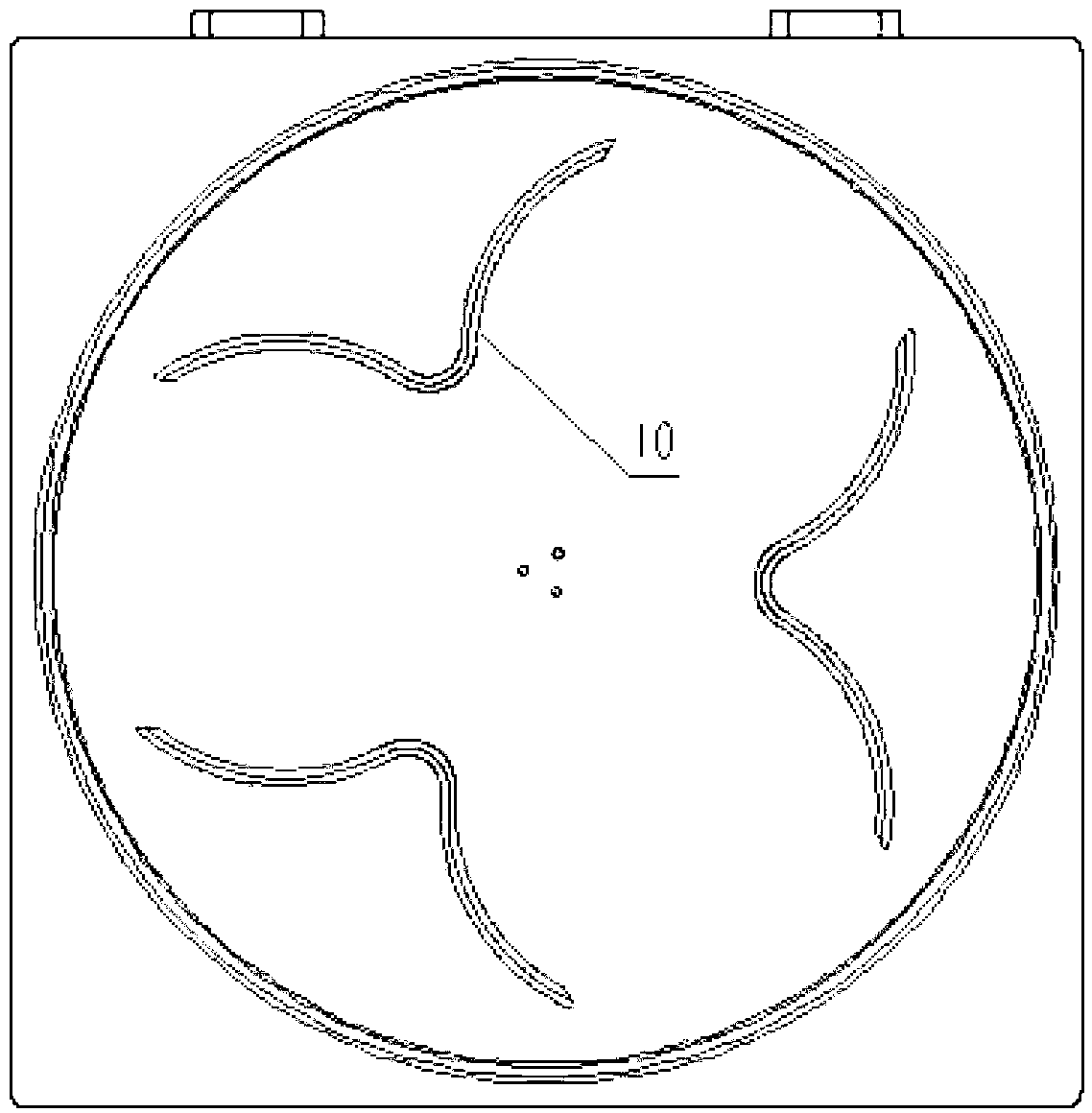

Plasma etcher chuck band

InactiveUS20150024517A1Semiconductor/solid-state device testing/measurementElectric discharge tubesPlasma etcherSemiconductor

A plasma etch tool includes a wafer chuck with a chuck base and at least one functional component layer attached to the chuck base. A perimeter of the functional component layer has a polymer material permanently attached to it that extends to within 2 millimeters of a top surface of the chuck. The top surface of the wafer chuck contacts a bottom surface of a semiconductor wafer during an etch process for forming an integrated circuit. The polymer material is protected from an etch ambient by a plasma etcher chuck band installed around the perimeter of the functional component layer, extending over a portion of the chuck base. An integrated circuit may be formed by installing the plasma etcher chuck band on the chuck of the plasma etch tool, and subsequently performing an etch process in the plasma etch tool on a semiconductor wafer containing the partially formed integrated circuit.

Owner:TEXAS INSTR INC

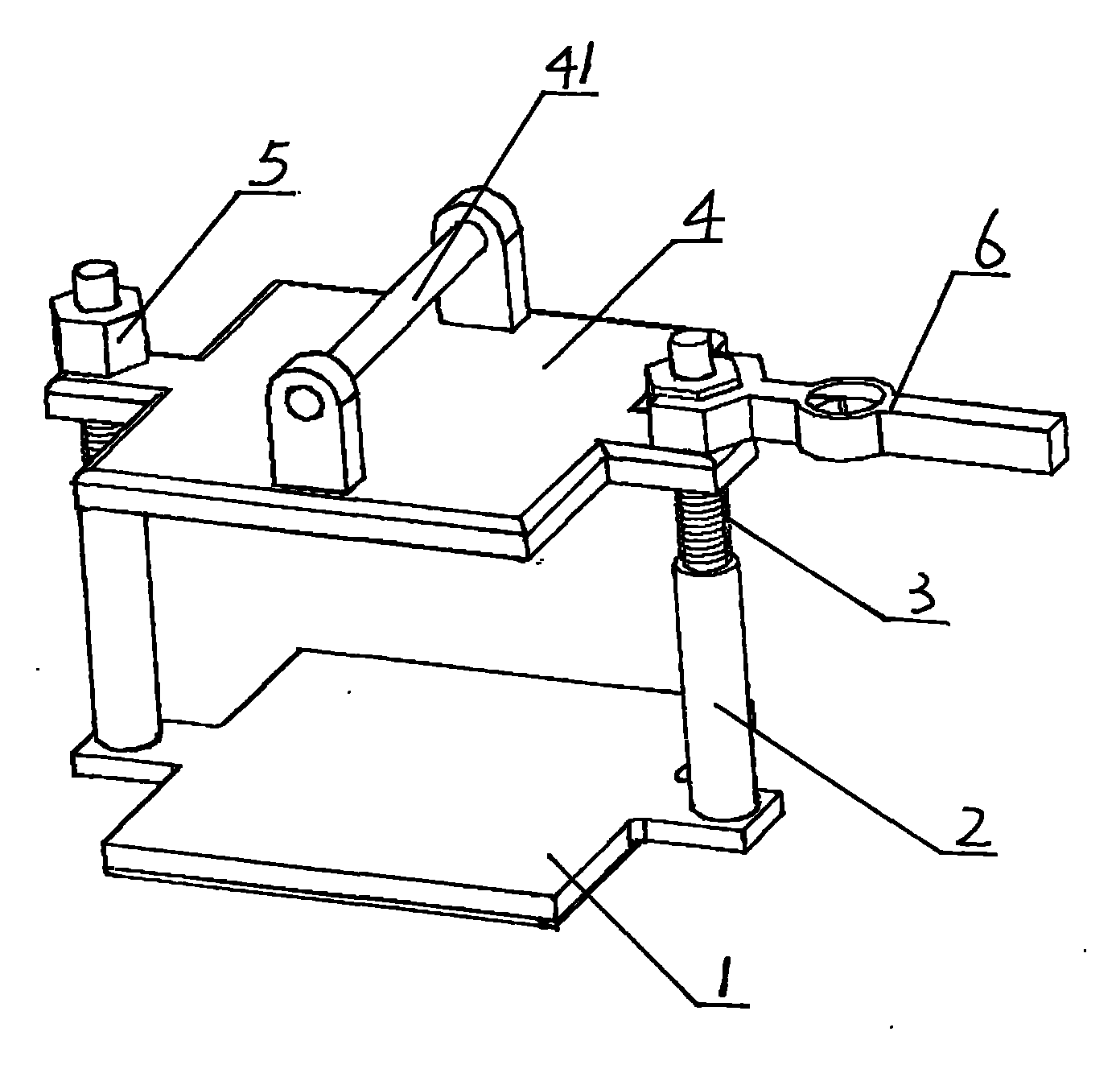

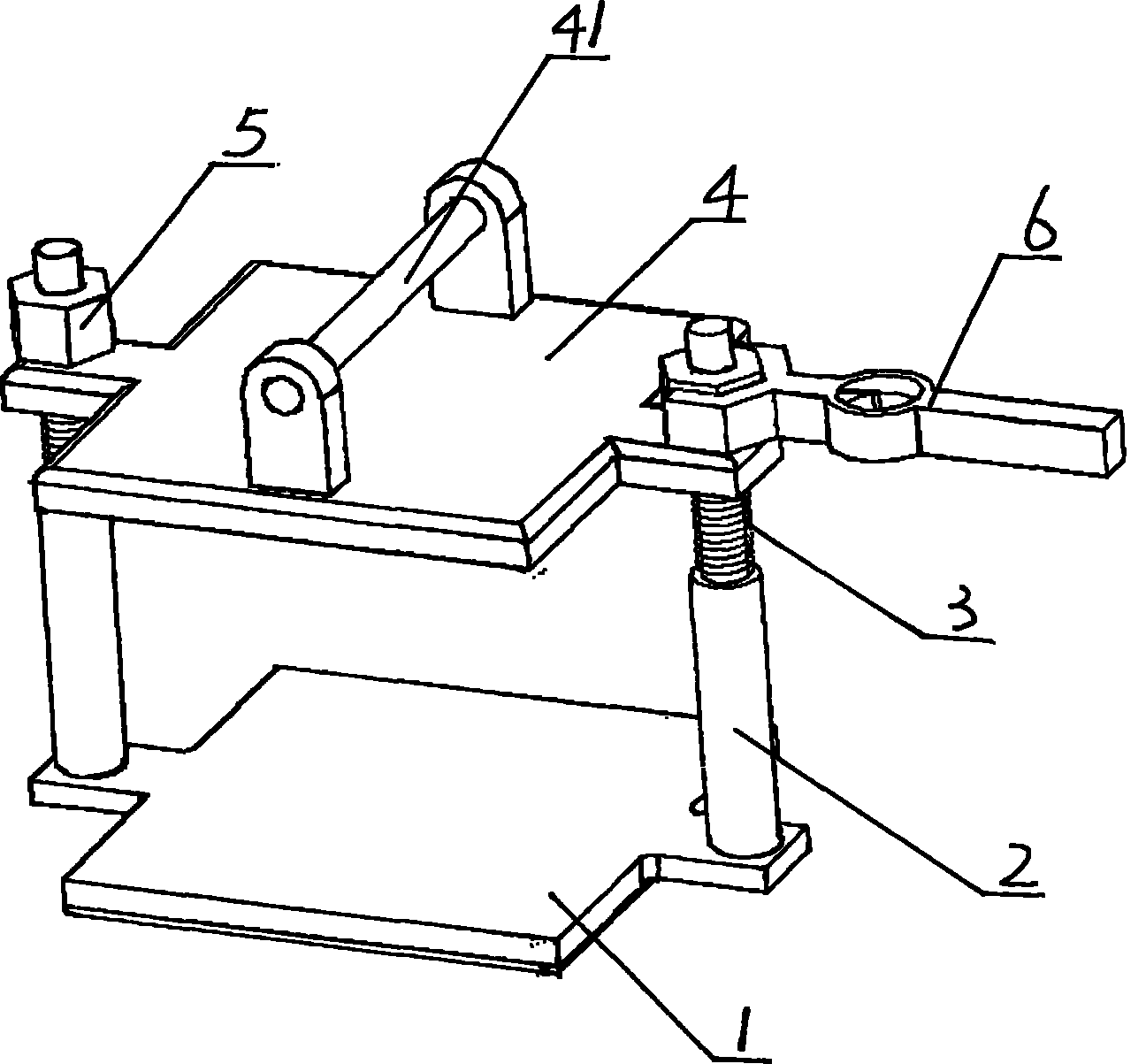

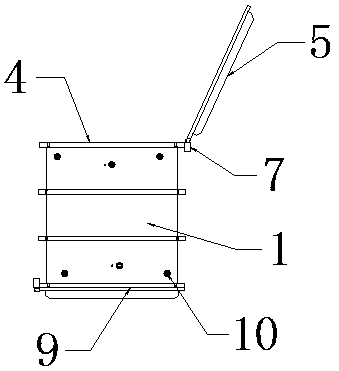

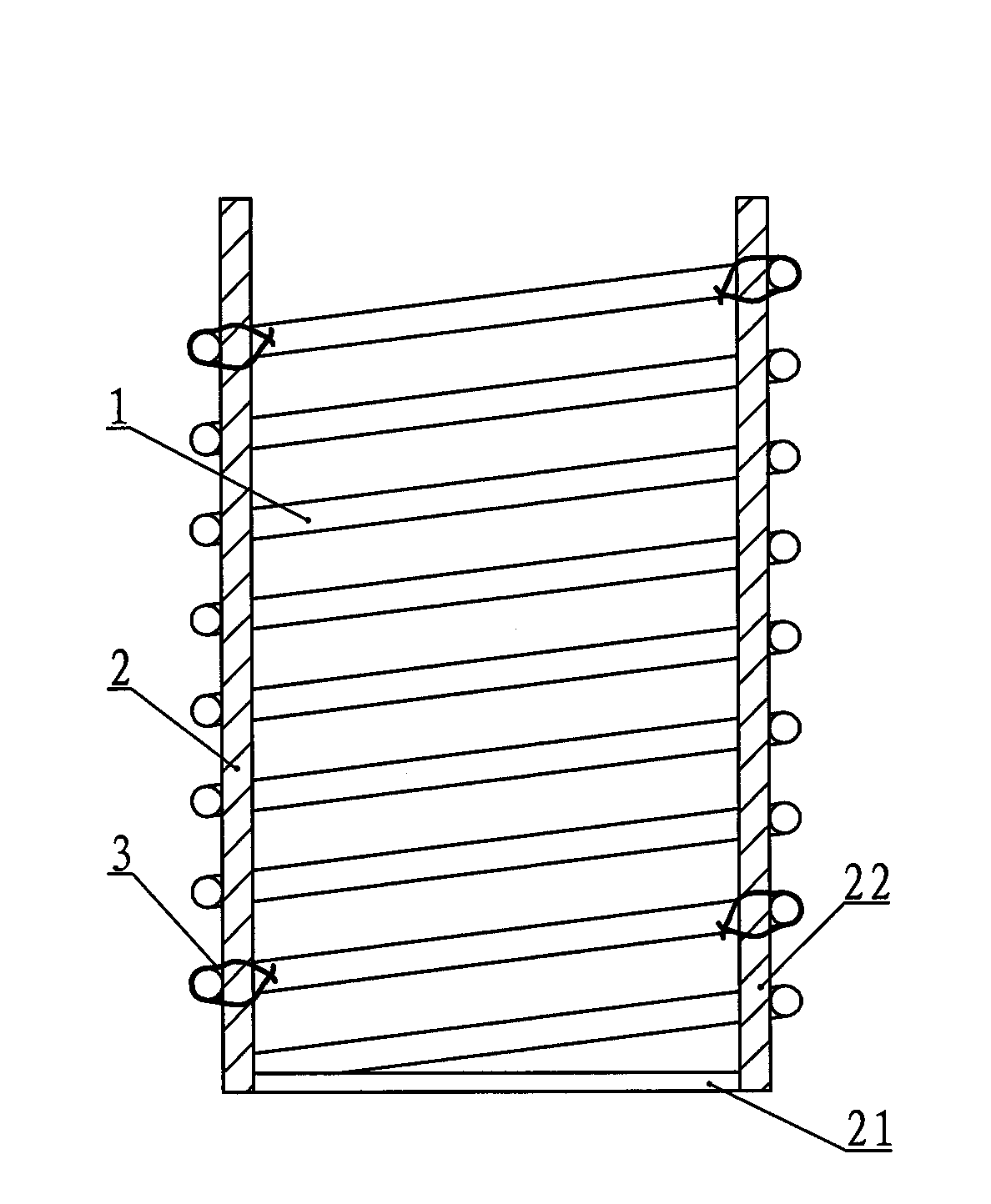

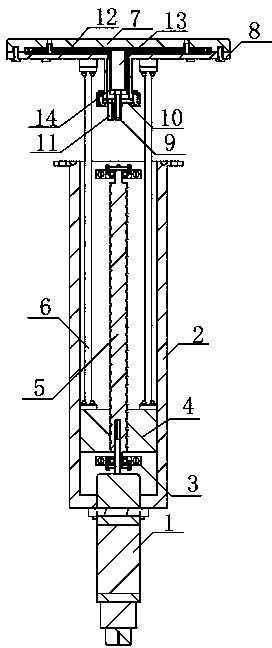

Silicon wafer pressure setting and applying clamp for plasma etcher

InactiveCN102082064AAchieving constant pressurePrecise pressure controlElectric discharge tubesFinal product manufactureNumerical controlEngineering

The invention relates to a silicon wafer pressure setting and applying clamp for a plasma etcher, which comprises a clamp body, upright post screws, reset springs, pressing plates, tightening nuts and a numerical control torque wrench. The lower ends of the two upright post screws are fixed on the clamp body. The upper segments of the two upright post screws are provided with screw threads. The reset springs are sleeved on the upper segments of the upright post screws. The pressing plates are sleeved on the two upright post screws and are tightened by the tightening nuts. The tightening nuts are tightened by the numerical control torque wrench in a torque fixing mode. The whole stack of silicon wafers are arranged between the clamp body and the pressing plate and the pressing plate is tightened by the numerical control torque wrench through the two tightening nuts in a torque fixing mode, so that the pressure is set and applied to the whole stack of silicon wafers through the pressing plate. Therefore, the pressure of the whole stack of silicon wafers can be accurately controlled, nonuniform stress around the silicon wafers can be reduced, the products have consistent performance, and the etching effect is good.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

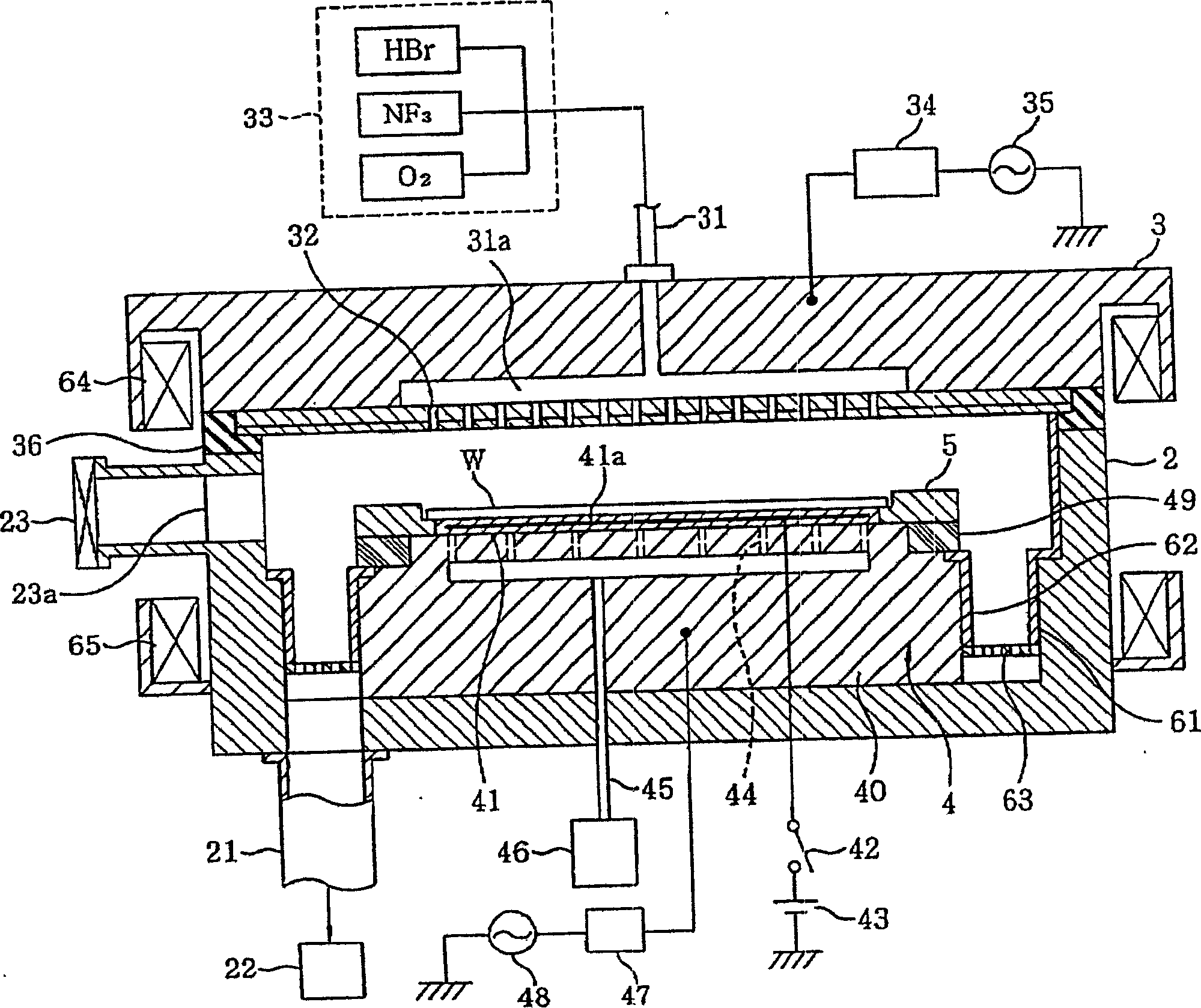

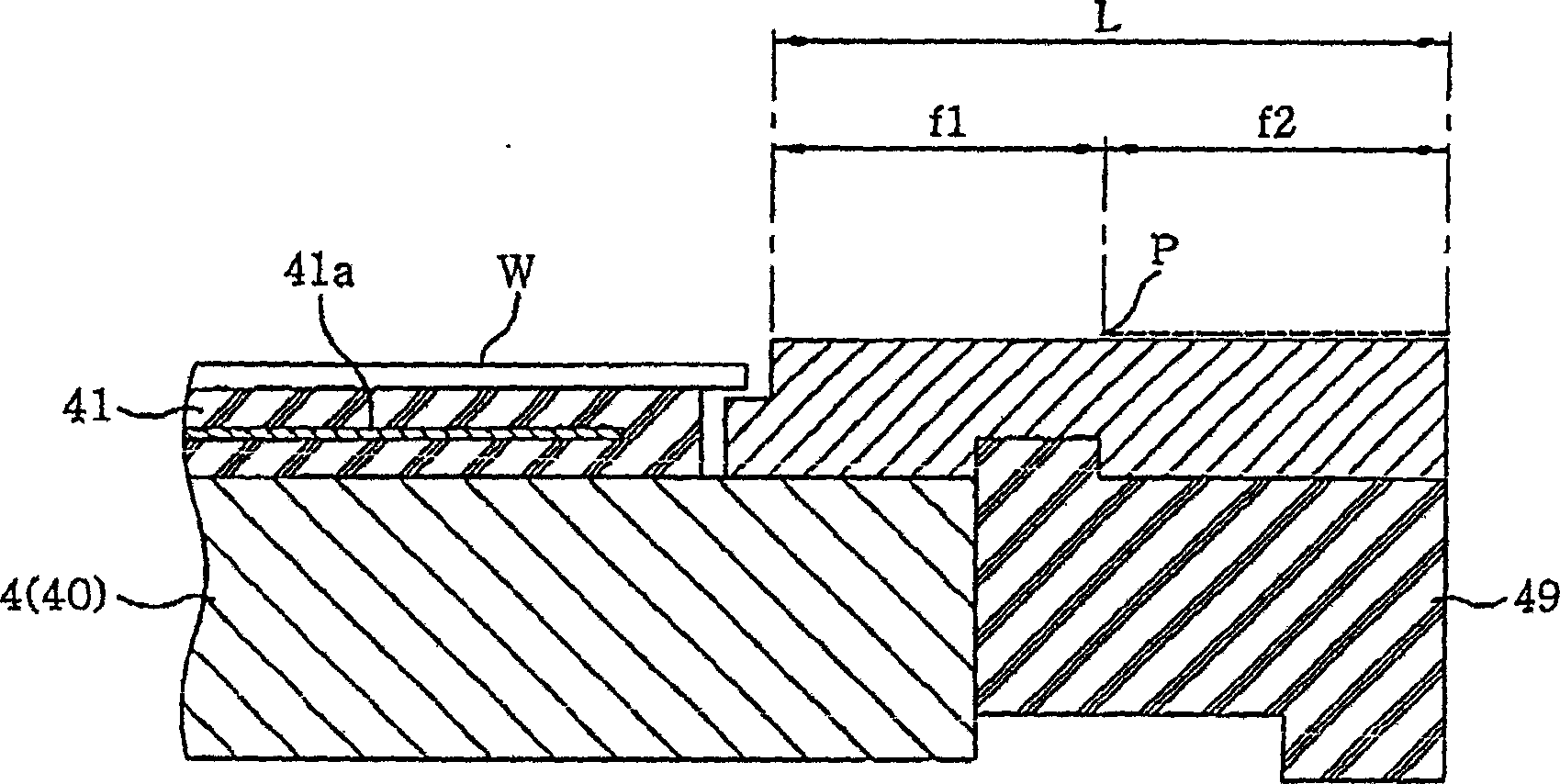

Focus ring, plasma etching apparatus and plasma etching method

InactiveCN1776889AAvoid accumulationPollution suppressionElectric discharge tubesSemiconductor/solid-state device manufacturingSurface roughnessPlasma etcher

PROBLEM TO BE SOLVED: To suppress the adhesion of a reaction product at a semiconductor wafer periphery for forming trenches by etching e.g., a silicon layer with plasma to suppress the reduction of an etching rate. SOLUTION: An inner region on the surface of a focus ring is finish-worked at mean surface roughness Ra in e.g., 0.1 or less as fine as suppressing the adhesion of a reaction product in an etching process, and an outer region is finish-worked at mean surface roughness Ra e.g., 3.2 or less. The boundary between the inner and outer regions is taken as a portion where the level of consumption changes when the focus ring is incorporated in a plasma etcher to etch a substrate with plasma. COPYRIGHT: (C)2006,JPO&NCIPI

Owner:TOKYO ELECTRON LTD

Enhanced plasma etch process

InactiveUS7181306B2Reduce unevennessIncreasing flow rate windowElectric discharge tubesVacuum gauge using ionisation effectsHigh rateEngineering

A method of operating a plasma etcher wherein gas is introduced into the etcher at a substantially higher rate than a previous standard rate for a desired etch selectivity, and the throttle valve's open value is set to a substantially greater open value than a previous standard open value for the desired etch selectivity. The method may also include introducing the gas at a lower pressure than the pressure of the previous standard pressure for a desired etch selectivity.

Owner:INTERSIL INC

Inductive coupling plasma etching machine platform and electrode arrangement thereof

InactiveCN1505112AIncrease temperatureVolatileSemiconductor/solid-state device manufacturingPlasma techniqueElectrical conductorDielectric layer

The invention is an induction coupled plasma etching machine platform and its electrode construction, mainly composed of a reaction chamber, an upper electrode and a lower electrode. Wherein, the upper one is set in the reaction chamber and composed of a coil, a first dielectric layer, a second dielectric layer and a heater, the first dielectric layer on the coil, and the second dielectric layer on the first dielectric. The heater is set between the first and second dielectric layers. The lower one is set in the reaction chamber and composed of a conductor electrode and a third dielectric layer set on the conductor electrode. It uses the heater to raise the temperature in the reaction chamber to make easily volatile resultant of etching.

Owner:AU OPTRONICS CORP

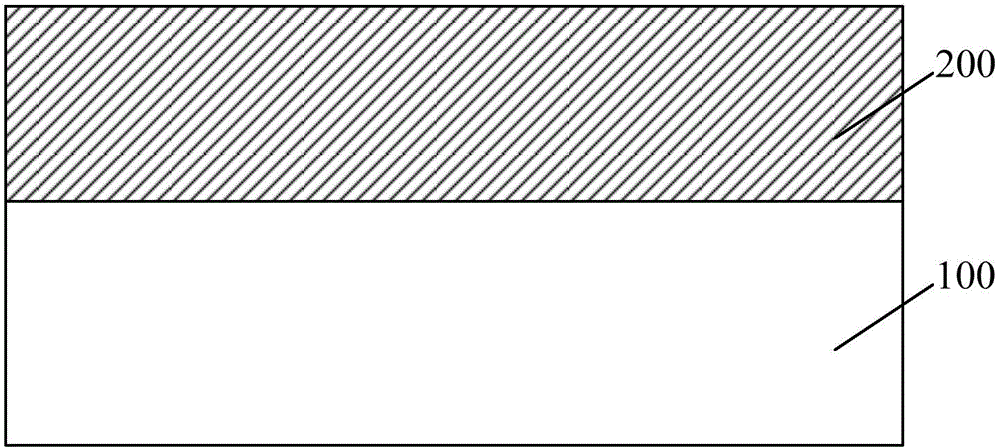

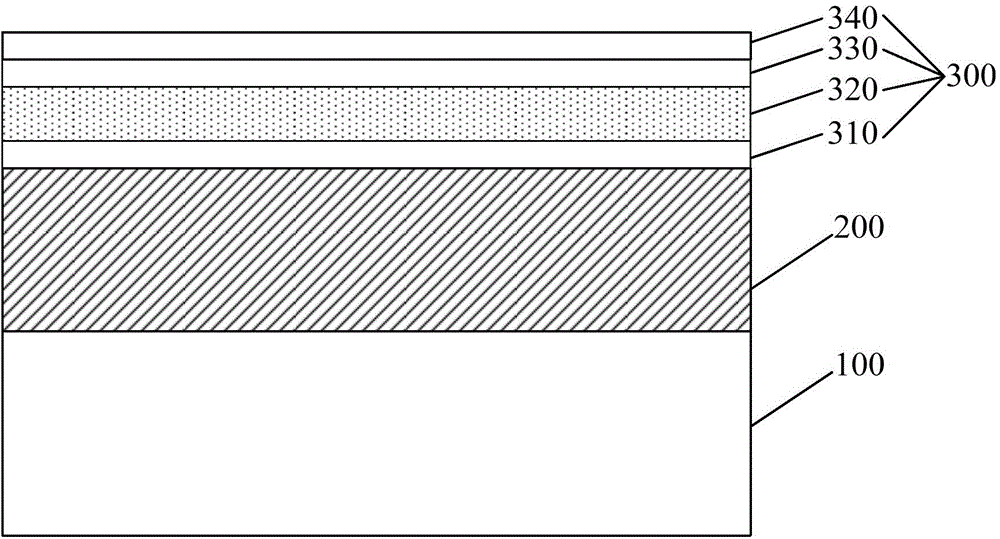

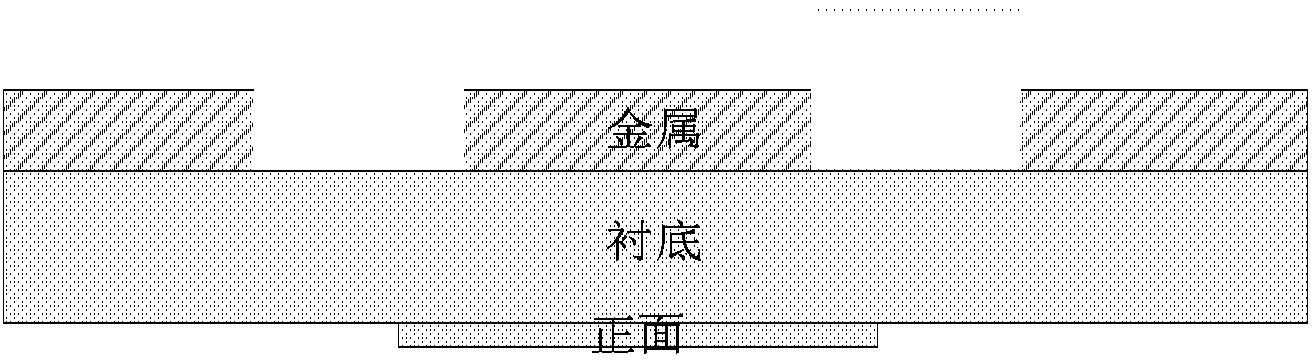

Grid electrode formation method and transistor formation method

ActiveCN104979175AReduce the degree of impactReduce lossSemiconductor/solid-state device manufacturingSemiconductor devicesElectron temperaturePlasma etcher

The invention provides a grid electrode formation method and a transistor formation method. The grid electrode formation method comprises steps of providing a substrate; forming a material layer of a grid electrode on the substrate; and performing plasma etching on the material layer of the grid electrode using a plasma etcher, so as to form the grid electrode, wherein the plasma etching comprises a step of enabling the plasma etcher to output pulse-type power so as to perform pulse etching on the material layer of the grid electrode. The invention also provides the transistor formation method. The transistor formation method comprises a step of forming the grid electrode of a transistor using the abovementioned method. The invention has the beneficial effects that etching in the etching mode can achieve a discontinuous etching effect, so that the electron temperature of plasma can be lowered to a certain degree during etching interruption, reduction in the electron temperature of plasma is facilitated, the influence on the substrate is further reduced, that is to say, loss of the substrate is reduced when the grid electrode is formed by etching, and recesses are prevented from being formed in the substrate.

Owner:SEMICON MFG INT (SHANGHAI) CORP

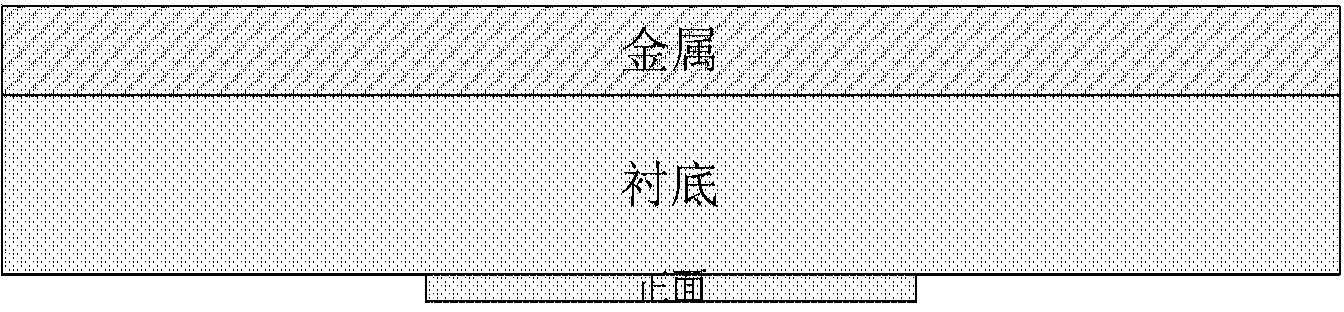

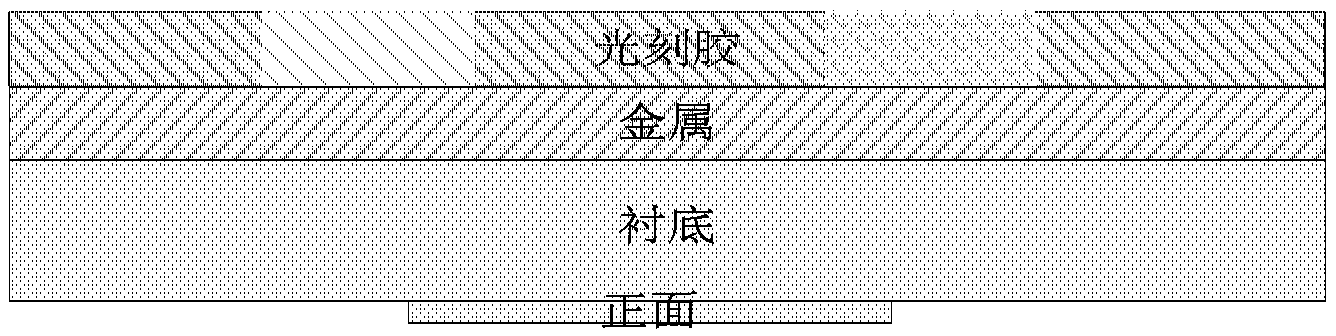

Method for reducing plasma etcher cavity pollution in back hole process

ActiveCN103730348AAchieve cleaningReduce the difficulty of cleaningElectric discharge tubesSemiconductor/solid-state device manufacturingPhotoresistPlasma etcher

The invention discloses a method for reducing plasma etcher cavity pollution in a back hole process. The method comprises the steps of sputtering or evaporating a metal mask layer on the back of a SiC substrate; enabling the metal mask layer to be coated with photoresist, and drying the photoresist; performing photoetching on the photoresist to form a photoresist pattern; utilizing the formed photoresist pattern to corrode the metal mask layer, and forming a metal mask graph; performing plasma bombardment on the back of the SiC substrate of the formed metal mask graph in a plasma etcher, sputtering the photoresist on the metal mask layer to an inner wall of a cavity of the plasma etcher, and forming a photoetching layer on the inner wall of the cavity of the plasma etcher; utilizing the formed metal mask graph to etch the SiC back in the plasma etcher, and forming a back hole until the back hole is communicated with SiC front source metal. By utilizing the method, the pollution to the inner wall of the plasma etcher cavity caused by a metal mask in the back hole process is reduced, and using efficiency of the plasma etcher is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

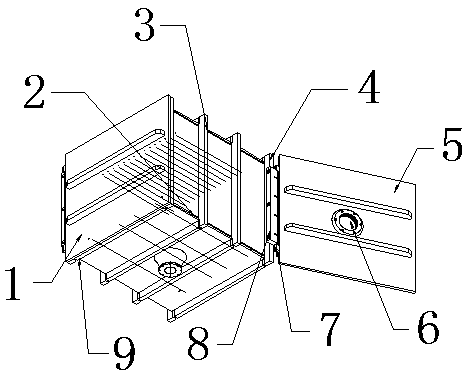

A reaction chamber cavity based on an aerodynamic configuration of a plasma etcher

InactiveCN108987236AEvenly distributedEasy to installElectric discharge tubesEngineeringPlasma etcher

The invention discloses a reaction chamber cavity based on the pneumatic configuration of a plasma etching machine. The cavityinclude a cavity, a mounting baseand a chamber door, A first mounting plate and a second mounting plate are respectively arranged at one end of both sides of the cavity, the two ends of the second mounting plate and the two ends of the first mounting plate are respectivelyrotatably connected with the two sides of one end of the cavity door through rotary joints, both chambers have viewing windows in the middle, according to the invention, the processing gas of the device is diverted once through the cloth pipe, uniformly distribute in the lower groove and the two sides of the product, the by-product of the reaction product and the non-ionized gas are diverted for the second time through the side plate of the rectangular box on the bottom surface of the cavity, and then are diverted for the third time through the diameter-changing pipe on the outside of the bottom surface of the cavity. The aerodynamic configuration can effectively ensure that the process gas is uniformly distributed in each tank and on both sides of the processed product, so that the gas flow and ions in the reaction chamber are stably exchanged, and the reaction is stable, uniform and free of plain flow.

Owner:珠海安普特科技有限公司

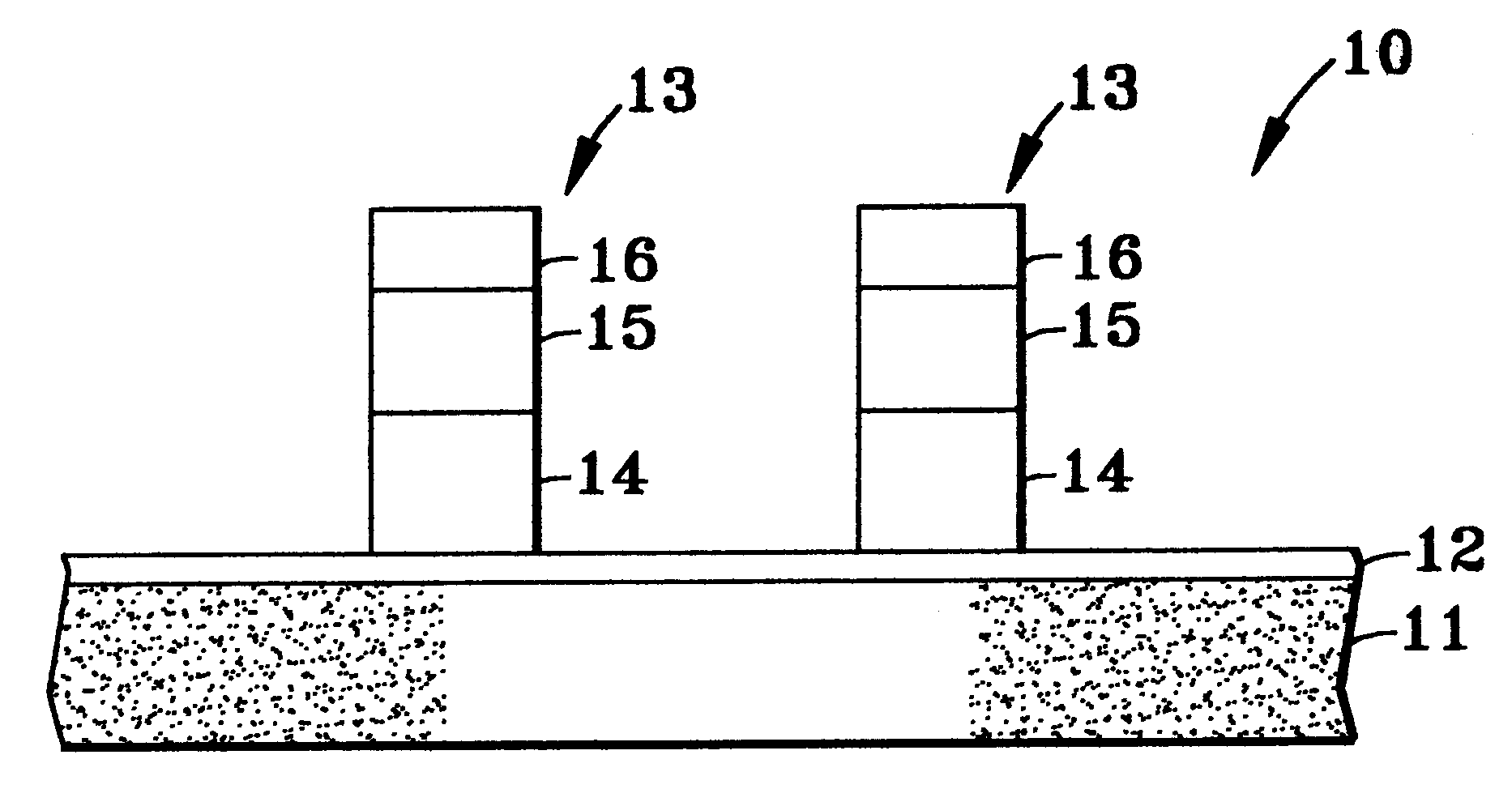

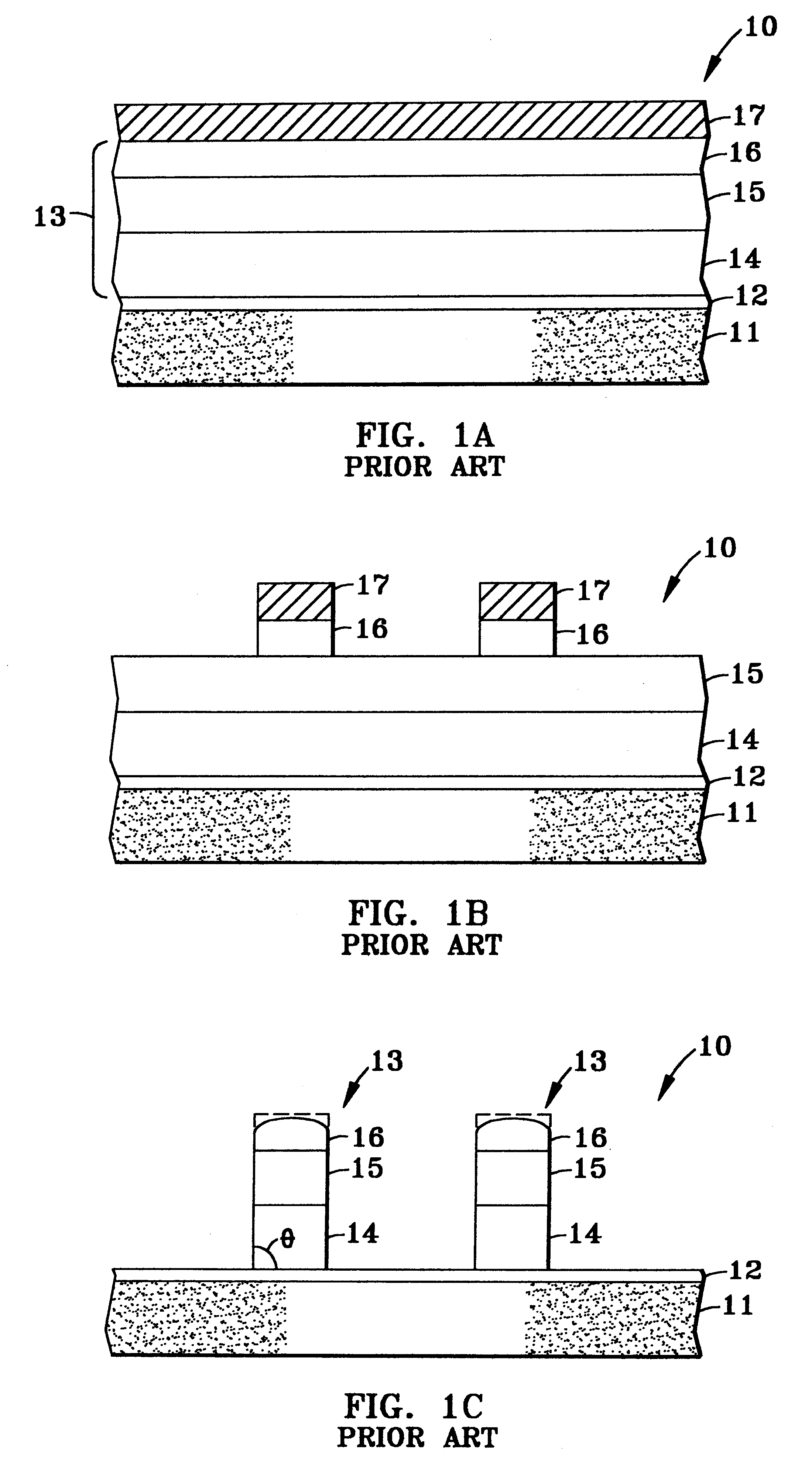

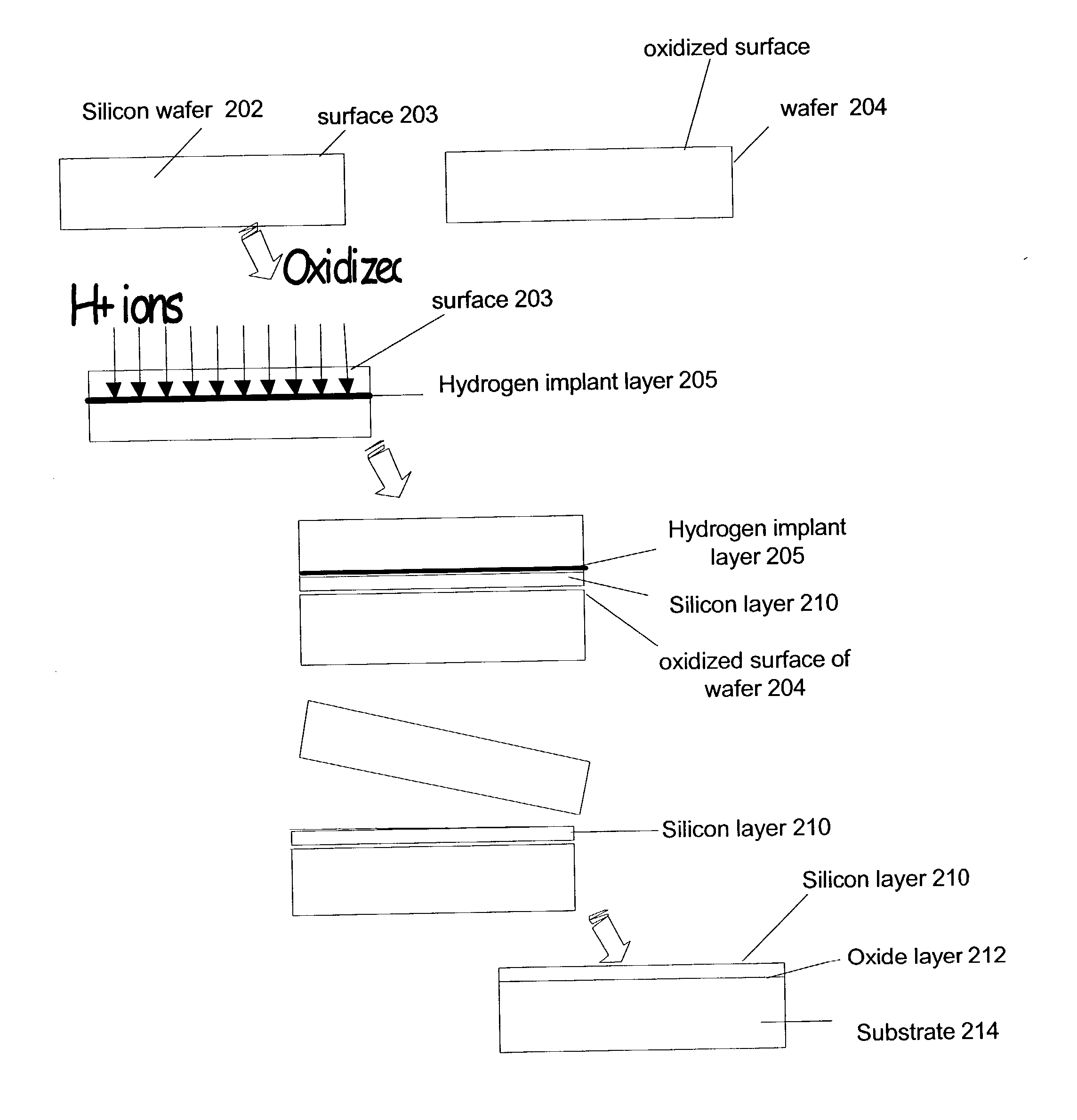

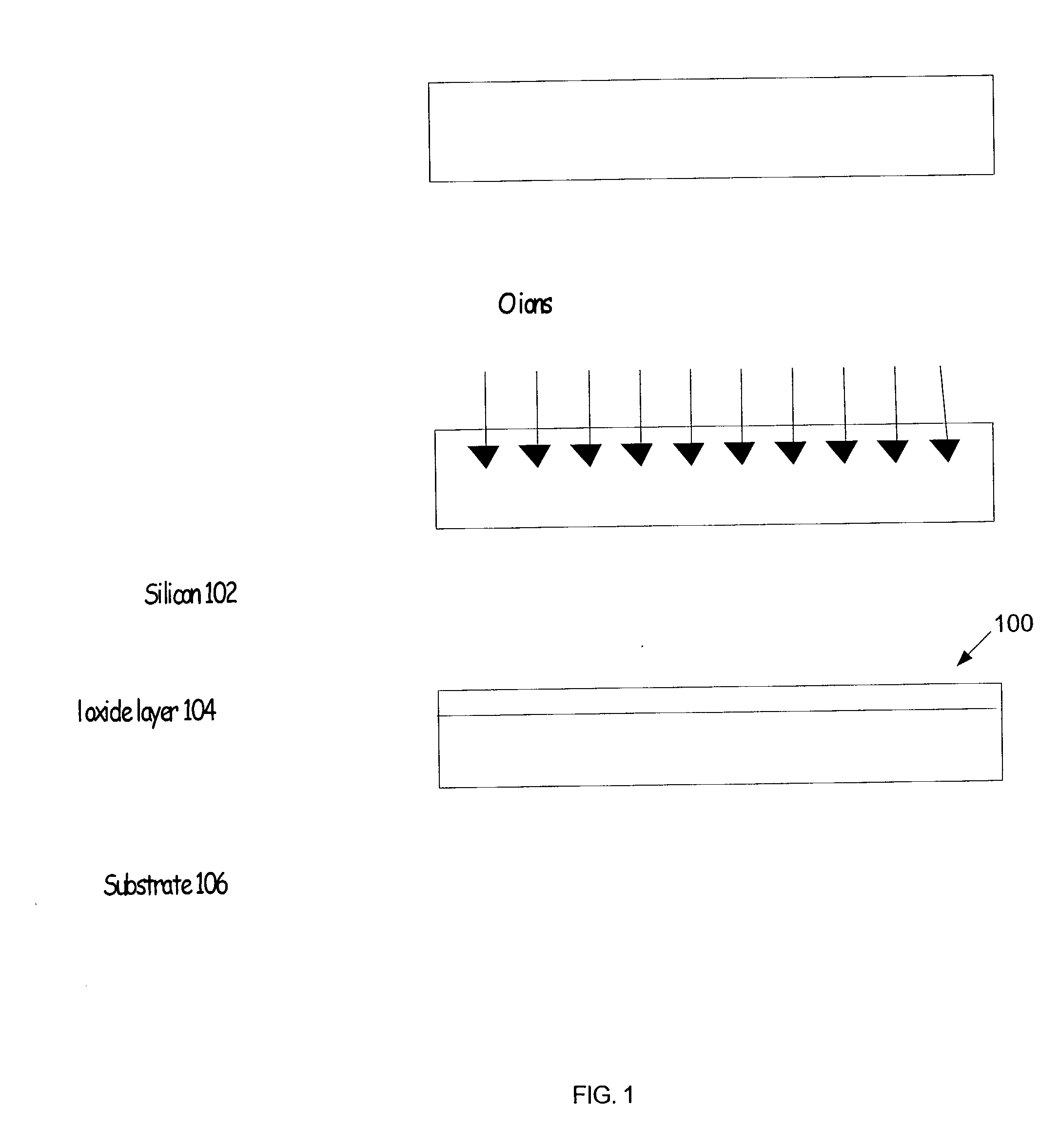

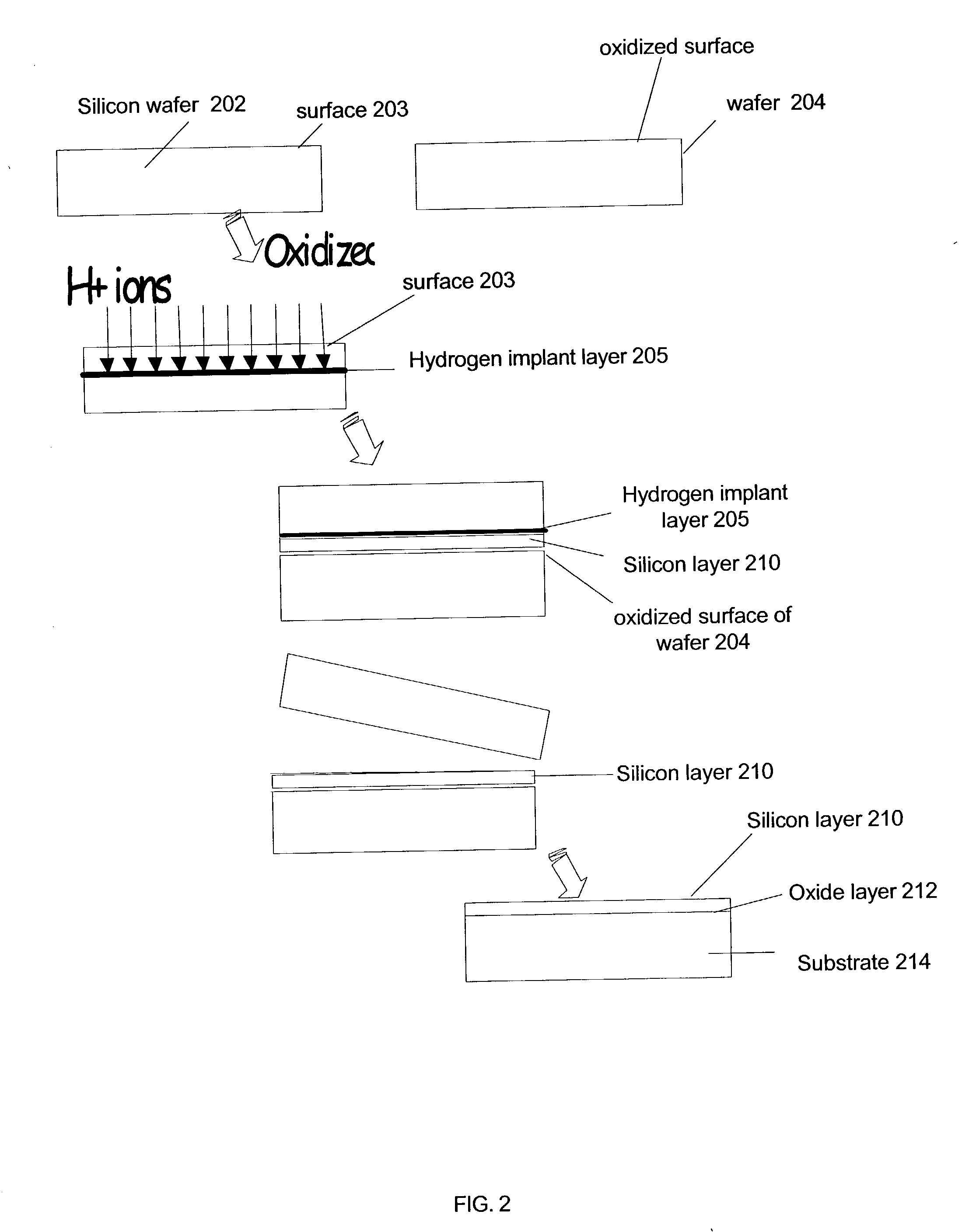

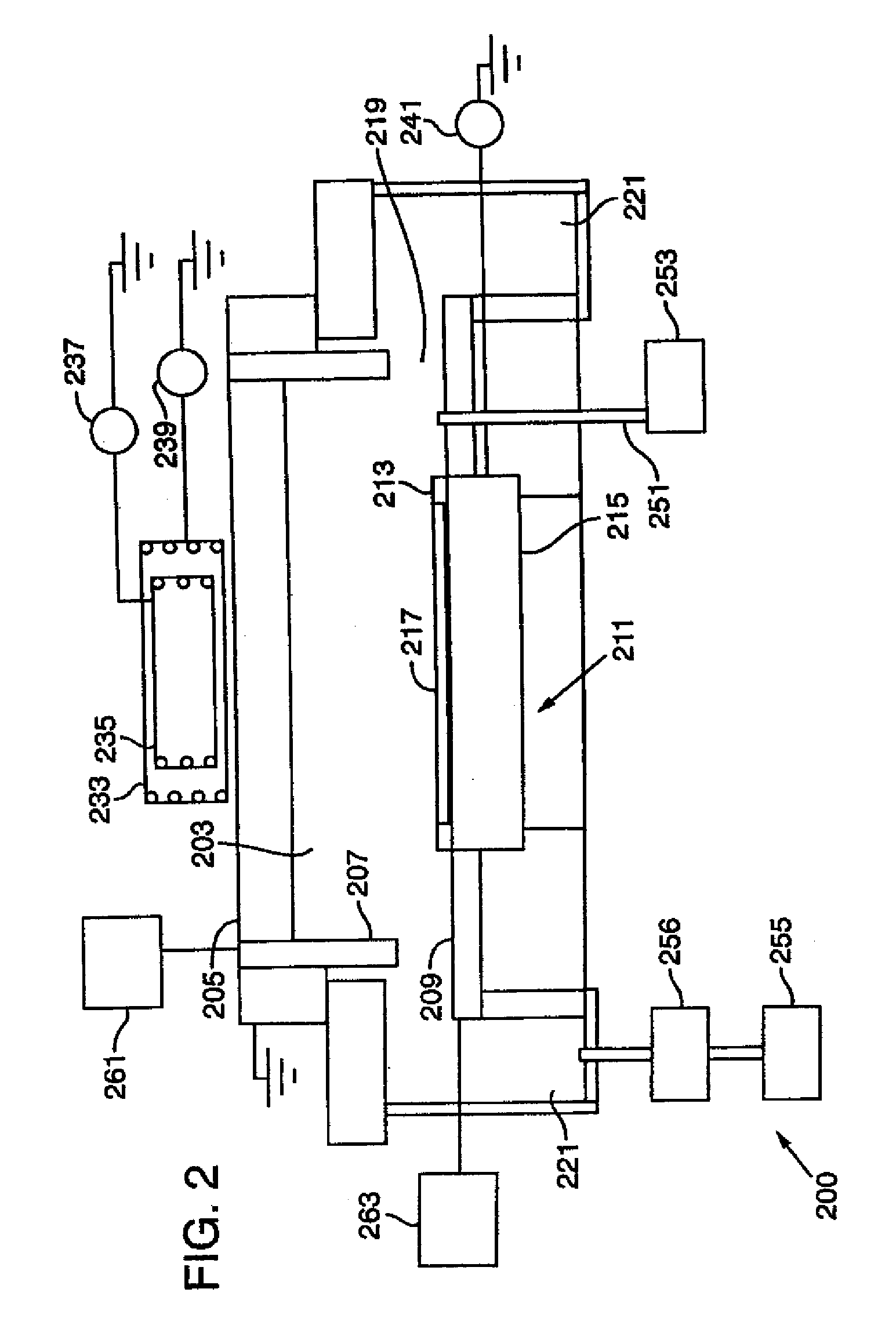

Silicon-on-insulator devices and methods for fabricating the same

InactiveUS20040110314A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEtchingMetrology

Techniques for local and selective thinning of silicon using a combination of real time metrology for film thickness measurement accompanied by local etching of the silicon to thin the silicon to the desired value. Etching is accomplished using a miniature plasma etcher with activated etch gases. The etch tool and the metrology tool are stepped across the wafer surface to achieve wafer level thinning of the top silicon.

Owner:INTEL CORP

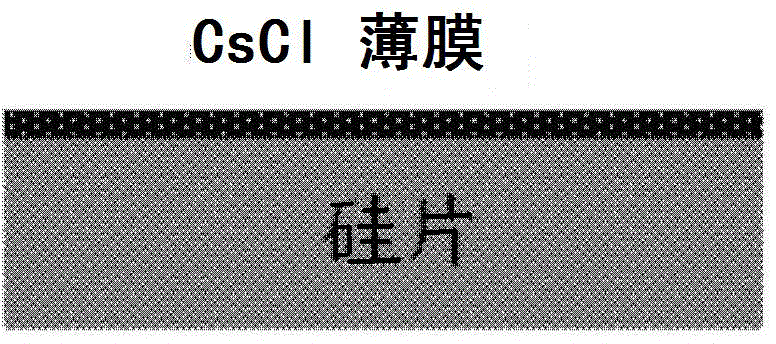

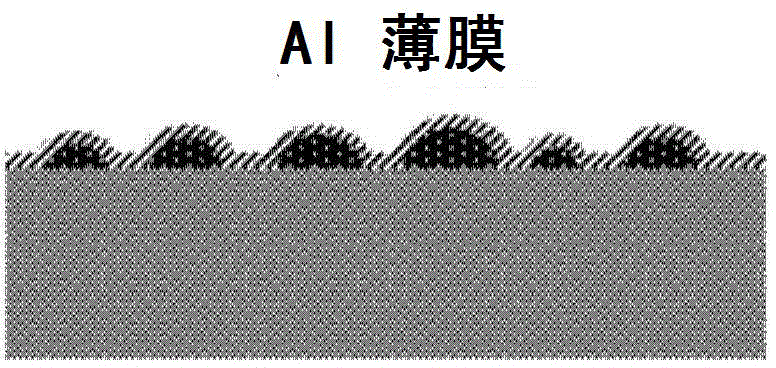

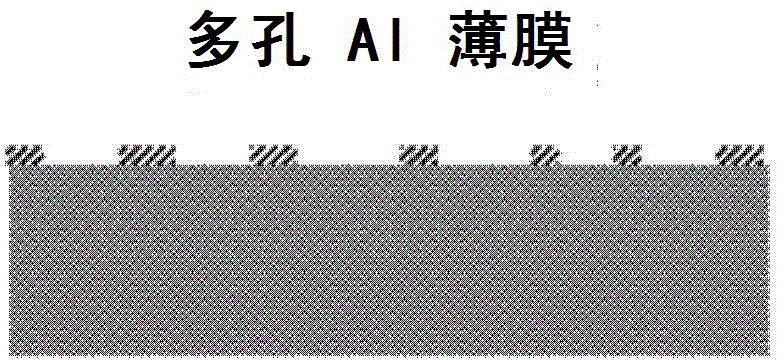

Preparation method of nanoporous structures on surfaces of silicon wafers

InactiveCN104528631ADecorative surface effectsChemical vapor deposition coatingChlorideAluminum metal

The invention discloses a preparation method of nanoporous structures on surfaces of silicon wafers. The method comprises the following steps: preparing cesium chloride island structures on the surfaces of the silicon wafers; plating aluminum metal films on the surfaces of the silicon wafers with the cesium chloride island structures in a vacuum manner, putting the silicon wafers into deionized water to ultrasonically peel, removing the cesium chloride island structures and the aluminum metal films on the silicon wafers to obtain porous aluminum films; deeply etching the surfaces of the silicon wafers in an etching cavity of a plasma etcher by taking the porous aluminum films as masks; and removing the porous aluminum films on the surfaces of the silicon wafers to obtain the nanoporous structures on the surfaces of the silicon wafers. The nanoporous structures on the surfaces of the silicon wafers prepared by the method are distributed on the surfaces of the silicon wafers in unordered positions; the nanoporous structures are different in sizes and similar in depth, and has Gaussian distribution of diameters and unsmooth side walls.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

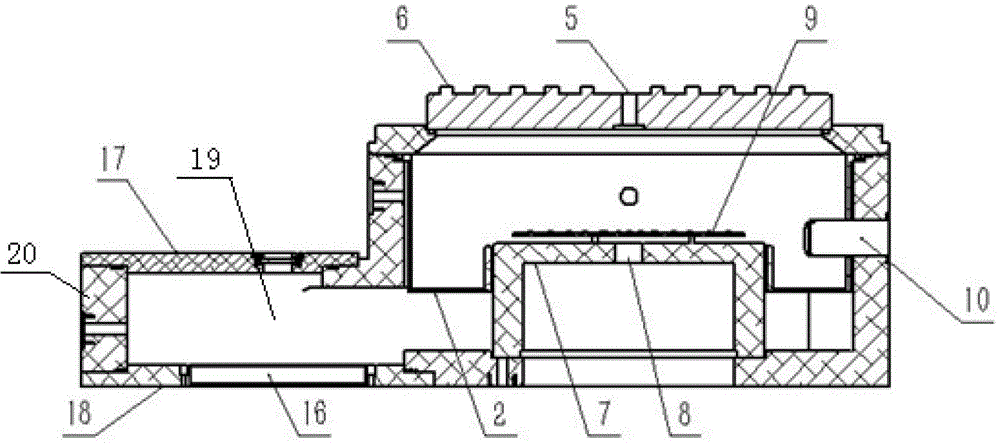

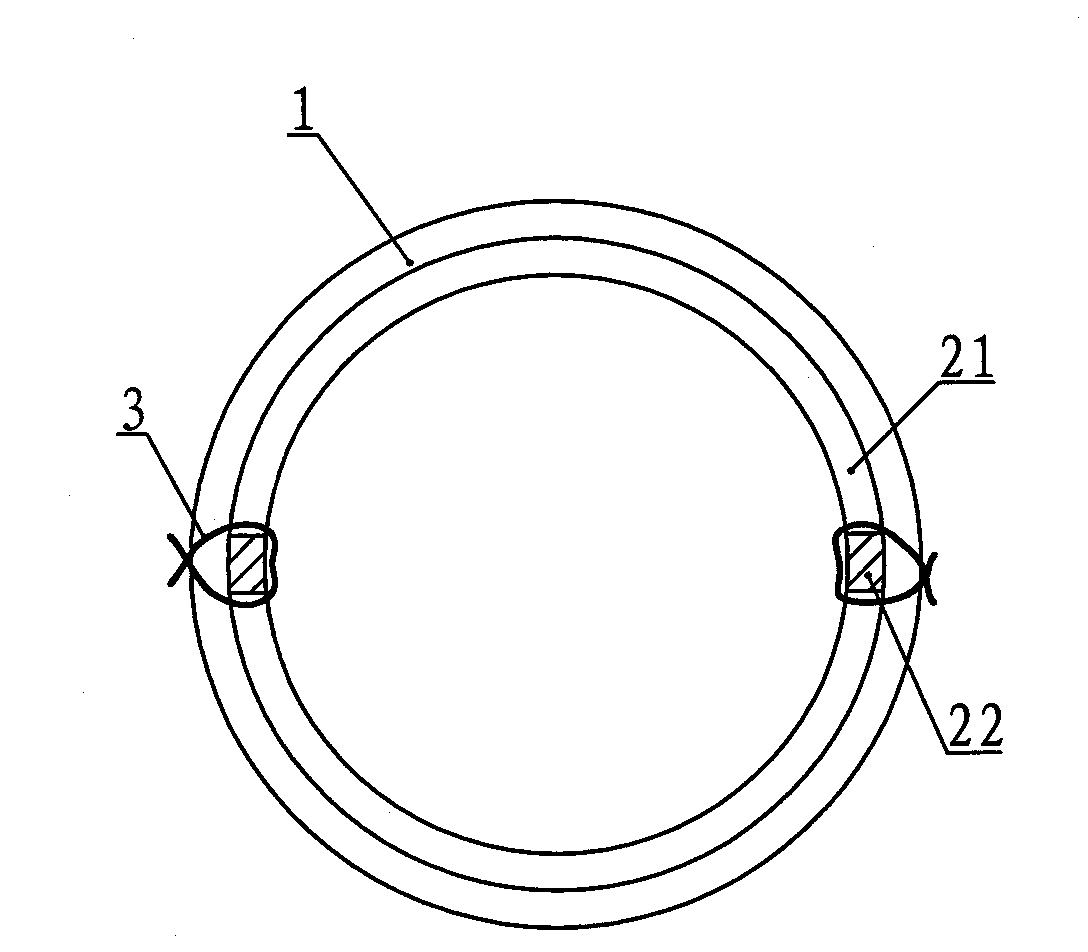

Reaction chamber of dry plasma etcher

InactiveCN103337444AReduce in quantityImprove sealingElectric discharge tubesEngineeringPlasma etcher

A reaction chamber of a dry plasma etcher comprises a cylindrical reaction chamber and an upper cover covering the cylindrical reaction chamber, wherein an air inlet hole is formed in the center of the upper cover, the cylindrical reaction chamber is formed by a side wall, a bottom wall and the upper cover, a substrate to be etched is placed in the center of the bottom wall of the reaction chamber, and a substrate picking and delivering port for picking up and delivering the substrate is formed in the reaction chamber; a uniform-flow inner lining matched with the reaction chamber is arranged in the reaction chamber and comprises a cylindrical main body, a transmission hole corresponding to the substrate picking and delivering port is formed in the main body, a circle of ring-shaped baseplate extending inwards is arranged at the bottom of the main body and corresponds to the substrate to be etched in position, and uniform-flow slotted holes are uniformly distributed in the ring-shaped baseplate; a mounting flange connected with the reaction chamber is arranged at the top of the main body and a sealing groove is formed between the mounting flange and the reaction chamber. The reaction chamber has the advantages of clean cavity, little pollution, good atmosphere and uniformity in the chamber and long service life.

Owner:TDG MACHINERY TECH

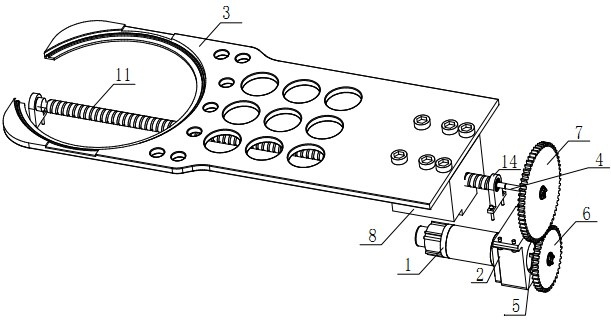

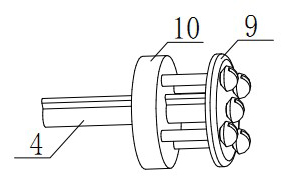

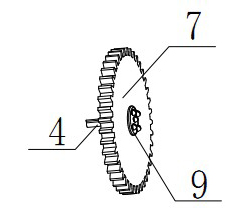

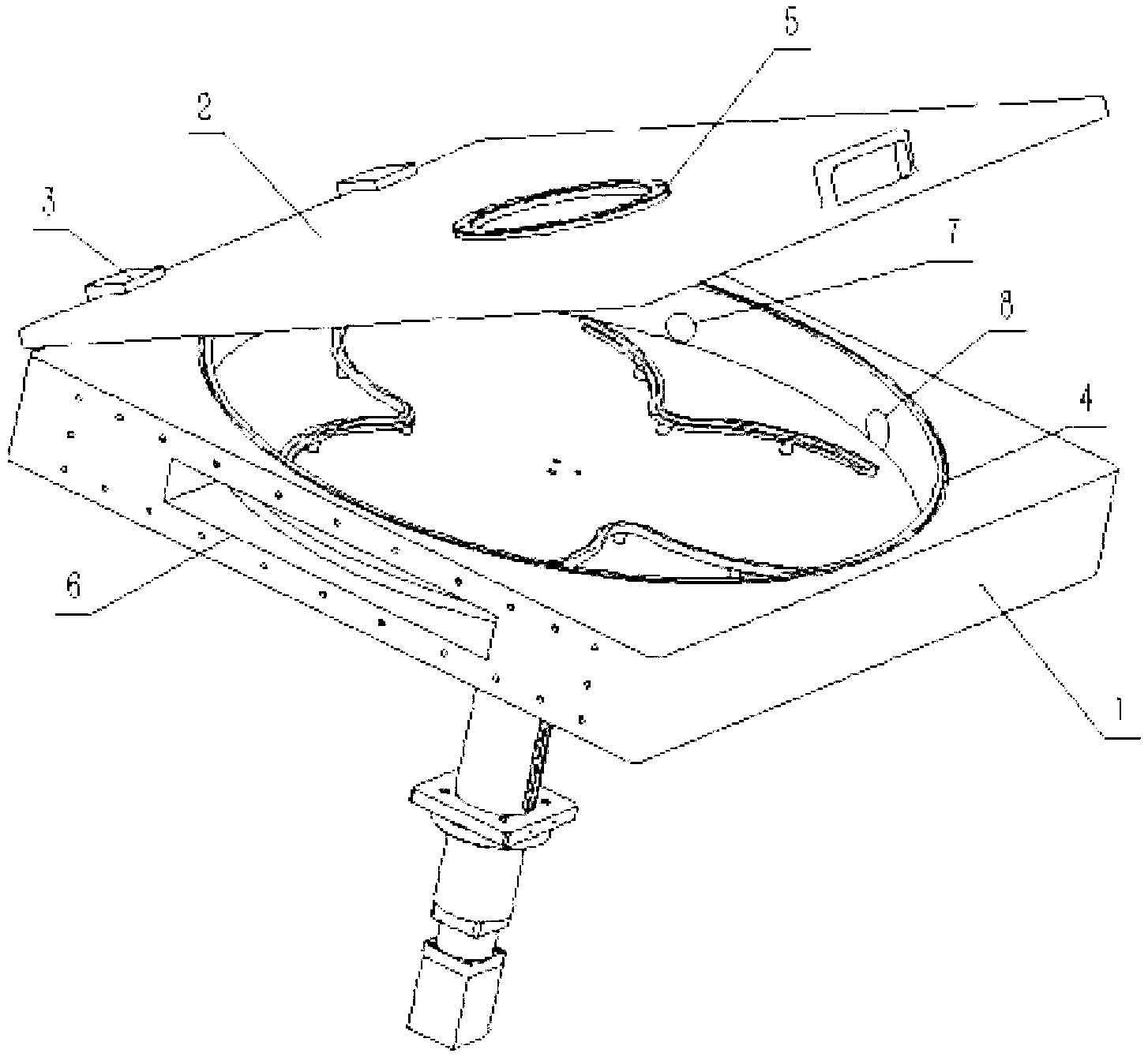

Chip transporting system of plasma etcher for carrying out dry etching on inorganic material substrate

InactiveCN102368474AChange direction of movementImprove reliabilityProgramme-controlled manipulatorElectric discharge tubesTransport systemEngineering

The invention relates to a chip transporting system of a plasma etcher for carrying out dry etching on an inorganic material substrate, which is arranged in a forevacuum cavity and comprises a manipulator for transporting a chip dish. The manipulator is fixedly connected onto a screw nut for driving the manipulator to move. The screw nut is arranged on a screw. The screw is connected with a servo motor through a gear pair. The gear pair comprises a main gear connected with a rotor of the servo motor and a pinion connected with a rotor of the screw. The main gear is in meshed connection with the pinion. The chip transporting system has the beneficial effects of high chip transporting efficiency, high reliability and simple and reasonable structure.

Owner:JIAXING KEMIN ELECTRONICS EQUIP TECH

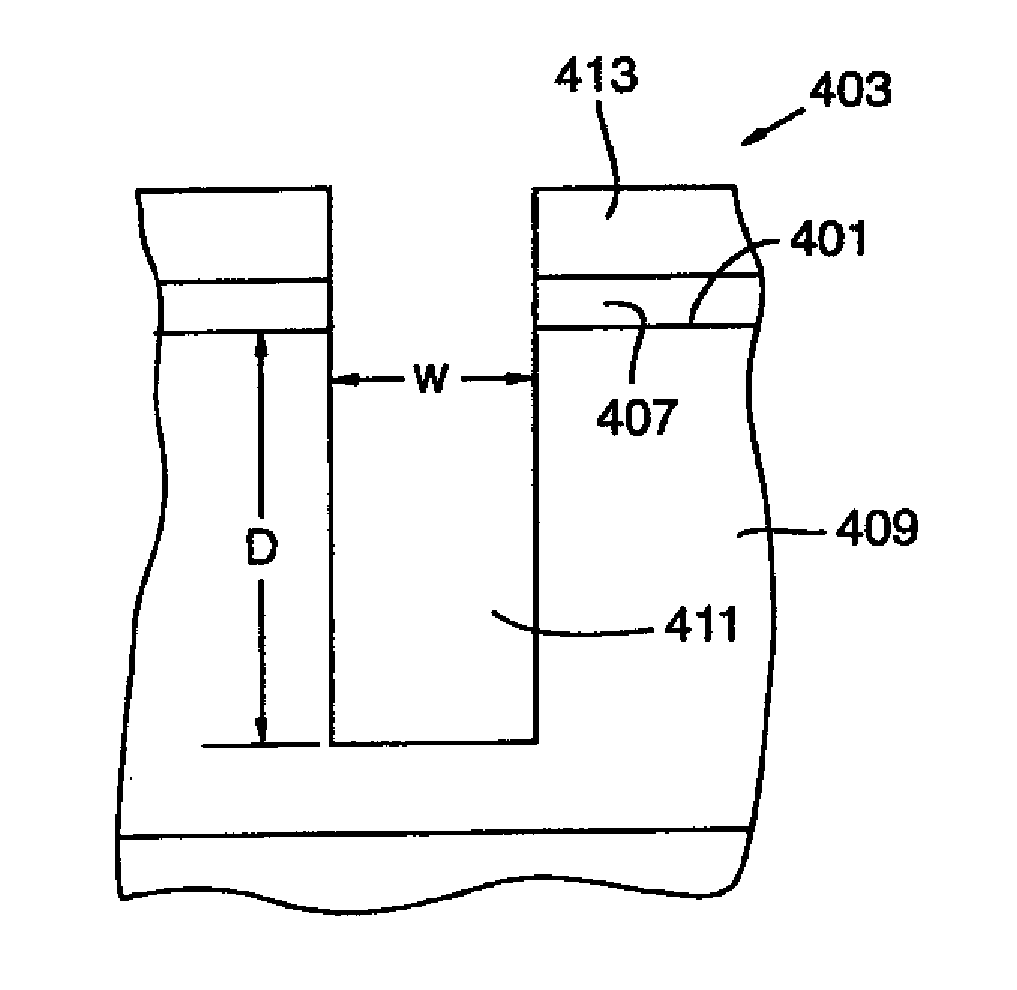

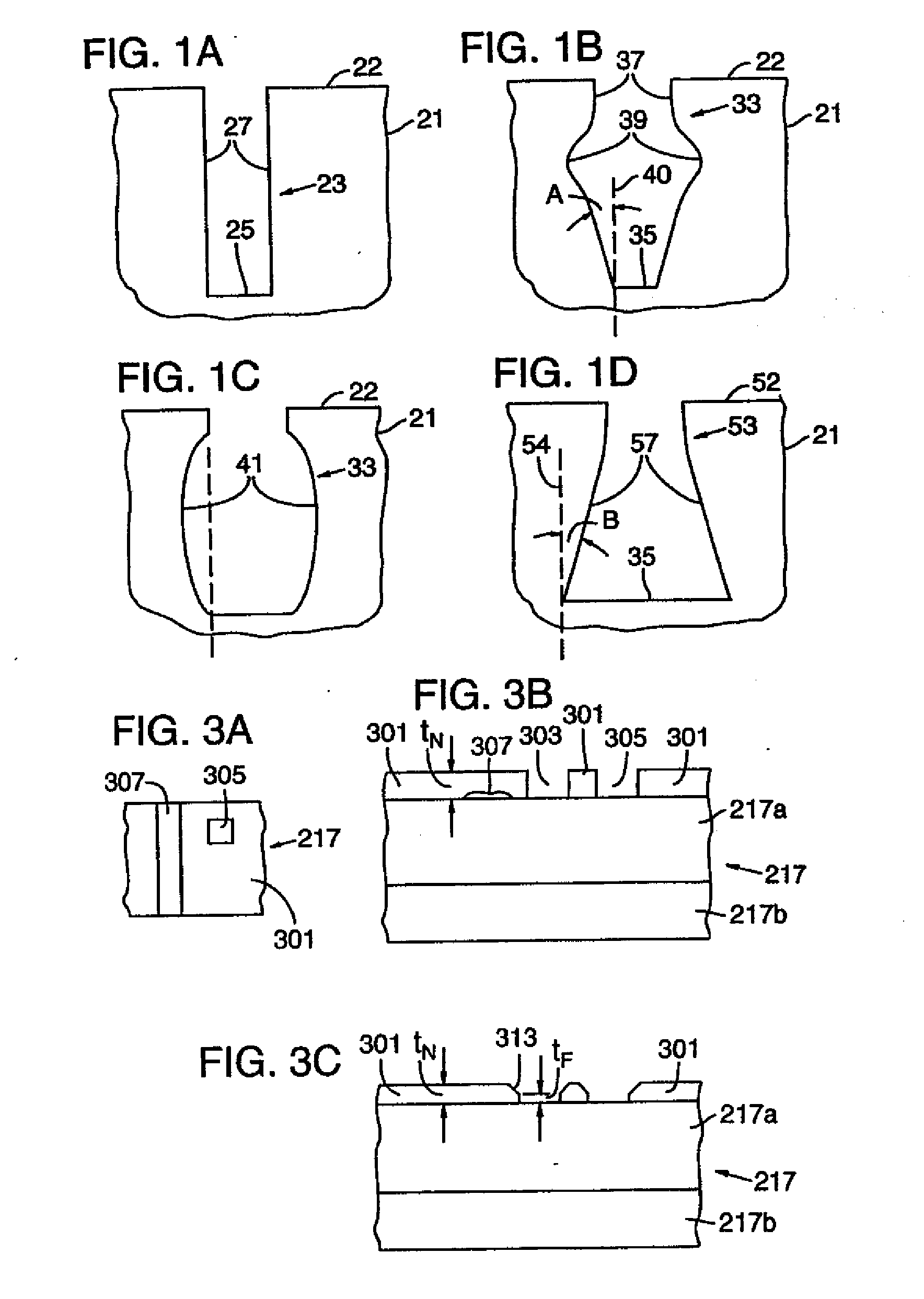

Etching methods and apparatus and substrate assemblies produced therewith

InactiveUS20070077724A1Increasing the thicknessElectric discharge tubesSemiconductor/solid-state device manufacturingResistPlasma etcher

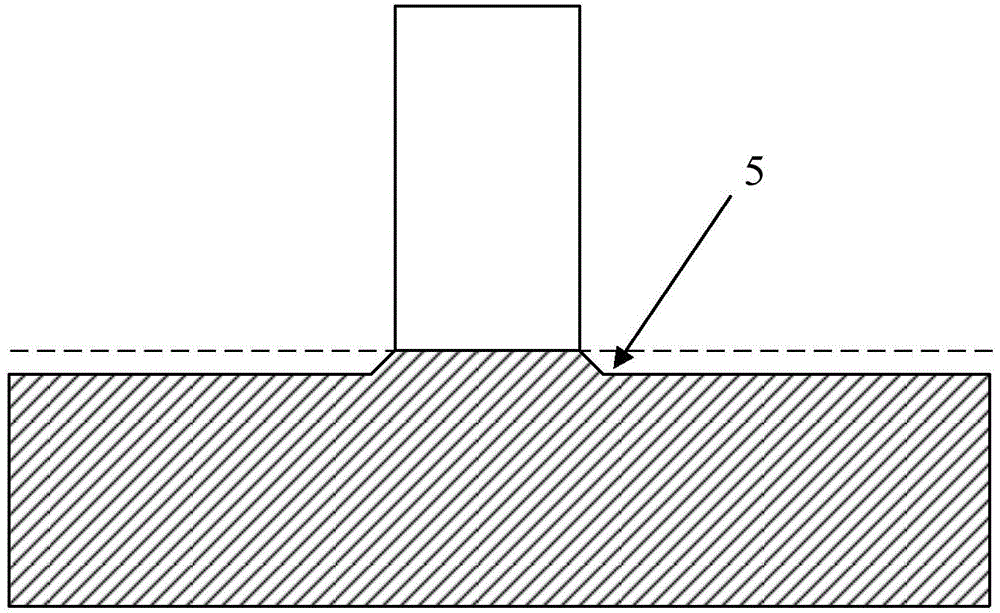

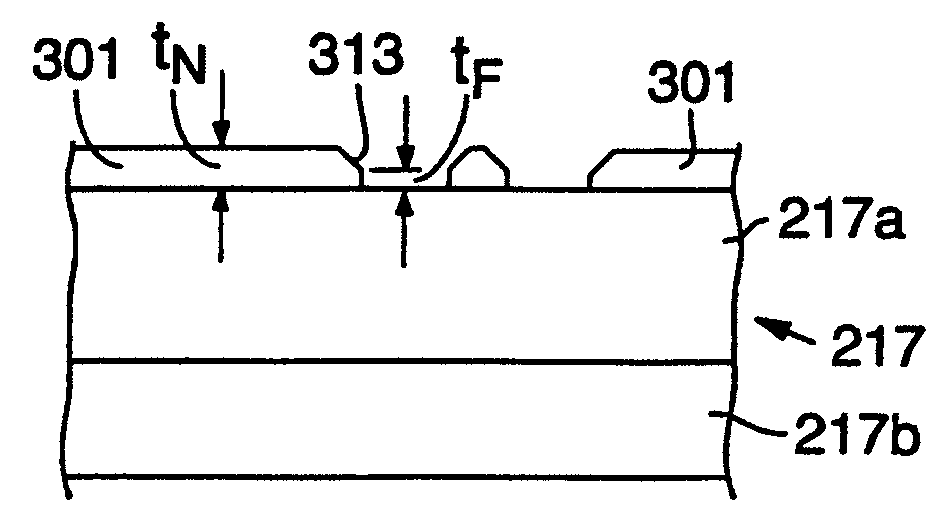

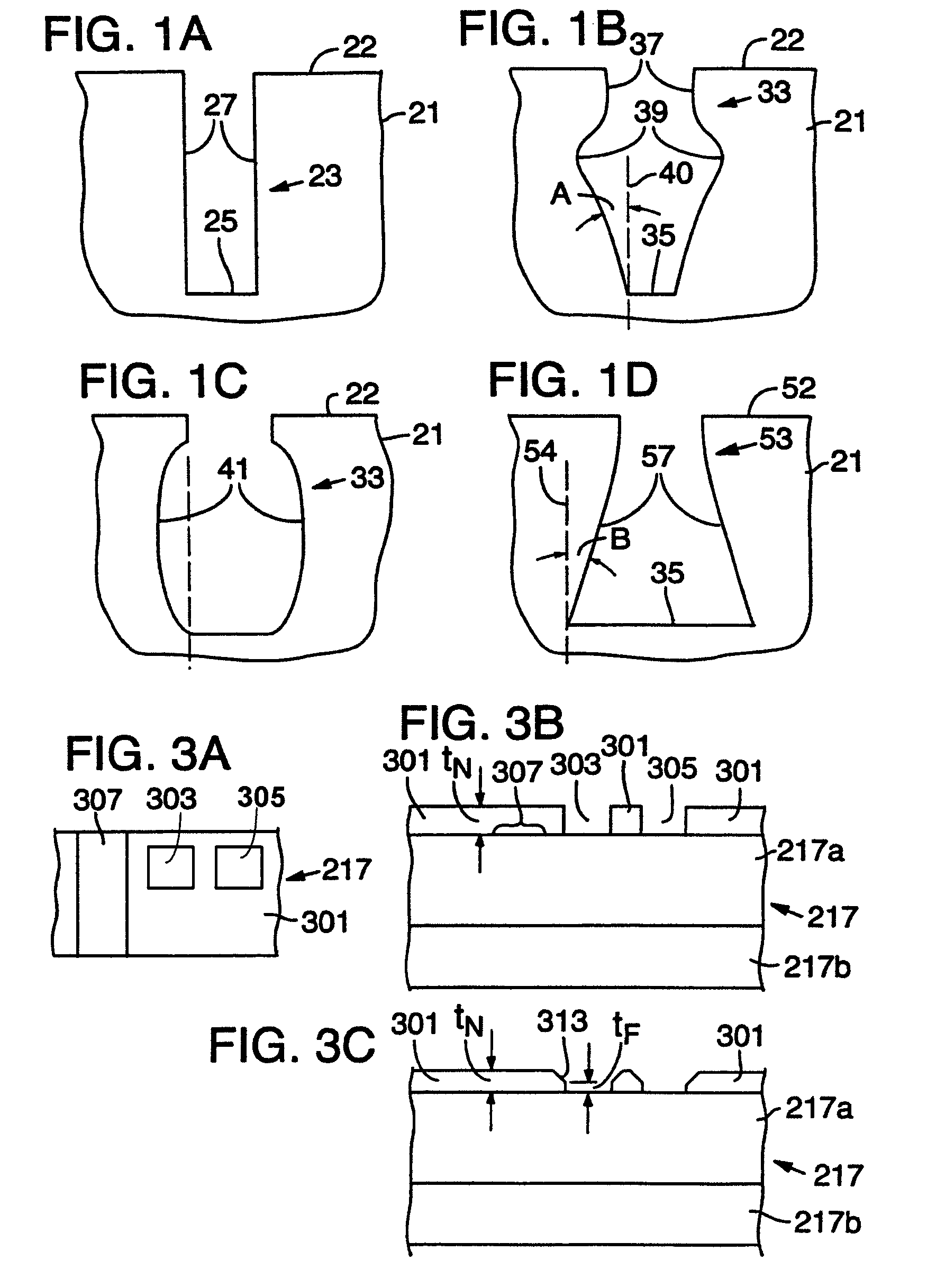

Methods and apparatus for etching substrates such as silicon wafers are provided. In one specific approach, a surface of the substrate assembly is covered with a resist that is patterned to define features to be etched. In this approach, the surface is then exposed to a plasma in a plasma etcher so that surface areas not covered with the resist are etched, while the thickness of the resist increases or etches at a rate that is at least ten times slower than that of the exposed areas of the surface. This etching process can be followed with a conventional plasma etch. By combining the etching that increases the resist thickness with the conventional etching of resist in which the resist thins during etching, features having high-aspect-ratios can be etched.

Owner:MICRON TECH INC

Plasma etcher

InactiveCN1591792AElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringPlasma etcher

A plasma etcher is provided, which includes: a chamber; top and bottom plasma electrodes provided top and bottom positions of the chamber; a gas injection pipe connected to the chamber; a plurality of diffusion plates provided between the top plasma electrode and the gate injection pipe; and a power generator supplying a plasma voltage to the top and bottom electrodes, wherein the top plasma electrode has a plurality of primary injection holes and the diffusion plates have a plurality of secondary injection holes.

Owner:SAMSUNG ELECTRONICS CO LTD

Etching methods and apparatus and substrate assemblies produced therewith

InactiveUS7125804B2Increasing the thicknessElectric discharge tubesDecorative surface effectsResistPlasma etcher

Methods and apparatus for etching substrates such as silicon wafers are provided. In one specific approach, a surface of the substrate assembly is covered with a resist that is patterned to define features to be etched. In this approach, the surface is then exposed to a plasma in a plasma etcher so that surface areas not covered with the resist are etched, while the thickness of the resist increases or etches at a rate that is at least ten times slower than that of the exposed areas of the surface. This etching process can be followed with a conventional plasma etch. By combining the etching that increases the resist thickness with the conventional etching of resist in which the resist thins during etching, features having high-aspect-ratios can be etched.

Owner:MICRON TECH INC

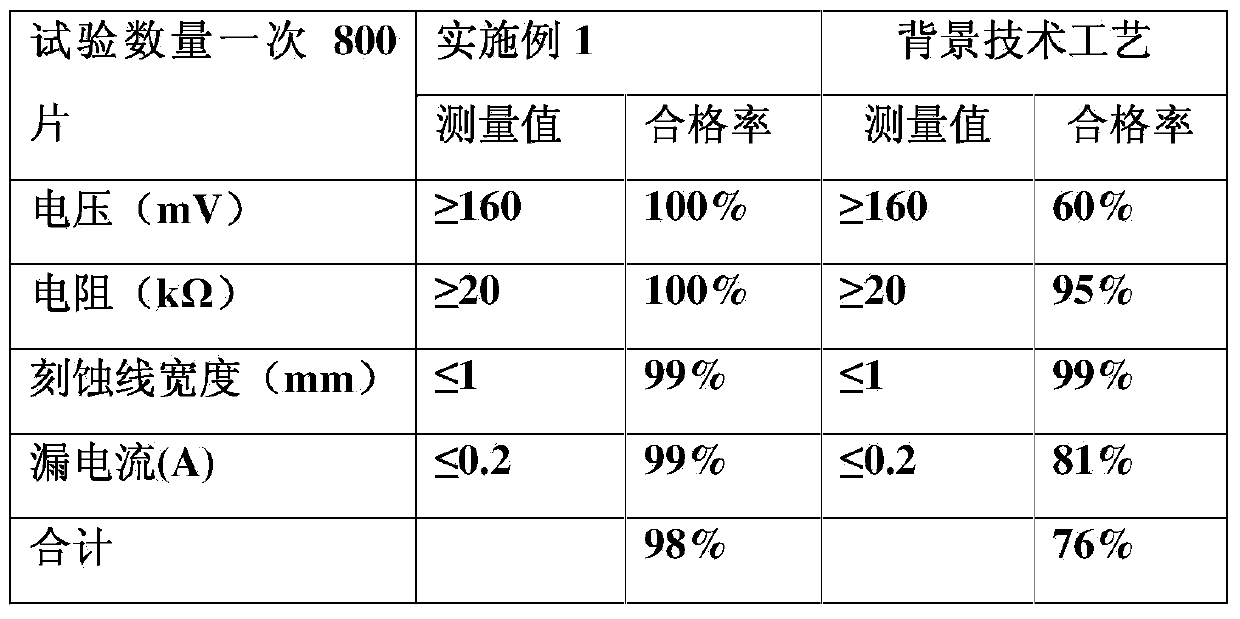

Dry etching technology of monocrystalline silicon solar cells

InactiveCN103746029AMeet the process requirementsFinal product manufactureSemiconductor/solid-state device manufacturingVacuum pumpingWorking pressure

The invention relates to a dry etching technology of monocrystalline silicon solar cells. The dry etching technology is characterized by comprising the following steps: (1) a fixture equipped with 200-1000 silicon wafers is put into a plasma etcher cavity; (2) vacuum-pumping is carried out; (3) reactant gases CF4 and O2 are blown in and flow of CF4 and flow of O2 are respectively controlled within 190-210 sccm and within 25-35sccm until working pressure reaches 200-220psig; (4) glow discharge is carried out and the gases react; (5) vacuum-pumping is carried out again and normal pressure is recovered; and (6) the door of the cavity is opened, the fixture is taken out, and the wafers are removed. The invention provides a dry etching technology of monocrystalline silicon solar cells by a physical metallurgy method. The technology is suitable for 125*125mm of monocrystalline silicon solar cells by a physical metallurgy method. By the adoption of the technology, short circuit ring on the edge of silicon wafers after diffusion can be removed; etched silicon wafers meet technological requirements; and over-etching or under-etching is completely eradicated.

Owner:NINGXIA YINXING ENERGY

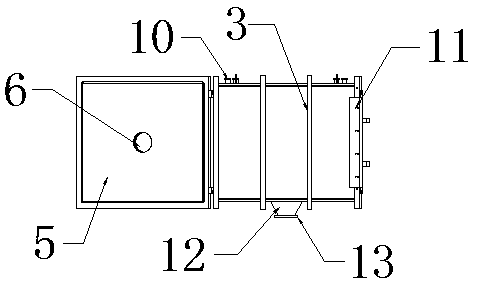

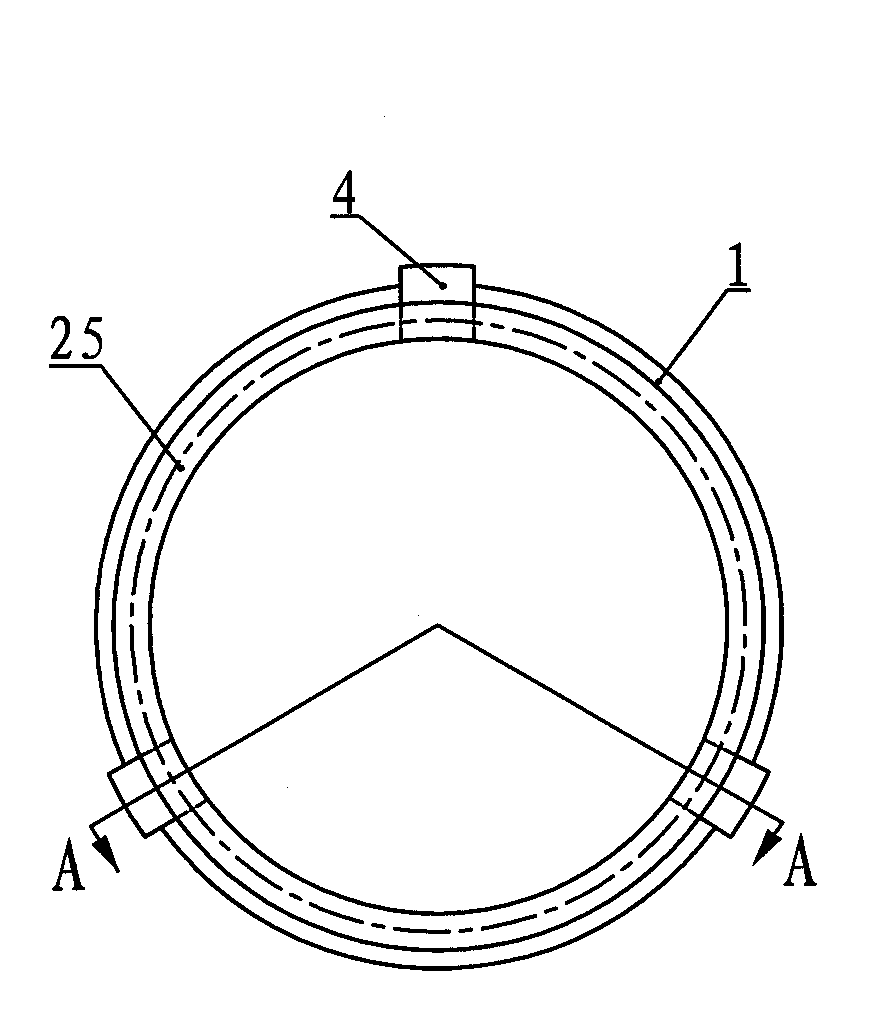

Plasma etcher loading system

InactiveCN103219218ARealize continuous automatic etchingIncrease productivityElectric discharge tubesEngineeringManipulator

A plasma etcher loading system comprises a loading cavity body and a cavity cover, a sealing ring is arranged between the loading cavity body and the cavity cover, a manipulator sheet taking and sending opening is formed in one side of the loading cavity body, a gate valve is arranged in the sheet taking and sending opening and connected with a manipulator cavity body, the loading cavity body is connected with a vacuum mechanical pump and an external air source, a tray rack of a supporting sheet tray is arranged inside the loading cavity body, the tray rack is provided with a plurality of supporting positions of the supporting sheet tray, each supporting position is provided with a notch which allows the sheet tray to leave, the tray rack is fixed on a base frame which is connected with a lifting rotating device, the lifting rotating device comprises a lifting operation portion and a rotating operation portion, the lifting operation portion comprises a guide rod, a lifting motor and a lifting transmission mechanism, the rotating operation portion comprises a rotating motor and a rotating transmission mechanism which is used for connecting the guide rod with the rotating motor, and a gap between the guide rod and the cavity body is sealed. The plasma etcher loading system has the advantages of being large in productivity of the sheet tray and capable of achieving batch machining.

Owner:TDG MACHINERY TECH

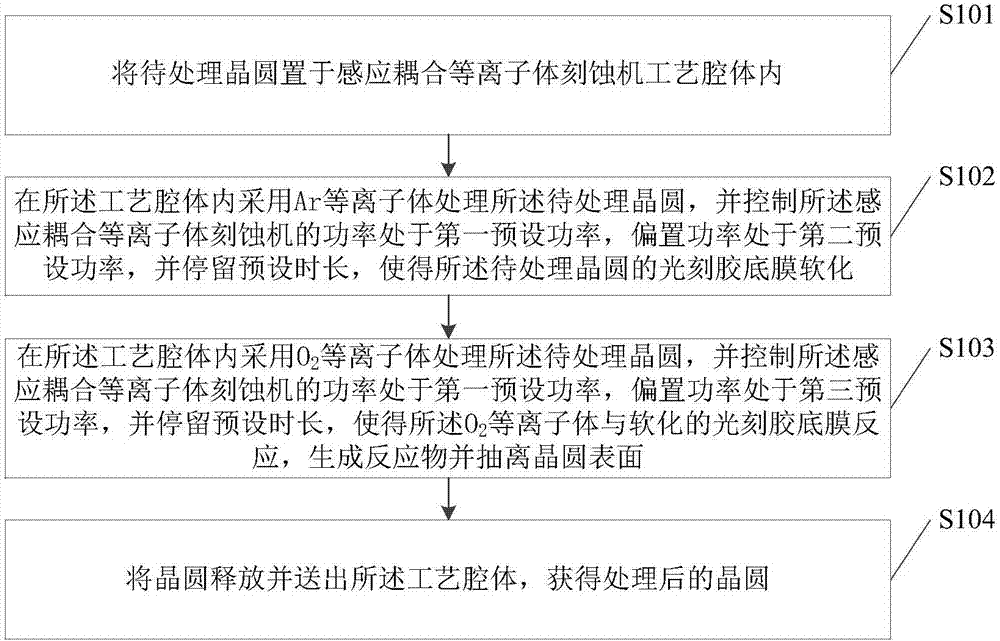

Technological method for removing basic membrane of photoresist

ActiveCN107464750AWon't hurtControl Bias PowerSemiconductor/solid-state device manufacturingO2 plasmaPlasma etcher

The invention relates to the field of compound semi-conductor processing manufacture and discloses a technological method for removing a basic membrane of a photoresist. The technological method comprises the following steps: sending wafers to be processed into a technological cavity of an inductive coupling plasma etcher by use of a transfer arm, and retrieving the transfer arm; after the positions of the wafers are fixed, processing the wafers to be processed in the technological cavity by Ar plasma, controlling the power of the inductive coupling plasma etcher to be first preset power and bias power to be second preset power, and staying for a preset period of time; processing the wafers to be processed in the technological cavity by O2 plasma, controlling the power of the inductive coupling plasma etcher to be first preset power and bias power to be third preset power, and staying for a preset period of time; and releasing the wafers, sending the wafers out of the technological cavity to obtain processed wafers, and further effectively removing the basic membrane of the photoresist.

Owner:CHENGDU HIWAFER SEMICON CO LTD

Machining technology for electronic screen

InactiveCN107326328AQuality improvementReduce processing costsVacuum evaporation coatingSputtering coatingSurface stressWork in process

The invention provides a processing technology for an electronic screen, which includes the following steps: (1) forming a sapphire blank; (2) grinding: using double-sided grinding equipment to perform double-sided grinding on the sapphire blank; (3) plasma etching: grinding the sapphire blank Place the semi-finished sapphire electronic screen flat in the etching chamber of the plasma etching machine, close the chamber cover, remove the damage on the surface of the semi-finished sapphire electronic screen, and remove the surface stress; (4) Double-sided polishing: use double-sided polishing equipment to clean the electronic Chemical mechanical polishing of the semi-finished screen; (5) Chamfering: use a chamfering machine to chamfer the edge of the semi-finished electronic screen after double-sided polishing; (6) Coating: use a vacuum coating machine to coat the semi-finished electronic screen after chamfering , to obtain the finished electronic screen. The invention can greatly improve the strength of the electronic screen and meet the strength requirement of the electronic screen.

Owner:合肥展游软件开发有限公司

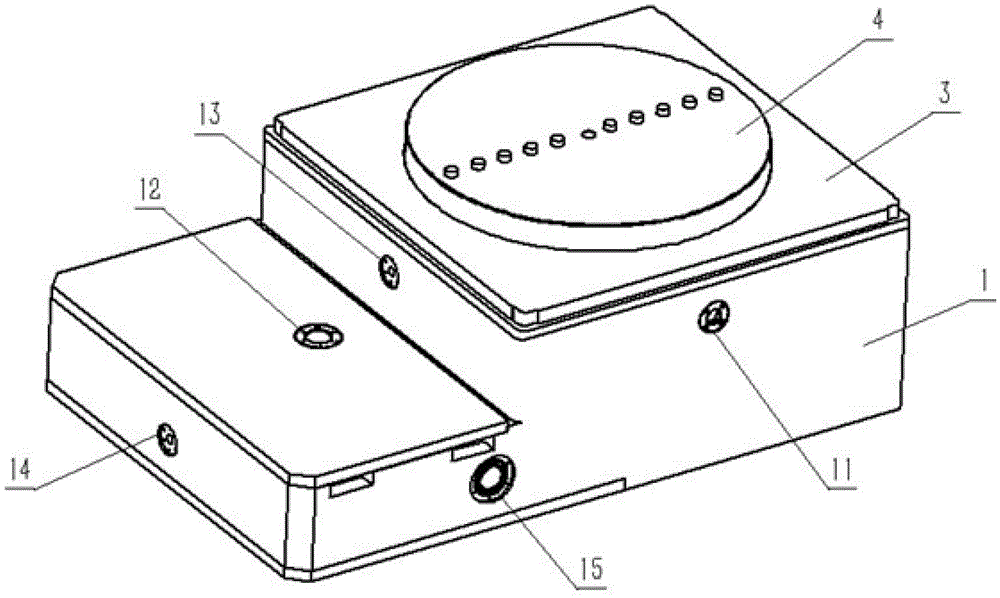

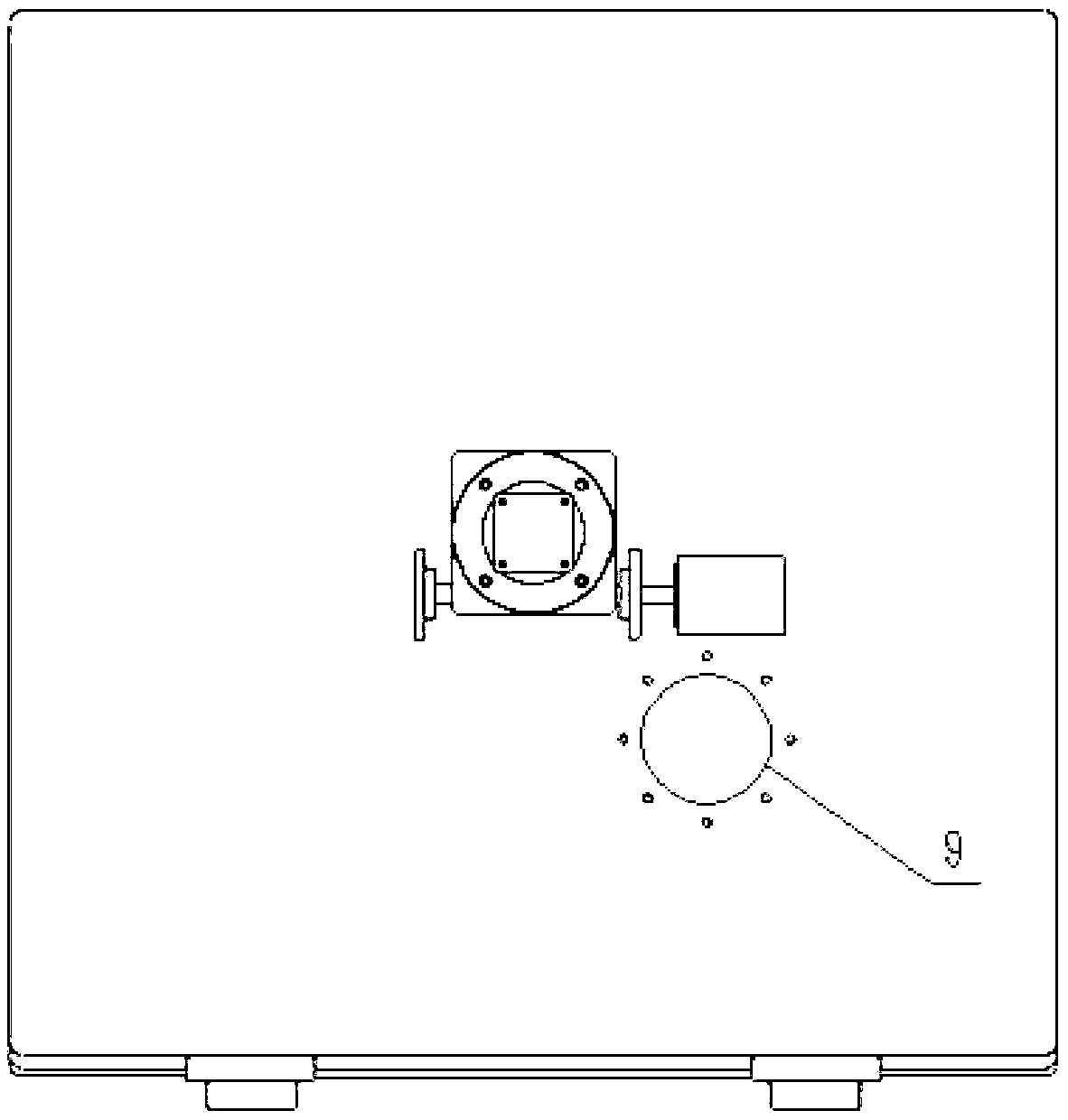

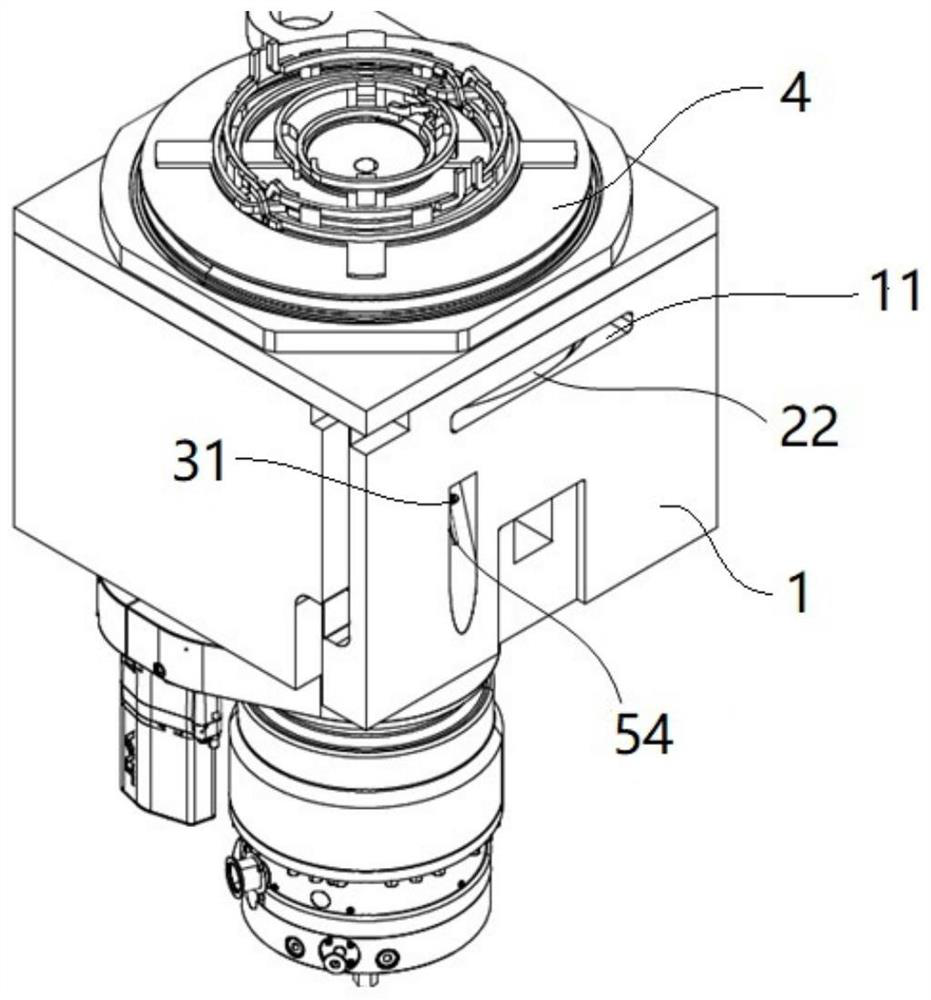

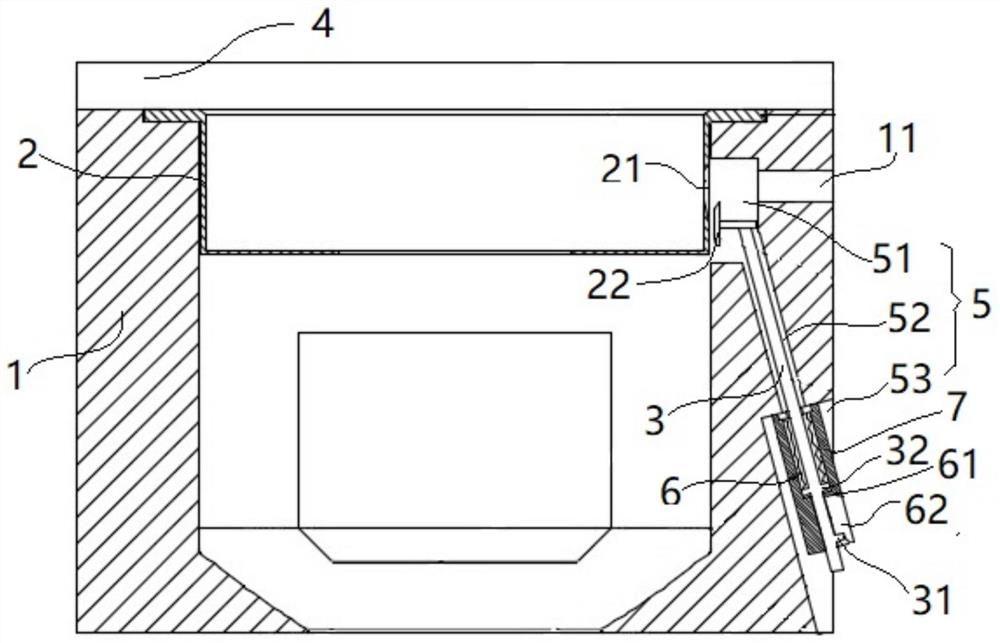

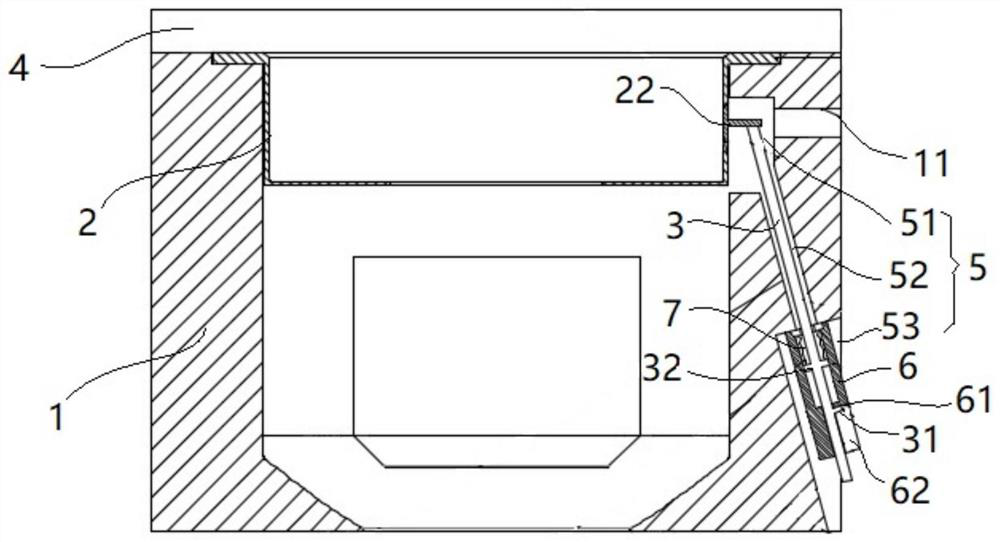

Plasma etcher

The invention discloses a plasma etching machine, which comprises a reaction chamber body (1), a chamber cover (4) and an inner liner (2) surrounding a substrate processing position space, and the chamber cover is detachably sealed on the reaction chamber body On the other hand, the inner liner is detachably arranged in the reaction chamber body, and the side wall of the reaction chamber body is provided with a through groove (11) for the manipulator to enter and exit, and the side wall of the inner liner is provided with an open slot (21), and the open slot Corresponding to the position of the through groove, the side wall of the reaction chamber body is also provided with an operation groove (5) which is arranged at an angle to the side wall of the inner liner. The through groove is connected, and the plasma etching machine also includes a baffle (22) and a pushing mechanism. The pushing mechanism is arranged in the operating groove, and the baffle is connected with the pushing mechanism. In the closed position, the baffle blocks the opening slot, and in the open position, the baffle completely exposes the opening slot.

Owner:JIANGSU LEUVEN INSTR CO LTD

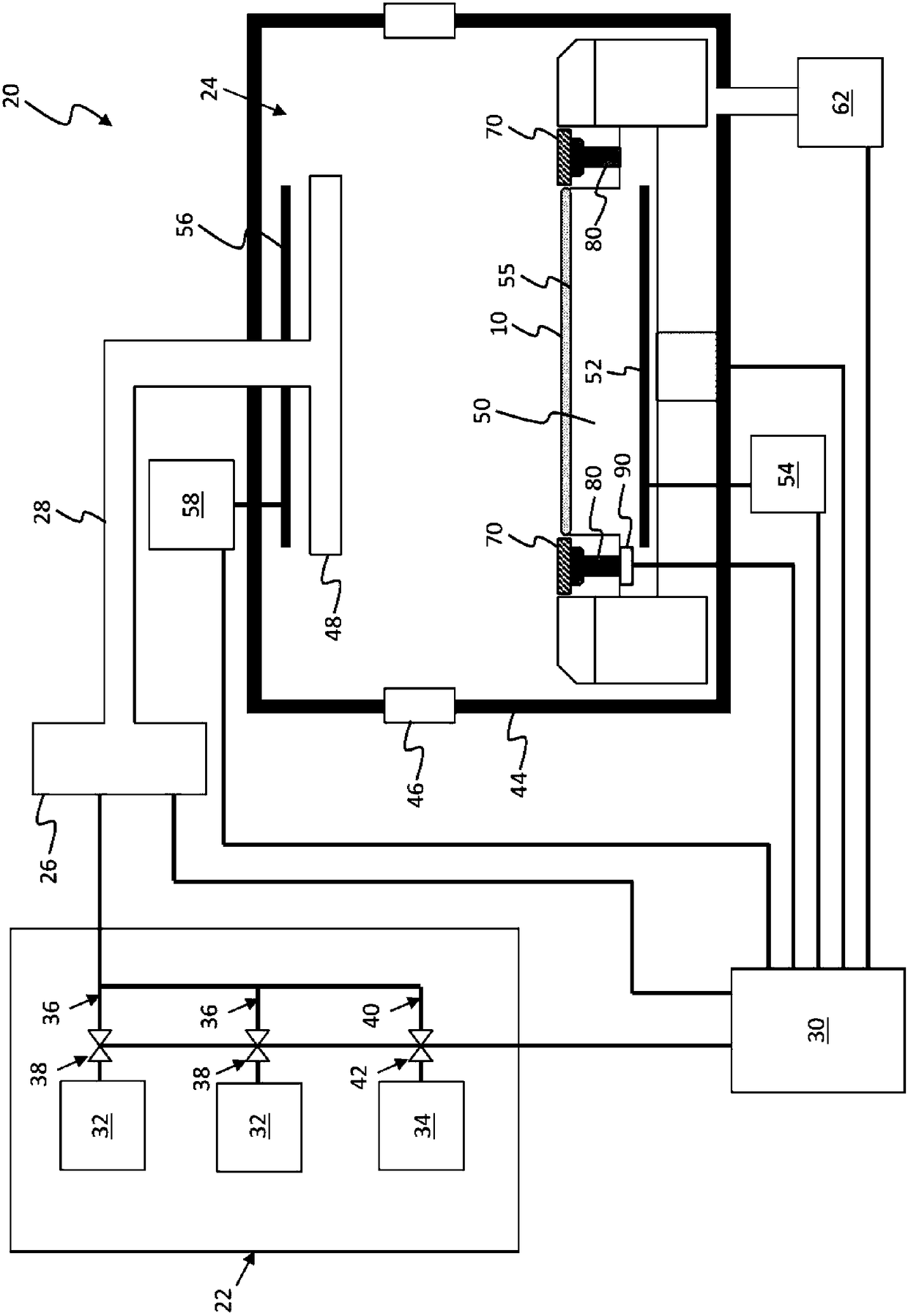

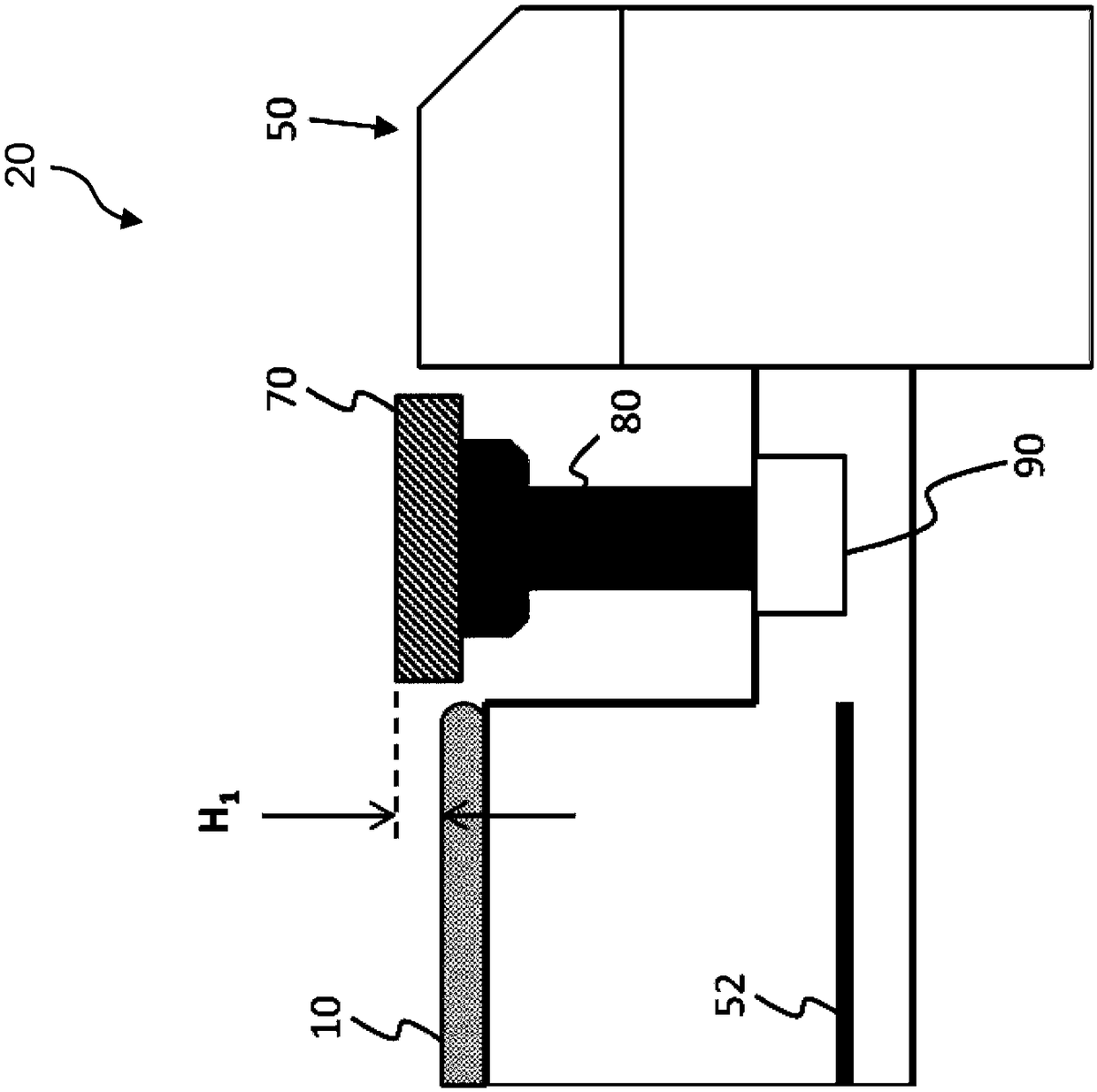

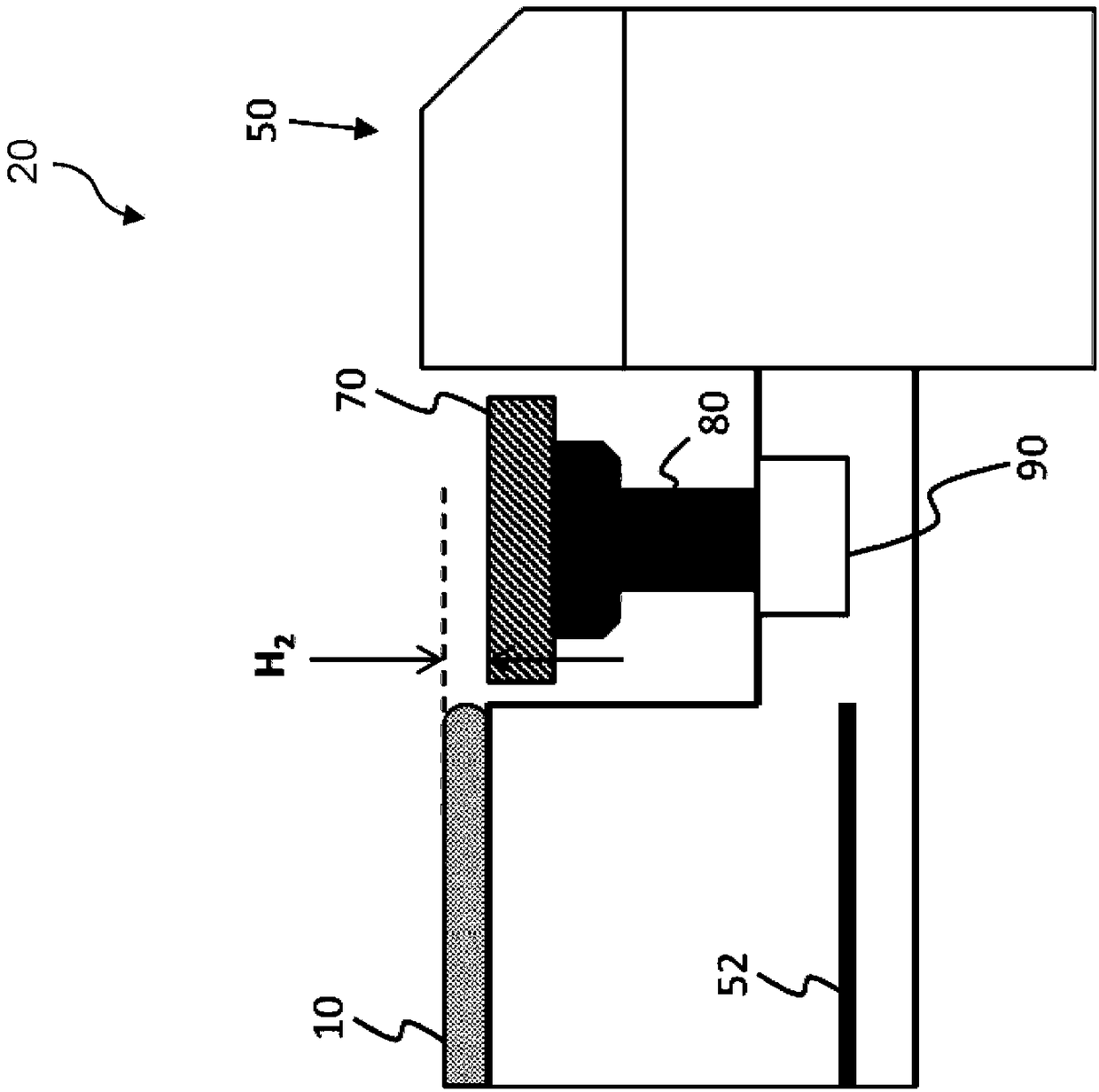

Method and apparatus of moving focus ring for plasma etcher

InactiveCN108122748AElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringActuator

A semiconductor manufacturing method and a semiconductor manufacturing tool for performing the same are disclosed. The semiconductor manufacturing tool includes a plasma chamber, a mounting platform disposed within the plasma chamber, a focus ring disposed within the plasma chamber, and at least one actuator mechanically coupled to the focus ring and configured to move the focus ring vertically. The actuator is configured to move the focus ring vertically when a plasma is present in the plasma chamber. The provided semiconductor manufacturing method can be used to dynamically control the etching speed of etching process.

Owner:TAIWAN SEMICON MFG CO LTD

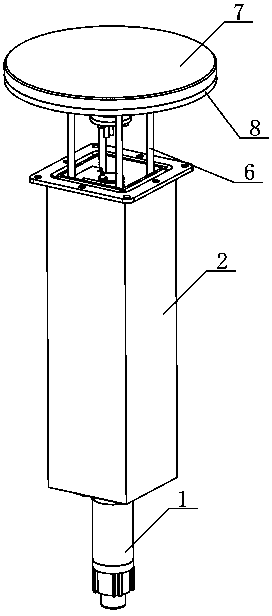

High-voltage coil fixing device of plasma etcher

InactiveCN101800147AWon't breakExtended service lifeElectric discharge tubesHigh pressureConductor Coil

The invention relates to a high-voltage coil fixing device of a plasma etcher. A coil skeleton of the device comprises a bottom end connecting ring, upright posts with a groove and a top end connecting ring, wherein more than three upright posts with a groove are uniformly arranged between the bottom end connecting ring and the top end connecting ring; line containing grooves are arranged on each upright post with a groove at equal intervals; the outer side of the upright posts with a groove is provided with a strip pressing plate, and a line pressing groove corresponding to a high-voltage coil is arranged on the strip pressing plate; and the strip pressing plate and the upright posts with a groove are fixedly connected into a whole by bolts. Because the coil skeleton with better rigidity and the strip pressing plate are used to fix the high-voltage coil, the high-voltage coil cannot deform and be separated from the coil skeleton so as to radically eliminate accidents of striking a quartz reaction tube because a winding of the high-voltage coil separates from the coil skeleton, thereby guaranteeing the normal service life of the quartz reaction tube, improving the use reliability of the plasma etcher and saving the production cost.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Electrode of plasma etcher for carrying out dry etching on hard inorganic material substrate

ActiveCN102368466BImprove cooling effectImprove etching effectElectric discharge tubesStatic indicating devicesBiochemical engineeringCooling effect

The invention relates to an electrode of a plasma etcher for carrying out dry etching on a hard inorganic material substrate, which comprises a guide rail device for being fixedly connected with an etching cavity. A lifter capable of taking the lifting and descending motion in the guide rail device is arranged in the guide rail device. The lifter is fixedly connected with a lower electrode tray. The lower electrode tray is arranged above the guide rail device. The lower electrode tray comprises a top disk and a bottom disk which are fixedly connected. The lower part of the top disk is provided with a cylindrical groove. A gas homogenizing disk is fixedly arranged in the cylindrical groove. Gaps are reserved between the gas homogenizing disk and the top disk as well as between the gas homogenizing disk and the bottom disk. The center of the gas homogenizing disk is provided with a frist through hole for ensuring gas to be communicated to the top disk. The first through hole is communicated with a cooling gas inlet. The center of the bottom of the bottom disk is provided with a second through hole. The second through hole is isolated from the first through hole. The bottom end of the second through hole is connected with a sealed tube. The second through hole is communicated with a cooling gas outlet. The electrode has the beneficial effect that the cooling effect is good so that the etching effect is good.

Owner:TDG MACHINERY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com