High-voltage coil fixing device of plasma etcher

A technology of high-voltage coils and fixing devices, which is applied to circuits, discharge tubes, electrical components, etc., can solve problems such as unreliable fixing of high-voltage coils, achieve stable magnetic field strength, prolong service life, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific mode of the present invention is described in detail below in conjunction with accompanying drawing:

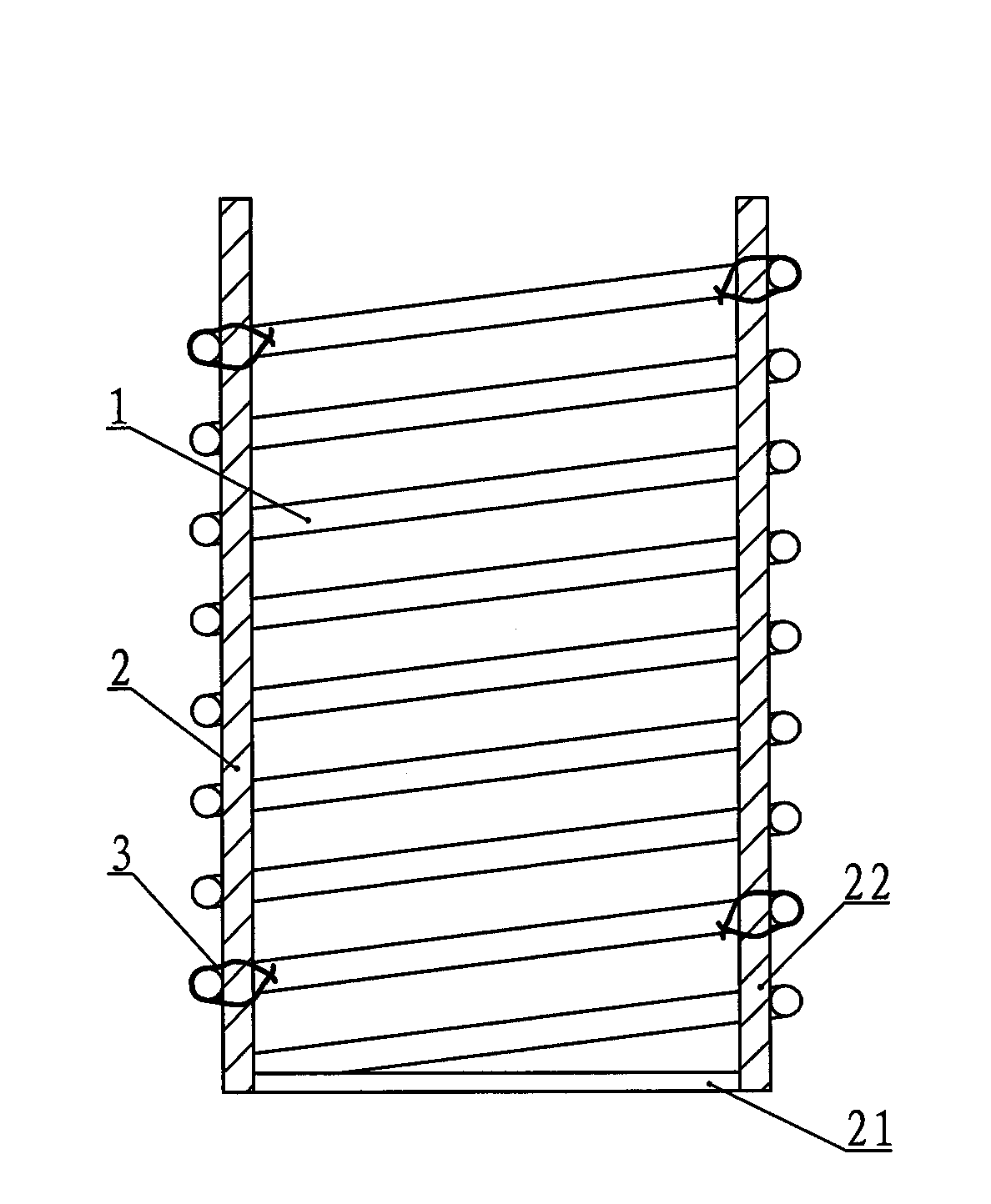

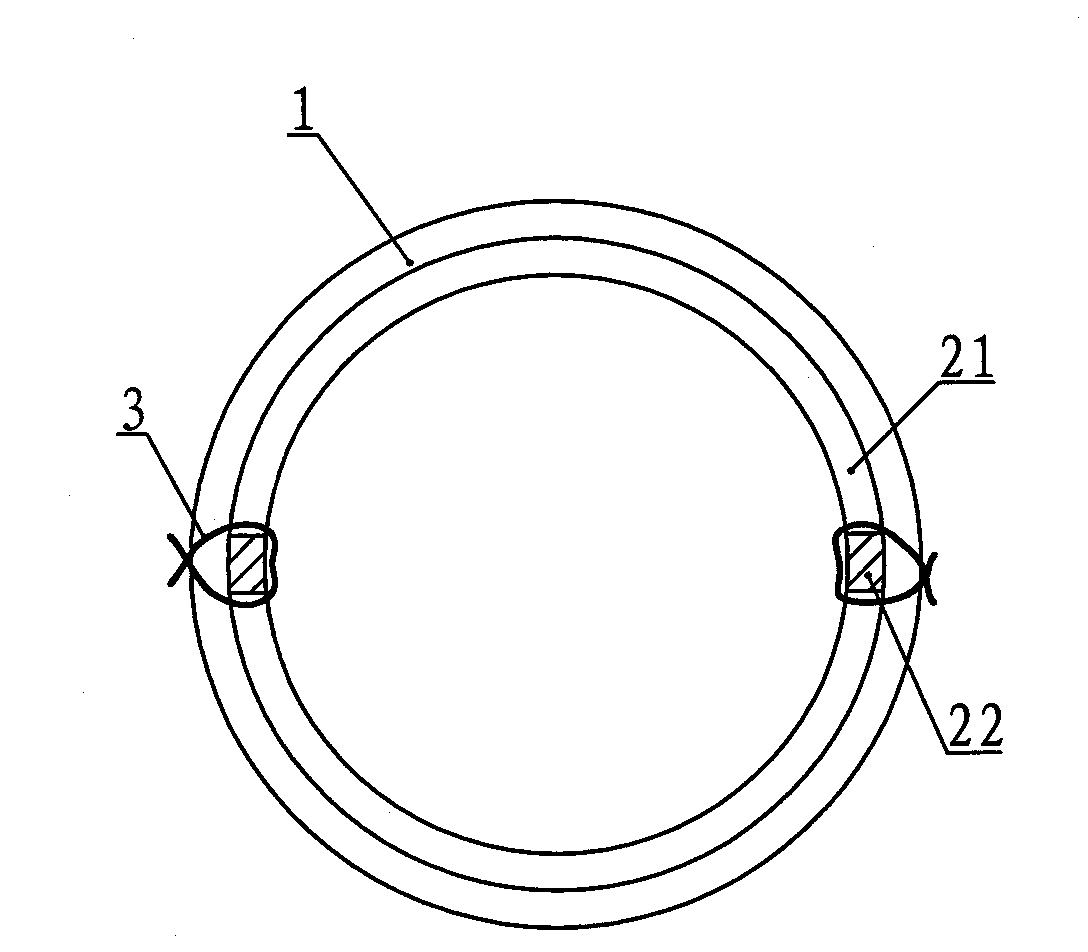

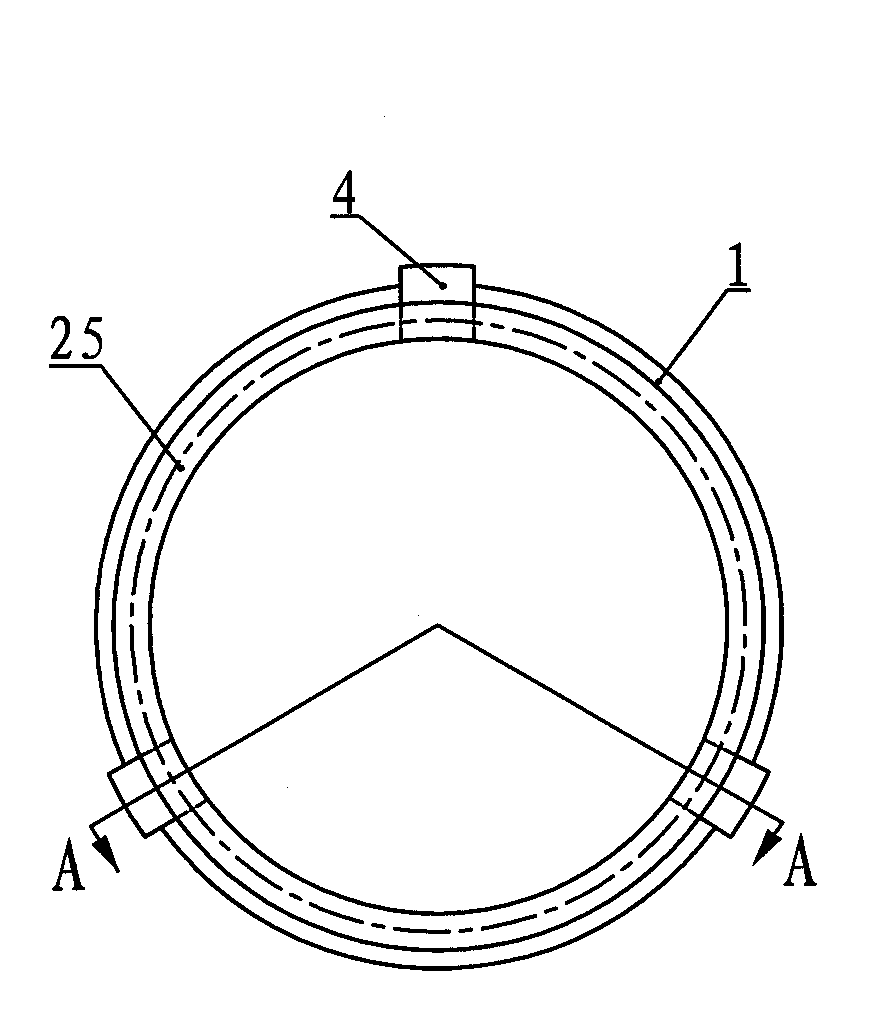

[0018] The high-voltage coil fixing device of the plasma etching machine, such as Figure 3 ~ Figure 5 As shown, it includes a high-voltage coil 1 and a bobbin 2, and the bobbin 2 includes a bottom connection ring 23, a slotted column 24 and a top connection ring 25, and the bottom connection ring 23 and the top connection ring 25 are evenly spaced There are three slotted columns 24, and each slotted column 24 is equidistantly provided with wire slots 26, and the winding inner circle of the high-voltage coil 1 is pressed into the wire slots 26 on the slotted columns 24. The outer side of the slotted column 24 is provided with a strip-shaped pressure plate 4, on which the strip-shaped pressure plate 4 is provided with a crimping groove 41 corresponding to the high-voltage coil 1, and the strip-shaped pressure plate 4 and the slotted column 24 are fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com