Process for homogenizing aluminum alloy

A process method and homogenization technology, which is applied in the field of heat treatment of non-ferrous metals, can solve problems such as uneven matrix structure, achieve the effect of short holding time and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] High-quality 6061 aluminum alloy for the lining of the reaction chamber of the plasma etching machine, the alloy composition is as follows: Si0.50wt%, Mg0.93wt%, Cu0.23wt%, Cr0.18wt%, Fe<0.14wt%, Mn0.036wt% %, Ti<0.15wt%, Al balance. The alloy contains less Fe as an impurity, and also contains Cr and Mn. Smelting and casting are carried out according to the following steps and processes.

[0026] The casting process is electromagnetic casting, the mold pulling speed is 700r / min, the cooling water pressure is 0.07MPa, the pouring temperature is 760°C, the stirrer current is 70A, the stirrer frequency is 15Hz, and the argon gas is passed for 5 minutes to degas and remove slag, 720 ℃ plus 0.1wt% Al 3 After Ti refiner, let stand for 20min to pour. The 6061 aluminum alloy ingot with qualified composition without casting defect was produced by electromagnetic casting.

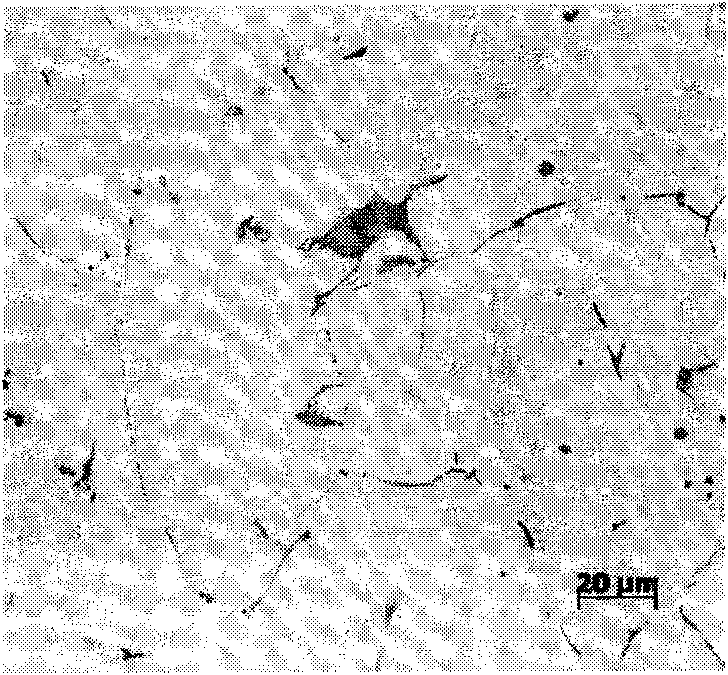

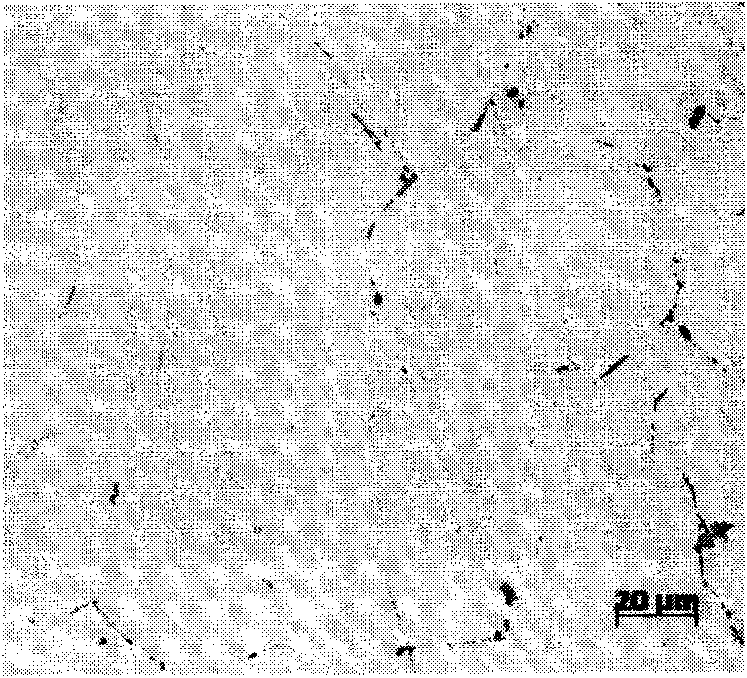

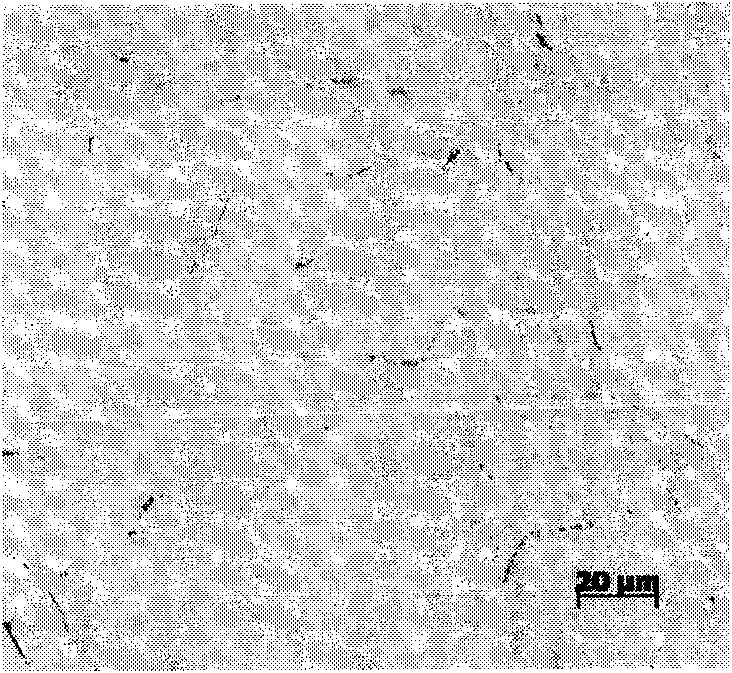

[0027] The 6061 aluminum alloy obtained above is subjected to a homogenization heat treatment process: ...

Embodiment 2

[0035] High-quality 6061 aluminum alloy used for the lining of the reaction chamber of the plasma etching machine, the alloy composition is as follows: Si0.40wt%, Mg1.2wt%, Cu0.15wt%, Cr0.35wt%, Fe<0.14wt%, Mn0.13wt% %, Ti<0.15wt%, Al balance. Melting and casting were carried out according to the steps and process of Example 1 to obtain a 6061 aluminum alloy ingot with qualified composition without casting defects.

[0036] The 6061 aluminum alloy obtained above is subjected to a homogenization heat treatment process: the aluminum alloy ingot is heated with the furnace, kept at 560°C ± 5°C for 9 hours, and then quenched with water at room temperature after being taken out of the furnace, and the transfer time does not exceed 1 minute.

Embodiment 3

[0038]High-quality 6061 aluminum alloy for the lining of the reaction chamber of the plasma etching machine, the alloy composition is as follows: Si0.60wt%, Mg0.8wt%, Cu0.4wt%, Cr0.04wt%, Fe<0.15wt%, Mn0.06wt% %, Ti<0.15wt%, Al balance. Melting and casting were carried out according to the steps and process of Example 1 to obtain a 6061 aluminum alloy ingot with qualified composition without casting defects.

[0039] The 6061 aluminum alloy obtained above is subjected to a homogenization heat treatment process: the aluminum alloy ingot is heated with the furnace, kept at 560°C±5°C for 9 hours, and then quenched with water at room temperature after being taken out of the furnace, and the transfer time does not exceed 1 minute.

[0040] For the 6061 aluminum alloys of Examples 2 and 3, after homogenizing heat treatment, the microstructure uniformity of the aluminum alloy matrix is improved, and the Mg 2 The re-dissolution of the Si phase makes the iron-containing phase sphero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com