FTIR spectrum monitoring based internal state maintenance method of plasma etcher

A plasma and internal state technology, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, electrical components, etc. Volume etching machine equipment utilization efficiency and other issues, to achieve the effect of enhancing strength and improving equipment utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0029] Below in conjunction with accompanying drawing, the plasma etching machine internal state maintenance method based on FTIR spectrum monitoring of the present invention comprises the following steps:

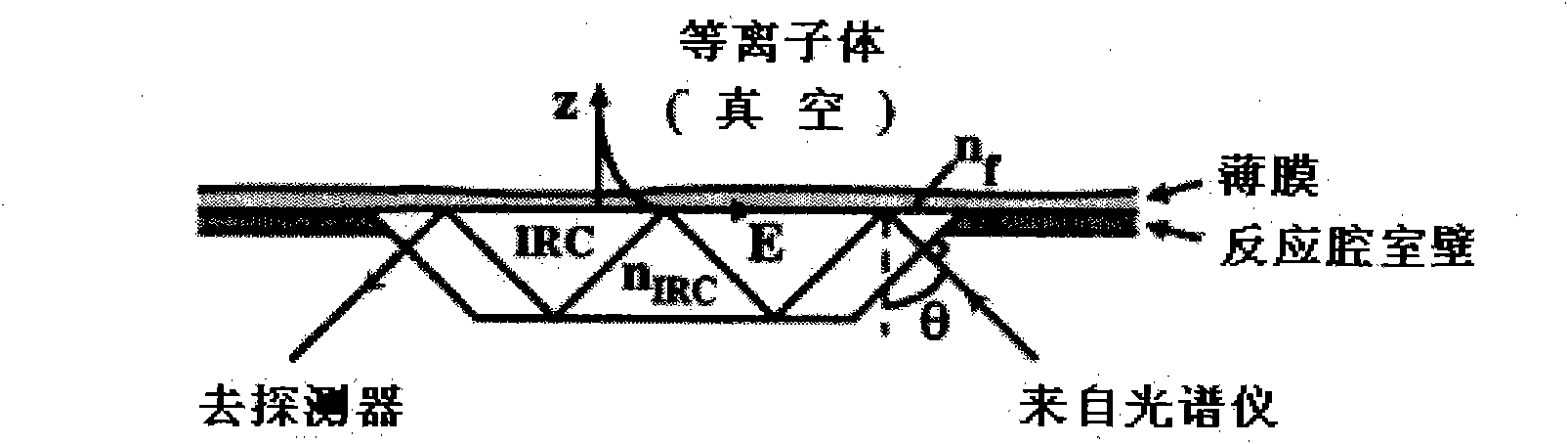

[0030] 1) Install the Fourier transform infrared spectroscopy probe system: see figure 1 , Open a window on the outer wall of the reaction chamber of the plasma etching machine. The window material is a transparent IRC internal reflection crystal. An ATR-FTIR attenuated total reflection Fourier transform infrared spectroscopy probe is installed on one end of the window, and an infrared probe is installed on the other end. Detectors, preferably mercury cadmium telluride detectors, after the light is incident from a transparent IRC crystal (internal reflection crystal), it will go back and forth multiple times at the interface between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com