Construction method of soil covering tank

A construction method and soil-covering technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., to achieve the effect of reducing construction intensity, reducing occurrence probability and operating costs, and increasing benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

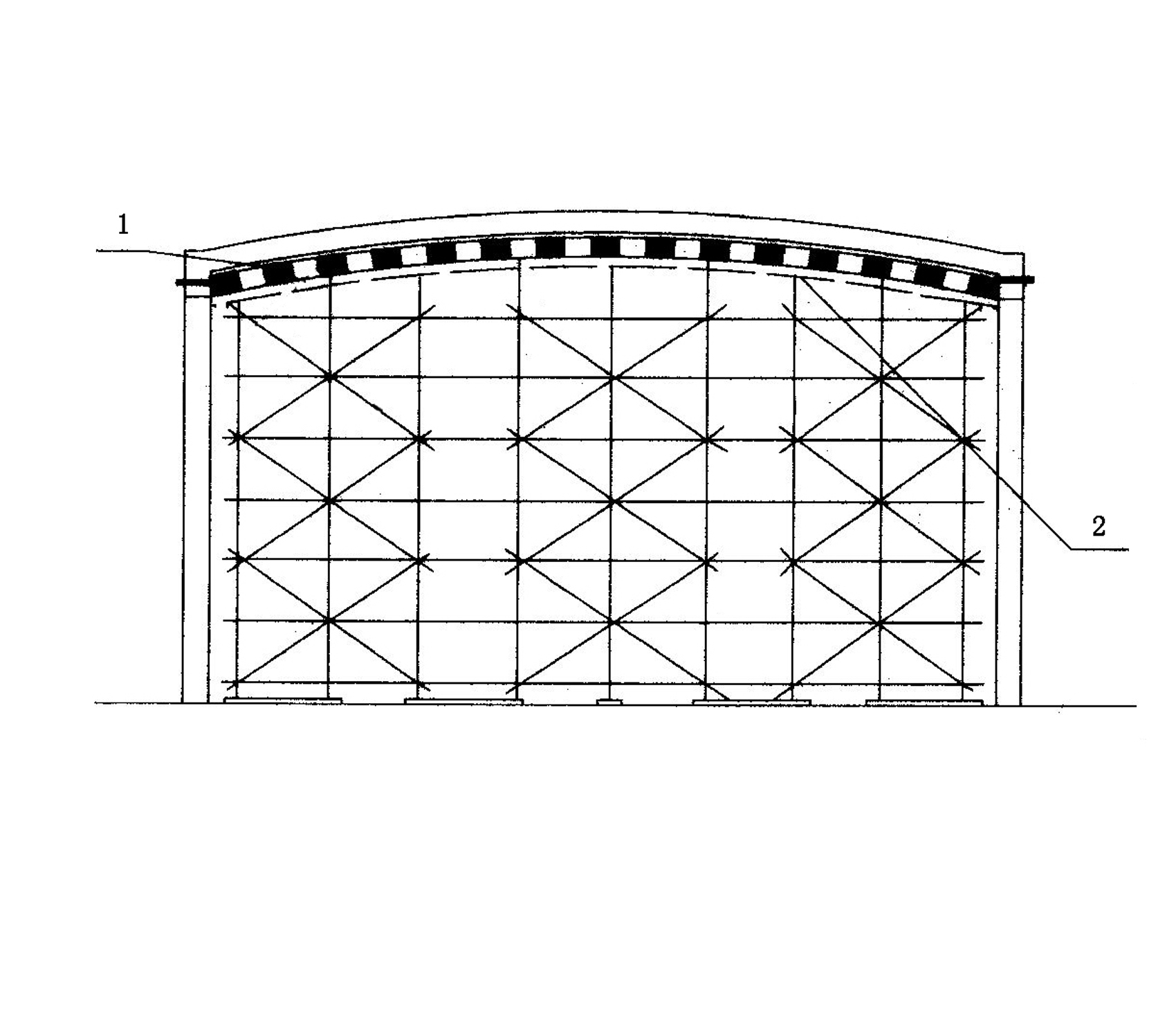

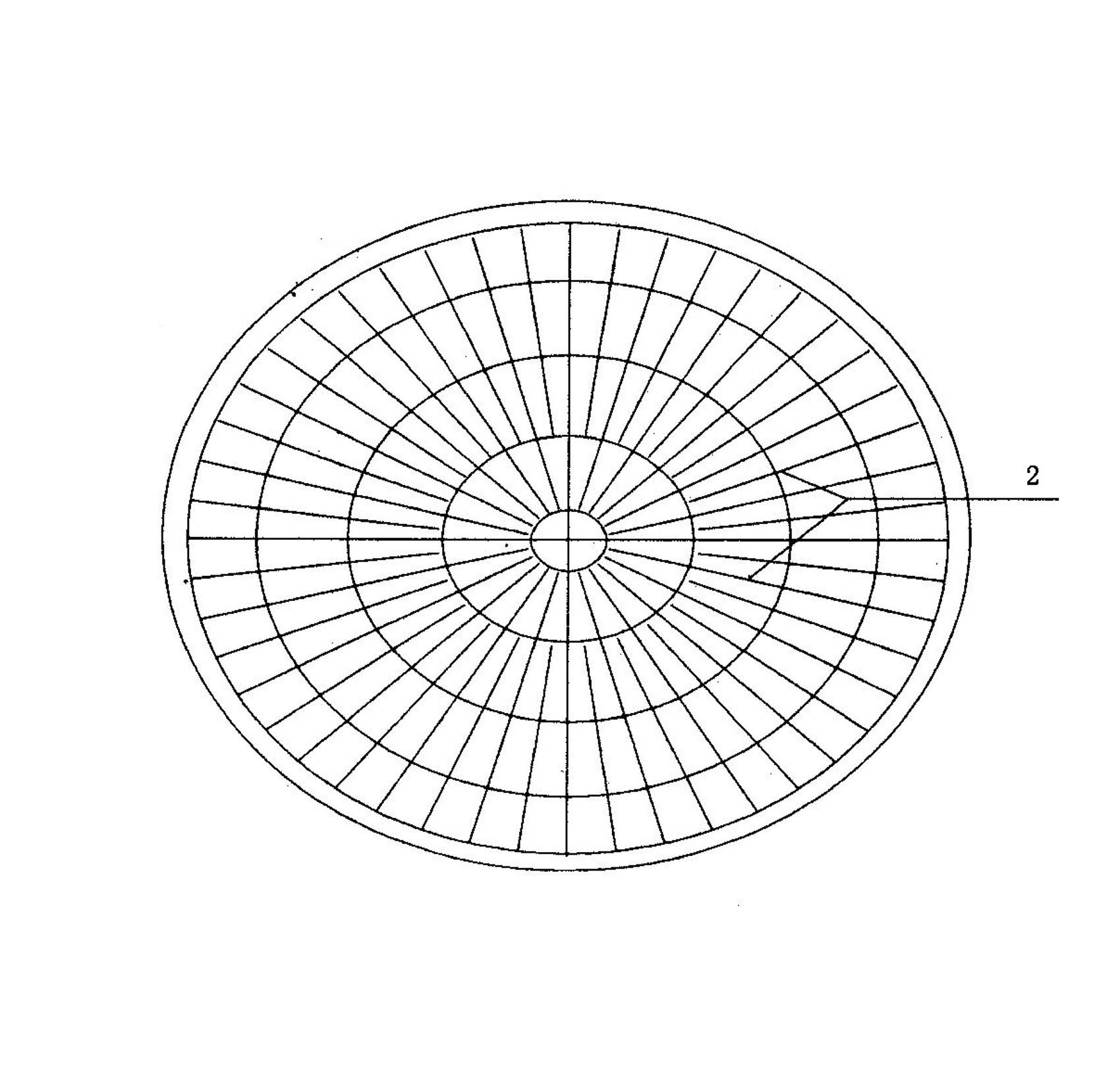

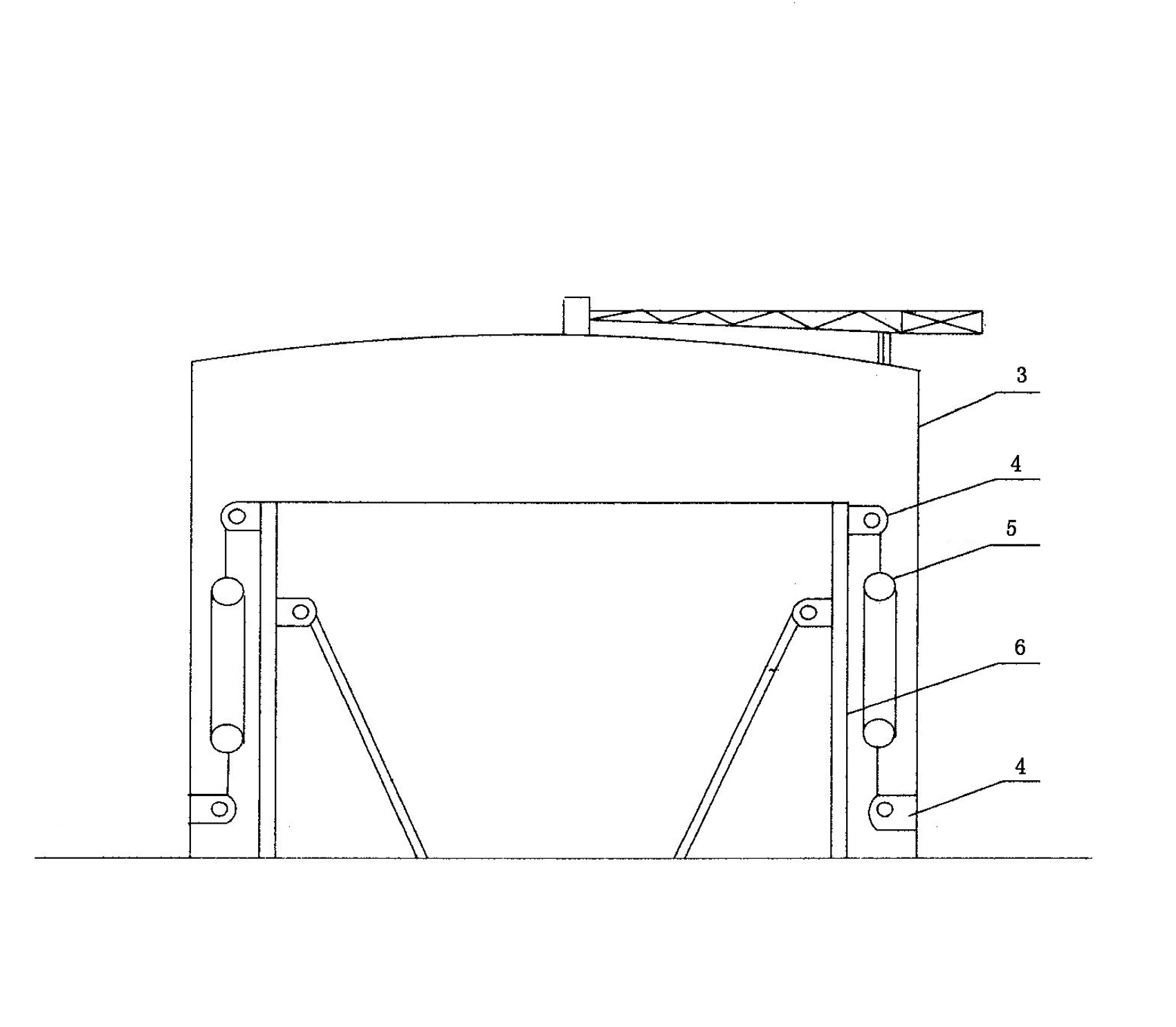

Method used

Image

Examples

specific Embodiment

[0038] A. Civil construction soil-covered tank chamber.

[0039] 1. Earth excavation:

[0040] The combination of backhoe excavator and manual excavation is used. In order to avoid disturbing the base soil when the backhoe excavates, an earthwork with a base elevation of 20-30cm is reserved during excavation, and manual cleaning is adopted; the width of the outer working surface of the foundation trench is 1800mm , the excavation is carried out according to the slope of 1:0.55, and adjusted according to the soil quality. If the height is too large, step back slope can be adopted, and slope protection can be adopted if necessary to avoid landslides; drainage ditches are dug around the foundation pit, and water collection is arranged reasonably The pit shall be drained with a φ50 sewage pump, and the temporary drainage facilities of the foundation pit shall be combined with the permanent facilities as far as possible; the plastic film shall be covered on the soil slope to preven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com