Treatment and construction method of super-pouring pile head

A construction method and pile filling technology, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems that affect the construction period and schedule, the poor quality of pile head removal, and the large noise in the operation process, so as to shorten the construction period, Low cutting difficulty and the effect of reducing construction noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

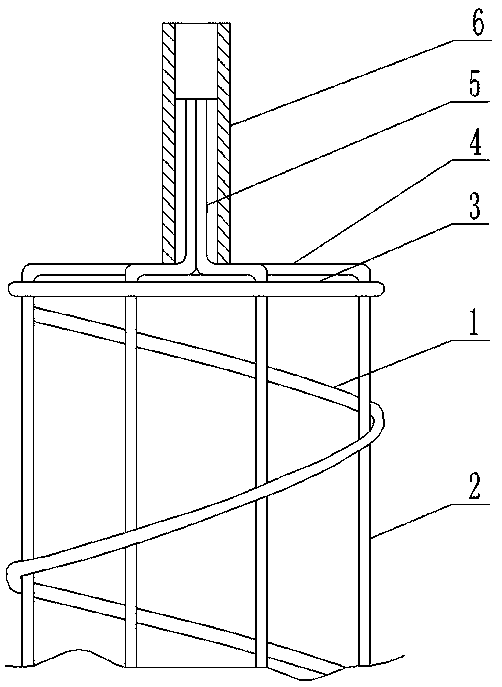

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] Such as figure 1 Shown, the super-filling pile head processing construction method in this specific embodiment may further comprise the steps:

[0021] (1) Make a reinforcement cage. The reinforcement cage includes the main reinforcement and the spiral reinforcement 1. The main reinforcement includes a plurality of vertical reinforcement 2 parallel to each other and equally spaced vertically on the same circumference to form a columnar structure. The spiral reinforcement 1 is in a spiral shape Hovering on the outside of the columnar structure surrounded by multiple longitudinal steel bars 2, the spiral steel bars 1 are fixedly connected with the longitudinal steel bars 2 respectively, the spiral steel bars 1 extend from one end of the main steel bar to the other end, and the spiral steel bars 1 are located at both ends of the main steel bar The part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com